WRX RA powered VW 1303 beetle cabrio with a bit of Porsche

Discussion

Well I've got another engine (secondhand wiht about 50k miles) and am currently stripping it down to a longblock for a clean up ready to take my modified intake manifold and other bits.

Looking over the engine block it seemed remarkably similar to my RA closed deck block and after a quick search it seems some very early WRXs came with them too! Looks like I lucked out on this engine! I'll be able to confirm tomorrow when I've taken the rear cambelt covers off to check for some typical hatching marks above the oil/water heat exchanger...

Should be back on the road in a couple of weeks

While it was all out I also got the flywheel skimmed as the surface finish was too course and causing clutch slip on boost, API did a good job and I didn't realise they were so local to me..

Looking over the engine block it seemed remarkably similar to my RA closed deck block and after a quick search it seems some very early WRXs came with them too! Looks like I lucked out on this engine! I'll be able to confirm tomorrow when I've taken the rear cambelt covers off to check for some typical hatching marks above the oil/water heat exchanger...

Should be back on the road in a couple of weeks

While it was all out I also got the flywheel skimmed as the surface finish was too course and causing clutch slip on boost, API did a good job and I didn't realise they were so local to me..

The replacement engine is now in and working well! The only issue I have is hitting the fuel cut with overboosting but this should be relatively easy to sort out and is an indication that my exhaust porting and downpipe are working better.

I'm doing some fine tuning of the set-up and found that the air dam was definitely a necessity, rather than put all my time into something untested I cleaned it up with a bit of paint and got it on the car and I'm pleased with how it looks and works.

I wanted the rear seat to look stock over the transmission tunnel so modified the seat framework to clear it.

All in and no evidence of what's underneath!

I'm doing some fine tuning of the set-up and found that the air dam was definitely a necessity, rather than put all my time into something untested I cleaned it up with a bit of paint and got it on the car and I'm pleased with how it looks and works.

I wanted the rear seat to look stock over the transmission tunnel so modified the seat framework to clear it.

All in and no evidence of what's underneath!

Time to finish off the dash... Some wooden strips were used as a guide to keep a constant thickness of the binnacle over the instruments

I then filled in the gaps frm underneath with some fibreglass matting

Cavity builders expanding foam was then used to build up the volume without adding too much weight, it is very easy to sculpt to about the right shape too

Then skimmed with filler. I just need to radius off all the edges and do some final finishing now..

I then filled in the gaps frm underneath with some fibreglass matting

Cavity builders expanding foam was then used to build up the volume without adding too much weight, it is very easy to sculpt to about the right shape too

Then skimmed with filler. I just need to radius off all the edges and do some final finishing now..

I really wasn't keen on the Porsche 'nipple' lenses so after carefully picking the surrounds off I was able to remove the lenses and make up some new flat ones from polycarbonate sheet. While they were apart I sandblasted and repainted the rims and they look brand new now.

All back in the car I'm happy with how it's all looking. I painted the dash binnacle as a temporary measure until it's re-trimmed in leather.

I also re-fitted the running board chrome trim and I think it finishes them off nicely.

I also made up a strut brace. Coming off it are a brake reservoir bracket and also a cover to protect the fuel pump and fuel level sender.

Next big job will be the heater but I have to figure out what matrix to use, I need one that is about 100x200mm, any ideas?

All back in the car I'm happy with how it's all looking. I painted the dash binnacle as a temporary measure until it's re-trimmed in leather.

I also re-fitted the running board chrome trim and I think it finishes them off nicely.

I also made up a strut brace. Coming off it are a brake reservoir bracket and also a cover to protect the fuel pump and fuel level sender.

Next big job will be the heater but I have to figure out what matrix to use, I need one that is about 100x200mm, any ideas?

I've cut into the wiper box cover to build a housing for the heater matrix. The corner piece had to be clearanced for the wiper mechanism and the tube connects straight up to the stock air ducting so all the stock dash controls can still be used.

Fiat cinquecento heater matrix in place, note the neat positions of the connections down the side of the car.

I initially planned to fit the stock fresh air blower fan roughly in the position shown but when connecting it up to a spare battery it was more a breeze than a decent flow.

This is the polo heater blower which gave much better flow and will also be easier to mount up to the matrix.

Fiat cinquecento heater matrix in place, note the neat positions of the connections down the side of the car.

I initially planned to fit the stock fresh air blower fan roughly in the position shown but when connecting it up to a spare battery it was more a breeze than a decent flow.

This is the polo heater blower which gave much better flow and will also be easier to mount up to the matrix.

Just to confirm the flow would be sufficient before finally plumping with the polo blower fan.

Here's the back face of the reworked bulkhead panel, the silicone pipe fits straight over the stock interface for the old fresh air blower motor. It was all given a good coat of epoxy mastic 121 as it will be very exposed to the elements...

All in and works very well! I fitted a short section of Rover 100 heater pipe as it has a neat moulded in bleed screw.

Under-bonnet parts all done now. I had to modify the windscreen.headlight washer tank to fit over the radiator cover. I will probably also make some finishing panels before carpeting this area.

A functional solution for how to fit the VW t25 heater switch to the dash. It has tiny features to try to make up some sort of retaining bracket and even those wouldn't clear properly, the rear end of it was also extremely close to the heater control cables so using some fibreglass filler was an acceptable solution for me. I was able to use the stock VW plug on the back of it and the wire colour coding matched the blower so all good... (the original switch was only a 2 speed which is why I changed it)

I also did some work on the 996:

As autumn is making an early appearance I thought I'd better get on and fit mesh to the front bumper intakes. These are very problematic on watercoled 911s and boxsters as they act as leaf funnels/traps and rot out the radiator and A/C matrix.

the front bumper comes off very easily, I took the opportuynity to give it all a really god cleanout. What you see on the floor literally just fell out from between the condensor and radiator, I also jet-washed out a lot of rotting matter from the cores which is sure to help cooling.

Nothing too complicated, a few 3mm holes and 2.5mm tie wraps hold on some mesh that I cut from a sheet.

The other thing I did was to re 'black' all the plastics of the intake as they seem to suffer quite badly from fading. I use Gtechniq C4 which is very easy to use and apparently gives a good couple of years of colour.

I finally got hold of a pair of facelift rear lights. Bought separately off ebay worked out much cheaper than buying a pair together.. While I was at it, I also removed/sand-blasted/painted all 3 wiper arms as they seem to have suffered more than the rest of the car for some reason..

Here's the back face of the reworked bulkhead panel, the silicone pipe fits straight over the stock interface for the old fresh air blower motor. It was all given a good coat of epoxy mastic 121 as it will be very exposed to the elements...

All in and works very well! I fitted a short section of Rover 100 heater pipe as it has a neat moulded in bleed screw.

Under-bonnet parts all done now. I had to modify the windscreen.headlight washer tank to fit over the radiator cover. I will probably also make some finishing panels before carpeting this area.

A functional solution for how to fit the VW t25 heater switch to the dash. It has tiny features to try to make up some sort of retaining bracket and even those wouldn't clear properly, the rear end of it was also extremely close to the heater control cables so using some fibreglass filler was an acceptable solution for me. I was able to use the stock VW plug on the back of it and the wire colour coding matched the blower so all good... (the original switch was only a 2 speed which is why I changed it)

I also did some work on the 996:

As autumn is making an early appearance I thought I'd better get on and fit mesh to the front bumper intakes. These are very problematic on watercoled 911s and boxsters as they act as leaf funnels/traps and rot out the radiator and A/C matrix.

the front bumper comes off very easily, I took the opportuynity to give it all a really god cleanout. What you see on the floor literally just fell out from between the condensor and radiator, I also jet-washed out a lot of rotting matter from the cores which is sure to help cooling.

Nothing too complicated, a few 3mm holes and 2.5mm tie wraps hold on some mesh that I cut from a sheet.

The other thing I did was to re 'black' all the plastics of the intake as they seem to suffer quite badly from fading. I use Gtechniq C4 which is very easy to use and apparently gives a good couple of years of colour.

I finally got hold of a pair of facelift rear lights. Bought separately off ebay worked out much cheaper than buying a pair together.. While I was at it, I also removed/sand-blasted/painted all 3 wiper arms as they seem to have suffered more than the rest of the car for some reason..

I finally had enough of the restricted steering, tyre rubbing and compromised steering geometry so found a set of wider front wings in conjunction with some concentric wheel spacers. I also plan to rebuild the steering rack with adjustable end stops to maximise the lock available. The wings will also need modifying to provide a better mounting surface for the air damn. From a quick drive around it is significantly better.. The front bumper brackets will need to be extended slightly to give a bit more space to the wings too but I think it will end up looking better with more flowing lines.

Bit overdue an update!

Plenty of stone chip was sprayed on underneath the wings and then high build primer, final colour and clear before letting the paint settle for a week or so and then refitting them.

I actually got some stonechip overspray on the air damn so ended up giving that a full coat along with satin black paint as it could do with the protection anyway.

All re-fitted!

I don't think the car looks noticeably different but with the wheel spacers and re-done steering rack with adjustable end stops I now have a lot more steering lock as well as a much more predictable and nice feeling balance to the car.There was far too much negative scrub radius with everything forced inboard to fit under stock width wings.

Another mod I've done is switch to smaller 5/8" brake master cylinders along with a calculated balance bar position and this has made the brakes MUCH more confidence inspiring with less pedal effort and a bit more travel!

I made up this metal cover to cover the shifter base and allow trimming, still not sure how I will do it but it's a start.

I've been putting this off for a while... The old vinyl roof shrunk whilst in storage folded up so when I came to close it on the car the stress broke the wooden bow over the rear window. This meant a new bow and roof!

Bow from the original tooling was sourced from Germany along with a new roof outer skin, in Sonnenland (similar to mohair) this time around and a change of colour. A fair amount of repair of sound deadening material as well as repainting sections of the roof frame were done at the same time.

Here's the roof ready for it's new outer skin. The foam strip over the bow is to cover up the staples holding fabric to the bow and stop wear on the outer hood.

Almost there! I'm letting it all settle for a few days now before I get the knife out and cut the rear window aperture out. All seals and wires are refitted in this picture, just a couple of screws to fit at the base of the C pillars to take up any final slack in the material.

Plenty of stone chip was sprayed on underneath the wings and then high build primer, final colour and clear before letting the paint settle for a week or so and then refitting them.

I actually got some stonechip overspray on the air damn so ended up giving that a full coat along with satin black paint as it could do with the protection anyway.

All re-fitted!

I don't think the car looks noticeably different but with the wheel spacers and re-done steering rack with adjustable end stops I now have a lot more steering lock as well as a much more predictable and nice feeling balance to the car.There was far too much negative scrub radius with everything forced inboard to fit under stock width wings.

Another mod I've done is switch to smaller 5/8" brake master cylinders along with a calculated balance bar position and this has made the brakes MUCH more confidence inspiring with less pedal effort and a bit more travel!

I made up this metal cover to cover the shifter base and allow trimming, still not sure how I will do it but it's a start.

I've been putting this off for a while... The old vinyl roof shrunk whilst in storage folded up so when I came to close it on the car the stress broke the wooden bow over the rear window. This meant a new bow and roof!

Bow from the original tooling was sourced from Germany along with a new roof outer skin, in Sonnenland (similar to mohair) this time around and a change of colour. A fair amount of repair of sound deadening material as well as repainting sections of the roof frame were done at the same time.

Here's the roof ready for it's new outer skin. The foam strip over the bow is to cover up the staples holding fabric to the bow and stop wear on the outer hood.

Almost there! I'm letting it all settle for a few days now before I get the knife out and cut the rear window aperture out. All seals and wires are refitted in this picture, just a couple of screws to fit at the base of the C pillars to take up any final slack in the material.

Roof just about done now...

I'm going for the light tan colour leather on the right for the interior, I was originally going to go for a cocoa colour but having thought about it I think it would be too much of the same and some contrast is called for.

Seat backs are a bit marked and as the seats will soon be dismantled for trim now is the perfect time to colour-code the backs to body colour.

The old trim panels were moisture damaged so I've made up some new ones. I will also be making some new moisture barriers to keep these ones dry!! You can also see in the background I've put sound deadening in the door panels

These are the cut-down aluminium Porsche 944 spring plate covers with much wider aftermarket urethane bushes to better locate the spring plates.

I'm going for the light tan colour leather on the right for the interior, I was originally going to go for a cocoa colour but having thought about it I think it would be too much of the same and some contrast is called for.

Seat backs are a bit marked and as the seats will soon be dismantled for trim now is the perfect time to colour-code the backs to body colour.

The old trim panels were moisture damaged so I've made up some new ones. I will also be making some new moisture barriers to keep these ones dry!! You can also see in the background I've put sound deadening in the door panels

These are the cut-down aluminium Porsche 944 spring plate covers with much wider aftermarket urethane bushes to better locate the spring plates.

Seat backs after a lot of work with paint stripper, etch and high-build primer

before finally getting the body colour top coats..

More sound deadening pads fitted to the floor panels and new MDF trim panels made up to fit speakers under the back seat

Door membranes to stop the new door panels suffering from water damage (I've also painted them in yacht varnish before I give them to the trimmer)

Automotive underlay cut to shape for the floor, only lightly glued in case they need to be removed to dry out if I ever get caught out by rain!

The first piece of carpet going in. I've spent far too much time planning the layout in my head to minimise joins and exposed edges to give it a more OEM look.

First panel finished...

Then on to the tunnel section. I bonded on a metal reinforcement to the handbrake hole, this means I can fit the standard type rubber which will hide the cut edge nicely and the hole won't get opened up. A bit of foam also stops any potential rattles.

Passenger bit now done, just behind the back seat to sort out. Still undecided what to do about under the bonnet

Front end done. The floor and bulkhead panels will go to the trimmer to have the edges bound.

before finally getting the body colour top coats..

More sound deadening pads fitted to the floor panels and new MDF trim panels made up to fit speakers under the back seat

Door membranes to stop the new door panels suffering from water damage (I've also painted them in yacht varnish before I give them to the trimmer)

Automotive underlay cut to shape for the floor, only lightly glued in case they need to be removed to dry out if I ever get caught out by rain!

The first piece of carpet going in. I've spent far too much time planning the layout in my head to minimise joins and exposed edges to give it a more OEM look.

First panel finished...

Then on to the tunnel section. I bonded on a metal reinforcement to the handbrake hole, this means I can fit the standard type rubber which will hide the cut edge nicely and the hole won't get opened up. A bit of foam also stops any potential rattles.

Passenger bit now done, just behind the back seat to sort out. Still undecided what to do about under the bonnet

Front end done. The floor and bulkhead panels will go to the trimmer to have the edges bound.

The old engine is still i the corner under a bench, I'll probably open it up later on. I'm fairly sure the cause of failure was oil starvation due to a fault on the oil pick-up pipe.

I've been trying to keep myself busy while the trimmer has been doing exactly nothing! I'm following up a lead on a new one now I have got my parts back.

LSD as received with the gearbox when I bought it, bit of an unknown quantity!

The ramps show it is out of a 964 RS/turbo which means 20% lock on acceleration and 100% lock on overun. This has really helped the car feel much more predictable and also stable, especially after the suspension unloads after hard acceleration. I was going to have a go at fitting it myself but was unable to measure everything accurately enough. The trans had different brands of bearing either side of the differential so during the swap I had to replace: bearings, ring gear bolts (longer on LSDs), seals, oil, shims. With labour that lot added up to £580!!!

The main reason for taking the engine out (other than boredom waiting for the trimmer), was to sort out a minor oil leak coming from behind the engine, a very common fault with subarus.

Here's the updated subaru part, steel plate and new screws fitted with a sealant. The black screw is supplied with dry loctite on it, forgot to look why, probably as it was a through hole so needed sealing?

After being messed about by 'Car Audio Centre' for the best part of two months (avoid them at all costs!!) I bought a secondhand head unit from a friend. I wanted Alpine to go with my steering wheel controls. I ended up with an IDA-X001 which is a media head unit with graphic display and ipod/iphone controls. Rather than use a wire and screen mount I have hacked up a dock which fits snuggly into the ashtray with minimal mods.

Happy with how it looks! Lucky this head unit has the main control centrally so out of the way of the phone. I'll use it for satnav and music as well as keeping my phone charged.

I've been trying to keep myself busy while the trimmer has been doing exactly nothing! I'm following up a lead on a new one now I have got my parts back.

LSD as received with the gearbox when I bought it, bit of an unknown quantity!

The ramps show it is out of a 964 RS/turbo which means 20% lock on acceleration and 100% lock on overun. This has really helped the car feel much more predictable and also stable, especially after the suspension unloads after hard acceleration. I was going to have a go at fitting it myself but was unable to measure everything accurately enough. The trans had different brands of bearing either side of the differential so during the swap I had to replace: bearings, ring gear bolts (longer on LSDs), seals, oil, shims. With labour that lot added up to £580!!!

The main reason for taking the engine out (other than boredom waiting for the trimmer), was to sort out a minor oil leak coming from behind the engine, a very common fault with subarus.

Here's the updated subaru part, steel plate and new screws fitted with a sealant. The black screw is supplied with dry loctite on it, forgot to look why, probably as it was a through hole so needed sealing?

After being messed about by 'Car Audio Centre' for the best part of two months (avoid them at all costs!!) I bought a secondhand head unit from a friend. I wanted Alpine to go with my steering wheel controls. I ended up with an IDA-X001 which is a media head unit with graphic display and ipod/iphone controls. Rather than use a wire and screen mount I have hacked up a dock which fits snuggly into the ashtray with minimal mods.

Happy with how it looks! Lucky this head unit has the main control centrally so out of the way of the phone. I'll use it for satnav and music as well as keeping my phone charged.

You're not the first to say that, this project seems to be getting more people drawn in than others! My original plan was to build it and then play with engines for a while rather than full builds but scooby tuning can get very pricey, bang for bucks this set up will be hard to beat. I'll have to finish it first and then see how I feel.. I've just had a rough tot up of the main costs, bit frightening, but I suppose it has been drawn out over a few years for this one.

The old 944 CVs were clicking a bit and my plan was to upgrade to 930 CVs anyway. Here are the bits needed for conversion; new stub axles, I already had G50 trans drive-flanges, custom length axles (16 1/4") in 28 spline to match the CVs.

Here are the GKN CVs, I cleaned up the flanges that came with my gearbox but needed an extra pair. After getting up off the floor after being quoted £120 each from Porsche I found some cheaper options from prolinx.

CVs are being 'clocked' as this gives them the best alignment relative to each other, just like you do with a UJ.

All ready to go on the car

And fitted!

Clearance is very tight to the coil-over but is pass-able (this is worst case compression clearance). I spent ages trying to get some smaller motorsport CV boots from GKN only to find that they had stopped making the size I needed!

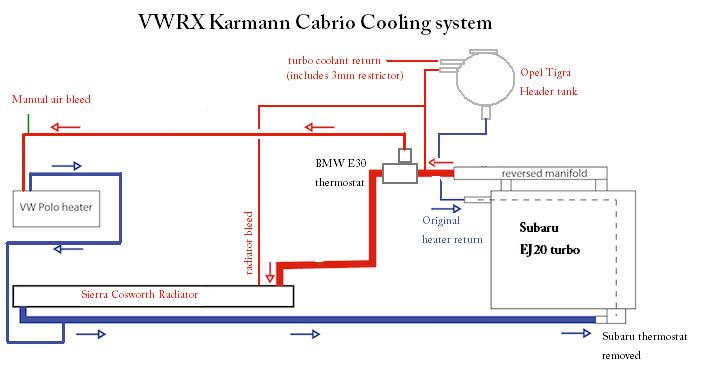

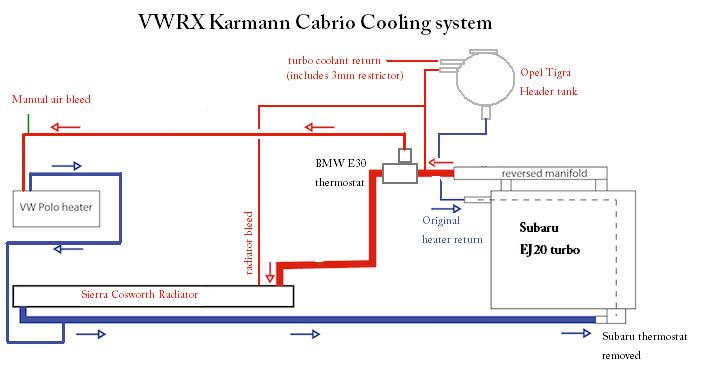

I've been asked so many times about my cooling system I've finally modified a schematic to show how it is all plumbed up. This system works perfectly, gets up to temperature fast and stays at a constant temperature. The other bonus is that I don't even have to bleed the system from an empty fill as it is completely self bleeding!

Here are the GKN CVs, I cleaned up the flanges that came with my gearbox but needed an extra pair. After getting up off the floor after being quoted £120 each from Porsche I found some cheaper options from prolinx.

CVs are being 'clocked' as this gives them the best alignment relative to each other, just like you do with a UJ.

All ready to go on the car

And fitted!

Clearance is very tight to the coil-over but is pass-able (this is worst case compression clearance). I spent ages trying to get some smaller motorsport CV boots from GKN only to find that they had stopped making the size I needed!

I've been asked so many times about my cooling system I've finally modified a schematic to show how it is all plumbed up. This system works perfectly, gets up to temperature fast and stays at a constant temperature. The other bonus is that I don't even have to bleed the system from an empty fill as it is completely self bleeding!

After 9 weeks of chasing, my second trimmer only managed to get the door panels and roof hinge covers done... I've now bitten the bullet and gone with a very good guy I've used before, just more expensive, but I know that he will do very good work and for my deadline which is the end of June.

I also had issues with the iphone dock, it seems the docks aren't straight through electrically and Alpine have a particular way of connecting together. I tried opening it up and making more connections but it still doesn't work... Any ideas?!?

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff