Instructions to change fuel maps on 14CUX Griffith, Chimaera

Discussion

Discoveryunlimited said:

Amazing to see how busy this topic still is.

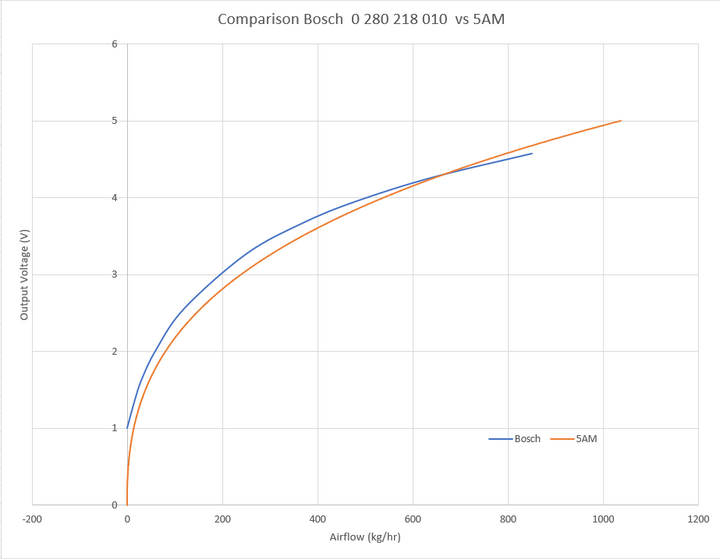

One of the things that has always got me is the AFM, I have been using the Bosch 0 280 218 010 meter with the remap but as we know the MAF curve is a fair bit different than the 5AM. (I am running a range rover classic not a grif...... and pushing 3 tonnes with everything on it)

This is the chart comparing the two meters: (I also have ADC counts if anyone is interested)

I have spent a lot of time in the rebuild code looking at the MAF related code and the interactions with it in the system as a whole. I am slowing working through how it uses the readings from the airflow meter. In the mean time I have created a little airflow converter that takes in the signal from the bosch and maps that to the equivalent signal of the 5AM. My setup is running the fuel rail at 3.5bar with EV6 injectors (4 hole spray), using a GEMS system plenum top with a 200 count air idle control stepper motor (code modified from the 180 count).

I just ran some test today with it (of course with new base maps) and I do think the car runs better. I use to find at the top end the car would get flat and I believe that this is because the bosch curve flattens out at the top end, how the 14CUX linearises the curve and uses it for load indexing it appears the load is reducing. When comparing the linearised MAF load with and without the airflow converter, the MAF load is higher at idle and in lower throttle positions. Once corrected the MAF loading is reduced for lower loads and increased for higher loads.

Overall I find the car much more responsive with a smoother idle when hot (I have kept throttle maps, coolant table etc the same and only changed the relevant fuel maps and scalars). Based on what I understand (which is limited) from the code and what I have seen today I do believe that while the 14CUX can be made to work with the bosch directly it is not particularly ideal and actually makes the system run sub-optimal.

My ultimate goal would be to modify the rebuild project to natively use the bosch meter, that is the linearisation of the MAF and its load indexing is correct for the airflow, so I am slowly chipping away at this.

Has anyone else looked at this? I am also be interested in the thoughts from the people that have spent a lot of time in the rebuild code and have spent many hours tuning the 14CUX.

Also as a side note using chatGPT for working through code sections is really a big help.

Cheers,

Josh

I went down the route of producing a small box that interfaced either the 20 AM or Bosch AFM to mimic the exact airflow characteristics of the 5AM. I tried this with both analogue electronics to modify the wave forms and a commercial system using a digital lookup table. I made the naively made mistake of thinking that I could use the increased airflow without remapping (This was way before the days of reverse engineering the fuel maps of the 14CUX). Now I realise that without increasing the fuel in the map, no power gains can be made, and subsequent rolling road tests of my unit proved this to be true.One of the things that has always got me is the AFM, I have been using the Bosch 0 280 218 010 meter with the remap but as we know the MAF curve is a fair bit different than the 5AM. (I am running a range rover classic not a grif...... and pushing 3 tonnes with everything on it)

This is the chart comparing the two meters: (I also have ADC counts if anyone is interested)

I have spent a lot of time in the rebuild code looking at the MAF related code and the interactions with it in the system as a whole. I am slowing working through how it uses the readings from the airflow meter. In the mean time I have created a little airflow converter that takes in the signal from the bosch and maps that to the equivalent signal of the 5AM. My setup is running the fuel rail at 3.5bar with EV6 injectors (4 hole spray), using a GEMS system plenum top with a 200 count air idle control stepper motor (code modified from the 180 count).

I just ran some test today with it (of course with new base maps) and I do think the car runs better. I use to find at the top end the car would get flat and I believe that this is because the bosch curve flattens out at the top end, how the 14CUX linearises the curve and uses it for load indexing it appears the load is reducing. When comparing the linearised MAF load with and without the airflow converter, the MAF load is higher at idle and in lower throttle positions. Once corrected the MAF loading is reduced for lower loads and increased for higher loads.

Overall I find the car much more responsive with a smoother idle when hot (I have kept throttle maps, coolant table etc the same and only changed the relevant fuel maps and scalars). Based on what I understand (which is limited) from the code and what I have seen today I do believe that while the 14CUX can be made to work with the bosch directly it is not particularly ideal and actually makes the system run sub-optimal.

My ultimate goal would be to modify the rebuild project to natively use the bosch meter, that is the linearisation of the MAF and its load indexing is correct for the airflow, so I am slowly chipping away at this.

Has anyone else looked at this? I am also be interested in the thoughts from the people that have spent a lot of time in the rebuild code and have spent many hours tuning the 14CUX.

Also as a side note using chatGPT for working through code sections is really a big help.

Cheers,

Josh

Hardware wise I was presented with various problems during long term testing. Using an analogue box the voltages tended not to be stable in the extreme temperature shifts of the engine bay, that would lead to mixture shifts and unstable idle. I probibibly could have over come this by putting the conversion unit inside the car but it stopped it being an easy plug and play solution. Once switched to digital conversion the extra internal electronics could not cope with the lightning storm HT system that spikes with both RF interference and corrupting the 12v supply line, especially in an unshielded glass fibre body. This constantly wiped the look up table in the NV ram.

As the new dawn of RoverGauge and Tuner pro made remapping a possibility the project sat in the back of the workshop and progressed no further as Id already wasted enough of my life on such follies.

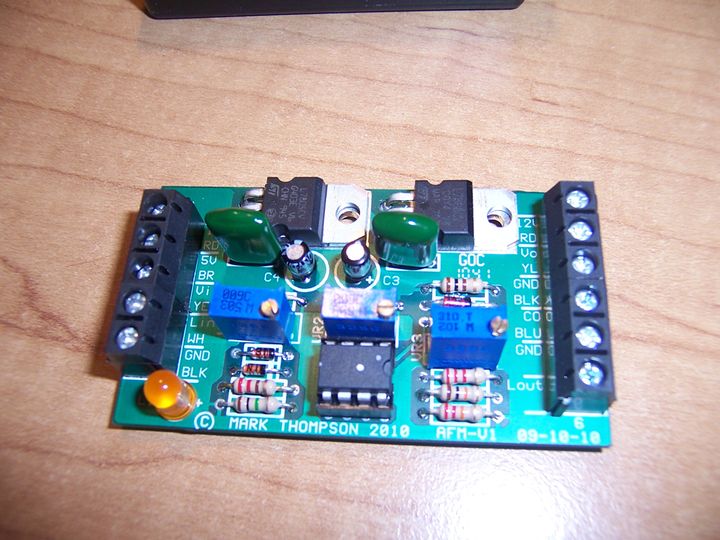

This is analogue conversion unit

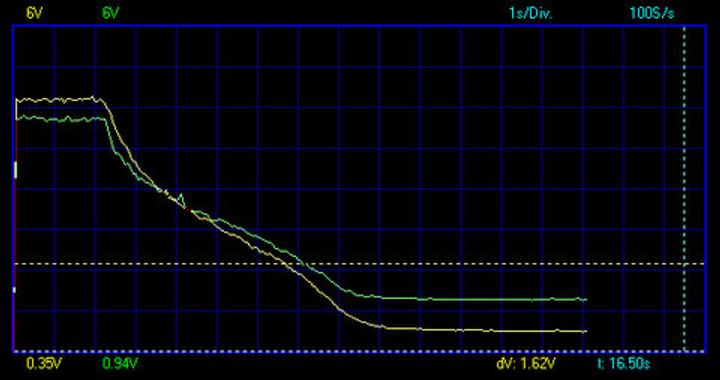

This is the two response curves for the 5AM vs the Bosch

The response curve having been analogue recalibrated.

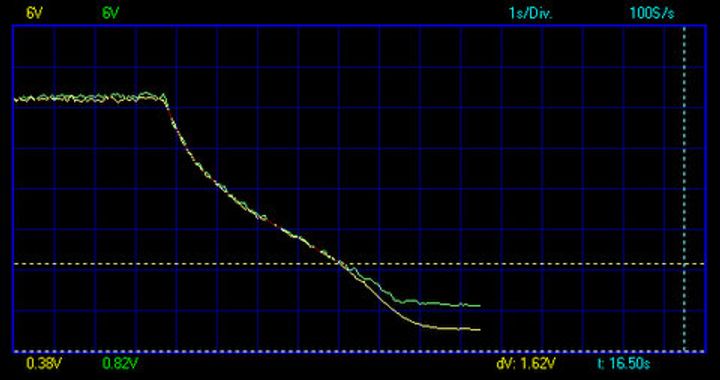

Digital recalibration output.

Calibrating airflow does present various issues as you need to outflow the AFM to reach peak saturation, and the only way I could do this was with a petrol powered leaf blower. At one point I ended up with the whole assembly blowing apart across the workshop as the back pressure had built up so much with the smaller 5AM. Makes you realise how much air a 5ltr TVR pumps under full load and RPM !

Edited by blitzracing on Tuesday 14th May 08:55

Josh (Discoveryunlimited)

Thanks for your Bosch & 5AM comparison graph, excellent work & certainly confirms everyone’s thoughts and findings.

I'm sure your little Bosch airflow converter would be very popular if its plug & play and you overcome the issues Mark experienced as it won’t require a remap. We all know 5AMs are now all very old and failing and therefore could be the death of the 14CUX. Bosch 4.6L MAFs are still available new and its replaceable hot film cartridge is also used on some BMWs so hopefully will remain available new for a long time.

Furthermore, we currently can’t properly remap a 3.5, 3.9 & 4L to use the Bosch 4.6L MAF as the AFM scalar can’t be increased enough. This means a 4L with the Bosch 4.6L MAF don't flow enough air to use the bottom few rows of the main fuel table. As a result I really hope you can get your head around the AFM linearization code and workout what the linearization parameters do at prom offsets $1C3 $1C5. Dan once said its very impressive code for a 1980s processor without a maths co-processor. I personally think Motorola wrote the linearization code to help sell their processors to the motor trade, sadly I didn't pay attention enough in my physics lessons to King's law of hot wire & 4th order linearization polynomial equations because I never thought I’d use pure maths & differential equations again.

I’ve personally got excellent results remapping my home made 4.5BV with a Bosch 4.6 MAF by increasing both the AFM scalar (prom offset $483) and the AFM offset (prom offset $1C9). The scalar effectively amplifies the whole of the AFM output curve to hit the bottom row of the fuel table on full load and increasing the offset pulls the active row back up to the top of the fuel table on overrun. Works really well & my Bosch MAF has been 100% reliable but won’t work on a 4L.

Josh, do you know what vehicle uses your EV6 injectors? I’m hoping they are available in the UK.

Good luck with your airflow converter, I don’t mind testing its reliability on my Griff.

Steve

P.S, Good to hear you're using Dan’s assembler code and a GEMS 200 step stepper motor.

Thanks for your Bosch & 5AM comparison graph, excellent work & certainly confirms everyone’s thoughts and findings.

I'm sure your little Bosch airflow converter would be very popular if its plug & play and you overcome the issues Mark experienced as it won’t require a remap. We all know 5AMs are now all very old and failing and therefore could be the death of the 14CUX. Bosch 4.6L MAFs are still available new and its replaceable hot film cartridge is also used on some BMWs so hopefully will remain available new for a long time.

Furthermore, we currently can’t properly remap a 3.5, 3.9 & 4L to use the Bosch 4.6L MAF as the AFM scalar can’t be increased enough. This means a 4L with the Bosch 4.6L MAF don't flow enough air to use the bottom few rows of the main fuel table. As a result I really hope you can get your head around the AFM linearization code and workout what the linearization parameters do at prom offsets $1C3 $1C5. Dan once said its very impressive code for a 1980s processor without a maths co-processor. I personally think Motorola wrote the linearization code to help sell their processors to the motor trade, sadly I didn't pay attention enough in my physics lessons to King's law of hot wire & 4th order linearization polynomial equations because I never thought I’d use pure maths & differential equations again.

I’ve personally got excellent results remapping my home made 4.5BV with a Bosch 4.6 MAF by increasing both the AFM scalar (prom offset $483) and the AFM offset (prom offset $1C9). The scalar effectively amplifies the whole of the AFM output curve to hit the bottom row of the fuel table on full load and increasing the offset pulls the active row back up to the top of the fuel table on overrun. Works really well & my Bosch MAF has been 100% reliable but won’t work on a 4L.

Josh, do you know what vehicle uses your EV6 injectors? I’m hoping they are available in the UK.

Good luck with your airflow converter, I don’t mind testing its reliability on my Griff.

Steve

P.S, Good to hear you're using Dan’s assembler code and a GEMS 200 step stepper motor.

Paul (TRIUMPHBULLET)

Sorry for the delayed reply, I've been busy in the garage but you're always welcome send me a message to get my attention.

Yes you're right.

The code uses the throttle pot input to detect sudden throttle increases & decreases, the throttle table is used to calculate the amount and duration of the extra burst of fuel required for about a second when suddenly flooring it.

There are 5 throttle tables in TunerPro, 12&3 for non-cat maps and 4&5 for cat maps, here's an example how the throttle table works with your R2832 map2.

To increase your sudden throttle opening fuelling you need to increase the hex values in the throttle table on the 4th row at the required temperatures, you could also increase the duration by increasing the hex values on the 5th row. The column on the left comes into play when the temperature is between the columns and unfortunately its trial and error, good luck.

I also have a copy of the UK 3.5L version if you want to try it

www.remap-14cux.uk/bins/LR_R2667_3.5_UK_Disc.bin

Which fuel map do you run, non-cats or cat and are you in Australia?

Please let us know if Sardonicus suggestion worked, advancing the ignition timing, would be good to know. If not and your running a non-cat map its worth checking your CO TRIM in RoverGauge is over 1.25volts as you could be running generally too lean below 3,400rpm. If you don’t have RoverGauge you could try increasing you’re CO TRIM by turning the AFM screw clockwise half a turn at a time.

Good luck, its all good fun & let me know if you have any further questions

Steve

Sorry for the delayed reply, I've been busy in the garage but you're always welcome send me a message to get my attention.

Yes you're right.

The code uses the throttle pot input to detect sudden throttle increases & decreases, the throttle table is used to calculate the amount and duration of the extra burst of fuel required for about a second when suddenly flooring it.

There are 5 throttle tables in TunerPro, 12&3 for non-cat maps and 4&5 for cat maps, here's an example how the throttle table works with your R2832 map2.

98°89°73°46°29°17°6°-4°–11–17 - Top row is temperature in hex but here’s Degs C.

18 21 31 5A 7C 99 B3 CC DD EA - coolant temperature (low hex is hot)

06 08 0C 10 14 1C 26 30 33 33 - Detect Throttle opening sensitivity (Accel clamp)

07 07 07 07 07 00 00 00 00 00 - Detect Throttle Closing Sensitivity (Decel clamp)

3C 3C 3C 64 96 FF FF FF FF FF – Accel Fuel Multiplier for throttle opening

50 3C 32 1E 19 1E 1E 1E 19 19 - Accel time multiplier for throttle opening

55 55 55 55 55 1E 1E 1E 1E 1E - Decel time Multiplier for throttle closing

Decel Fuel multiplier is the same at all temperatures & found in each fuel map1-5.

Dan created this table so we can convert hex temperatures to degrees C.

first Hex digit down then second Hex digit across, then see Degs C in the table

0 1 2 3 4 5 6 7 8 9 A B C D E F

0 130,129,127,126,124,123,121,120,118,117,115,114,112,111,109,108, 0

1 106,105,104,103,102,101,100, 99, 98, 97, 96, 95, 94, 93, 92, 91, 1

2 90, 89, 88, 87, 86, 85, 84, 83, 82, 81, 80, 79, 78, 77, 76, 75, 2

3 74, 73, 72, 71, 70, 70, 69, 68, 67, 66, 65, 64, 63, 63, 62, 61, 3

4 60, 59, 59, 58, 58, 57, 56, 56, 55, 55, 54, 54, 53, 52, 52, 51, 4

5 51, 50, 50, 49, 49, 48, 48, 47, 47, 46, 46, 45, 45, 44, 44, 43, 5

6 43, 42, 42, 41, 41, 40, 40, 39, 39, 38, 38, 37, 37, 36, 36, 35, 6

7 35, 35, 34, 34, 33, 33, 32, 32, 31, 31, 30, 30, 29, 29, 28, 28, 7

8 28, 28, 27, 27, 26, 26, 26, 25, 25, 24, 24, 23, 23, 23, 22, 22, 8

9 22, 21, 21, 20, 20, 19, 19, 18, 18, 17, 17, 16, 16, 15, 15, 14, 9

A 14, 14, 13, 13, 12, 12, 11, 11, 10, 10, 9, 9, 8, 8, 7, 7, A

B 7, 7, 6, 6, 6, 5, 5, 5, 4, 4, 3, 3, 3, 2, 2, 2, B

C 2, 1, 1, 0, 0, -1, -1, -2, -2, -3, -3, -4, -4, -5, -5, -6, C

D -6, -6, -7, -7, -8, -8, -8, -9, -9,-10,-10,-11,-11,-11,-12,-12, D

E -12,-13,-13,-14,-14,-15,-15,-16,-16,-17,-17,-18,-18,-19,-19,-20, E

F -20,-20,-21,-21,-22,-22,-22,-23,-23,-23,-24,-24,-24,-25,-25,-25 F

0 1 2 3 4 5 6 7 8 9 A B C D E F

To increase your sudden throttle opening fuelling you need to increase the hex values in the throttle table on the 4th row at the required temperatures, you could also increase the duration by increasing the hex values on the 5th row. The column on the left comes into play when the temperature is between the columns and unfortunately its trial and error, good luck.

I also have a copy of the UK 3.5L version if you want to try it

www.remap-14cux.uk/bins/LR_R2667_3.5_UK_Disc.bin

Which fuel map do you run, non-cats or cat and are you in Australia?

Please let us know if Sardonicus suggestion worked, advancing the ignition timing, would be good to know. If not and your running a non-cat map its worth checking your CO TRIM in RoverGauge is over 1.25volts as you could be running generally too lean below 3,400rpm. If you don’t have RoverGauge you could try increasing you’re CO TRIM by turning the AFM screw clockwise half a turn at a time.

Good luck, its all good fun & let me know if you have any further questions

Steve

blitzracing said:

I went down the route of producing a small box that interfaced either the 20 AM or Bosch AFM to mimic the exact airflow characteristics of the 5AM. I tried this with both analogue electronics to modify the wave forms and a commercial system using a digital lookup table. I made the naively made mistake of thinking that I could use the increased airflow without remapping (This was way before the days of reverse engineering the fuel maps of the 14CUX). Now I realise that without increasing the fuel in the map, no power gains can be made, and subsequent rolling road tests of my unit proved this to be true.

Hardware wise I was presented with various problems during long term testing. Using an analogue box the voltages tended not to be stable in the extreme temperature shifts of the engine bay, that would lead to mixture shifts and unstable idle. I probibibly could have over come this by putting the conversion unit inside the car but it stopped it being an easy plug and play solution. Once switched to digital conversion the extra internal electronics could not cope with the lightning storm HT system that spikes with both RF interference and corrupting the 12v supply line, especially in an unshielded glass fibre body. This constantly wiped the look up table in the NV ram.

As the new dawn of RoverGauge and Tuner pro made remapping a possibility the project sat in the back of the workshop and progressed no further as Id already wasted enough of my life on such follies.

This is analogue conversion unit

This is the two response curves for the 5AM vs the Bosch

The response curve having been analogue recalibrated.

Digital recalibration output.

Calibrating airflow does present various issues as you need to outflow the AFM to reach peak saturation, and the only way I could do this was with a petrol powered leaf blower. At one point I ended up with the whole assembly blowing apart across the workshop as the back pressure had built up so much with the smaller 5AM. Makes you realise how much air a 5ltr TVR pumps under full load and RPM !

Hi Mark,Hardware wise I was presented with various problems during long term testing. Using an analogue box the voltages tended not to be stable in the extreme temperature shifts of the engine bay, that would lead to mixture shifts and unstable idle. I probibibly could have over come this by putting the conversion unit inside the car but it stopped it being an easy plug and play solution. Once switched to digital conversion the extra internal electronics could not cope with the lightning storm HT system that spikes with both RF interference and corrupting the 12v supply line, especially in an unshielded glass fibre body. This constantly wiped the look up table in the NV ram.

As the new dawn of RoverGauge and Tuner pro made remapping a possibility the project sat in the back of the workshop and progressed no further as Id already wasted enough of my life on such follies.

This is analogue conversion unit

This is the two response curves for the 5AM vs the Bosch

The response curve having been analogue recalibrated.

Digital recalibration output.

Calibrating airflow does present various issues as you need to outflow the AFM to reach peak saturation, and the only way I could do this was with a petrol powered leaf blower. At one point I ended up with the whole assembly blowing apart across the workshop as the back pressure had built up so much with the smaller 5AM. Makes you realise how much air a 5ltr TVR pumps under full load and RPM !

Edited by blitzracing on Tuesday 14th May 08:55

I thought that I wouldn’t have been the first person to tackle the AFM. Interesting to hear your experience and it certainly highlights many of the aspects that were concerning me as I have embarked on this project.

I am very impressed with the converter that you have there and I can imagine the time you would have spent on getting it working especially calibrating an analogue device.

I have tackled the problem in a similar manner to what you did later, using off the shelf products. I have used an AVR board to take in the signal from the Bosch AFM. I then use a look up table to output the corrected signal corresponding to 5AM airflow, this is a PWM signal which feeds into a 10 bit DAC for analogue feed to the 14CUX.

I was able to make the table from the 5AM AFM data from Colin and Dan’s testing and then the data from the bosch HFM 5 AFM data sheet. I matched the mass airflow of the two which gives each corresponding voltage and from that I calculated the ADC counts which is what is in my table.

I, like you wanted to try and test this across the full range so first tried with a leaf blower. I also have a 200CFM extraction fan. When testing with both I found the blower is not suitable as the pressure buildup VS the pressure drop from sucking changes the signal, my conclusion was the sucking better matches what happens in the engine bay.

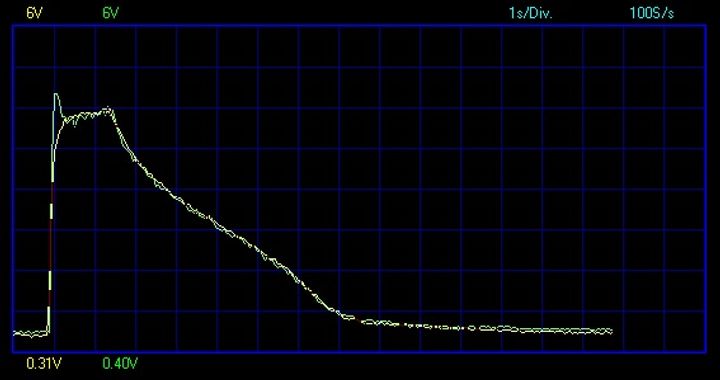

I bench tested from no flow up to the max flow for the exhaust fan and the curves were spot on to what I expected and matched the 5AM that I was comparing to. Knowing this I then used a potentiometer to simulate the Bosch AFM input from 0V to 5V and check the corresponding output of the DAC to what was expected. The plot from the potentiometer is below showing the full range. Like you said when you start trying to test you realise just how much air these engines flow and how much 500CFM actually is.

I currently have my first converter protype running in the car (along with a full remap etc. as required for my setup using the Moates ostrich). The converter is mounted away from the AFM, spark plug leads and heat in the engine bay (I’ll have to get a picture of it and update as I’m away at the moment with work). I also have it running off a dedicated 12V to 5V DC-DC converter (which also powers the AFM), essential for the correct output as both the AFM and converter need the same 5V reference.

I have driven about 10 hours total with the converter with the longest single trip being 200kms, so far I haven’t had any hiccups with it. Obviously, it needs much longer-term testing which I am doing to see what issues I encounter. The biggest upsides that I have noticed compared to my tune with the bosch AFM is more pull in the higher load region and the air idle is more open, this results in a much smoother and more controlled idle. The setup I am running is a 4.8L stroked motor with EV6 four spray injectors running a fuel rail pressure of 3.8bar using the 4.6L gems top and the 200 count stepper motor (code adjusted from the 180 steps).

Ultimately with what Dan and Colin have done with the reverse engineering of the 14CUX I am trying to adjust the linearisation aspect of the AFM in the rebuild project as this would be the most ideal solution. I’m slowly working on it but for the time being I’ll continue to test the converter and see if I encounter the issues you did. If you want to chat more feel free to contact me directly or I'll be checking back here regularly.

Gassing Station | Griffith | Top of Page | What's New | My Stuff