T4 Marks Volvo S40 T4 build

Discussion

(From APRIL 08) :

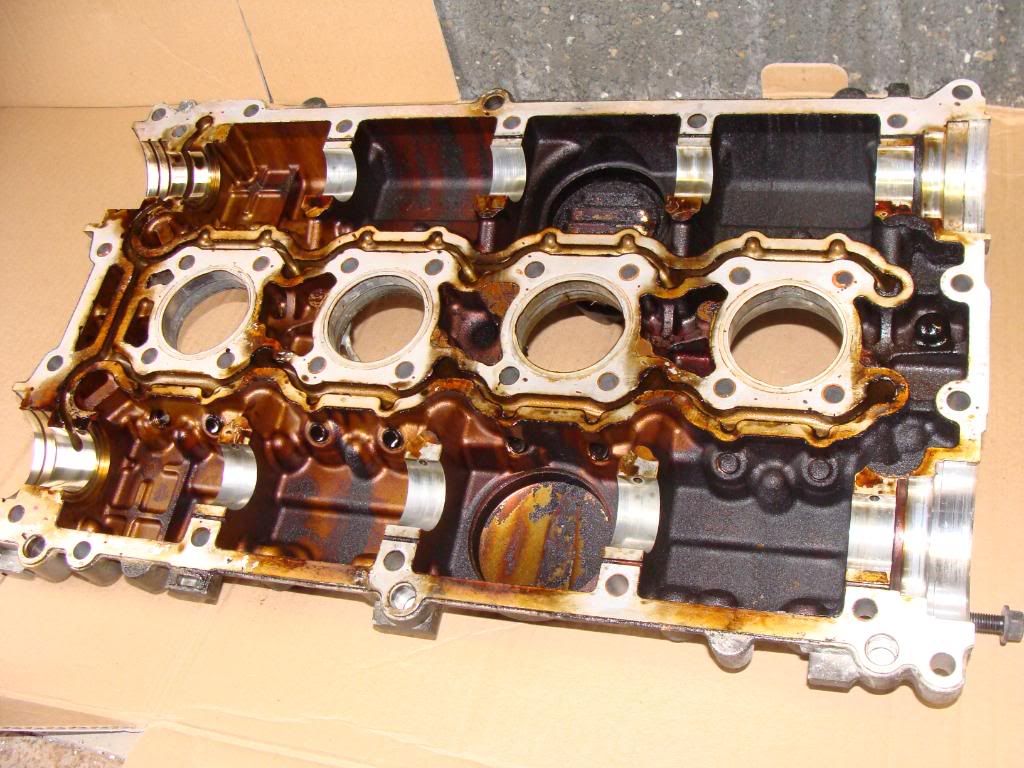

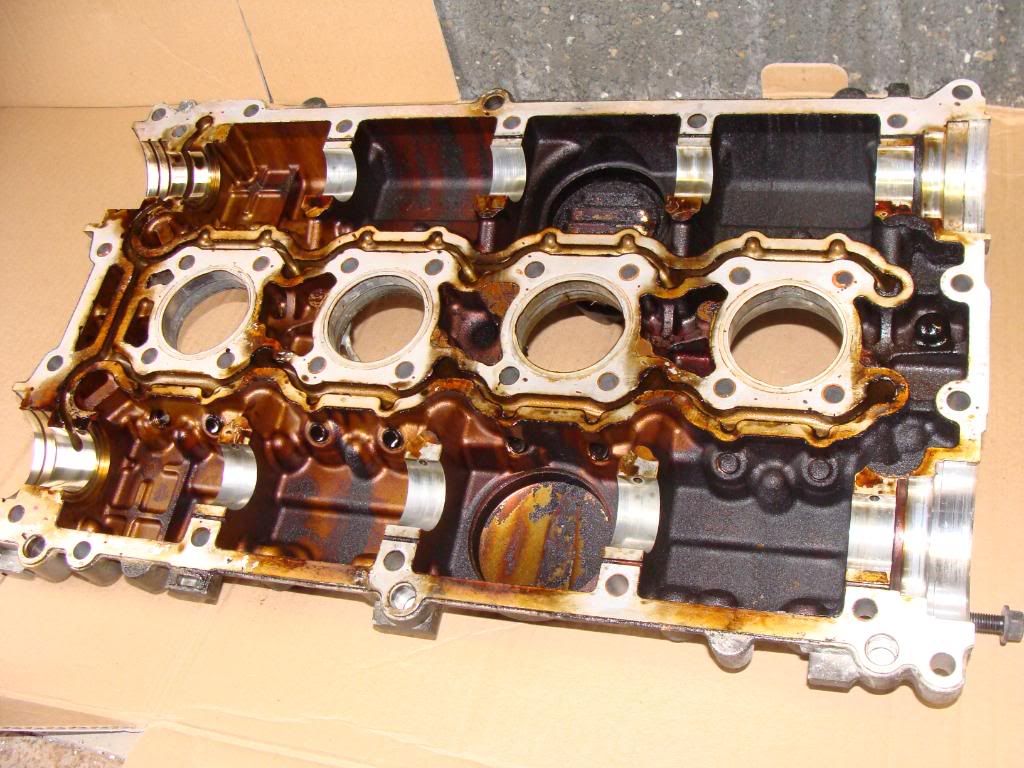

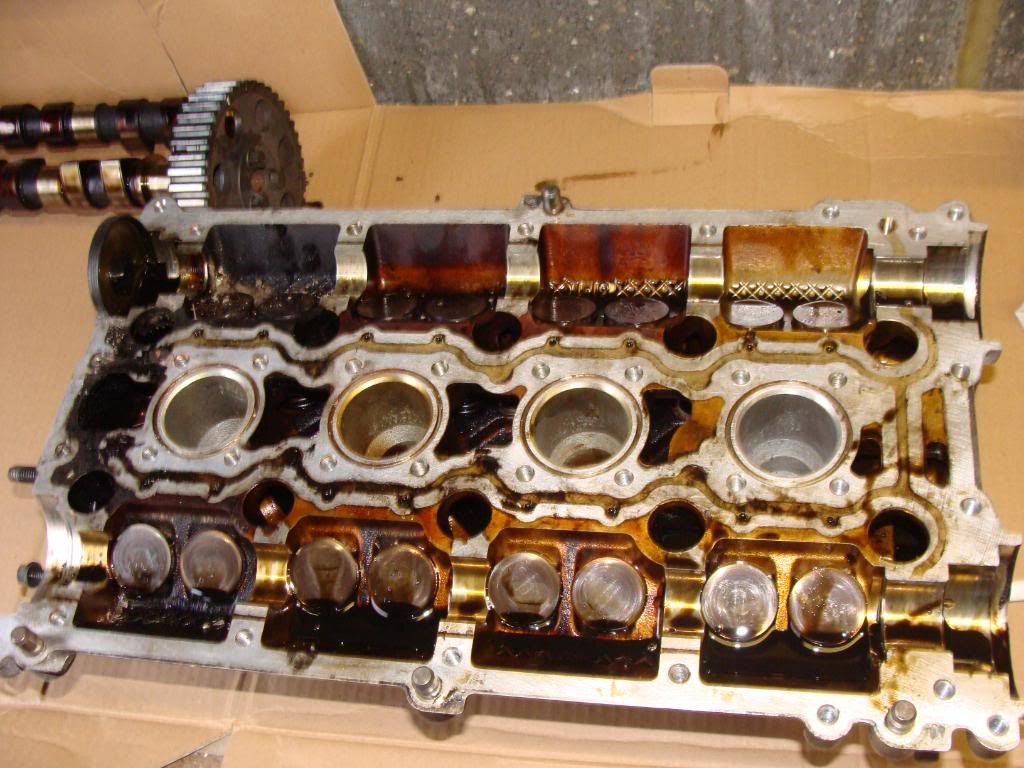

Remains of a Rod

Close up

Close up

Close up

And here are some shots of the block. It is hard to see in the picture, but the cylinder wall has been completely blown away.

The damage occured at about 5000 rpm in 4th gear on a private road. There was an intermittant misfire for a few seconds followed by a bottom end rattle and then a loud explosion followed by smoke (oil fire under the bonnet). Looks like 303 ft lb's is beyond the limit of stock internals.

Between April 08 and Feb 09 I saved for parts to re-build the car bigger and better.

Mark

Remains of a Rod

Close up

Close up

Close up

And here are some shots of the block. It is hard to see in the picture, but the cylinder wall has been completely blown away.

The damage occured at about 5000 rpm in 4th gear on a private road. There was an intermittant misfire for a few seconds followed by a bottom end rattle and then a loud explosion followed by smoke (oil fire under the bonnet). Looks like 303 ft lb's is beyond the limit of stock internals.

Between April 08 and Feb 09 I saved for parts to re-build the car bigger and better.

Mark

STAGE 1 :

Bits purchased:

THS Performance Rods:

Forged Rods & ARP bolts

www.thsperformance.co.uk Web quote

"Volvo S40, T4 Conrods

THSROD-VT4139

The THS H-Beam rods are made from high quality forged steel offering extreme reliability and stability over the standard Volvo rods. They come with a doweled cap design and 3/8" ARP 2000 Rod bolts.

Fits the following Models

Volvo S40 T4

These rods will handle in excess of 600bhp

Specifications

Forged Steel Conrods

Length = 139.5mm

Journal = 53mm

Pin = 23mm

Weight - 550grms

3/8" ARP 2000 Bolts

Dowelled Cap for Precision Fit

Balanced to within +/- 1.5 gram

All big and small ends are finished with SUNNEN cross grinder.

Bronze wrist pin bushings are made to withstand higher impact force.

Forged steel, vacuumed to remove impurities.

All surfaces are 100% machined.

Shot peened to relieve stress.

Multi Stage Heat Treated

Supports 600+BHP"

And £1,500 worth of seals, gasgets, bearings, rings, bosch green injectors etc from Volvo.

Mark

Bits purchased:

THS Performance Rods:

Forged Rods & ARP bolts

www.thsperformance.co.uk Web quote

"Volvo S40, T4 Conrods

THSROD-VT4139

The THS H-Beam rods are made from high quality forged steel offering extreme reliability and stability over the standard Volvo rods. They come with a doweled cap design and 3/8" ARP 2000 Rod bolts.

Fits the following Models

Volvo S40 T4

These rods will handle in excess of 600bhp

Specifications

Forged Steel Conrods

Length = 139.5mm

Journal = 53mm

Pin = 23mm

Weight - 550grms

3/8" ARP 2000 Bolts

Dowelled Cap for Precision Fit

Balanced to within +/- 1.5 gram

All big and small ends are finished with SUNNEN cross grinder.

Bronze wrist pin bushings are made to withstand higher impact force.

Forged steel, vacuumed to remove impurities.

All surfaces are 100% machined.

Shot peened to relieve stress.

Multi Stage Heat Treated

Supports 600+BHP"

And £1,500 worth of seals, gasgets, bearings, rings, bosch green injectors etc from Volvo.

Mark

Stage 2

1 month after engine failure, we (Me, kerryt5r, Rob T4, & Barrysc on here and Kerrys brother) managed to find a T4 with the better & much rarer T4 block : B4194-T2 (as the car already had).

The car was up in Lincoln and a 2000 model T4 in an undesirable flat purple colour with full service history and motorway miles. We set of in Robs T4 and drove 4 hours (210 miles) no bother at all.

After test driving the car, it drove perfectly so we handed over £750 only, as managed to get an ebay bargain. The car then drove perfectly back without missing a beat.

The car was then stripped with all the good bits sold on ebay : we made £700 back and still have 4 x crater wheels with tyres to sell. The engine was then removed and the rest of the car scrapped. It took me and Barry 3 days to remove the engine and ancilleries and we saved all sensors and the gearbox as spares.

Stage 3

Last week imacca, Barrysc, kerryt5r and I started work on the donor engine:

We first of all removed the cam cover:

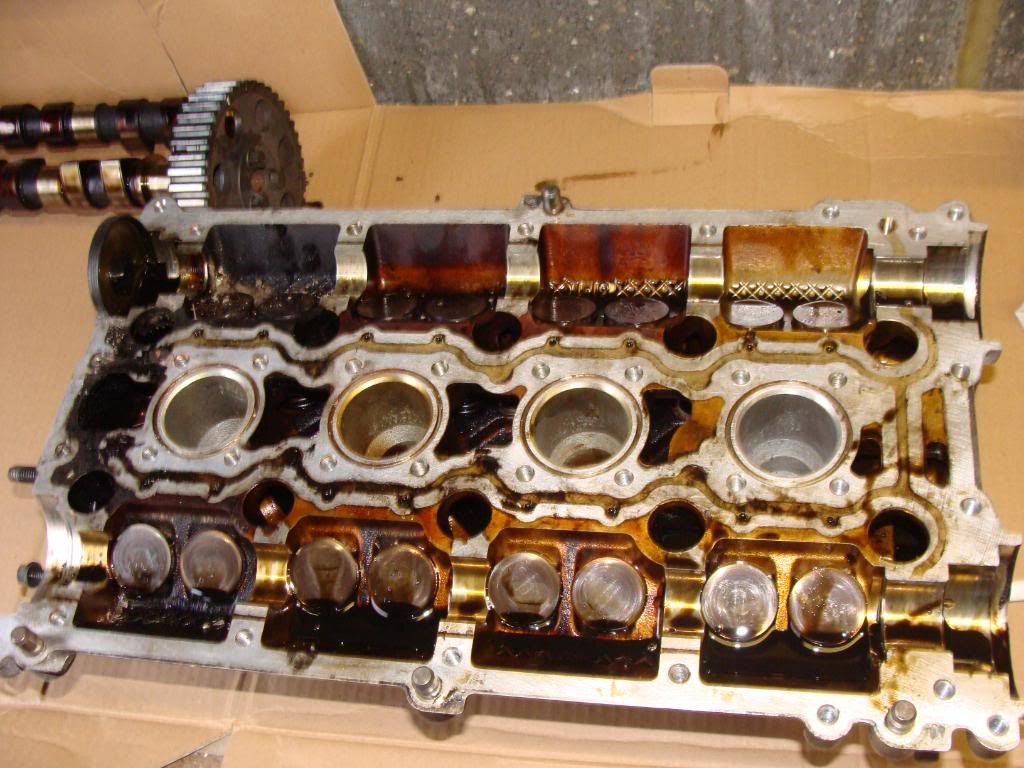

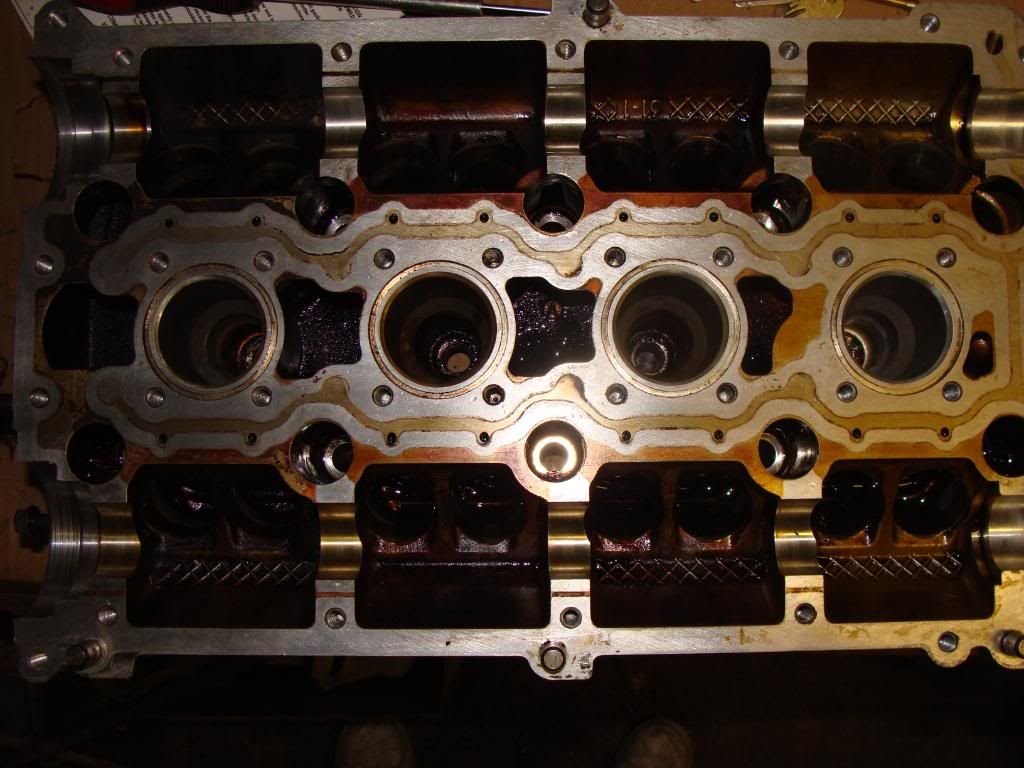

Then undid the head bolts in the correct order and removed the head:

The next step was to use a valve spring compressor so that the cuplets, valves and springs could be removed and cleaned up. We took care to note which position each one came from:

Mark

1 month after engine failure, we (Me, kerryt5r, Rob T4, & Barrysc on here and Kerrys brother) managed to find a T4 with the better & much rarer T4 block : B4194-T2 (as the car already had).

The car was up in Lincoln and a 2000 model T4 in an undesirable flat purple colour with full service history and motorway miles. We set of in Robs T4 and drove 4 hours (210 miles) no bother at all.

After test driving the car, it drove perfectly so we handed over £750 only, as managed to get an ebay bargain. The car then drove perfectly back without missing a beat.

The car was then stripped with all the good bits sold on ebay : we made £700 back and still have 4 x crater wheels with tyres to sell. The engine was then removed and the rest of the car scrapped. It took me and Barry 3 days to remove the engine and ancilleries and we saved all sensors and the gearbox as spares.

Stage 3

Last week imacca, Barrysc, kerryt5r and I started work on the donor engine:

We first of all removed the cam cover:

Then undid the head bolts in the correct order and removed the head:

The next step was to use a valve spring compressor so that the cuplets, valves and springs could be removed and cleaned up. We took care to note which position each one came from:

Mark

FEB 2009 weekend 4

Fair amout of progress this weekend. Firstly we removed the crankshaft pulley securing nut and the locating bolts - with the help of my Eastbourne Tyres work van air powered truck gun.

:thumbs_up:

Then removed the sump and intermediate section :

Then removed the crank shaft sprocket and oil pump.

And with the rest of the daylight we started removing the head from the broken engine, the cover, inlet manifold and exhaust manifold are removed :

Cheers,

Mark

Fair amout of progress this weekend. Firstly we removed the crankshaft pulley securing nut and the locating bolts - with the help of my Eastbourne Tyres work van air powered truck gun.

:thumbs_up:

Then removed the sump and intermediate section :

Then removed the crank shaft sprocket and oil pump.

And with the rest of the daylight we started removing the head from the broken engine, the cover, inlet manifold and exhaust manifold are removed :

Cheers,

Mark

APRIL 2009

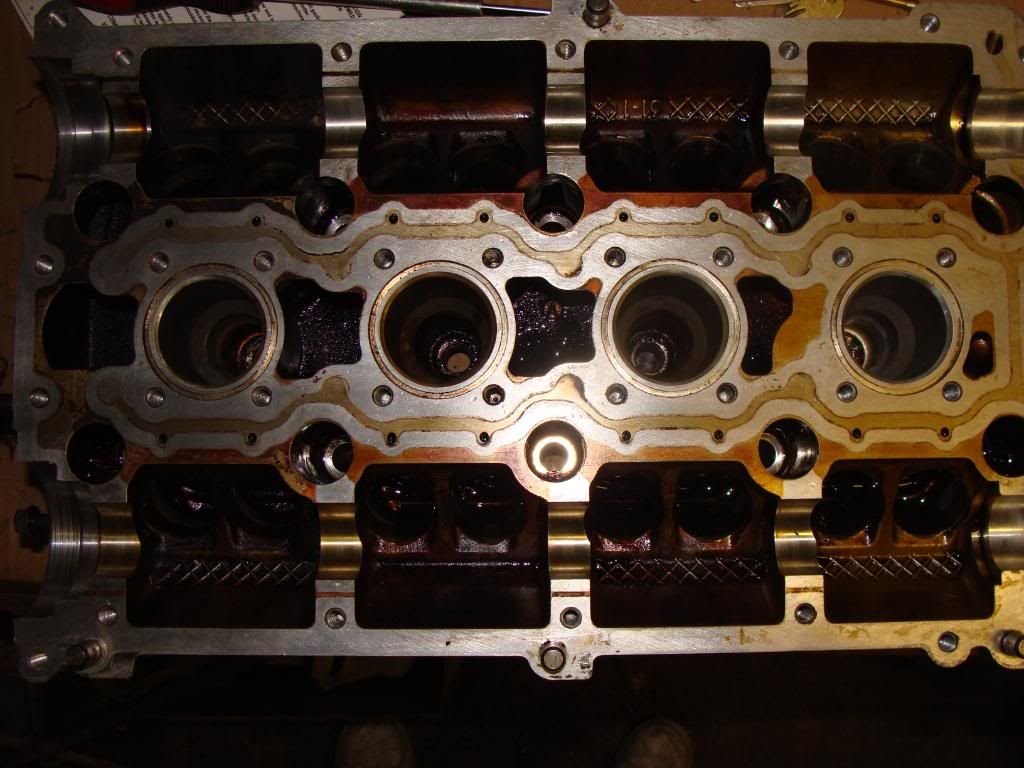

Next step was to get the head skimmed, ported and re-assembled and the block re-honed. It was done at QEP : http://www.q-e-p.co.uk/ They did a brilliant job, here is a pic of the inlet side:

Next a few bits arrived :

Ferrita cat back exhaust

Gaz Gold fully adjustable coilovers. Ride height, damping, camber etc.

Old engine out!

Barrysc in the engine bay!

Cheers Mark

Next step was to get the head skimmed, ported and re-assembled and the block re-honed. It was done at QEP : http://www.q-e-p.co.uk/ They did a brilliant job, here is a pic of the inlet side:

Next a few bits arrived :

Ferrita cat back exhaust

Gaz Gold fully adjustable coilovers. Ride height, damping, camber etc.

Old engine out!

Barrysc in the engine bay!

Cheers Mark

Here are the pictures from the end May 2009 :

The engine is now timed

The next pics are from May up to today

Front coilovers are fitted, unfortunately no pics! But I do have a comparison pic of the old shocks and springs compared to the coilovers:

Clutch and flywheel fitted

Standard turbo on (im using the standard turbo for running in etc)

Gearbox on (with Quaife diff inside ) :

) :

Ready to go in:

In the car:

Ancillaries, radiator, intercooler, oil cooler etc

Same as above with bonnet back on:

As it is this evening (after turning around - knackered after that!) - getting close to finishing now!

More updates to follow soon....

Cheers,

Mark

The engine is now timed

The next pics are from May up to today

Front coilovers are fitted, unfortunately no pics! But I do have a comparison pic of the old shocks and springs compared to the coilovers:

Clutch and flywheel fitted

Standard turbo on (im using the standard turbo for running in etc)

Gearbox on (with Quaife diff inside

) :

) :

Ready to go in:

In the car:

Ancillaries, radiator, intercooler, oil cooler etc

Same as above with bonnet back on:

As it is this evening (after turning around - knackered after that!) - getting close to finishing now!

More updates to follow soon....

Cheers,

Mark

There has been a few updates over the last year....

Shot of new Ferrita exhaust on the car:

Had a play around with the ride height

Next the car went up to RT Mechanics & MA Developments for some more serious upgrades :

[LIST]

Custom Wiring loom by Rod Tarry

Standalone Vipec ECU with launch control & anti lag

Siemens 660cc injectors

Walbro 255 lph fuel pump

Secondary ignition amp

secondary coolant temp sensor

Custom remap by Mark Shead of MA Developments

Carbotech XP10 Mitsubishi Evo pads [/LIST]

Pic of the VIPEC ECU :

Next was time to enjoy the car for a few miles, a couple of poor quality camera pics on the way to goodwood breakfast club :

More updates to follow..

Shot of new Ferrita exhaust on the car:

Had a play around with the ride height

Next the car went up to RT Mechanics & MA Developments for some more serious upgrades :

[LIST]

Custom Wiring loom by Rod Tarry

Standalone Vipec ECU with launch control & anti lag

Siemens 660cc injectors

Walbro 255 lph fuel pump

Secondary ignition amp

secondary coolant temp sensor

Custom remap by Mark Shead of MA Developments

Carbotech XP10 Mitsubishi Evo pads [/LIST]

Pic of the VIPEC ECU :

Next was time to enjoy the car for a few miles, a couple of poor quality camera pics on the way to goodwood breakfast club :

More updates to follow..

After enjoying the car for a few miles, it was time for an oil and filter change along with new 850R flywheel & Clutch as the original clutch was slipping and the map on the car was set to 0.7 bar.

Here are a few pics..

Old standard dual mass flywheel :

New 850R Flywheel :

Flywheel fitted :

Old hydraulic clutch release bearing :

New release bearing fitted :

Old Clutch :

New 850R clutch fitted :

Took me and my uncle 6 hours to do, also replaced the drop links as they were making slight noises.

The 850R clutch and solid flywheel make a good difference. Much firmer bite and more feel and in the future should stand more power.

Car went back to MA developments and now has 1.1 - 1.2 bar boost, pulling 1.4 bar in fifth gear, very happy with the car - will post current spec soon.

Here are a few pics..

Old standard dual mass flywheel :

New 850R Flywheel :

Flywheel fitted :

Old hydraulic clutch release bearing :

New release bearing fitted :

Old Clutch :

New 850R clutch fitted :

Took me and my uncle 6 hours to do, also replaced the drop links as they were making slight noises.

The 850R clutch and solid flywheel make a good difference. Much firmer bite and more feel and in the future should stand more power.

Car went back to MA developments and now has 1.1 - 1.2 bar boost, pulling 1.4 bar in fifth gear, very happy with the car - will post current spec soon.

Took some pics after cleaning my car yesterday at beachy head, the green T-5R in some of the pictures belongs to Kerry_T-5R (see his project here : http://www.pistonheads.co.uk/gassing/topic.asp?h=0...) Here are the pics of mine :

See the full set of photos of both cars here : http://www.pistonheads.co.uk/gassing/topic.asp?h=0...

Mark

See the full set of photos of both cars here : http://www.pistonheads.co.uk/gassing/topic.asp?h=0...

Mark

T4Mark said:

The damage occured at about 5000 rpm in 4th gear on a private road. There was an intermittant misfire for a few seconds followed by a bottom end rattle and then a loud explosion followed by smoke (oil fire under the bonnet). Looks like 303 ft lb's is beyond the limit of stock internals.

Between April 08 and Feb 09 I saved for parts to re-build the car bigger and better.

Mark

Hi Mark, Between April 08 and Feb 09 I saved for parts to re-build the car bigger and better.

Mark

I'm boosting over 2.3 Bar on stock T4 internals, the engine produces 530HP and 610Nm at the moment without any problem. Your engine failed because of a bad tune or simply you had a bad luck. My wote goes to the first statement

.

.Your car looks nice, keep up with good work!

Tom

tcode said:

Hi Mark,

I'm boosting over 2.3 Bar on stock T4 internals, the engine produces 530HP and 610Nm at the moment without any problem. Your engine failed because of a bad tune or simply you had a bad luck. My wote goes to the first statement .

.

Your car looks nice, keep up with good work!

Tom

What turbo are you running and what map / setup?I'm boosting over 2.3 Bar on stock T4 internals, the engine produces 530HP and 610Nm at the moment without any problem. Your engine failed because of a bad tune or simply you had a bad luck. My wote goes to the first statement

.

.Your car looks nice, keep up with good work!

Tom

Gallen said:

What turbo are you running and what map / setup?

Feel free to ask whatever you want

http://www.pistonheads.com/gassing/topic.asp?h=0&a...

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff