Renovating an old wooden sports boat, am I mad?

Discussion

OldJohnnyYen said:

Are you enjoying it so far?

Yup, it's nice to see something come together like this. I've never done such a big project so it's a little daunting at times. I think I've got a handle on it though, have a good idea about how it'll all eventually fit together anyway.I'm a little concerned about the deck camber which is very different on the frame drawings to the camber pattern, it doesn't match up at all. This won't matter in the slightest until I go to fit the engine and fit it's too tall for the deck, by which time it's all a bit late. Worst case, I can double up the deck camber, but it'll make a right old mess to clear up.

Looks like I might need an engine as soon as it's turned over, just to throw in and see if the deck camber is tall enough.

Anyway, there's a long way to go yet!

MOTORVATOR said:

I had a feeling this would come up.

The first decision you need to make is transmission. Straight drive, Down Angle, Drop Box, V Drive?

I'm going to make a wild guess looking at the picture you posted that the boat will sit fairly neutral in attitude, but a fairly severe propshaft angle which would indicate that you're probably going to be best served by a down angle transmission to keep the engine in it's best operating position.

The set up you go for also wants to reduce that shaft angle against the keel as much as you possibly can for efficiency. No power trim here!

That transmission choice then dictates the stringer heights and lateral position required and hence the mounting height of the engine.

It's dependant on the vee that you might need the stringers pushed apart so that an engine mounting cradle can be formed to get the engine down to where you want to go.

But just to give you a quick measure up, say a 350 mag with velvet drive?

www.mercurymarine.com/media/mercury/drawings/86477...

Other options are available.

Ooh, you're good. Yes, down angle is what's in the plans. About 9 degrees I think (without checking the plans, I might be wrong).

The first decision you need to make is transmission. Straight drive, Down Angle, Drop Box, V Drive?

I'm going to make a wild guess looking at the picture you posted that the boat will sit fairly neutral in attitude, but a fairly severe propshaft angle which would indicate that you're probably going to be best served by a down angle transmission to keep the engine in it's best operating position.

The set up you go for also wants to reduce that shaft angle against the keel as much as you possibly can for efficiency. No power trim here!

That transmission choice then dictates the stringer heights and lateral position required and hence the mounting height of the engine.

It's dependant on the vee that you might need the stringers pushed apart so that an engine mounting cradle can be formed to get the engine down to where you want to go.

But just to give you a quick measure up, say a 350 mag with velvet drive?

www.mercurymarine.com/media/mercury/drawings/86477...

Other options are available.

Haven't heard great things about the velvet drive, but there's other options. A bit of a minefield for the uninitiated though. I'll crack on with the hull and planking, when I'm a bit further along and it's looking like the turn is imminent, I'll get an engine lined up ready to drop in for testing.

I need to put the shaft in before it's turned over, which makes things a little difficult not being able to test and line up first!

gwm said:

maser_spyder said:

Looks like I might need an engine as soon as it's turned over, just to throw in and see if the deck camber is tall enough.

Anyway, there's a long way to go yet!

What sort of engine are you looking at fitting? How much room do you have to play with?Anyway, there's a long way to go yet!

I think 6.2L Mercruiser, something pretty standard and easy for parts.

Room, should be plenty but I'd like to know for sure a long time before the deck starts going on....

MOTORVATOR said:

maser_spyder said:

Ooh, you're good. Yes, down angle is what's in the plans. About 9 degrees I think (without checking the plans, I might be wrong).

Haven't heard great things about the velvet drive, but there's other options. A bit of a minefield for the uninitiated though. I'll crack on with the hull and planking, when I'm a bit further along and it's looking like the turn is imminent, I'll get an engine lined up ready to drop in for testing.

I need to put the shaft in before it's turned over, which makes things a little difficult not being able to test and line up first!

Hmm. At what point do the engine stringers go in. Upside down or after the event and housed around the frames rather than the other way?Haven't heard great things about the velvet drive, but there's other options. A bit of a minefield for the uninitiated though. I'll crack on with the hull and planking, when I'm a bit further along and it's looking like the turn is imminent, I'll get an engine lined up ready to drop in for testing.

I need to put the shaft in before it's turned over, which makes things a little difficult not being able to test and line up first!

Down angle drops the selection of boxes to a couple of options. In fairness the velvet drive should be no problem for your application, they take a lot more horses than you are talking about putting through and you won't have the continual on and off of torque that you get with a ski boat going round in circles trying to get an incompetent skier out of the water. Biggest destroyer of gearboxes is leaving the water with an inexperienced throttle man and the sudden releases and reintroduction of torque. Hopefully you are not going there though!

I'm going to be pottering about with the odd blast to blow the cobwebs away. Nothing too much, but I'd still like it to be reliable.

MOTORVATOR said:

maser_spyder said:

The motor stringers are full length from transom to second from front frame, the idea is just to add brackets and to suit the engine and line it up with the pre-installed shaft.

I'm going to be pottering about with the odd blast to blow the cobwebs away. Nothing too much, but I'd still like it to be reliable.

I think you're going to be pretty well stuck with either ZF/Hurth or Velvet if you go the Mercruiser route. PCM might be worth a look as they do a downward looking box but I have heard bits about leaks. And Crusader hook up to most boxes.I'm going to be pottering about with the odd blast to blow the cobwebs away. Nothing too much, but I'd still like it to be reliable.

For rough sizing though the 6.2mpi with Hurth and Velvet.

www.mercurymarine.com/media/mercury/drawings/drw57...

www.mercurymarine.com/media/mercury/drawings/drw57...

Not a huge difference in lengths so placement is going to be similar. And keep an eye on the layouts as you're bulding as there is nothing more annoying than finding something like the raw water pump won't fit down inside the stringers where it needs to be. Then the discovery that the whole of the front of the engine is covered in indirect cooling stuff and there just is nowhere else to get a belt take off without taking a chainsaw to your fresh resin work!

And when you want that Mercruiser give me a buzz and I'll put you in touch with the right man. He has the enjoyable task at the moment of dropping the crank out of the brand new 502 that we blew up this year during a poker run and prepping the boy's new outboard for racing offshore 3A this year so he knows what's what.

I'm quite lucky with access, in front will be the seat, which I can easily make a removable panel for engine access, and likewise the rear (although I'll probably have more than enough room already). The whole engine bay is quite over-sized, I'll try and dig out a pic from another build so you can see what others have done.

This thread must be popular, that's 10Gb of pic bandwidth in just over 2 weeks. Lots of lurkers! Need to Go Pro, will do that later....

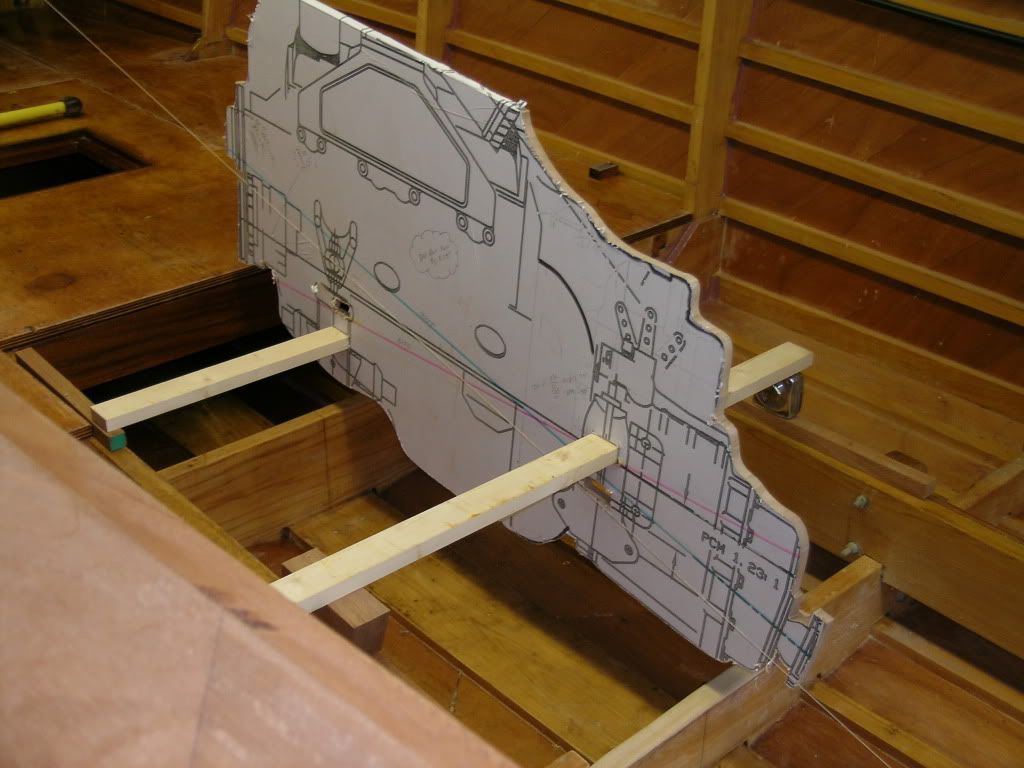

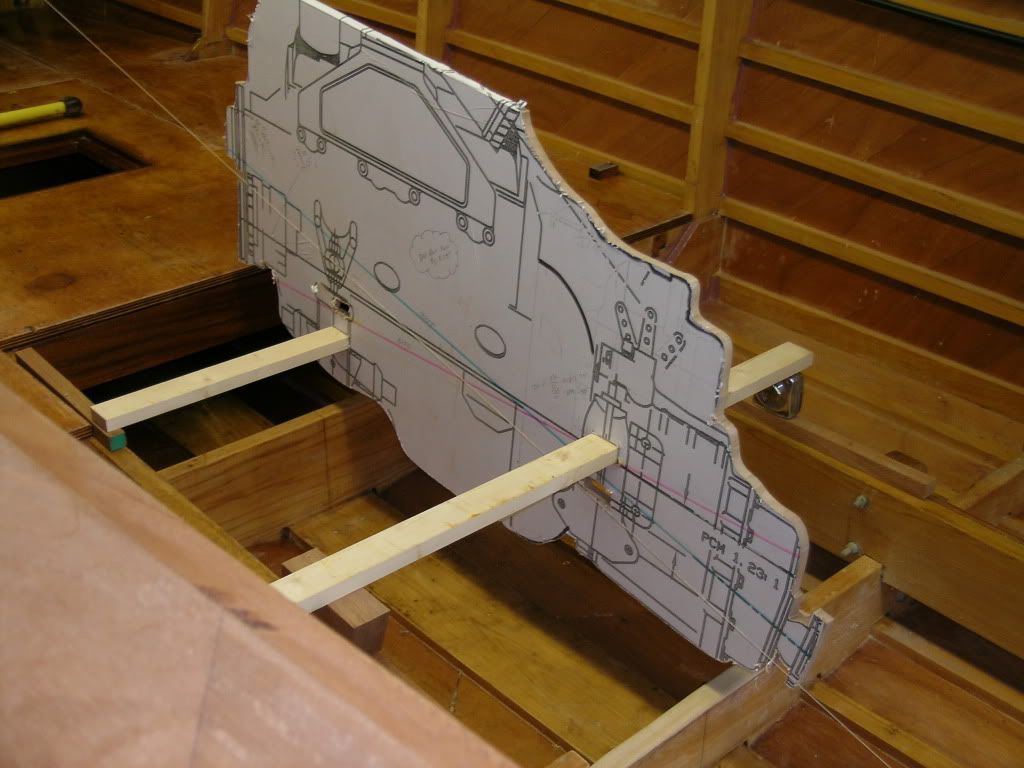

Here's what another builder did with their engine mounting;

I like their idea of doing a cut-out of the engine 'life size', which I could easily do by running off that diagram on my big printer and sticking it to some MDF. Much easier to fettle with a small bit of cardboard than a hulking great engine.

As you can see, plenty of room aft of the engine. Not much room forward, but the seat can be made removable easily enough.

From checking this chap's pics, his deck camber is the same as mine (it's much more pronounced on the frame drawings than the camber pattern), and still loads of clearance on top of the engine, so I should be OK.

I like their idea of doing a cut-out of the engine 'life size', which I could easily do by running off that diagram on my big printer and sticking it to some MDF. Much easier to fettle with a small bit of cardboard than a hulking great engine.

As you can see, plenty of room aft of the engine. Not much room forward, but the seat can be made removable easily enough.

From checking this chap's pics, his deck camber is the same as mine (it's much more pronounced on the frame drawings than the camber pattern), and still loads of clearance on top of the engine, so I should be OK.

benters said:

so we wont be seeing a Lambo engine in it then

The hull wouldn't take it! It's a home-made wooden boat, not a strengthened racer.

And it's an idiot building it, I'll be lucky if it floats, drives, and doesn't kill anybody, so I'm not tempting fate by putting something too heavy under the hood that'll mess up the weight distribution and possibly shred the thing to pieces!

I'll keep a look out though, if an 'interesting' engine/gearbox package comes up somewhere I might re-think the Mercruiser idea.

For the moment though, I want something I can get relatively easily, off the shelf, and with easy to find parts. They've also got a proven track record of reliability, which isn't something you can say for an old marinised car engine.

Apologies I'm playing safe!

MOTORVATOR said:

You probably know it Maser but the PCM / Mercruiser / Crusader / Volvo are all basically the same base chevy engine. In this case small block. So if you really wanted to play then the route would be to build up your own chevy then it is easy to equip with ancilliaries, but you'll end up spendng more than just buying the package for no real gain.

Auto engines are a pain in the neck as cams etc are wrong to deliver the right torque curves for marine use. Then you have the problem of hooking them up to bellhousings, drive plates and so forth. Sumps are all the wrong size and shape for the sloshing around of oil that happens at sea. No remote mounting of oil filters etc, wrong size / cooling alternators, no raw water pumps, no heat exchangers and that's before you start to think about suitable exhaust risers and the rest. That's all finished off with Ali parts not being the best thing to see near salt water.

The duty on a marine engine is totally different to auto with no gearing and the engine will spend it's life being demanded to produce most if not all of it's power for extended periods. So the agricultural nature of american lumps of cast iron works well.

Personally I would stick with Mercruiser, as you say easy for parts and good track record.

With this one, I have the feeling that I'm building a boat, and I don't feel the need to build the engine as well. Realistically, how far do you go with it? I haven't hand-cut the lumber, I used machine tools. I haven't planed the lumber myself, I got a pro to do it. But I still feel like I'm building it all myself.Auto engines are a pain in the neck as cams etc are wrong to deliver the right torque curves for marine use. Then you have the problem of hooking them up to bellhousings, drive plates and so forth. Sumps are all the wrong size and shape for the sloshing around of oil that happens at sea. No remote mounting of oil filters etc, wrong size / cooling alternators, no raw water pumps, no heat exchangers and that's before you start to think about suitable exhaust risers and the rest. That's all finished off with Ali parts not being the best thing to see near salt water.

The duty on a marine engine is totally different to auto with no gearing and the engine will spend it's life being demanded to produce most if not all of it's power for extended periods. So the agricultural nature of american lumps of cast iron works well.

Personally I would stick with Mercruiser, as you say easy for parts and good track record.

I've spotted other builders who really go to town on doing absolutely everything themselves, but I just don't want to go down that route. If there's a method that will get it done quicker, I'll use it.

So, if I can make a call, pay some money, and have somebody deliver a shiny engine in a crate that's ready to fit, I'll still feel like I've built my own boat.

I'm sure I'd feel more close to the project if I built my own engine and made my own veneers, but I'm just not that fussed about learning even more new skills. What I'm already doing is enough!

OneDs said:

maser_spyder said:

Here's what another builder did with their engine mounting;

Pics

I like their idea of doing a cut-out of the engine 'life size', which I could easily do by running off that diagram on my big printer and sticking it to some MDF. Much easier to fettle with a small bit of cardboard than a hulking great engine.

As you can see, plenty of room aft of the engine. Not much room forward, but the seat can be made removable easily enough.

From checking this chap's pics, his deck camber is the same as mine (it's much more pronounced on the frame drawings than the camber pattern), and still loads of clearance on top of the engine, so I should be OK.

Maser did you see this post about the deck camber on the Glen L site?Pics

I like their idea of doing a cut-out of the engine 'life size', which I could easily do by running off that diagram on my big printer and sticking it to some MDF. Much easier to fettle with a small bit of cardboard than a hulking great engine.

As you can see, plenty of room aft of the engine. Not much room forward, but the seat can be made removable easily enough.

From checking this chap's pics, his deck camber is the same as mine (it's much more pronounced on the frame drawings than the camber pattern), and still loads of clearance on top of the engine, so I should be OK.

http://www.glen-l.com/phpBB2/viewtopic.php?f=15&am...

But, that said, I think it'll be ok, and is actually possible to change before you start making the deck up properly. At this stage, it makes no difference to the build, and I'll crack on. But, before I start putting the deck together, I really need to install the engine to get a clearance level before the deck goes on.

So, I'll leave my frames correct as the plans and not trim them yet. After the turn, I'll fit the engine and get a top level. If my existing deck beams fit, I'll carry on as normal. If not, I'll cut some new ones (have got plenty of timber), fit them over the existing and then start on the deck strong backs, beams etc. after I know the maximum height.

I'd actually prefer a flatter deck, I think it looks better, so as long as the engine will fit I'll go with a lower deck pattern.

Having said all that, it goes to show how much self-involvement there is in the build process. The plans are good, but that's a BIG mistake, and not good for a novice builder who's dipping a toe in the water for the first time. It's bad enough trying to get your head around the plans without having mistakes to deal with!

MOTORVATOR said:

You're right you're rambling Simpo.

Do you know Maser I keep going back to that photo of the engine in place and the sringers. It just isn't how I perceived it to be if you know what I mean. When you look at the engine it is effectively supported across the two frames. I was envisaging the stringers to be full depth down to the skin with relief holes for bilge water which is how we would see a glass boat laid up.

That's going to keep me awake at nights now until Huntsman comes along and calls me a modernist idiot with no concept of traditional cold moulded boat skills.

The stringers are about 17' long, with plenty of strength, and the frames are very firmly fixed in place too.

Do you know Maser I keep going back to that photo of the engine in place and the sringers. It just isn't how I perceived it to be if you know what I mean. When you look at the engine it is effectively supported across the two frames. I was envisaging the stringers to be full depth down to the skin with relief holes for bilge water which is how we would see a glass boat laid up.

That's going to keep me awake at nights now until Huntsman comes along and calls me a modernist idiot with no concept of traditional cold moulded boat skills.

I guess the idea is the motor is effectively bolted to two 17' lengths of timber, with a hull built around them on frames and battens. Think of the stringers as the bulk of the hull.

Mine look a bit weedy at the moment, but once I've lined it all up, fitted the frames in place properly, and have the frame/stringer blocking coach bolted in place, it'll make a bit more sense.

Not much will happen for a week or so now, I'm off to Germany for a few days. Hoping to crack on at a good pace in February though, plenty of time put aside to get the lining up done, frames fitted, and chine/deck logs and keel fitted which will leave me ready for fairing.

At this rate, I'm putting a finished date of early 2015, inshallah.

Edited by maser_spyder on Thursday 30th January 09:30

OneDs said:

It also looks like it was recognised and not corrected years ago, looking at my plans there will be so much interpretation/interpolation that the end result will be an evolution from a set of overview plans rather than a accurate reproduction. Some people (gifted craftsmen) like this sort of challenge, me I'd prefer methodical build plan akin to a caterham kit.

Yup, that's what I have too, some outlines and recommendations for timber thickness, but with a lot of scope for change and interpretation. For me, that adds an extra layer of complication to be dealt with! Which is part of the reason I want a crate engine, otherwise it'll never be finished.I think there's about half a dozen of these in a finished state that are documented online, I would guess none of them are more than about 80% matching under the surface.

Huntsman said:

MOTORVATOR said:

You're right you're rambling Simpo.

That's going to keep me awake at nights now until Huntsman comes along and calls me a modernist idiot with no concept of traditional cold moulded boat skills.

Sorry, been travelling.

That's going to keep me awake at nights now until Huntsman comes along and calls me a modernist idiot with no concept of traditional cold moulded boat skills.

Anyway, more importantly, there's now 500hp waiting patiently in my Huntsman!!!!

Stringers, or Hogs as I call them, tend to be fitted in one of two ways, as per the pics on the previous page with a framed boat, where they run along the top of the frames, some times notched in and sometimes with metal brackets, I prefer the metal bracket route as I preceive the nothces could be a weak point, although of course you could sister them up. My 1930's race boat is like this.

The other route, per my Huntsman, is more often found in a hot or cold moulded hull, is the bottom of the hog is chamfered to fit the hull, its then glued and bolted into place with a set of 'intercostals' ie little tiny bulkheads, joining then across the middle, out to the chines and a few inches up the topsides.

Remember, a wooden boat gets its strength through the continuity of the timber, ie lots of long bits. You can;t make a strong boat from a million little offcuts and a big drum of epoxy.

Interesting to hear the Huntsman method, I could fairly easily adapt mine to add a bit of strength around the engine section using the same idea, extending the stringer to the hull and fairing it before planking.

Fishtigua said:

Just to motivate you a tad, a mate has just launched his little 26 homebuilt sailing boat this week. He also has his daily driver E-type and Alfa Spiders in the shed too.

https://www.facebook.com/media/set/?set=a.21023354...

Excellent job. I was a bit surprised to see it was built from scratch the 'right way up'. The keel must have been torture on his knees and back!https://www.facebook.com/media/set/?set=a.21023354...

I'm hoping to get a bit of progress made over the next few weeks, almost on top of other things at last.

Update.

Loosely fitted frames and roughly laid out stringers are now lined up and properly cut to within 1mm accuracy.

It doesn't look very different to last time, but is almost ready for blocking to fix it all in place. I've made one. 15 more to go.

I need to pick up a new spirit level and big set square tomorrow, just to make sure it's totally lined up before I start fixing things in place. I'll probably make all the blocking as well and fit them all in one go. That'll be a big step forwards as it'll mean the frame is set to it's final shape.

Next up, fit the keel, chines and battens before fairing.

Loosely fitted frames and roughly laid out stringers are now lined up and properly cut to within 1mm accuracy.

It doesn't look very different to last time, but is almost ready for blocking to fix it all in place. I've made one. 15 more to go.

I need to pick up a new spirit level and big set square tomorrow, just to make sure it's totally lined up before I start fixing things in place. I'll probably make all the blocking as well and fit them all in one go. That'll be a big step forwards as it'll mean the frame is set to it's final shape.

Next up, fit the keel, chines and battens before fairing.

Eleven said:

maser_spyder said:

Stuff

Did you uncover that old car just for tease value, or has its identity been revealed elsewhere in the thread?But hiding the full number plate was a mistake, although it should prevent anybody from looking it up on the MID or something.

So, what is it?.....

rolando said:

Hillman Minx is my best guess

Bingo! Top spotting, help yourself to some petrol head points.1936 Hillman Minx tourer. My old man used to play in her when he was a boy, she was tucked away in a barn. He went back years later, still there, so he bought her for £15. A lot of money back then. 15 year restoration including making a lot of panels and parts himself as there just aren't any left. Back on the road in about 1987 if I recall.

So, not particularly valuable or sought after, but a very elegant machine and one of two known in the world, so worth looking after.

Anyway, enough of the car, the damned boat!

Gassing Station | Boats, Planes & Trains | Top of Page | What's New | My Stuff

What about the boat, dammit.

What about the boat, dammit.