Posh Shed / Garden Room DIY Build

Discussion

I'm looking to move my workshop which is currently in the cellar to a posh shed in the garden. The cellar would then become a child free zone/cinema/xbox room. Something along the lines of this.....

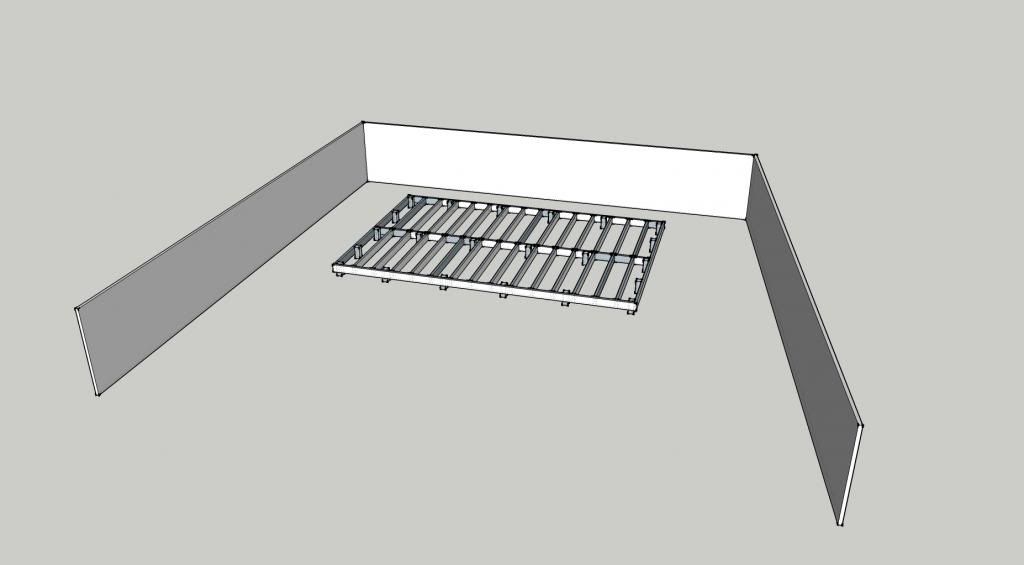

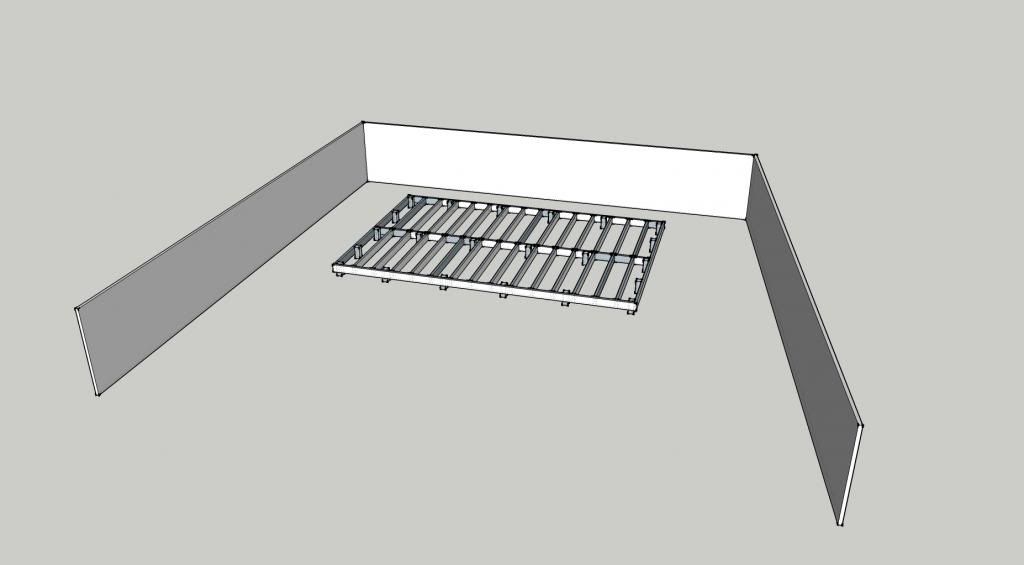

The posh shed would be 6.5 x 4m split into two - 3.5x4m workshop & 3x4m garden room/office. The walls constructed out of 4x2"s at 400mm centres. It needs to be useable all year round so its going to be insulated with Kingspan or similar, clad with cedar & plaster boarded inside. At the moment the base is to be constructed out of 6x2"s at 400mm centres held up on 50mm galvanised steel box section posts. Like this....

If OK, how long should posts be - I'm thinking concreting in 30-40cm should be fine.

Also what's the best way of constructing the frame? Concrete the posts in first then attach the 6x2s or use the squared up frame as a guide for positioning the posts. Posts and frame must be perfectly square and level otherwise the walls and roof will be on the p1ss.

Suggestions gratefully received

Cheers

The posh shed would be 6.5 x 4m split into two - 3.5x4m workshop & 3x4m garden room/office. The walls constructed out of 4x2"s at 400mm centres. It needs to be useable all year round so its going to be insulated with Kingspan or similar, clad with cedar & plaster boarded inside. At the moment the base is to be constructed out of 6x2"s at 400mm centres held up on 50mm galvanised steel box section posts. Like this....

If OK, how long should posts be - I'm thinking concreting in 30-40cm should be fine.

Also what's the best way of constructing the frame? Concrete the posts in first then attach the 6x2s or use the squared up frame as a guide for positioning the posts. Posts and frame must be perfectly square and level otherwise the walls and roof will be on the p1ss.

Suggestions gratefully received

Cheers

Main base frame is now finished......pics to follow.

Question, what should I be laying underneath the frame?

Weed fabric to control any weeds but allows water to drain

or

Damp proof membrane to stop weeds but also prevents water socking up into the timber base?

Suggestions appreciated - floor joists going down in the next couple of days.

Cheers

Question, what should I be laying underneath the frame?

Weed fabric to control any weeds but allows water to drain

or

Damp proof membrane to stop weeds but also prevents water socking up into the timber base?

Suggestions appreciated - floor joists going down in the next couple of days.

Cheers

speedyguy said:

mikees said:

I would REALLY REALLY lay a concrete base. Surely this s only a few hundred quid. Mike

http://www.minimix.co.ukHandy for working bits out and ball park figures if your doing the base yourself.

Any way it's too late - 28 galvanised posts have been concreted in and 6x2 frame bolted to it!

The previous summer house concrete base was wrecked by the nearby tree roots so I discounted the slab.

Most of the garden room suppliers use either timber or steel framed bases so didn't think I would go too far wrong

So....Weed fabric or damp proof membrane?

Updated pics........

main framed laid out - levelled and squared & then marked out the hole positions

Holes dug using a petrol post hole borer, a lot easier than digging by hand but still hard work

hard work

Finished frame ready for joists. Doesn't look like its going anywhere, the wife says its over engineered, I say its robust

Next step floor joists and walls.

Was planning to use 18mm WBP plywood for the floor - any cheaper options???

Assume 38x89mm CLS is good for the walls?

Thanks

main framed laid out - levelled and squared & then marked out the hole positions

Holes dug using a petrol post hole borer, a lot easier than digging by hand but still

hard work

hard work

Finished frame ready for joists. Doesn't look like its going anywhere, the wife says its over engineered, I say its robust

Next step floor joists and walls.

Was planning to use 18mm WBP plywood for the floor - any cheaper options???

Assume 38x89mm CLS is good for the walls?

Thanks

Thread resurrection!

There's been a bit of a change of plan following a impulse Ebay purchase

SIP Panels

Seemed cheap for the size of panels, phoned up the guy and the deal was done.

Was only then I considered how was I going to get 2500kg of panels from Huddersfield to Leicester.

Was advised to get a 7.5 ton lorry by the guy selling so I hired & pitched up in a box lorry with a tail lift. Wrong! With hindsight a 7.5 ton flat bed would have been a lot easier. After man-handling 16off 5m & 6m lenghs into the back with the aid of a forklift it dawned on me how the F**k I was going to offload at the other end.

While driving back i was frantically phoning round local buddies to give me a hand but no one was picking up....... managed to rope in a couple of neighbors but it still took 2 hours to unload.

managed to rope in a couple of neighbors but it still took 2 hours to unload.

Anyway - anyone have any experience building a SIPs?? The walls and roof of the garden room / posh will be made out of them.

Doesn't look difficult but could do with some pointers.

Cheers

There's been a bit of a change of plan following a impulse Ebay purchase

SIP Panels

Seemed cheap for the size of panels, phoned up the guy and the deal was done.

Was only then I considered how was I going to get 2500kg of panels from Huddersfield to Leicester.

Was advised to get a 7.5 ton lorry by the guy selling so I hired & pitched up in a box lorry with a tail lift. Wrong! With hindsight a 7.5 ton flat bed would have been a lot easier. After man-handling 16off 5m & 6m lenghs into the back with the aid of a forklift it dawned on me how the F**k I was going to offload at the other end.

While driving back i was frantically phoning round local buddies to give me a hand but no one was picking up.......

managed to rope in a couple of neighbors but it still took 2 hours to unload.

managed to rope in a couple of neighbors but it still took 2 hours to unload.Anyway - anyone have any experience building a SIPs?? The walls and roof of the garden room / posh will be made out of them.

Doesn't look difficult but could do with some pointers.

Cheers

V8RX7 said:

I guess it depends what you want but surely a SIPS panel is effectively 2 sheets of OSB and a sheet of Kingspan / Celotex.

Baring in mind you wouldn't want to look at either side - so have to clad it I can't see there is any saving in a shed build.

Absolutely - SIPS is not the cheap option for a shed. I was always going to clad the exterior and plasterboard the interior but at £80 for a 6100 x 1200 x 140mm sheet it works out cheaper than a wooden frame and Kingspan. Baring in mind you wouldn't want to look at either side - so have to clad it I can't see there is any saving in a shed build.

Total overkill for a posh shed/garden room however it should end up being very strong and thermally efficient. Supported one of the panels at each end and stood in the unsupported middle - very little deflection which was impressive.

Need to update this thread, anyway......

Yes the box sections were galvanised - I cut up some 2.4m long fence posts.

Some of the offcuts are still kicking around the garden with very signs of rust even on the cut edges

Yes the box sections were galvanised - I cut up some 2.4m long fence posts.

Some of the offcuts are still kicking around the garden with very signs of rust even on the cut edges

ludsonline said:

Hi Russ,

Are you using galvanised box sections for your supports you concreted in?

Cheers

Paul

Are you using galvanised box sections for your supports you concreted in?

Cheers

Paul

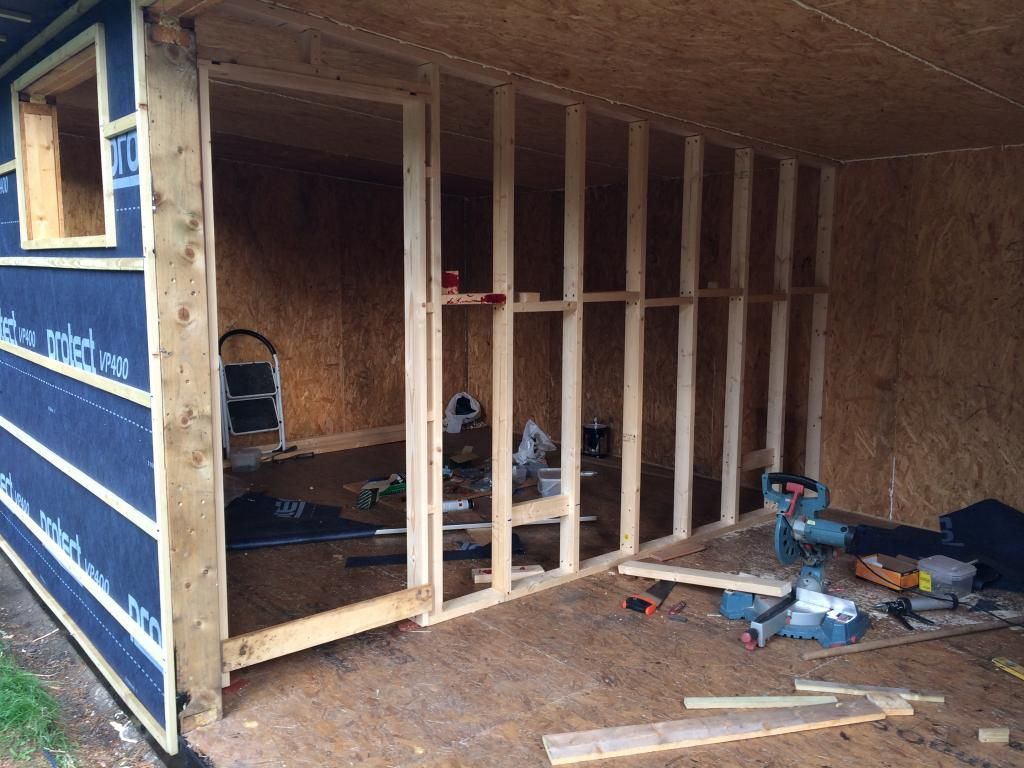

Apologies for being so slack with the thread updates

Here goes................

SIPS ready for EPDM rubber roof. Went for the hopefully fit and forget option

EPDM roof installed. Should have been simple but it was a very hot day and the glue went off really quick so there are patches that didn't stick down. Stuck down securely at the edges which is the main thing.

Started cladding the shed with Cedar

More Cladding

Guttering around the back

All finished outside. Painted the cedar with two coats of OSMO UV oil

All electrics done - 2 outside sockets, alarm, PIR and lights & provision for deck lights

Electrician has done his thing inside, batten the walls & plasterboard. CAT6 and TV points in both rooms

Skimmed and painted white

Here goes................

SIPS ready for EPDM rubber roof. Went for the hopefully fit and forget option

EPDM roof installed. Should have been simple but it was a very hot day and the glue went off really quick so there are patches that didn't stick down. Stuck down securely at the edges which is the main thing.

Started cladding the shed with Cedar

More Cladding

Guttering around the back

All finished outside. Painted the cedar with two coats of OSMO UV oil

All electrics done - 2 outside sockets, alarm, PIR and lights & provision for deck lights

Electrician has done his thing inside, batten the walls & plasterboard. CAT6 and TV points in both rooms

Skimmed and painted white

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff