Mazda MX-5e Tesla Powered

Discussion

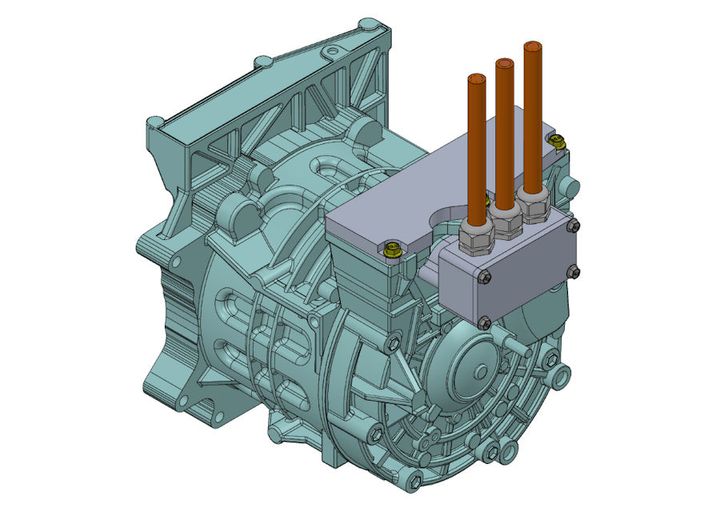

More shiny bits in the post from Inductive Automotive (USA based). This 3-part kit allows us to remotely mount the Nissan Leaf inverter from the Nissan Leaf motor and to supply 400V dc to the inverter. Lots of billet aluminium parts. Yes, it was expensive but, this level of fabrication is beyond my skill set. When we come to register the MX-5e as an EV, we want the DVLA inspector to look at and think these guys did it right

We are on the home straight! It feels like it has taken ages but, restoring a 30+ year old car does take a while. We have now removed the rear sub-frame and the fuel tank, so we can clean up and treat the last part of the car. This will then be painted with Buzzweld glass reinforced primer and several coats of Buzzweld WAR underseal.

The sub-frame is being shot blasted and powder coated, along with the suspension arms. These will then be fitted to my son's 1990 Eunos Roadster. I have a newly powder coated sub-frame and suspension parts to go back on the MX-5e.

The empty fuel tank weighs 11.1kg. The underside of the car is in pretty good condition, with just a few bits of surface rust.

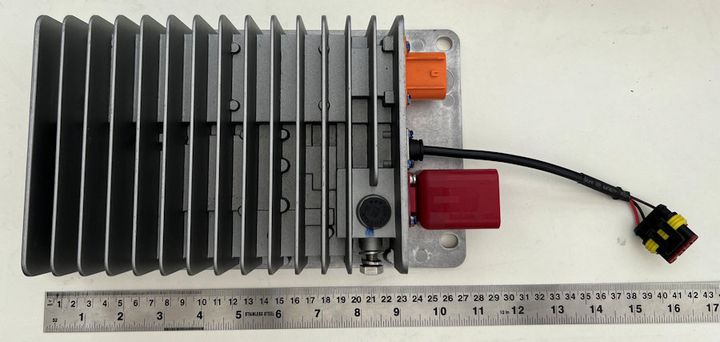

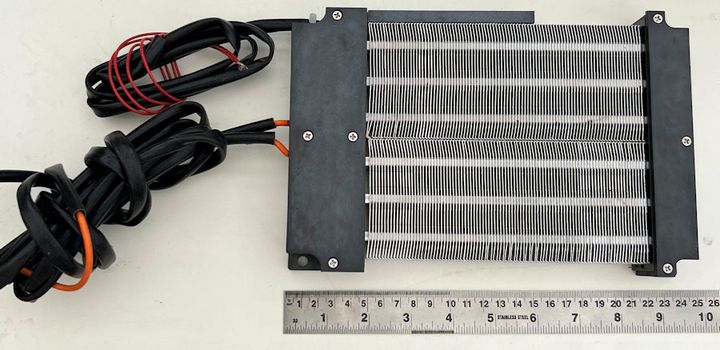

A delivery from Fellten today. We now have a dc-dc converter to run the 12V side of the car and to charge the 12V battery from our HV battery pack. It weighs 2505g and is air cooled. Also have a 3kW PTC heater to fit into the old Eunos heater matrix. It weighs just 1500g.

The sub-frame is being shot blasted and powder coated, along with the suspension arms. These will then be fitted to my son's 1990 Eunos Roadster. I have a newly powder coated sub-frame and suspension parts to go back on the MX-5e.

The empty fuel tank weighs 11.1kg. The underside of the car is in pretty good condition, with just a few bits of surface rust.

A delivery from Fellten today. We now have a dc-dc converter to run the 12V side of the car and to charge the 12V battery from our HV battery pack. It weighs 2505g and is air cooled. Also have a 3kW PTC heater to fit into the old Eunos heater matrix. It weighs just 1500g.

Yay! We have finally finished restoring the underside of the car. It has been stripped back to bare metal, any rust treated and then painted with Buzzweld glass reinforced primer and WAR underseal. It's been a massive job and very time consuming. Hopefully this car will now see out another 30+ years on UK roads.

We have been stripping the old sub-frame and will soon be sending all the parts off to be powder coated. We have quite a few parts ready to go on the MX-5e though.

Getting the old drive shafts out has been a bit of a nightmare. We eventually managed to get the driveshaft nuts off with a larege impact driver. We have now bought a 10-ton bench press to get the last stubborn driveshaft out. Our 'new' driveshafts have a different sized thread but fortunately the new bearing kist come with both sizes.

We are fitting new brake pipes and hoses, so we have a quality brake pipe flaring tool to do a proper job. We have bought new suyspension bolts from MX5 Parts as the old ones were too rusty to refit.

We have been stripping the old sub-frame and will soon be sending all the parts off to be powder coated. We have quite a few parts ready to go on the MX-5e though.

Getting the old drive shafts out has been a bit of a nightmare. We eventually managed to get the driveshaft nuts off with a larege impact driver. We have now bought a 10-ton bench press to get the last stubborn driveshaft out. Our 'new' driveshafts have a different sized thread but fortunately the new bearing kist come with both sizes.

We are fitting new brake pipes and hoses, so we have a quality brake pipe flaring tool to do a proper job. We have bought new suyspension bolts from MX5 Parts as the old ones were too rusty to refit.

With the second drive shaft finally removed from the rear hub, we set about cleaning up the hubs and hub carriers, then adding a primer coat.

Whilst doing this, we realised that we reached a milestone today. We have now taken off every single nut, bolt, bracket, pipe, clip, wire, bush, bearing, hose, etc. on our MX-5e whilst restoring it and preparing it for the EV conversion. The only two nuts we have not undone are the two front hub nuts, because we don't need to. We have even taken off the doors and had them apart to fit new electric window cables and guides. From here on in, we are only putting stuff back on the car

tight fart said:

Looking good but you could have cut the exhaust hangers off

No. It was very tempting to save a little bit more weight

But ... the DVLA wants the chassis and bodywork to be unmolested when it comes to registering the car as EV and drilling holes and cutting bits off is not a good idea. Maybe later

But ... the DVLA wants the chassis and bodywork to be unmolested when it comes to registering the car as EV and drilling holes and cutting bits off is not a good idea. Maybe later

The backend is pretty much complete now. We have freshly powder coated subframes and suspension parts, new coilovers, new polybushes all round, new bolts and alignment bolts. We have a 3.6:1 Super Fuji LSD with upgraded internals by McNeill Engineering and welded diff casing arms by G19 Engineering. We have refrubished as new brake calipers, new discs and pads. We have refurbished uprights with new wheel bearings and new bushes for the ARB parts, which have also ben powder coated as new. It's all looking very shiny but, should be able to withstand the 215hp / 400Nm torque now.

The car is now back on the ground. We will torque everything up but it going for a full geometry set up soon.

Currently designing the HV battery pack. It looks like we can fit 32kWh in this space quite easily and if using Svolt batteries the battery pack would be about 135kg + cooling plates and enclosure. We have space where the fuel tank was and if we used this as well could probably get the range closer to 200 miles but, our focus is on light weight. This is a fun weekend car and we don't need more than 120 miles range.

Edited by robcollingridge on Wednesday 22 May 14:22

It's an interesting question. My preference is for a single 32kWh battery pack in the engine bay as this keeps the CoG as low as possible and massively simplifies and shortens the HV wiring to the motor (sits in the tunnel) and the inverter (sits above the batteries). It also massively simplifies the cooling system and volume of coolant required.

The plan is to fit a mounting plate over the fuel tank space and to mount the dc-dc converter in the underside and in the air flow (it is air cooled) and the charger above it, close to the charging port (inside the existing petrol filler cap). This makes for a very tidy solution with minimal materials and weight.

I'm not sure how big an impact this will have on the F/R distribution as we have a much smaller cooling system in the space where the radiator and fans previous sat. We have also lost a lot of other stuff that was in the engine bay, including over 5kg of wiring to support the ICE, air intake system, air conditioning hardware, power steering hardware, etc.

My feeling is that the F/R weight distribution will be very similar to the stock car and any changes will not really be noticable. I think the power and torque improvements will be the thing you notice first As a new car back in 1992 it had 86kW (115bhp) at 6,500 rpm and 136Nm of torque at 5,500 rpm. We must have lost some of that over the last 32 years and it being an automatic really didn't help! My son's 1990 Eunos Roadster 1.6 manual felt a lot quicker. As an MX-5e it will have 136kW (182bhp) and 350Nm of torque from zero rpm, with a top speed of 109mph. We also have an upgrade path to 215bhp/400Nm/119mph, which adds no more extra weight

As a new car back in 1992 it had 86kW (115bhp) at 6,500 rpm and 136Nm of torque at 5,500 rpm. We must have lost some of that over the last 32 years and it being an automatic really didn't help! My son's 1990 Eunos Roadster 1.6 manual felt a lot quicker. As an MX-5e it will have 136kW (182bhp) and 350Nm of torque from zero rpm, with a top speed of 109mph. We also have an upgrade path to 215bhp/400Nm/119mph, which adds no more extra weight  Lots of other dynamic improvements made too, including a fully rebuilt and upgraded LSD.

Lots of other dynamic improvements made too, including a fully rebuilt and upgraded LSD.

The plan is to fit a mounting plate over the fuel tank space and to mount the dc-dc converter in the underside and in the air flow (it is air cooled) and the charger above it, close to the charging port (inside the existing petrol filler cap). This makes for a very tidy solution with minimal materials and weight.

I'm not sure how big an impact this will have on the F/R distribution as we have a much smaller cooling system in the space where the radiator and fans previous sat. We have also lost a lot of other stuff that was in the engine bay, including over 5kg of wiring to support the ICE, air intake system, air conditioning hardware, power steering hardware, etc.

My feeling is that the F/R weight distribution will be very similar to the stock car and any changes will not really be noticable. I think the power and torque improvements will be the thing you notice first

As a new car back in 1992 it had 86kW (115bhp) at 6,500 rpm and 136Nm of torque at 5,500 rpm. We must have lost some of that over the last 32 years and it being an automatic really didn't help! My son's 1990 Eunos Roadster 1.6 manual felt a lot quicker. As an MX-5e it will have 136kW (182bhp) and 350Nm of torque from zero rpm, with a top speed of 109mph. We also have an upgrade path to 215bhp/400Nm/119mph, which adds no more extra weight

As a new car back in 1992 it had 86kW (115bhp) at 6,500 rpm and 136Nm of torque at 5,500 rpm. We must have lost some of that over the last 32 years and it being an automatic really didn't help! My son's 1990 Eunos Roadster 1.6 manual felt a lot quicker. As an MX-5e it will have 136kW (182bhp) and 350Nm of torque from zero rpm, with a top speed of 109mph. We also have an upgrade path to 215bhp/400Nm/119mph, which adds no more extra weight  Lots of other dynamic improvements made too, including a fully rebuilt and upgraded LSD.

Lots of other dynamic improvements made too, including a fully rebuilt and upgraded LSD.Before we rewire the backend of the MX-5e, we are stripping the boot and tidying it up a bit. We have resprayed parts of it. The boot hinge/springs have also been removed and cleaned up.

The rewiring from scratch is progressing well. Fabricating a custom, light-weight loom which is colour coded for diagnostics.

We have decided to rework the radiator shroud and add a second fan. The fans weigh just 850g. This means we should be better able to maintain a stable 400V battery temperature under higher loads and in hotter weather. The whole radiator assembly is just 5.2Kg and less than half the weight of what was originally on the car. Less coolant also saves more weight in the engine bay. When we have finalised the design, the mounting plate will be powder coated too.

We are currently fitting the Inductive Autoworks connection kit to the Nissan Leaf motor and inverter, so that we can finalise the position of the motor in the centre tunnel and start fabricating a mounting frame for this and the battery pack.

The rewiring from scratch is progressing well. Fabricating a custom, light-weight loom which is colour coded for diagnostics.

We have decided to rework the radiator shroud and add a second fan. The fans weigh just 850g. This means we should be better able to maintain a stable 400V battery temperature under higher loads and in hotter weather. The whole radiator assembly is just 5.2Kg and less than half the weight of what was originally on the car. Less coolant also saves more weight in the engine bay. When we have finalised the design, the mounting plate will be powder coated too.

We are currently fitting the Inductive Autoworks connection kit to the Nissan Leaf motor and inverter, so that we can finalise the position of the motor in the centre tunnel and start fabricating a mounting frame for this and the battery pack.

There are some great suppliers out there when it comes to EV conversions and general car modifications. We are really lucky to have G19 Engineering very close by. Doug at G19 sells a range of parts to upgrade MX-5s and he's done a custom modification on our old automatic pedal box, to mount to our Tesla iBooster. He has then strengthened it and added two-position mounts for the MX-5 mk 3 digital throttle pedal, which will work perfectly with our Thunderstruck VCU. The whole thing has then been zinc plated.

Doug also supplied a second-hand mk 3 throttle pedal and new connector for it. Stuff like this makes our conversion look much more professional and saves us a whole heap of time in the process.

Doug also supplied a second-hand mk 3 throttle pedal and new connector for it. Stuff like this makes our conversion look much more professional and saves us a whole heap of time in the process.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff