Rover 200 BRM - 1.8 K-Series turbo project

Discussion

Thanks guys. I'm still enjoying the process and she now looks exactly how I envisioned. Everything is how I want it except the engine, so I'm very excited for the new build. I've learned a lot from the two engines that haven't worked out, so I've no regrets!

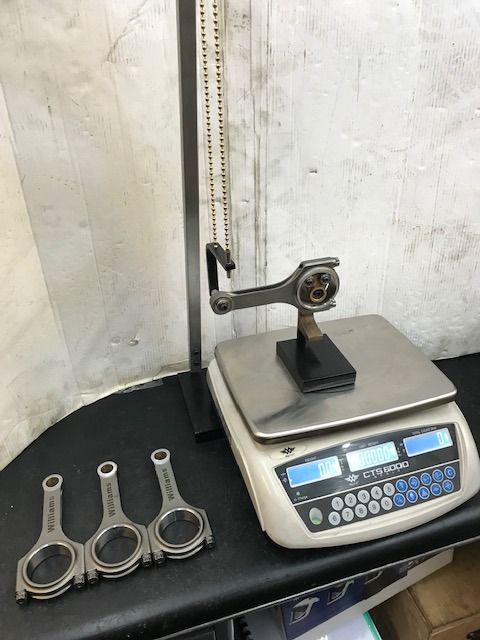

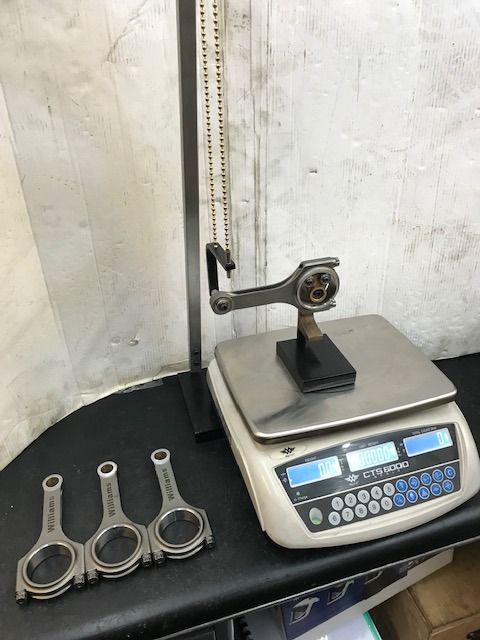

The new pistons will produce a static compression of just under 9:1 and are tall enough to maintain squish with the shorter rods (meaning the ring lands are chunky as 'eck). I have new steel rods and a new crank is on the way, plus a lighter flywheel. Everything will be balanced. I'll be using a brand new block with Westwood ductile iron liners.

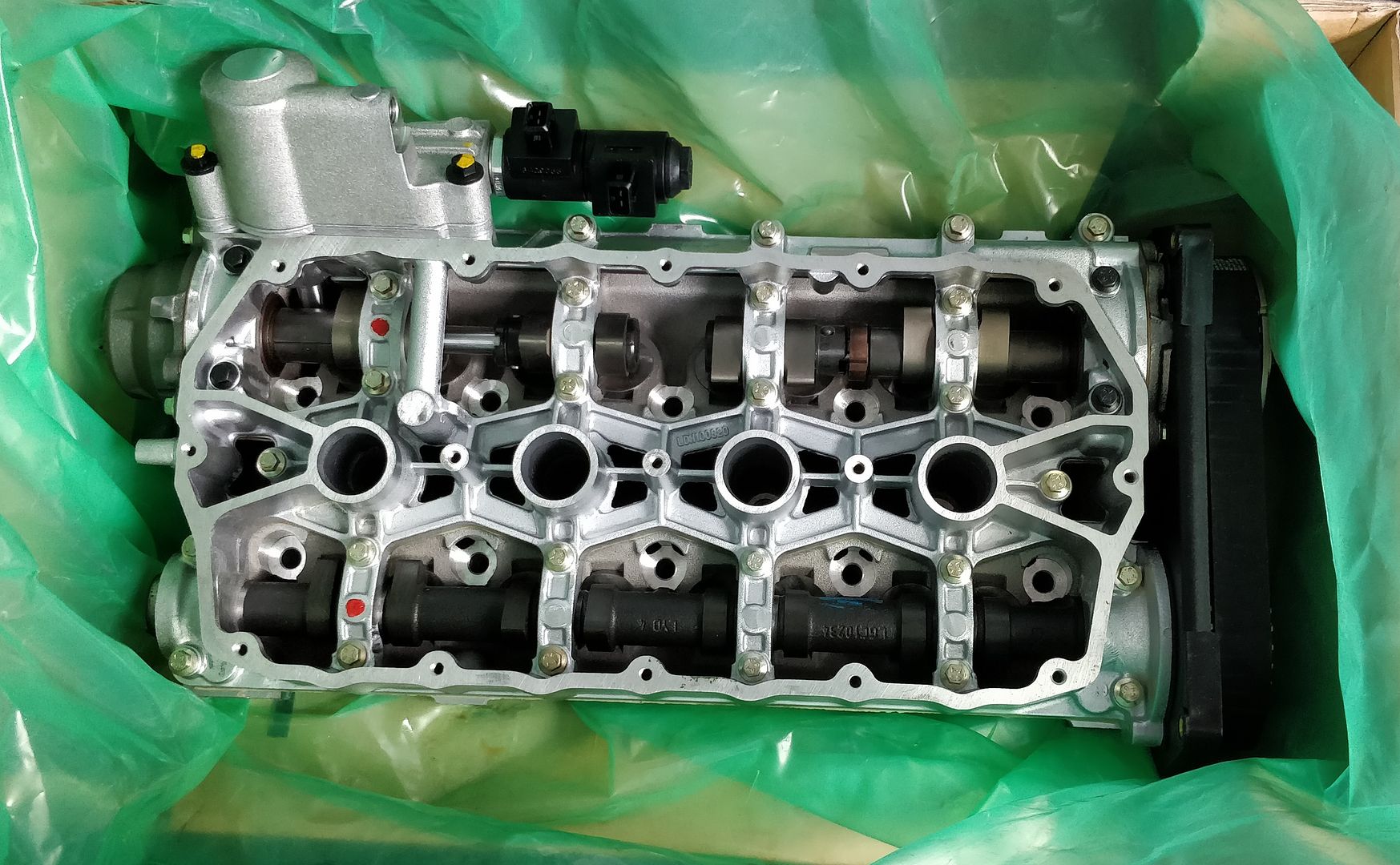

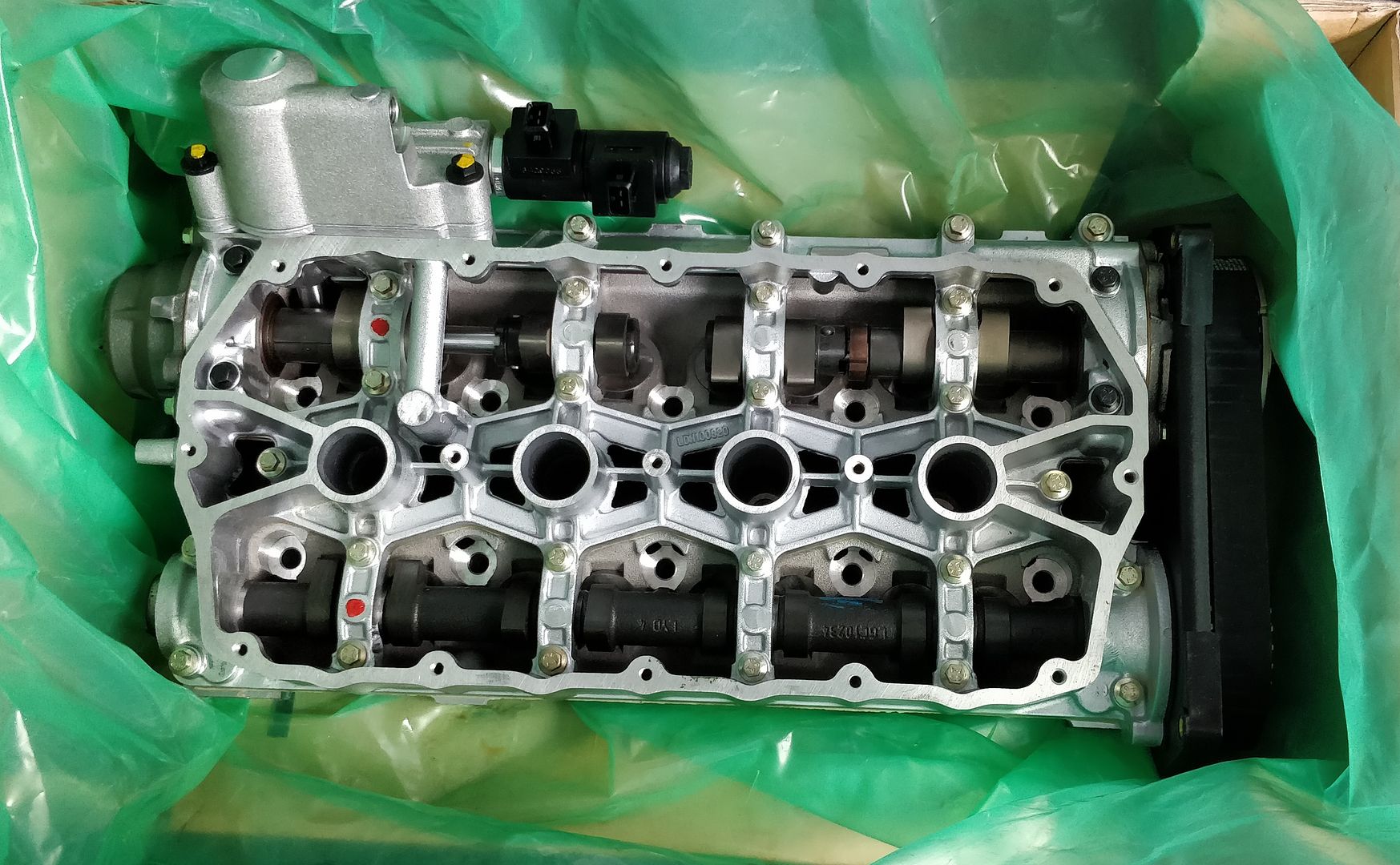

The icing on the cake is the brand new in box VVC cylinder head I was able to source. To avoid exposing any porosity (sometimes an issue with these) I'll not be fettling it except perhaps port-matching the inlet side.

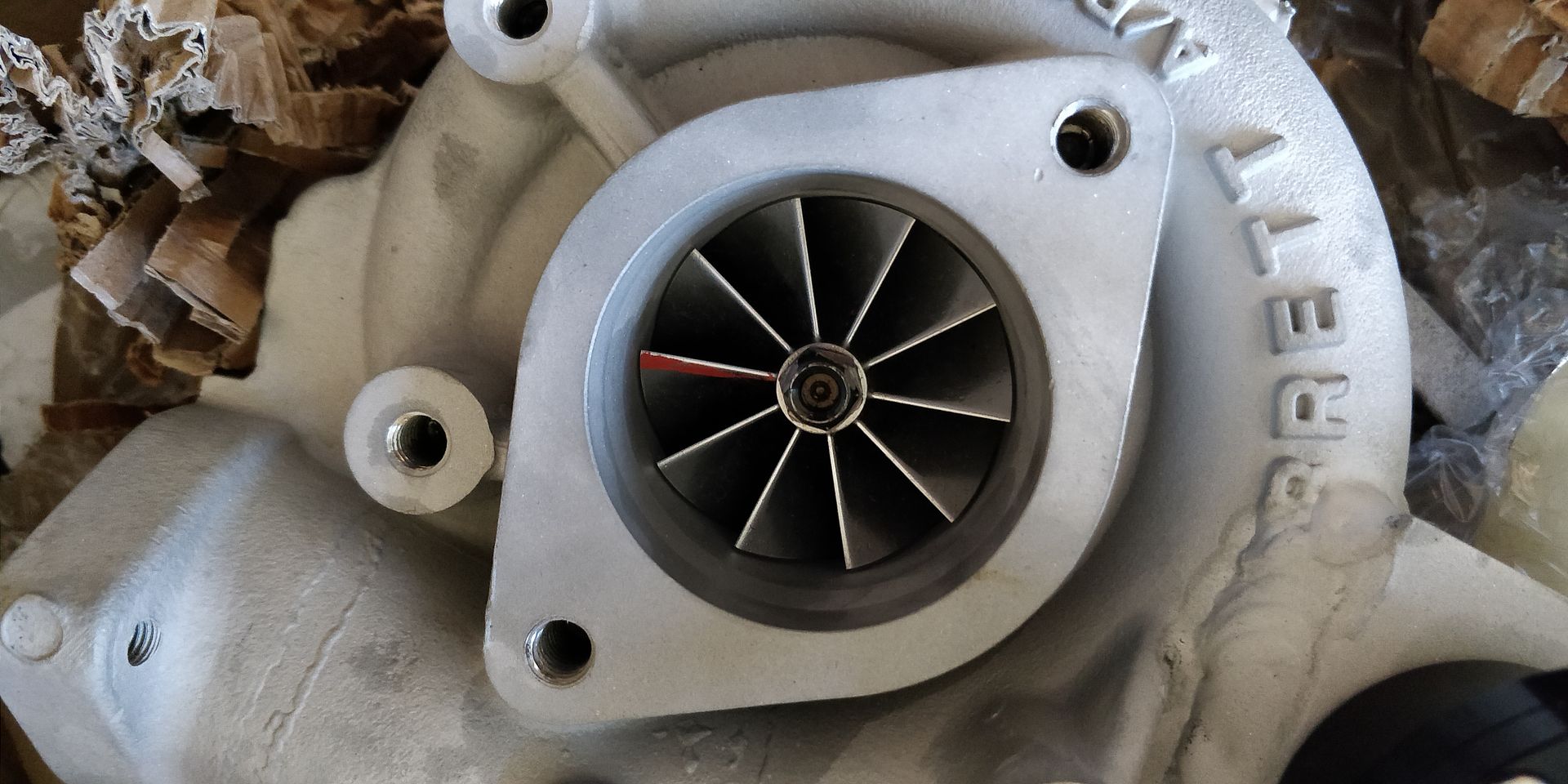

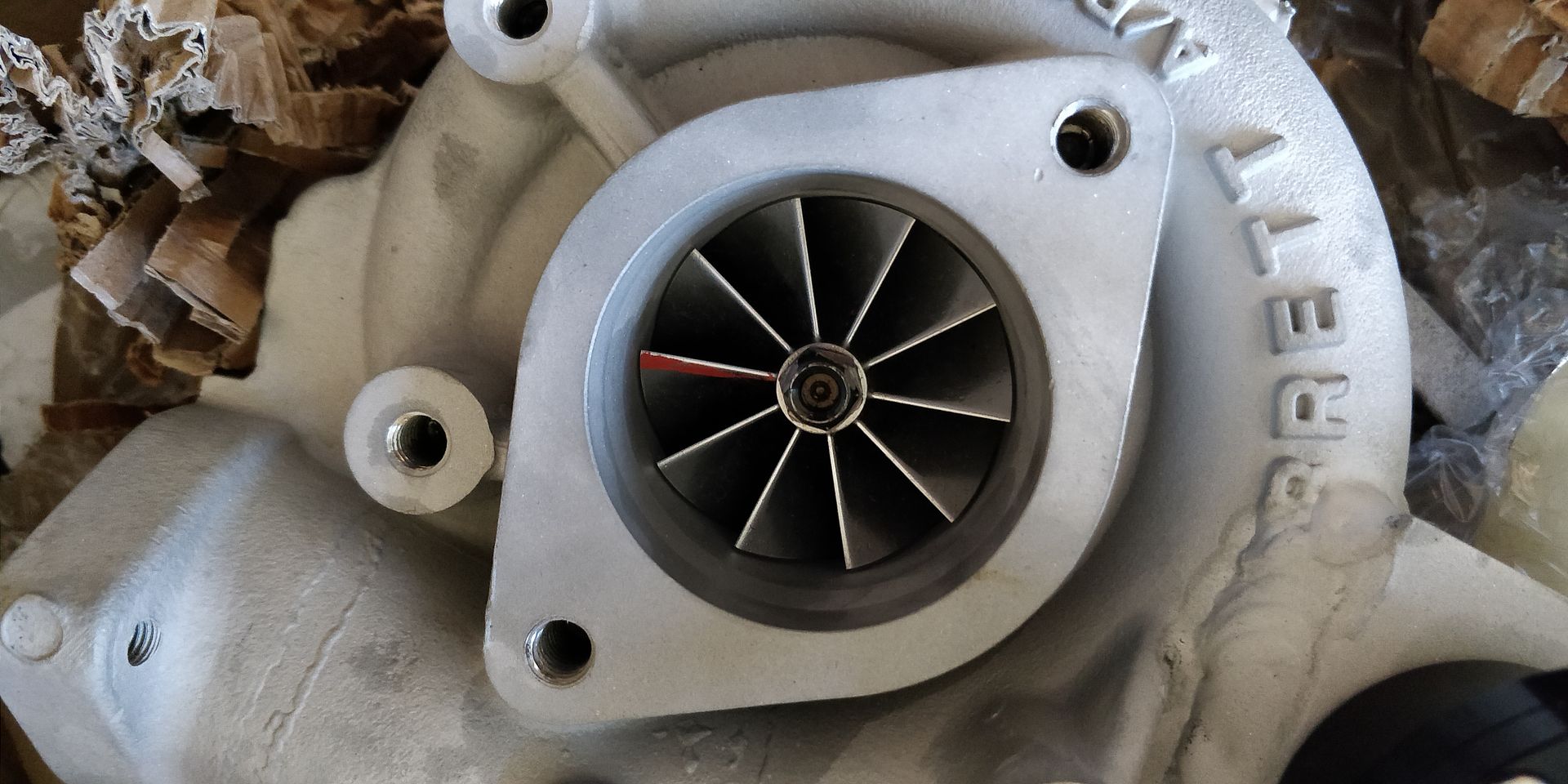

I'm currently talking to Owen Developments about turbo choice. Over the years the car has moved away from a daily road car so I'm prepared to go a little more extreme, whilst still keeping in mind the limitations of the drivetrain. A larger turbine (than the gt2560r on it previously) will help the whole thing breathe and reduce ebp which was costing power at the top end on the last build. I'm currently leaning towards a Gen 2 Garrett GTX2867R. I could run that at a safe 250bhp on low boost but would have scope for 350-400bhp if I ever felt the need.

The new pistons will produce a static compression of just under 9:1 and are tall enough to maintain squish with the shorter rods (meaning the ring lands are chunky as 'eck). I have new steel rods and a new crank is on the way, plus a lighter flywheel. Everything will be balanced. I'll be using a brand new block with Westwood ductile iron liners.

The icing on the cake is the brand new in box VVC cylinder head I was able to source. To avoid exposing any porosity (sometimes an issue with these) I'll not be fettling it except perhaps port-matching the inlet side.

I'm currently talking to Owen Developments about turbo choice. Over the years the car has moved away from a daily road car so I'm prepared to go a little more extreme, whilst still keeping in mind the limitations of the drivetrain. A larger turbine (than the gt2560r on it previously) will help the whole thing breathe and reduce ebp which was costing power at the top end on the last build. I'm currently leaning towards a Gen 2 Garrett GTX2867R. I could run that at a safe 250bhp on low boost but would have scope for 350-400bhp if I ever felt the need.

Well I've had a mental year this year what with getting married and having to move house unexpectedly (the week before the wedding) to a house with no garage (I know). The BRM has therefore taken a back seat (and been banished to a random lockup 15 miles away from my house).

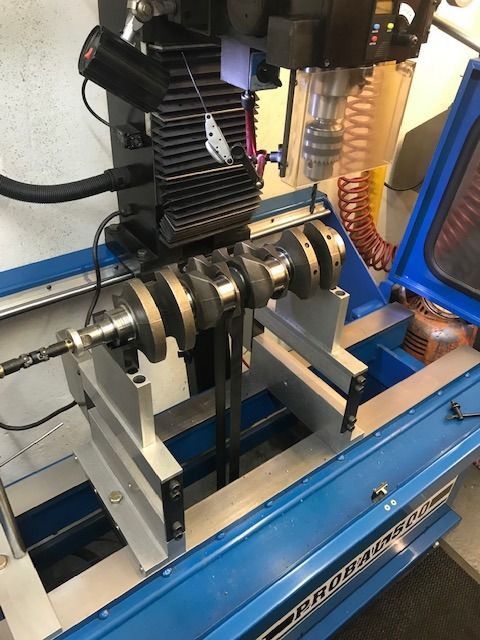

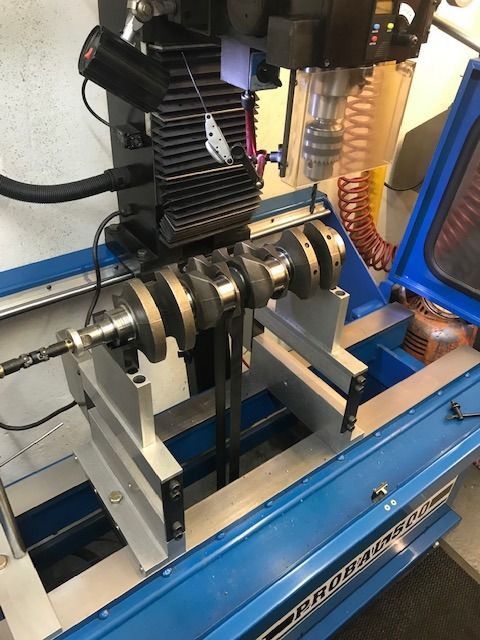

Earlier this year I did manage to get all of the new engine components balanced AND I've also had my turbo modified to a similar spec to gtx2867r. It's basically my old turbo's front and rear housings machined to fit bigger wheels, and a whole new centre housing.

I have a lovely timber garage going up next month so that will give me somewhere to unpack all my tools and stuff and finally build the new engine and get it in. Plan is just to have the car maps and run in before the end of the year.

Earlier this year I did manage to get all of the new engine components balanced AND I've also had my turbo modified to a similar spec to gtx2867r. It's basically my old turbo's front and rear housings machined to fit bigger wheels, and a whole new centre housing.

I have a lovely timber garage going up next month so that will give me somewhere to unpack all my tools and stuff and finally build the new engine and get it in. Plan is just to have the car maps and run in before the end of the year.

s3 akr said:

I wondered what had happened here. I read the piece from end to end a while back and it just stopped. Keep it going - interesting read and a lot of work going into a very rare car.

Thanks. I expect most people have stopped reading it now given all the problems and questionable decisions, but I feel compelled to keep it goingitcaptainslow said:

Nice to see something at the other end of the scale to my standard one!

Thanks. Seen yours and it looks tidy!

Thanks for the comments

Updates are on the way. I've recently been collecting parts and just setting up to start the new build. Hopefully get the piston rings gapped and plastigauge the main and big end to ensure clearances are within spec after the crank was polished.

Starting this one with a brand new block...

Updates are on the way. I've recently been collecting parts and just setting up to start the new build. Hopefully get the piston rings gapped and plastigauge the main and big end to ensure clearances are within spec after the crank was polished.

Starting this one with a brand new block...

Stuballs said:

Thanks for the comments

Updates are on the way. I've recently been collecting parts and just setting up to start the new build. Hopefully get the piston rings gapped and plastigauge the main and big end to ensure clearances are within spec after the crank was polished.

Starting this one with a brand new block...

Where did you get the block, can't be that many new K series parts around on shelves somewhere can there?Updates are on the way. I've recently been collecting parts and just setting up to start the new build. Hopefully get the piston rings gapped and plastigauge the main and big end to ensure clearances are within spec after the crank was polished.

Starting this one with a brand new block...

I've always wondered if the block could be modified in any way to better support the bottom of the liners and try to prevent the dreaded liner sink.......

Max_Torque said:

Where did you get the block, can't be that many new K series parts around on shelves somewhere can there?

I've always wondered if the block could be modified in any way to better support the bottom of the liners and try to prevent the dreaded liner sink.......

I might be wrong, but I believe the Scholar 1.9 conversion deals with that issue, the block is bored out and the new liners are a light press fit.I've always wondered if the block could be modified in any way to better support the bottom of the liners and try to prevent the dreaded liner sink.......

Megaflow said:

Max_Torque said:

Where did you get the block, can't be that many new K series parts around on shelves somewhere can there?

I've always wondered if the block could be modified in any way to better support the bottom of the liners and try to prevent the dreaded liner sink.......

I might be wrong, but I believe the Scholar 1.9 conversion deals with that issue, the block is bored out and the new liners are a light press fit.I've always wondered if the block could be modified in any way to better support the bottom of the liners and try to prevent the dreaded liner sink.......

The std K has the through bolts, that pull the head to the block face, and take the majority of the load into the liners (to seal the fire face interface) and that load is passed down the liners, and into the lower zone of the block, through the main bearing webs, up against which the lower bedplate (with the other half of the main webs) is pulled by the head bolts.

The "liner sinking" is caused, iirc, by the liners fretting and expanding (thermal expansion difference to the ally block) and i think, wearing down into the supporting block material, but it also could be that the liners actual are yielding the block at that high load interface? Has anyone measured a "sagged" block and worked out where the sag actually occurred? Without being able to carry a higher load reliably in this area, then that prohibits the use of a higher head clamp load, which means forced induction or high CR engines are always going to suffer from top end sealing issues....

That block is a Chinese N-series block which are floating about now.

As far as liners sinking, I think it's really only a problem if the alloy gets a bit on the hot side although decking the block and lapping the liners into place with some paste to maximize bearing area probably helps, as does ensuring the liners are all the same height. The limiting factor on the shoulder area that the liner sits on is the bore pitch unless you get fancy with non-circular liners.

As far as liners sinking, I think it's really only a problem if the alloy gets a bit on the hot side although decking the block and lapping the liners into place with some paste to maximize bearing area probably helps, as does ensuring the liners are all the same height. The limiting factor on the shoulder area that the liner sits on is the bore pitch unless you get fancy with non-circular liners.

AER said:

That block is a Chinese N-series block which are floating about now.

As far as liners sinking, I think it's really only a problem if the alloy gets a bit on the hot side although decking the block and lapping the liners into place with some paste to maximize bearing area probably helps, as does ensuring the liners are all the same height. The limiting factor on the shoulder area that the liner sits on is the bore pitch unless you get fancy with non-circular liners.

Is there any scope for sandwiching a steel re-enforcing ring into the block to bedplate joint, or the bedplate to sump joint, and somehow having some load carrying supports come up to the area of the liner bottom faces?As far as liners sinking, I think it's really only a problem if the alloy gets a bit on the hot side although decking the block and lapping the liners into place with some paste to maximize bearing area probably helps, as does ensuring the liners are all the same height. The limiting factor on the shoulder area that the liner sits on is the bore pitch unless you get fancy with non-circular liners.

Elise Parts sell the blocks new. They're supposed to be "stronger" on account of the ribbing. I've seen other comments that the ribbing reduces noise from the engine, possibly allowing it to run a knock sensor. Not sure I buy any of that. I just wanted to rule out having a block that could have been overheated and sunk the liners. As you say, the weak link of this engine eally comes down to how narrow the liner seats are, and how easily the liners sink when the block is overheated.

The last built engine was a 1. 9 Scholar. My non-engineering brain figured an added bonus of the press-fit system was the liners would be harder to sink given the frictional forces between the bottom half of the liners and the alloy block. One reported problem with this conversion (but I have no evidence) was ovalisation. My engine suffered with epic engine noise and when I stripped it down to investigate and sort the pressurising coolant I discovered knarly pistion/bore contact inlet and exhaust sides. So bad in fact it had written off the block and the pistons. I had always intended to investigate and have everything measured properly by my engineering shop. However in a last minute unexpected house move (to a new place with no garage) I just chucked the lot in a skip!

There probably is a way to reinforce the liners, but ultimately it would come down to cost - benefit I guess? MaxTorque I'm no engineer so didn't follow a lot of what you said. The K-series was so widely used I expect if there was an affordable (or even an unaffordable) solution it would have been tried.

Of note: The 1.8t saic/kavachi/tci-tech engine in the mk1 mg6 (and used extensively in China) is effectively the same architecture as the K-series (different head) but doesn't suffer the same hgf issues the original K-series did. I really want to get hold of one and strip it down to see exactly what is different!

The last built engine was a 1. 9 Scholar. My non-engineering brain figured an added bonus of the press-fit system was the liners would be harder to sink given the frictional forces between the bottom half of the liners and the alloy block. One reported problem with this conversion (but I have no evidence) was ovalisation. My engine suffered with epic engine noise and when I stripped it down to investigate and sort the pressurising coolant I discovered knarly pistion/bore contact inlet and exhaust sides. So bad in fact it had written off the block and the pistons. I had always intended to investigate and have everything measured properly by my engineering shop. However in a last minute unexpected house move (to a new place with no garage) I just chucked the lot in a skip!

There probably is a way to reinforce the liners, but ultimately it would come down to cost - benefit I guess? MaxTorque I'm no engineer so didn't follow a lot of what you said. The K-series was so widely used I expect if there was an affordable (or even an unaffordable) solution it would have been tried.

Of note: The 1.8t saic/kavachi/tci-tech engine in the mk1 mg6 (and used extensively in China) is effectively the same architecture as the K-series (different head) but doesn't suffer the same hgf issues the original K-series did. I really want to get hold of one and strip it down to see exactly what is different!

The liners on the K are pretty slim so pressing them into a wobbly block isn't going to make for maintaining a round bore under thermal and mechanical loads. I'd suspect the K assembly needs to be kept loose aside from cylinder head to liner clamp loads which need to stay tight for obvious reasons.

IMO it's a bit of a silly engine to attempt to boost beyond its known power and pressure limitations because the structural limitations are flaming obvious. That and the piston crown height and rod length that has been pushed to slightly beyond ridiculous.

As an S1 Elise owner I browse for K pictures on the web from time to time with ambitions to up-engineer it. The reality is though, there are other engines out there now that are much more robust and very nearly as light these days - the Duratec, for example - with headroom for spectacular power upgrades due to better bore-stroke ratios, bigger valves and sensible conrod lengths. It just doesn't make any sense to thrown effort at the K . It's old technology - useful still, but old and limited.

IMO it's a bit of a silly engine to attempt to boost beyond its known power and pressure limitations because the structural limitations are flaming obvious. That and the piston crown height and rod length that has been pushed to slightly beyond ridiculous.

As an S1 Elise owner I browse for K pictures on the web from time to time with ambitions to up-engineer it. The reality is though, there are other engines out there now that are much more robust and very nearly as light these days - the Duratec, for example - with headroom for spectacular power upgrades due to better bore-stroke ratios, bigger valves and sensible conrod lengths. It just doesn't make any sense to thrown effort at the K . It's old technology - useful still, but old and limited.

I've seen a few bad Scholar installaions, mainly due to how they fitted the liners, i.e. not true.

When my old VHPD went pop it was found that the liner protrusion wasn't great. The solution, as I didn't want a new block was to remove everything and then dress the block surface back to get all four at the top of their tolerances.

Good thread. Thanks for the updates.

When my old VHPD went pop it was found that the liner protrusion wasn't great. The solution, as I didn't want a new block was to remove everything and then dress the block surface back to get all four at the top of their tolerances.

Good thread. Thanks for the updates.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff