BMW E30 M3 - S85 DCT [RNGTOY]

Discussion

s62 said:

The S85 is oversquare, ie. stroke is less than bore, 75.2mm vs. 92mm stock.

So basically it likes revs. With upgraded rods/pistons you can add some revs but you will run into limitations in the heads if you increase alot.

The sleeved block I have has the stock 92mm bore. Going to 83mm stroke would give me approx. 5.5L

Think the max stroke people are doing is 84mm.

5.5L would be plenty enough I recon, if it could see north of 600bhp and be reliable I would be a happy man So basically it likes revs. With upgraded rods/pistons you can add some revs but you will run into limitations in the heads if you increase alot.

The sleeved block I have has the stock 92mm bore. Going to 83mm stroke would give me approx. 5.5L

Think the max stroke people are doing is 84mm.

Project moving along at a snails pace

ARP rod bolts have arrived. Also have some very important parts like the OEM S85 ECU and an E60 M5 gas pedal!!!

Also, I decided to sell my old dry sump system apart from the tank in the back and the lines to/from it - will use that stuff.

So instead of making my own dry sump pan and mix with the old components, I have ordered a complete system for the S85. Decided that oil pressure is not something I want to experiment with and do development work on.

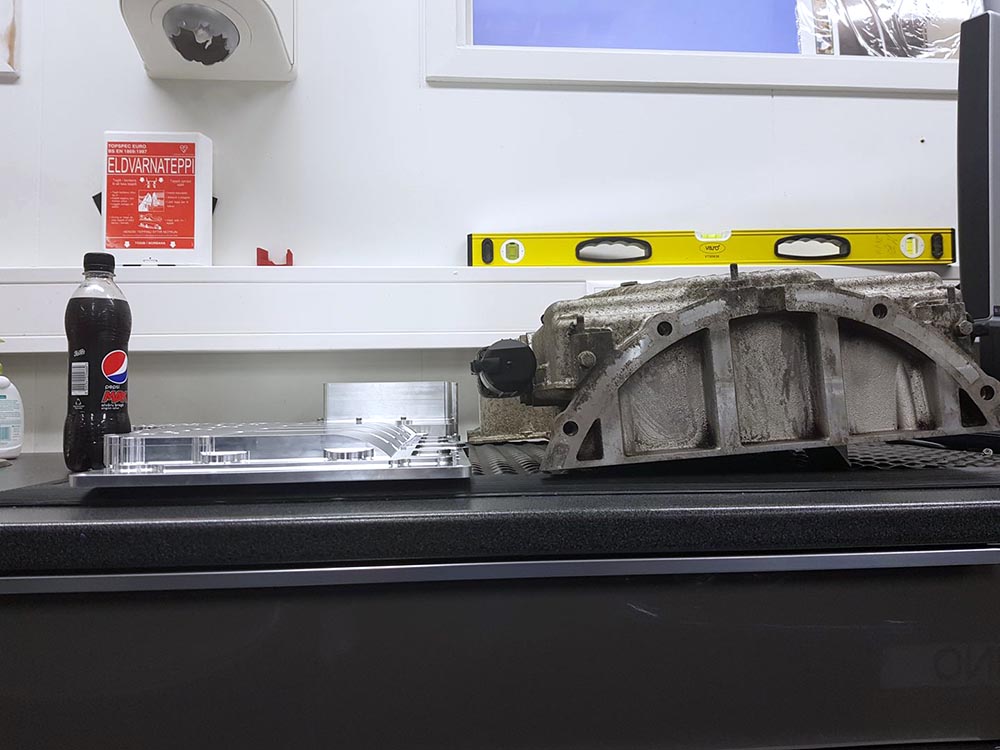

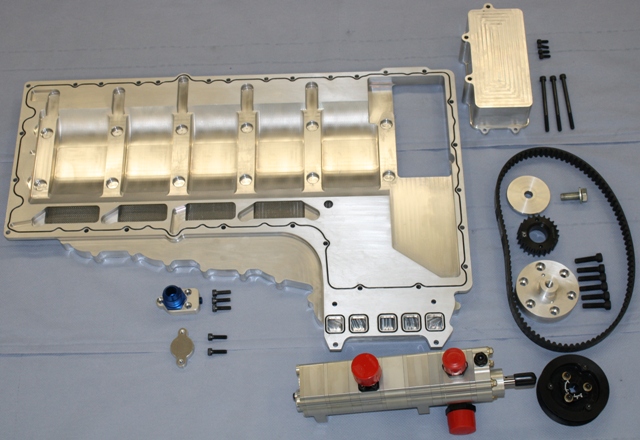

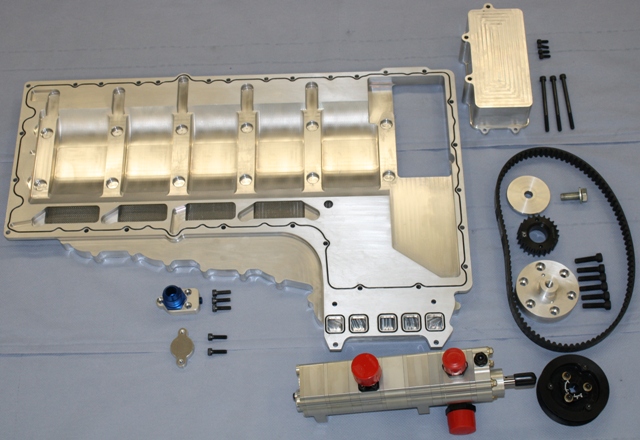

Here is the system I ordered:

So here the pump is bolted directly on the pan itself, no bracket. This is mostly based on components from Daileyengineering in the US. Here is a picture of an installed kit:

Hope to get it delivered in approx 3 weeks, then I can close the engine and start testfitting it to check clearances, figure out engine mounts, etc.

ARP rod bolts have arrived. Also have some very important parts like the OEM S85 ECU and an E60 M5 gas pedal!!!

Also, I decided to sell my old dry sump system apart from the tank in the back and the lines to/from it - will use that stuff.

So instead of making my own dry sump pan and mix with the old components, I have ordered a complete system for the S85. Decided that oil pressure is not something I want to experiment with and do development work on.

Here is the system I ordered:

So here the pump is bolted directly on the pan itself, no bracket. This is mostly based on components from Daileyengineering in the US. Here is a picture of an installed kit:

Hope to get it delivered in approx 3 weeks, then I can close the engine and start testfitting it to check clearances, figure out engine mounts, etc.

e30m3Mark said:

If honest, I don't have the technical expertise to know what everything I'm looking at actually is or does, but I love it all the same.  It's shaping up to be an awesome conversion.

It's shaping up to be an awesome conversion.

Nothing too complicated going on  It's shaping up to be an awesome conversion.

It's shaping up to be an awesome conversion.

Just making sure the engine will always have good oil pressure no matter what the g-loads are.

Looks very nice, mind me asking how much it was? did you buy the entire kit from them?

Does it also scavenge each head still as i see it eliminates the two electric pumps?

Wish the pump could also run the vanos, would make it a very cost effective solution if it could as the venous pump alone is thousands and could filter the oil into the vanos better to help the solenoids last.

Does it also scavenge each head still as i see it eliminates the two electric pumps?

Wish the pump could also run the vanos, would make it a very cost effective solution if it could as the venous pump alone is thousands and could filter the oil into the vanos better to help the solenoids last.

andygtt said:

Looks very nice, mind me asking how much it was? did you buy the entire kit from them?

Does it also scavenge each head still as i see it eliminates the two electric pumps?

Wish the pump could also run the vanos, would make it a very cost effective solution if it could as the venous pump alone is thousands and could filter the oil into the vanos better to help the solenoids last.

Bought the entire kit from KMS, crazy expensive Does it also scavenge each head still as i see it eliminates the two electric pumps?

Wish the pump could also run the vanos, would make it a very cost effective solution if it could as the venous pump alone is thousands and could filter the oil into the vanos better to help the solenoids last.

No scavenge pumps for the heads.

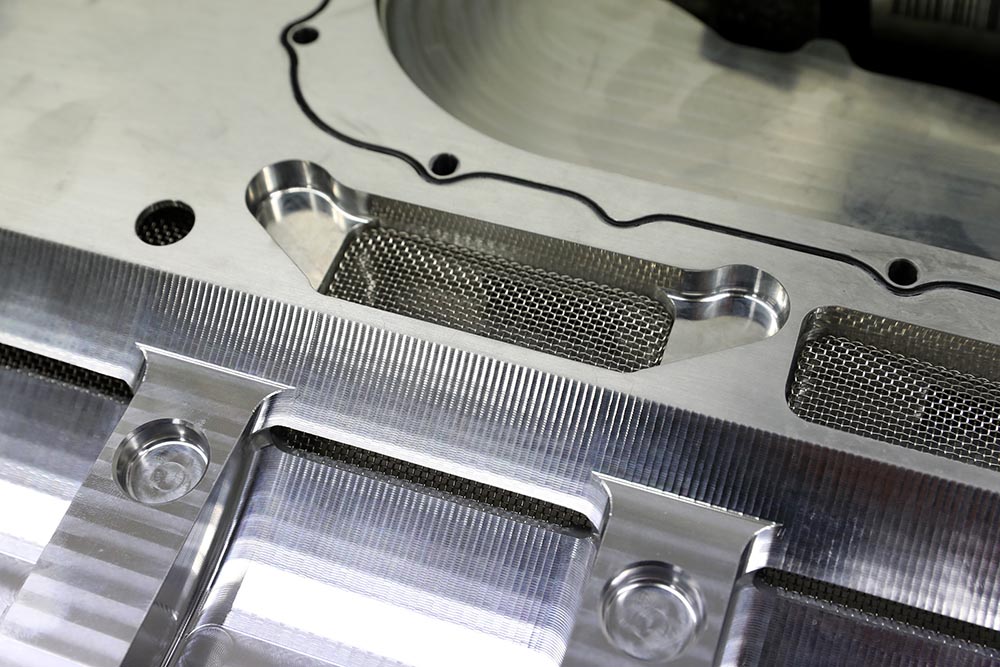

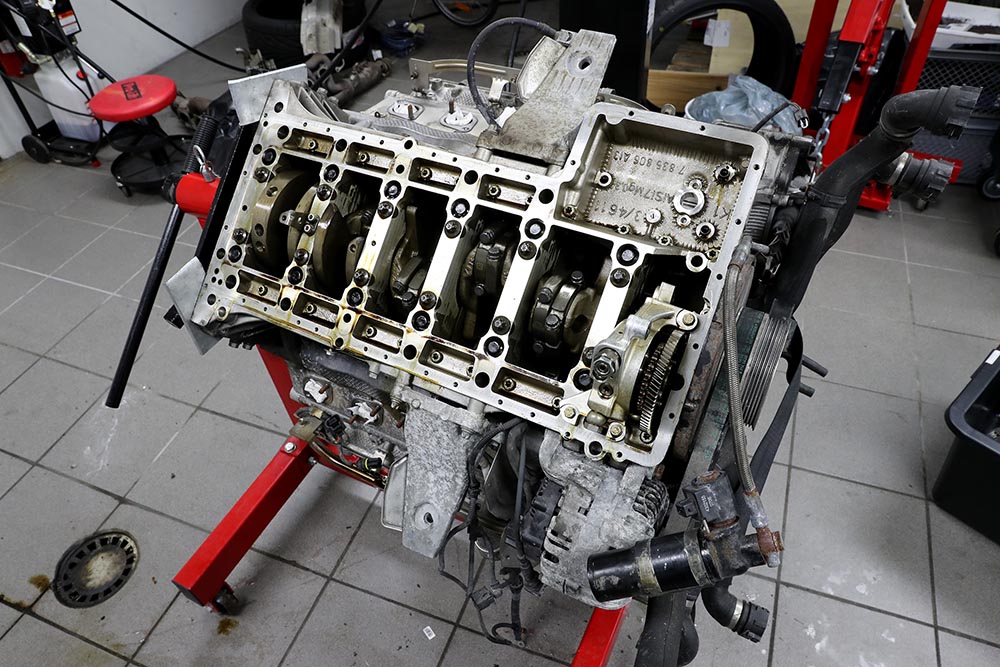

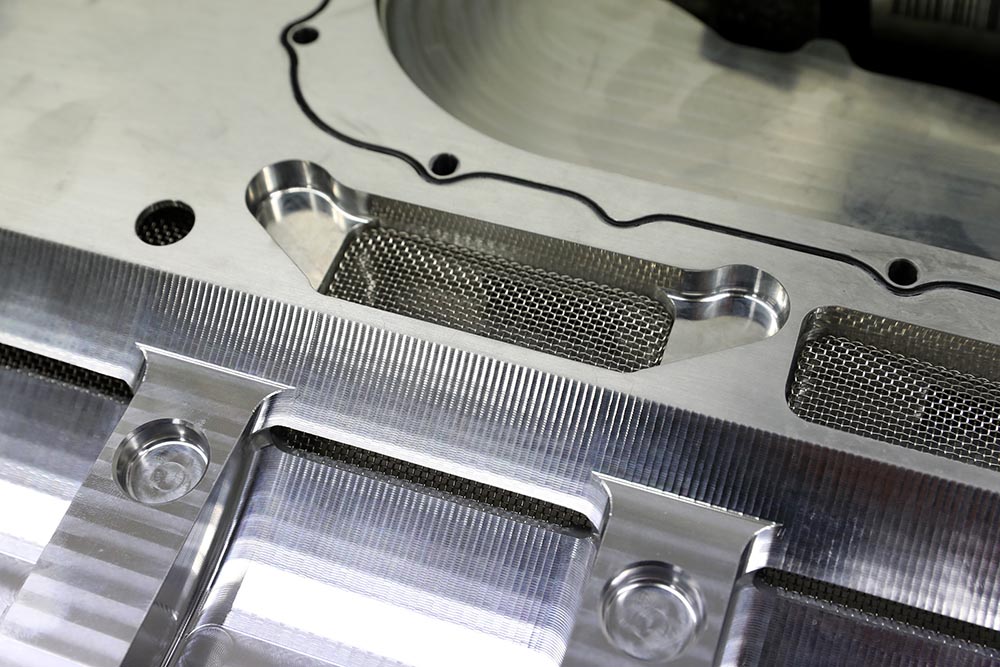

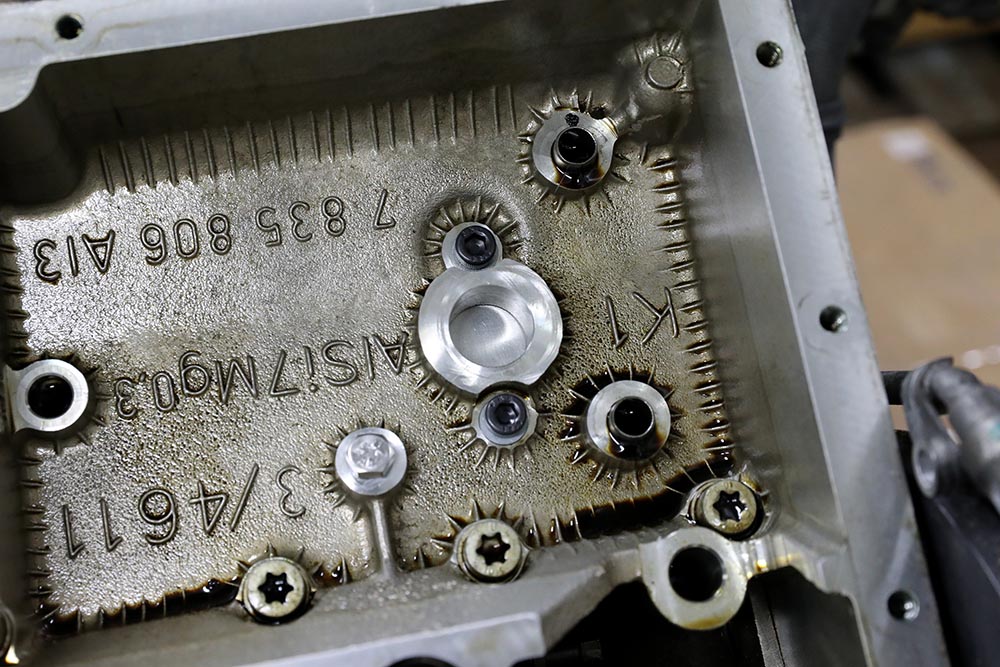

Some progress pics.

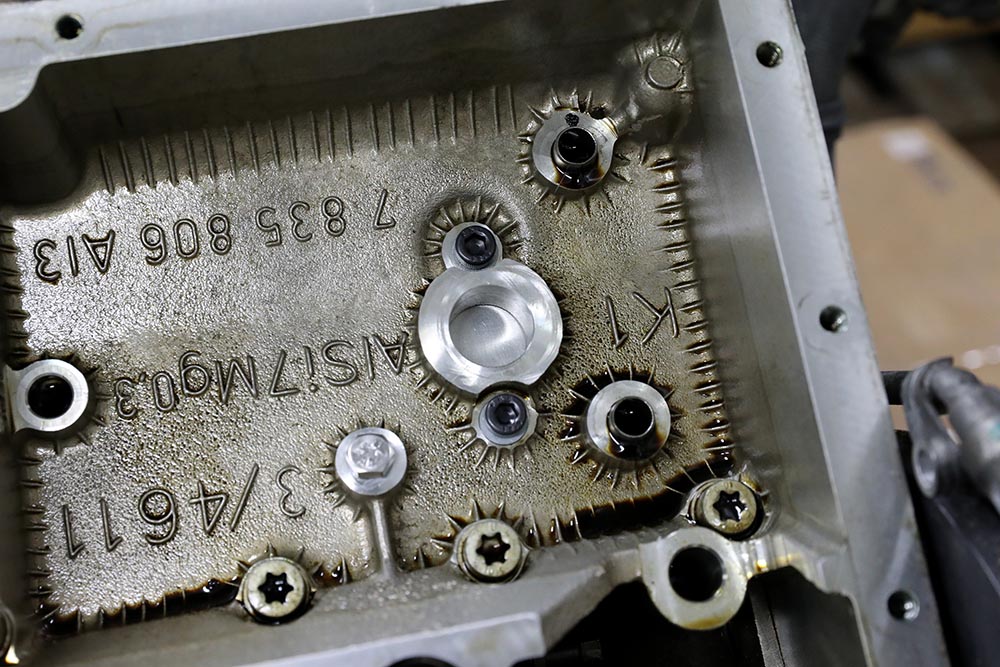

Needed to thread one hole and put a bolt in it to block it.

A good friend of mine that runs a CNC business is happy with the workmanship of the pan!

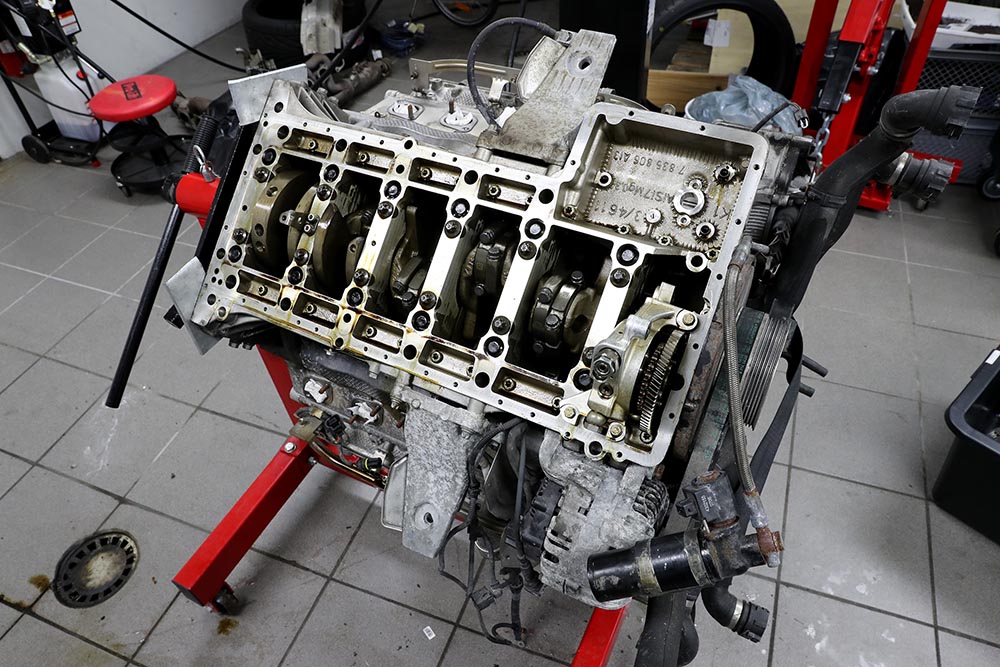

AC and steering pump have to go:

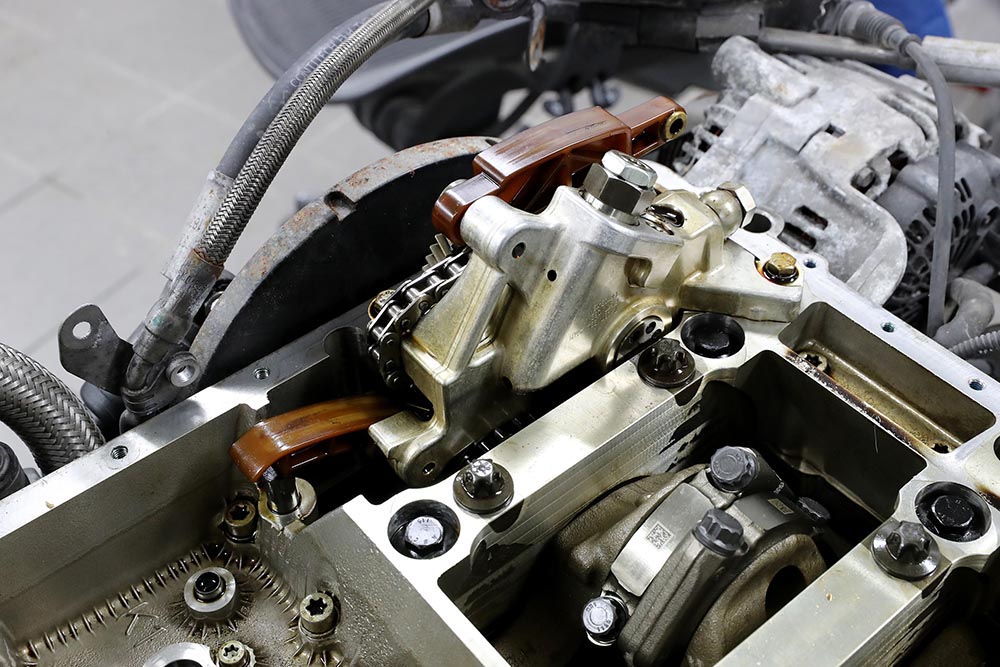

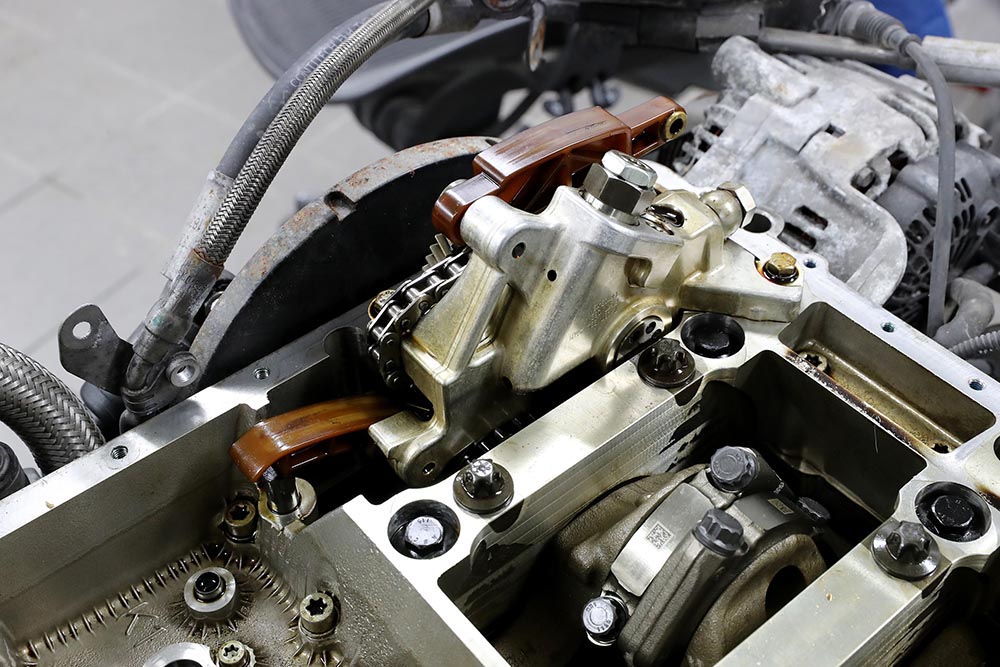

Also have to remove the chain that used to drive the stock oil pump as well as the chain guide/tensioner:

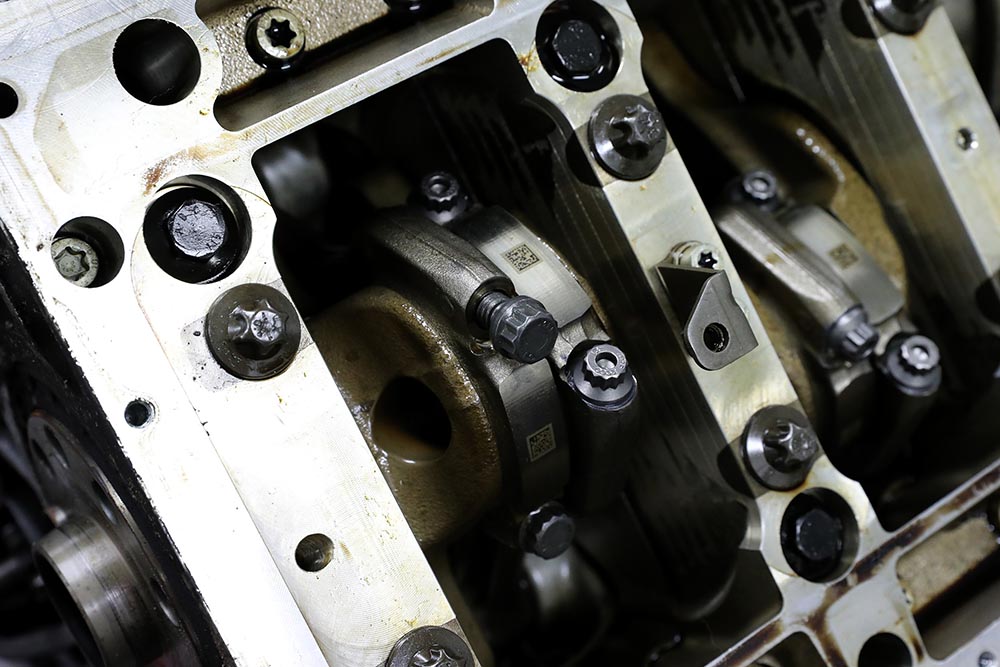

Pumps out of the way. There you can see the old output of the oil pump and the oil input into the block:

Chain off, had to loosen up the vanos pump to do so.

Stuff off:

Pumps and oil filter housing off:

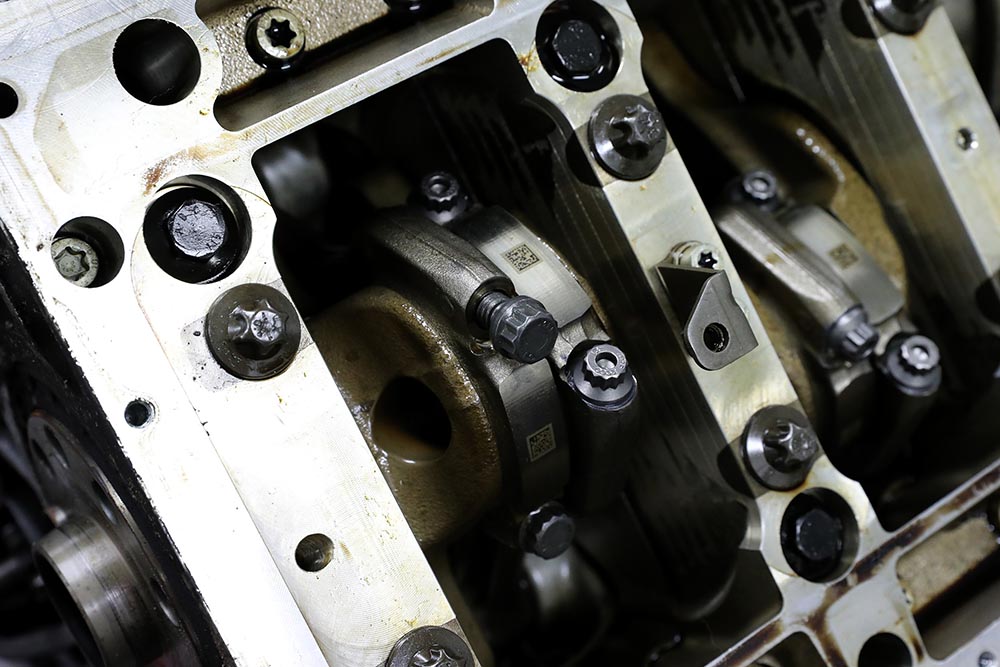

Here you can see better the original oil output and input into block:

Inserting the ARP bolts:

Blocking plate and new input for oil into block:

Output blocked:

Both installed:

Pan in place:

On the left is the new pulley for the dry sump pump. On the right is the stock crank pulley, need to machine the AC part off:

Here you can see how it fits together:

Needed to thread one hole and put a bolt in it to block it.

A good friend of mine that runs a CNC business is happy with the workmanship of the pan!

AC and steering pump have to go:

Also have to remove the chain that used to drive the stock oil pump as well as the chain guide/tensioner:

Pumps out of the way. There you can see the old output of the oil pump and the oil input into the block:

Chain off, had to loosen up the vanos pump to do so.

Stuff off:

Pumps and oil filter housing off:

Here you can see better the original oil output and input into block:

Inserting the ARP bolts:

Blocking plate and new input for oil into block:

Output blocked:

Both installed:

Pan in place:

On the left is the new pulley for the dry sump pump. On the right is the stock crank pulley, need to machine the AC part off:

Here you can see how it fits together:

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff