Bloodhound LSR Thread As Requested...

Discussion

IN51GHT said:

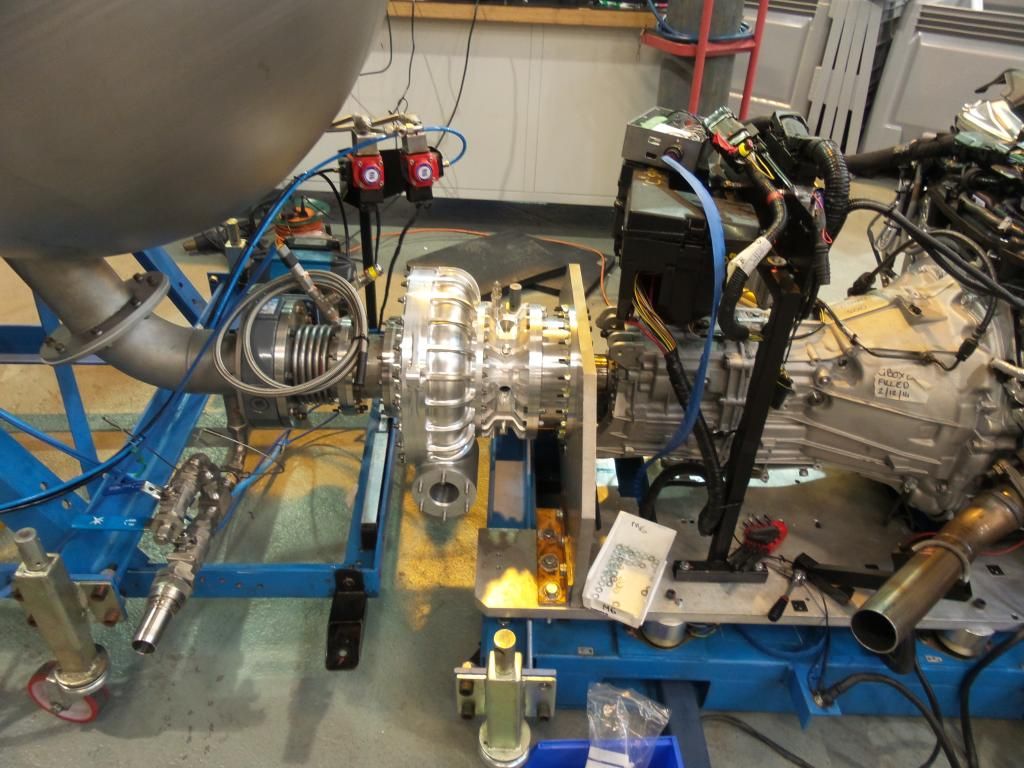

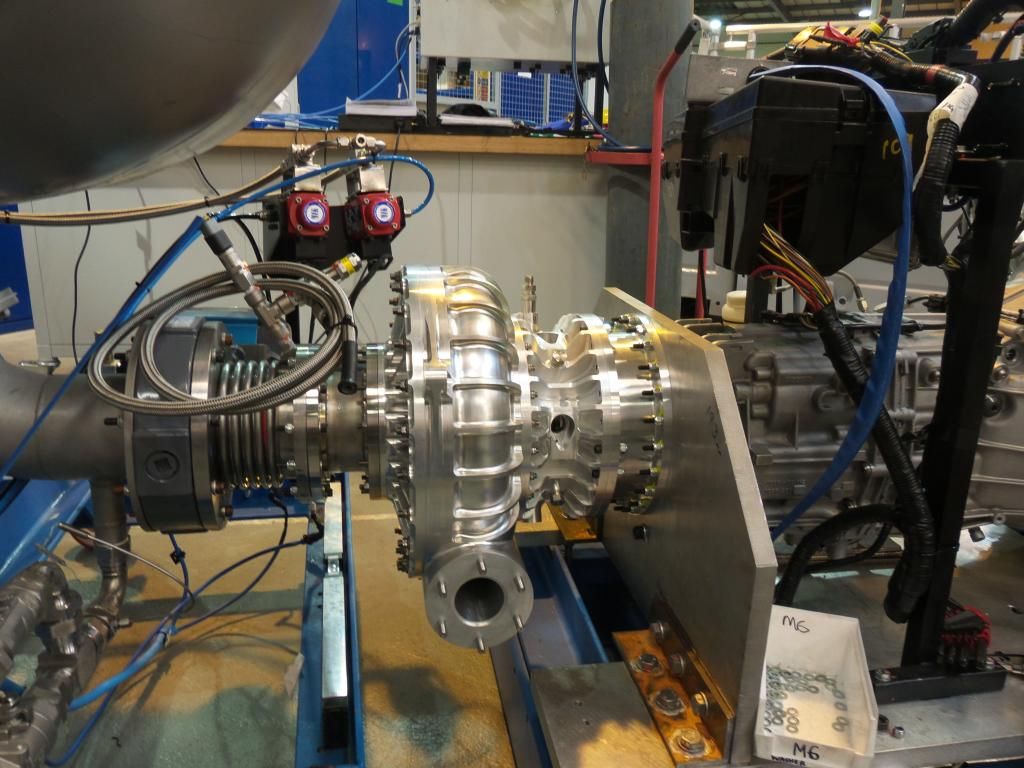

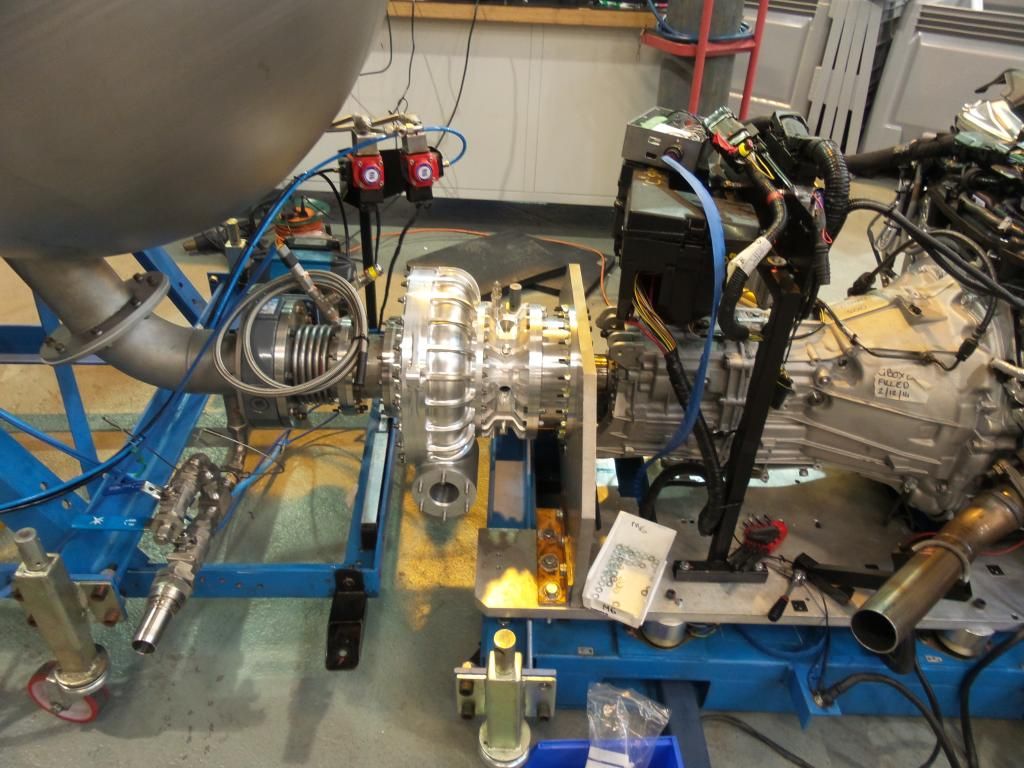

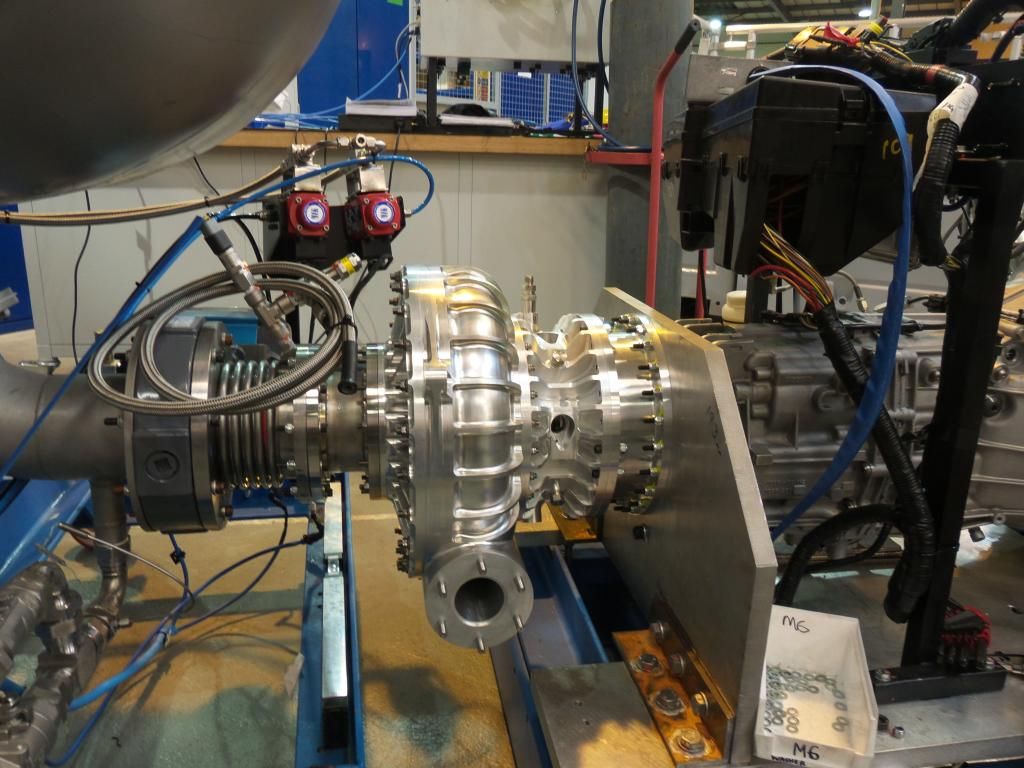

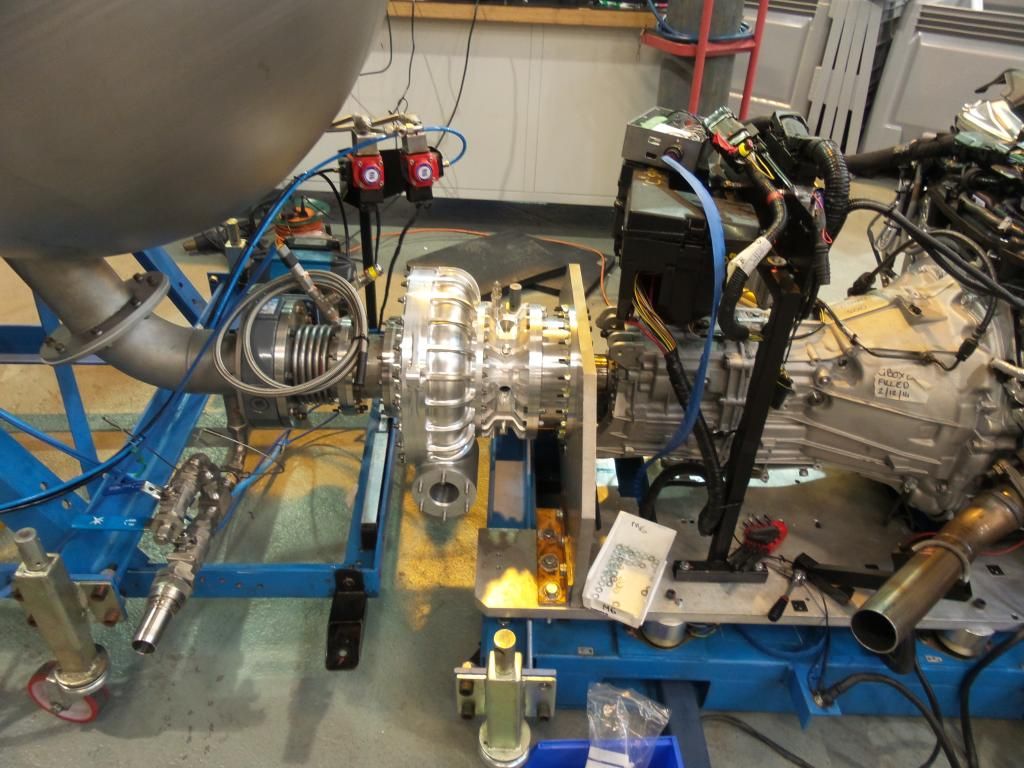

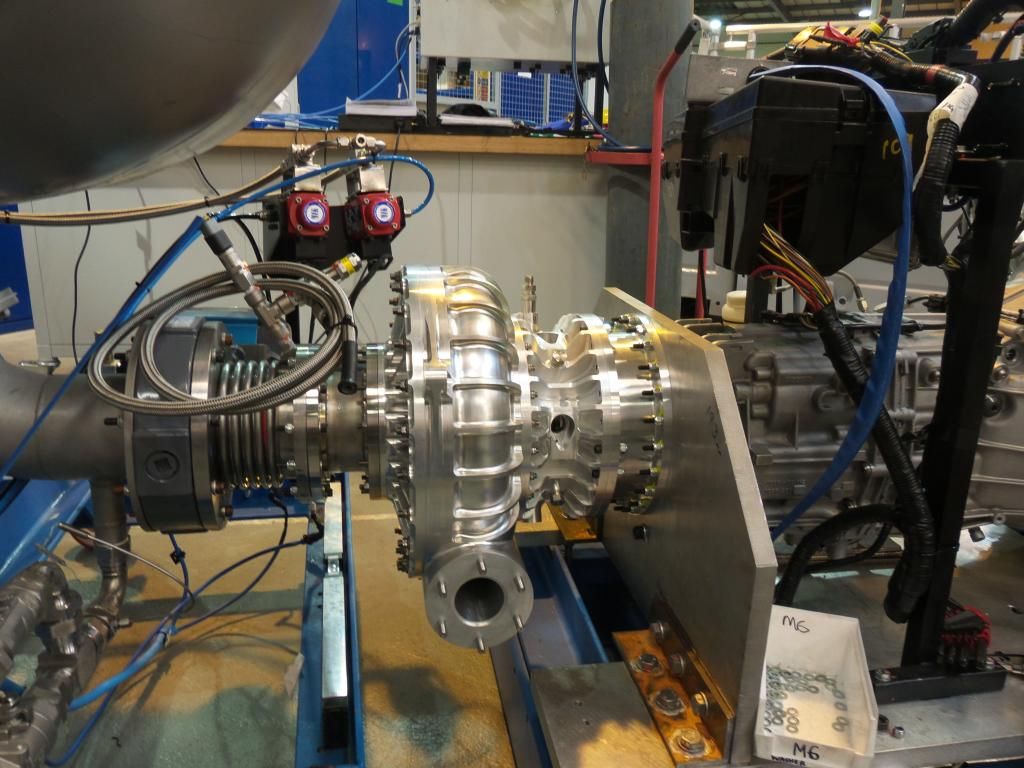

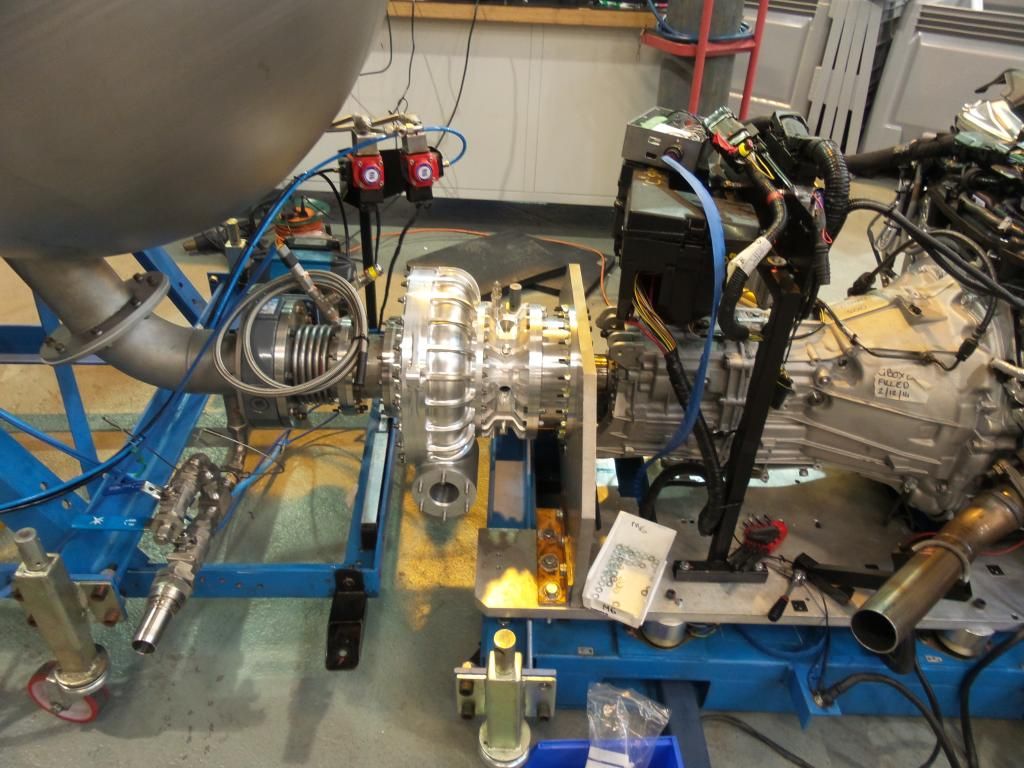

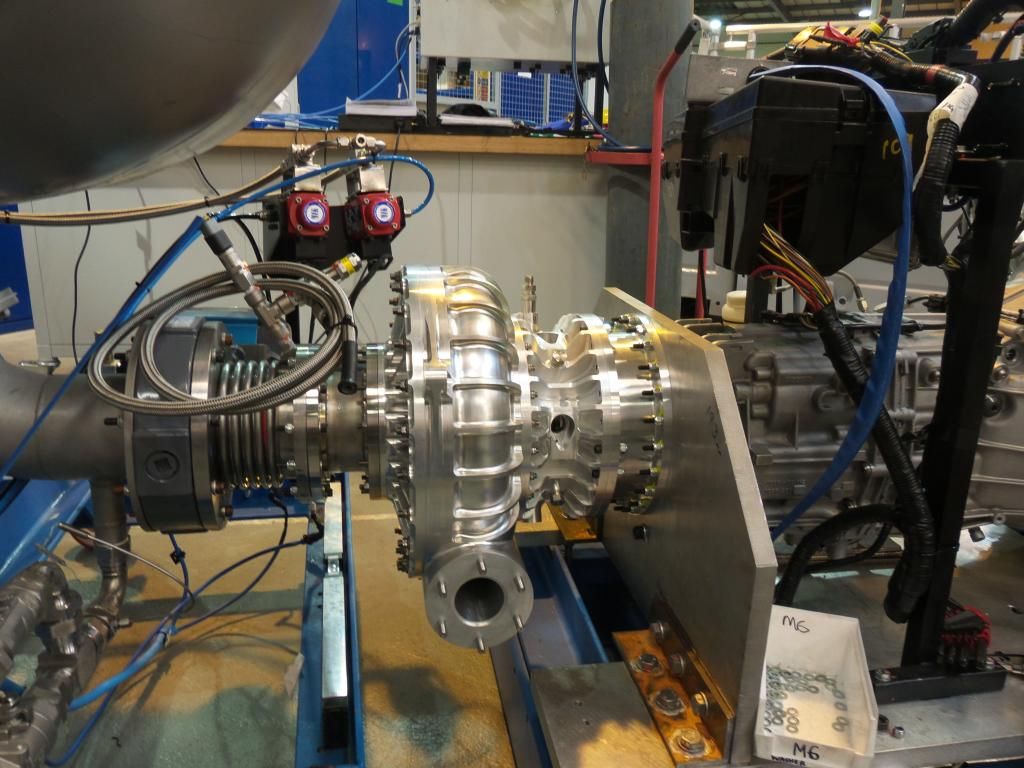

We were here late last night, myself, Lee, Jamie, Siobhan from the rocket team had had a late one last night (midnight) to ensure the pump was fully test installed on the rig, so if there were any issues we had today to sort them before the whole lot gets shipped to Newquay to start water pumping next week. Back in 6am this morning, but it's worth it.

Open pipes!

Make sure you video that bad boy running...

I assume with Jaguar's support it was easy to make it run without the rest of the car?

Megaflow said:

IN51GHT said:

We were here late last night, myself, Lee, Jamie, Siobhan from the rocket team had had a late one last night (midnight) to ensure the pump was fully test installed on the rig, so if there were any issues we had today to sort them before the whole lot gets shipped to Newquay to start water pumping next week. Back in 6am this morning, but it's worth it.

Open pipes!

Make sure you video that bad boy running...

I assume with Jaguar's support it was easy to make it run without the rest of the car?

Scuffers said:

Ok, here's a question...

Using water, just what velocity are you looking at at the pump exit?

And what does this translate to if you pointed it skyward, how high would it go?

Never really thought about it. we are however an education programme, so perhaps YOU could work it out!!!!Using water, just what velocity are you looking at at the pump exit?

And what does this translate to if you pointed it skyward, how high would it go?

IN51GHT said:

Our engine will be built with a steel crank, forged rods & uprated piston to reduce any chance of a very public failure, also gives us a little headroom should we wish to "turn it up to 11"

Jaguar presumably will have worked out some "art of the possible" stuff on this.It'd be interesting to know where the limits are.

What's happening to make the car lighter in year two by the way?

CraigyMc said:

Jaguar presumably will have worked out some "art of the possible" stuff on this.

It'd be interesting to know where the limits are.

What's happening to make the car lighter in year two by the way?

That will depend largely on what we discover during year one.It'd be interesting to know where the limits are.

What's happening to make the car lighter in year two by the way?

as we know the car is festooned with sensors for load, pressure temp etc, from the data these gather we'll be able to make a judgement on where we can safely lose weight.

IN51GHT said:

Our engine will be built with a steel crank, forged rods & uprated piston to reduce any chance of a very public failure, also gives us a little headroom should we wish to "turn it up to 11"

I can see why this has been done, but i suspect using custom parts is more likely to result in a failure! The AJ133 is fully production validated at >500bhp. It will run for 180hrs CONTINUOUSLY at peak power without failure. They make thousands of them, on a line where tollerance and quality have to be the watchwords.In this application, other than the environmental g loading (which steel internals can't help you with) the engine is really not that stressed, with runs lasting 2 minutes and driving really quite a nice load (a pump, rather than a car, with all sorts of shock loads etc)

The AJ133 has a nominal 100bar cylinder pressure limit, but this is for "production" durability, it will easily take 25% more than that for a lower number of cycles.....

Max_Torque said:

It will run for 180hrs CONTINUOUSLY at peak power

Lets say that it can shove something car shaped through the air at 186mph (300km/h) with that 500/550bhp. (No reason to doubt it; plenty of cars go faster with less).A 180 hour test would allow for 33,000 miles at that speed, for that duration.

(a) that's very impressive.

(b) I'd not like to be accountable for that fuel bill.

(c) I hope the power is used to do something useful, as well as validating the engine.

As for the steel/forged bits, is it possible that while they aren't in the main production engines, Jag have experience of them from the development process and/or fun stuff like the Bonneville car?

Max_Torque said:

I can see why this has been done, but i suspect using custom parts is more likely to result in a failure! The AJ133 is fully production validated at >500bhp. It will run for 180hrs CONTINUOUSLY at peak power without failure. They make thousands of them, on a line where tollerance and quality have to be the watchwords.

In this application, other than the environmental g loading (which steel internals can't help you with) the engine is really not that stressed, with runs lasting 2 minutes and driving really quite a nice load (a pump, rather than a car, with all sorts of shock loads etc)

The AJ133 has a nominal 100bar cylinder pressure limit, but this is for "production" durability, it will easily take 25% more than that for a lower number of cycles.....

That's one perspective to be sure, however methods for increasing an engines durability under racing or high-load conditions are well established. Stronger internals and a dry sump is the kind of stuff you do to an engine for race duty and expect implicitly that durability will be improved - there's not much worry there. If anything it's overkill but assembled by factory technicians using factory spec'd forged kit I think they'll be good to go.In this application, other than the environmental g loading (which steel internals can't help you with) the engine is really not that stressed, with runs lasting 2 minutes and driving really quite a nice load (a pump, rather than a car, with all sorts of shock loads etc)

The AJ133 has a nominal 100bar cylinder pressure limit, but this is for "production" durability, it will easily take 25% more than that for a lower number of cycles.....

ukpdxwrx said:

That's one perspective to be sure, however methods for increasing an engines durability under racing or high-load conditions are well established. Stronger internals and a dry sump is the kind of stuff you do to an engine for race duty and expect implicitly that durability will be improved - there's not much worry there. If anything it's overkill but assembled by factory technicians using factory spec'd forged kit I think they'll be good to go.

I think what Max is trying to say is this is not a race application, and you quite easily give the engine a harder time in the production car it was designed for.Max, just out of curiosity, what does running the engine at full power for 180hrs actually tell you? Surely from a mechanical validation point of view you'd be better off with labouring it, shock loads, both thermal and mechanical, etc.

Megaflow said:

ukpdxwrx said:

That's one perspective to be sure, however methods for increasing an engines durability under racing or high-load conditions are well established. Stronger internals and a dry sump is the kind of stuff you do to an engine for race duty and expect implicitly that durability will be improved - there's not much worry there. If anything it's overkill but assembled by factory technicians using factory spec'd forged kit I think they'll be good to go.

I think what Max is trying to say is this is not a race application, and you quite easily give the engine a harder time in the production car it was designed for.Max, just out of curiosity, what does running the engine at full power for 180hrs actually tell you? Surely from a mechanical validation point of view you'd be better off with labouring it, shock loads, both thermal and mechanical, etc.

The are plenty of other, generally much longer, tests that aim to cause thermal cycle failures for example, and these are also carried out before the engine is production signed off.

Max_Torque said:

The 180hr HST is about peak thermal and pressure loads. All the components will be operating at peak temperatures, and because the engine speed is high, it rapidly accrues "cycles" on components. So, if you're going to get a block crack, exhaust seat crack, conrod failure, bearing hammer or a million other failures, this test will show that!

The are plenty of other, generally much longer, tests that aim to cause thermal cycle failures for example, and these are also carried out before the engine is production signed off.

Thanks for that.The are plenty of other, generally much longer, tests that aim to cause thermal cycle failures for example, and these are also carried out before the engine is production signed off.

It's always interesting to learn how others run validation programs. I am not aware of us doing anything similar, ours tend to be based on accelerated usage cycles.

Gassing Station | General Gassing | Top of Page | What's New | My Stuff