Driven: Caterham Ecoboost

An Ecoboost engined Caterham - that sounds like a fun idea! It is, as Ford has proved by building exactly that...

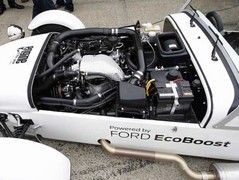

But nothing us got more excited than a promise of a drive in this: a Caterham with the new turbocharged lump fitted in place of the standard Roadsport 1.6-litre Sigma engine (also a Ford unit of course). The widespread availability of a small, powerful, charismatic lump like could be manna to the low-volume sports car maker.

The transplant has an inevitability about it in that the Ecoboost was developed to eventually replace the similarly powered 1.6 Sigma unit across Ford. Which means Caterham would have to do the same thing or look elsewhere.

Because they can

This isn't a Caterham project yet - this is Ford showing off the capabilities of its baby. Roger Ratley, petrol calibration engineer and one of the architects of the Nurburgring project, explains why Ford picked the Seven. "It's a light car and it would benefit from a relatively high torque, high-power engine".

In fact, although the engine benefits from the same dry sump as the one in the Formula Ford, power is closer to the Focus application at 120hp and similar to the 125hp as the entry Roadsport Caterham.

However the turbo plumps out the torque from 120lb ft to 147. We're not told how far down the rev range that's developed, but it's way lower than the 5,350rpm of the standard Caterham, which should better help push it out of corners at our playground for the day, the Indy circuit at Brands Hatch.

The Ecoboost engine is actually heavier than the standard Sigma, despite the lopped off cylinder, because it uses an iron block instead of an aluminum one. Not that it makes a huge amount of difference: Ford's car with the SV body weighs 588kg versus 575kg for the Caterham Roadsport SV. If you're wondering what that strange power bulge is on the bonnet, it's there because the Ecoboost unit is taller, even with the dry sump. Rearrange the turbo pipes and it'll fit, Ford says, but that wasn't possible within the time constraints. The Mountune boys that dropped the engine in did say that left-to-right weight distribution was nigh on perfect, however.

Enough torque

Right, enough chat. Let's drive the thing. The first tweak a standard fitment would need is something to fix the noise. There's not enough it. That three-cylinder off-beat thrum doesn't come through loud enough and it lacks drama.

That makes the acceleration surge even more bizarre. Here's a Caterham that doesn't require lots of gearbox manipulation to keep it in the power band, simply because the band is so wide. Yes we've driven we've the SP/300.Rthat shares its supercharged two-litre with the new R600, and the development hack for that car too, but down at entry level, this access-all-areas, drama-free muscle is a strange experience.

Frankly, it doesn't seem right. A Caterham should be a constant exploration of power at the top of the rev range - shifting the stubbiest gear lever known to man is one of those great joys in life. Even Ford engineer Ratley wasn't convinced. "I've got an old Caterham - you just want something that revs, not something that wafts along on huge amounts of torque."

Thing is, this is just the start. There's plenty you can do with this ultra tuneable engine. According to Ratley a lighter flywheel will take the maximum revs from the mid sixes to past 7,000rpm. It'll even clear 8,000 with stronger valve springs. And of course there's more power to come, given that the application in the Formula Ford made around 220hp, largely achieved by strapping on the bigger turbo from the 1.6 Ecoboost.

Cost is an issue of course. We spoke to Ford UK's parts outlet Power Torque and discovered that a crate 1.0 Ecoboost costs £4,500 (ex vat), versus £1,700 for a 1.6 Sigma. That's a fare whack to pass onto a customer. But smaller turbocharged engines are becoming a fact of life when even small scale manufacturers have to reduce their average CO2 emissions. As it stands, the Ecoboost needs work for satisfy the enthusiast, but relatively small tweaks to improve power, revs and aural drama would make this Ford unit into a winner.

CATERHAM ECOBOOST TEST CAR

Engine: 999cc, 3-cyl turbo

Transmission: 5-speed manual, rear-wheel drive

Power (hp): 120

Torque (lb ft): 147

0-62mph: N/A

Top speed: N/A

Weight: 588kg

MPG: N/A

CO2: N/A

Price: N/A

Slightly disappointed that it is a heavier unit however. I wonder what the reason behind using an iron block is.

Slightly disappointed that it is a heavier unit however. I wonder what the reason behind using an iron block is.

Might make more sense with the wick turned up a bit, but would that just make it feel laggy?

It will cost less to run being smaller and more economical

It has potential to be much more powerful

But I think the main goal here is not to show us that Caterhams will in the future be 1.0 3pots rather Ford telling is not to be scared of this engine.

I'm not old but I'm old school, I'd rather have my 3.0 N/A than a 1.6 turbo with the same power. I just prefer the way an N/A develops it.

But if some one showed me one that developed the power in a more NA like manner and as a bonus, did twice the MPG and cost half as much to tax i'd change up!

= It's a caterham, that's how you're meant to drive.

It will cost less to run being smaller and more economical

= Caterham, economy. Really???

It has potential to be much more powerful

= True, but if there's 2k of turbo lag to get there, count me out.

But I think the main goal here is not to show us that Caterhams will in the future be 1.0 3pots rather Ford telling is not to be scared of this engine.

I'm not old but I'm old school, I'd rather have my 3.0 N/A than a 1.6 turbo with the same power. I just prefer the way an N/A develops it.

But if some one showed me one that developed the power in a more NA like manner and as a bonus, did twice the MPG and cost half as much to tax i'd change up!

Revolutions per minutes?

But when you say increased warm up, is that of the oil or coolant? Because an alloy block should be more efficient at heat transfer. Are they wanting the oil to warm up quickly to save the turbo?

But when you say increased warm up, is that of the oil or coolant? Because an alloy block should be more efficient at heat transfer. Are they wanting the oil to warm up quickly to save the turbo?

But when you say increased warm up, is that of the oil or coolant? Because an alloy block should be more efficient at heat transfer. Are they wanting the oil to warm up quickly to save the turbo?

But when you say increased warm up, is that of the oil or coolant? Because an alloy block should be more efficient at heat transfer. Are they wanting the oil to warm up quickly to save the turbo?

But when you say increased warm up, is that of the oil or coolant? Because an alloy block should be more efficient at heat transfer. Are they wanting the oil to warm up quickly to save the turbo?

It was free and open to non-members: http://nearyou.imeche.org/near-you/UK

Gassing Station | General Gassing | Top of Page | What's New | My Stuff