Lund's MG Metro 1275 Engine Build

Discussion

Cooperman said:

It looks really good Tom. What a great job you are making of it.

Maybe when it's all done we will get the chance to see it at one of the Mini shows.

Peter

I certainly hope so Pete, one last push to get it done. I don't fancy putting it in in the snow however!Maybe when it's all done we will get the chance to see it at one of the Mini shows.

Peter

Removed the masking from the cylinder head, looks well. Abit thin in places, dad has said that I shouldn't have primed it as it will react with the top coat and flake off...

Edited by Mini_Lund on Monday 2nd November 20:25

Cooperman said:

The seats look fine with a good even width of seating for each valve.

One thing you could do would be to smooth out the small steps around the edges of the valve seats, but do it very carefully to avoid damage to the seats. Then if you have a set of old valves the same size, just lay them in and clean up the surface of each chamber with a 1" dia flap wheel in an electric drill. It just helps the airflow in and out slightly.

Alternatively, run what you have then, in time, get another head casting, say an MG Metro one, and gas-flow it yourself, fit new guides and valves and put the comp ratio up a bit to, say, 10.3:1. Then you'll gain quite a bit more.

Peter

Hi Peter,One thing you could do would be to smooth out the small steps around the edges of the valve seats, but do it very carefully to avoid damage to the seats. Then if you have a set of old valves the same size, just lay them in and clean up the surface of each chamber with a 1" dia flap wheel in an electric drill. It just helps the airflow in and out slightly.

Alternatively, run what you have then, in time, get another head casting, say an MG Metro one, and gas-flow it yourself, fit new guides and valves and put the comp ratio up a bit to, say, 10.3:1. Then you'll gain quite a bit more.

Peter

The valves have cleaned up excellent and the seating seems spot on with no play or wear. I do have another 1275 head; I think the valves are of the same size as the Metro head. It has new inlet valves, double valve springs and bronzed valveguides, however it is very coked up. I might have a play around with this head. How do you suggest removing the step from the chamber? I'll see about getting the MG head re-worked before It all goes in.

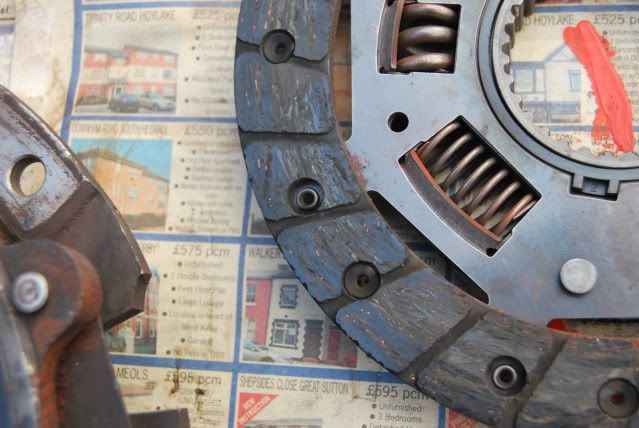

I have just disassembled the Verto clutch and flywheel, I'm after your expertise again, so don't go away just yet! How does this look to you?

Some macro images of the clutch plates;

Would it be wise to clean the whole lot in a bowl of hot soapy water, give it a scrub and dry it all out? I would then use brake cleaner to finally clean it.

Tom

FWDRacer said:

Tom - The Verto assembly is heavy - certainly no performance item. However the longevity is pretty much without question - Mine had over 118K on when the engine/box were finally pulled. Clutch still 100% even with a 30% power increase going through it.

Bare miniumum would be a new metro turbo clutch plate before you stick that little lot back together. Just wouldn't bother messing about with a 2nd hand clutchplate. You've not cut corners so far, why start here?

Bare miniumum would be a new metro turbo clutch plate before you stick that little lot back together. Just wouldn't bother messing about with a 2nd hand clutchplate. You've not cut corners so far, why start here?

Do you suggest I purchase this clutch plate;

Clutch Plate Road & Fast Road (HB8017) - GCP204AF

http://www.minispares.com/Product.aspx?ty=pb&p...

What other clutch Items would you think I require, as you stated the new clutch plate would be the bare minimum that you would change.

Edited by Mini_Lund on Wednesday 4th November 15:53

Guys, digging around the garage I found another mini clutch. I suspect its off the Metro 998 that I had as I removed it to get at the flywheel housing for spares. On closer inspection its a Valeo clutch. Does this suggest the clutch was changed at some point or is it standard. I can't tell the difference in weight between the two, but which do you suggest I use?

Fast road clutch should be with me sometime next week. I have already successfully cleaned up the ring gear & pressure plate.

Fast road clutch should be with me sometime next week. I have already successfully cleaned up the ring gear & pressure plate.

17/11/09

I began assembling the flywheel end cover today, I greased the arm and plunger & renewed the split pins. I am extremely pleased with the finish on the end cover, looks a tad dusty in the sunlight in the photo;

Yet another Minispares order revealed a new AP clutch (HB8017), genuine flywheel oil seal, dust shield & locating bracket for the verto slave.

Tom

I began assembling the flywheel end cover today, I greased the arm and plunger & renewed the split pins. I am extremely pleased with the finish on the end cover, looks a tad dusty in the sunlight in the photo;

Yet another Minispares order revealed a new AP clutch (HB8017), genuine flywheel oil seal, dust shield & locating bracket for the verto slave.

Tom

Cooperman said:

That all looks great Tom.

Don't forget to back the two large nuts, the overthrow stops, in the centre of the clutch cover right off before re-fitting, then set them accurately after installation and clutch bleeding. It helps to do this final setting before fitting the brake servo and fresh-air pipe (if fitted). The nut size is 15/16". You must use 2 spanners, one of which needs to be 'thin'. If you just use one you can easily snap the ball off the end of the clutch arm. Make sure you put no load on this ball-end when setting the stops.

Thanks for the tip Peter. I noticed that the haynes gave a standard setting of 0.26", was it wise to apply this setting or as you say, keep it all loosey lucy ready for refinement?Don't forget to back the two large nuts, the overthrow stops, in the centre of the clutch cover right off before re-fitting, then set them accurately after installation and clutch bleeding. It helps to do this final setting before fitting the brake servo and fresh-air pipe (if fitted). The nut size is 15/16". You must use 2 spanners, one of which needs to be 'thin'. If you just use one you can easily snap the ball off the end of the clutch arm. Make sure you put no load on this ball-end when setting the stops.

I can't quite get my head round how the slave locating bracket fits, but I'm sure it will become obvious as I fit the end cover. I gave the cylinder head one last clean up and assembled the top hats, springs, valves & collets, along with the rocker assembley.

The push rods were also cleaned and freshly oiled. I placed the head gasket between the block and head, having given the cylinder bores a wipe with oil ready for priming the engine. The cylinder head is now fitted, but not torqued up. I'll find the torque sequence and torque it up properly in the week.

Looking good guys!

Cheers, Tom

Hi guys, been busy again today;

Tom

- Re-painted the crankshaft pulley wheel, (as it had a notch on the 'V' which I filed back).

- Cleaned-up and sprayed the alternator brackets & bolts.

- A practise run of assembling the flywheel housing & slave locating bracket. (I understand how it all fits now.

Tom

Mini1275 said:

minipete said:

Looking great there Tom,only thing is you do know that Red engines are more powerful!lol!

Well obviously

, every mini person knows that.

, every mini person knows that.Today I have fitted the clutch oil seal, dust shield and centred the clutch as best I could. I require a centre bolt locating plate before I can complete the setup and fit the 'wok'.

I have been looking at samco hoses, as I'm sure I require all new hoses with the 1275? I assume the 850 hoses wont fit. I'm looking at £100, ouch. Blue or Black?

PS. Once you've had black

This is how she stands;

I've got quite abit going with her at the moment. Ideally I could do with a whole new front end, but I'll postpone that for now and try keep on top of it.

I stripped most of what I could from the 850 today, I'll get back out into the garage soon and continue cleaning parts! (I'm forever cleaning & respraying). The only thing that would let the 1293 down right now, is the state of the engine bay. However, this weather isn't great for spraying and I can't get my mini into the garage, due to the Mk111. I think I'll tidy up what I can and use my vermillion aerosol to spray the engine bay. See how I get on, I'm minus my mouse sander now as the bottom has completely fallen off!

I think I'm after a set of silicon hoses.

Tom

I've got quite abit going with her at the moment. Ideally I could do with a whole new front end, but I'll postpone that for now and try keep on top of it.

I stripped most of what I could from the 850 today, I'll get back out into the garage soon and continue cleaning parts! (I'm forever cleaning & respraying). The only thing that would let the 1293 down right now, is the state of the engine bay. However, this weather isn't great for spraying and I can't get my mini into the garage, due to the Mk111. I think I'll tidy up what I can and use my vermillion aerosol to spray the engine bay. See how I get on, I'm minus my mouse sander now as the bottom has completely fallen off!

I think I'm after a set of silicon hoses.

Tom

Update:

Water pump is fitted with the gasket dry. It's also now all torqued up. I have washed the yellow fan, cleaned most brackets/nuts/bolts/washers. Radiator cowling is in primer ready for a wet & dry and top coating gloss black. I sprayed my thermostat housing silver however the paint has reacted twice so I'm tempted to take it all back and start over again. Most brackets are in primer too. Water pump pulley is final coated in gloss black and it looks great.

However, there is one minor setback (There always is!)

I set about removing the stud from the head as I have decided to use the bolts. I was using the twin nut locking method and the stud snapped under the pressure. I filed the top of the remaining stud to allow me to get a nut on it, but it wont budge even with a bloody good clout with a BFH! I've left the mircale juice (Rockoil) to do its work overnight! As you can see I can't get another bolt on to remove the stud. Should'nt be too much of a problem, when dad gets the welder out to do the door, I'll just get him to weld the nut on. I will have some shallower nuts somewhere, but I'm reluctant just incase it snaps again.

I will have some shallower nuts somewhere, but I'm reluctant just incase it snaps again.

Water pump is fitted with the gasket dry. It's also now all torqued up. I have washed the yellow fan, cleaned most brackets/nuts/bolts/washers. Radiator cowling is in primer ready for a wet & dry and top coating gloss black. I sprayed my thermostat housing silver however the paint has reacted twice so I'm tempted to take it all back and start over again. Most brackets are in primer too. Water pump pulley is final coated in gloss black and it looks great.

However, there is one minor setback (There always is!)

I set about removing the stud from the head as I have decided to use the bolts. I was using the twin nut locking method and the stud snapped under the pressure. I filed the top of the remaining stud to allow me to get a nut on it, but it wont budge even with a bloody good clout with a BFH! I've left the mircale juice (Rockoil) to do its work overnight! As you can see I can't get another bolt on to remove the stud. Should'nt be too much of a problem, when dad gets the welder out to do the door, I'll just get him to weld the nut on.

I will have some shallower nuts somewhere, but I'm reluctant just incase it snaps again.

I will have some shallower nuts somewhere, but I'm reluctant just incase it snaps again.Coming together nicely now; I have fitted the fan, used two spacers as the large spacer wasn't really needed and the bolts wouldn't reach. I've been topcoating some of the brackets today.

Fan clearance:

I understand that the fan draws in when hot, but theres still a suffient gap. What do you reckon guys?

Radiator bracket;

Thermostat reacted, will need respraying;

Coil bracket;

Finished results;

Point Joints on the diff;

Drilled thermostat;

Cheers,

Tom

Fan clearance:

I understand that the fan draws in when hot, but theres still a suffient gap. What do you reckon guys?

Radiator bracket;

Thermostat reacted, will need respraying;

Coil bracket;

Finished results;

Point Joints on the diff;

Drilled thermostat;

Cheers,

Tom

Hi guys,

I now have the 1275 radiator bracket with new rubber collets, however I'm using an early thermostat housing. Do I really require a large bore, later type w/ sandwich plate or can I get away with using the early housing?

As the 1275 rad bracket doesn't have a fold to reach the lower early housing, I can use some 'hollow rod' spacers to reach the bracket. I'm also using the later type bolts, will they be too long for the shallower earlt housing?

Tom

I now have the 1275 radiator bracket with new rubber collets, however I'm using an early thermostat housing. Do I really require a large bore, later type w/ sandwich plate or can I get away with using the early housing?

As the 1275 rad bracket doesn't have a fold to reach the lower early housing, I can use some 'hollow rod' spacers to reach the bracket. I'm also using the later type bolts, will they be too long for the shallower earlt housing?

Tom

Update: The engine is now out. I managed to get that selector shaft pin out after alot of swearing & drifting!

Before; (ready to be lifted)

After;

Just waiting on a few clutch parts before I can hoist the new engine in!

Getting there;

Its still not looking quite how I want it, but I'll get that sorted soon!

Tom

Before; (ready to be lifted)

After;

Just waiting on a few clutch parts before I can hoist the new engine in!

Getting there;

Its still not looking quite how I want it, but I'll get that sorted soon!

Tom

Update: Firstly, happy new year to you all - a year has passed and it still isn't in yet!

I can't get my head round the logic of the verto setup. I have done it to the book, just in hope that it will work. Does it look right?

I spotted an MOT fail, one of the teardrops has come apart. Bugger!

On a lighter note, I'm just dressing parts of the engine bay, but I'm going to put the engine in this weekend, weather permitting. It's not pretty but does the job!

Re-sprayed my cooper freeflow manifold.

Wish me luck.

Tom

I can't get my head round the logic of the verto setup. I have done it to the book, just in hope that it will work. Does it look right?

I spotted an MOT fail, one of the teardrops has come apart. Bugger!

On a lighter note, I'm just dressing parts of the engine bay, but I'm going to put the engine in this weekend, weather permitting. It's not pretty but does the job!

Re-sprayed my cooper freeflow manifold.

Wish me luck.

Tom

dogfather said:

forgot to say, youve painted your manifold and i dont think it was wise. although it is high temp paint, the heat generated inside the manifold is extremly high and will almost certainly exceed the strength of the paint. i learnt this when i bought a complete system, it got knocked about befor it went on so i painted it. within the 1st 5minutes of starting it up it burnt the paint away to the metal and smoked like hell untill the paint was gone, dont mean to burst your bubble and hopfully it dont happen to yours but thought id let you know.

I used the same paint when i put the manifold on the 850. I used the paint on the whole system infact, the paint lasted it just had abit of surface rust on so i gave it a light sand and another coat. The 1293 shoudln't run any hottter than the 850. Thanks for the advice though.Edited by dogfather on Friday 1st January 20:40

Gassing Station | Classic Minis | Top of Page | What's New | My Stuff