R400D to R500D Anyone done it?

Discussion

I plan to use Ultimate's own 12.5/12mm cams - which I think are very similar to the R500. The CNC phase two head has +1mm oversize values. To keep costs under control, I am using the Caterham roller barrels and exhaust which are a bit small for this head so I'll be lucky to see more than 250 bhp. But really looking for some more rpm as much as anything.

sam919 said:

Andy Bell said:

real question is.. what do you expect to take off a lap at Knockhill

Whats realistic?

I got a 59.5 sec in the fury 919cc of it! haha. Sub 50 was the aim in the duratec/ slicks, but you got to keep your eyes closed going over Duffus to get close!

Take it your based in Scotland DSL? i remember chatting about hayabusa installs at one point. Is this the another chapter in the cateham book?

Ive got a nice selection of diffs if you fancy a change, concentrating on a different angle as well.....need some $$'s as its an under the radar operation

Take it your based in Scotland DSL? i remember chatting about hayabusa installs at one point. Is this the another chapter in the cateham book?

Ive got a nice selection of diffs if you fancy a change, concentrating on a different angle as well.....need some $$'s as its an under the radar operation

Yeah, Central Scotland. I've just bought a Titan diff and got R&R to fit it to a 3.92 diff. Before anyone says 3.92 and Duratec is mad, it is for the Superlap Scotland Championship at KH and I've kind of worked out that, if I can get 8500 RPM, it will minimise gear changes with the six speed box. Unfortunately a sequential is beyond my budget this year.

I dont think it is, you should be getting 130 in 6th at 8250 ish which means youll probably be spot on the rev limiter for the braking zone for the hairpin., ive been using a 5 speed Steve Perks HD type 9 with a 4.4-1 and it was perfect for Knockhill just about hitting the limiter in 5th at 8200 at the above mentioned point at around 130 ish, think it was 132 on the logger. On 235/45/13 Kumho Ecsta for rolling diameter figures. I ended up using an Elite LSD which after bedding in the plates has been very effective

Question is putting the power down and keeping the car balanced enough through the chicane, as it loads up the left hand side, its an intersting track and will be intersting to see the lap times, good luck

Question is putting the power down and keeping the car balanced enough through the chicane, as it loads up the left hand side, its an intersting track and will be intersting to see the lap times, good luck

A simple but good lap time simulation software is Optimum Lap: http://www.optimumg.com/software/optimumlap/

It can give you a hint of how much you'll gain in terms of lap time and accelleration. It is also free!

It can give you a hint of how much you'll gain in terms of lap time and accelleration. It is also free!

nicemd said:

A simple but good lap time simulation software is Optimum Lap: http://www.optimumg.com/software/optimumlap/

It can give you a hint of how much you'll gain in terms of lap time and accelleration. It is also free!

Had a look at this this morning. looks like a great bit of software to have some fun with. Unfortunately no Knockhill in the archive, so quite a bit of work to get that made. I'll give it a go one evening It can give you a hint of how much you'll gain in terms of lap time and accelleration. It is also free!

Was going well with a new national hill climb record at Prescott at the start of the year then on to Harewood National going under the record on my 2nd practice run after 5 years away feeling pretty happy with things before it all went wrong on the third practice! = End of season & still ain't got round to fixing it!

Time for a quick update . . .

Having thought about the risks involved with upgrading my existing engine, I decided there was a high possibility that I was going to end up with a non serviceable car for some time and putting myself under pressure to complete it prior to the start of the season. So, while the Duratecs are still cheap and available, I decided to buy a new engine and go for an all new build. The bonus of course is that I'll have a spare engine, should I ever need it.

So a nice shinny engine is sitting on my garage floor completely unaware of its fate.

For those that are interested here's a FB page covering the build https://www.facebook.com/Duratec.in.detail

Having thought about the risks involved with upgrading my existing engine, I decided there was a high possibility that I was going to end up with a non serviceable car for some time and putting myself under pressure to complete it prior to the start of the season. So, while the Duratecs are still cheap and available, I decided to buy a new engine and go for an all new build. The bonus of course is that I'll have a spare engine, should I ever need it.

So a nice shinny engine is sitting on my garage floor completely unaware of its fate.

For those that are interested here's a FB page covering the build https://www.facebook.com/Duratec.in.detail

Edited by DCL on Thursday 12th December 14:12

An update . . .

The pulley bolt first - this proved to be exceptionally tight. I've done a few now, but this one was the tightest I've come across. But the holding tool fabricated on my last rebuild and the 3/4'' socket with the 3 foot breaker bar wasn't going to be defeated.

I've never worked on a zero hour engine before so when I opened it up I was surprised to find it bone dry - no assembly lubricant to be seen anywhere! Even a hint of corrosion on the lifters. Those first few seconds on a new engine must be a tough time.

Another good hour this afternoon saw the strip down completed. It has clearly been built by a different operator from the head as it was swimming in oil Bores where honed to a higher finish than I expected and I am delighted with the quality of the bits that will be the basis of the new engine. More photos and details tomorrow.

Bores where honed to a higher finish than I expected and I am delighted with the quality of the bits that will be the basis of the new engine. More photos and details tomorrow.

Duratec Strip

http://www.youtube.com/watch?v=He76ogDVqDw

With the engine stripped down, I could compare the bits that need replaced. Supertech pistons and Carillo rods (right) will replace the cast Ford items (left), both are forged items and apart from being stronger and better quality, they are 100 grams lighter.

An interesting feature on the Ford rods are the sheared bearing caps. The rods are cast in one piece and then 'broken'. I guess it makes them cheaper to manufacture and provides a nice 'keyed' joint

Heat management in pistons is something that you don't necessarily think about but there are some interesting books on the subject. Here the Supertec piston uses the traditional method of oil hole position to help create a thermal break to the skirt, while Ford seem to have inlaid a different material, the oil drains being notches at the side - presumably to keep the strength of the weaker cast piston.

The ring height appears to be slightly lower on the Carillo piston - I guess to allow it to run in a worn bore. Something that had worried me and one of the reasons I went for a new engine. You live and learn!

The standard shells come in three grades (sizes) red, blue and green. They mix and match the grades to get the optimum clearance to compensate for manufacturing tolerances - this big end uses one blue and one red. All the others where fitted with blue which is the nominal size. The up-rated VP2 bearings that I will use come in just the nominal size. The increased tolerances appear to be acceptable on a rebuilt performance engine.

The grading system is not just confined to bearings shells. The pistons are also made in three grades 1, 2, & 3 to give optimum fit to the bore. All four piston on this engine seem to be grade 2. The Supertech is a 12.5:1 CR so has a proud crown and pockets for the value as both the lift and timing would otherwise cause contact. Again the replacement Supertech Pistons all come in the nominal size.

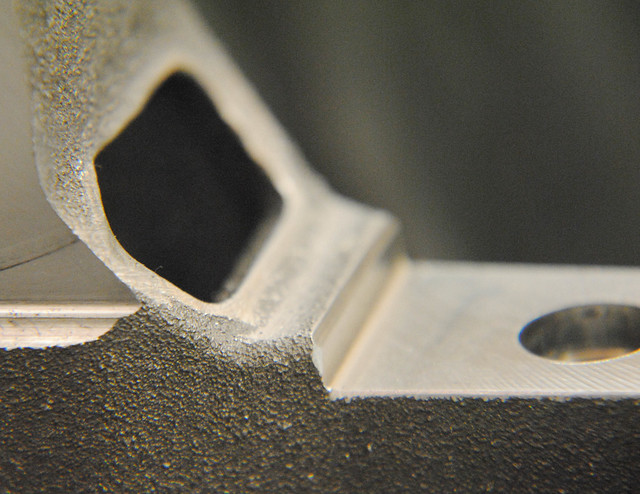

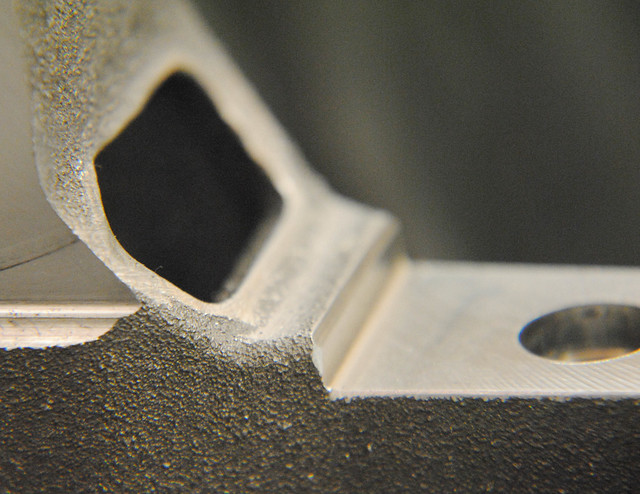

One thing I noted on the casting was a number of flakes and decided to de-burred the block casting. This photo shows the finish - clearly Ford think it is acceptable. It probably is in most cases, but bits could break away and this 'bit' would not do the oil pump much good.

I spent an hour or so de-burring the casting - and I'm glad I did. Lots of pieces were found loosely attached, the biggest bit being pictured below. Because of the number of bits coming off, I decided to extend the de-burring to all areas that I could see. The oil galleries seemed particularly bad. I remember when my R400 was new I found bits in the gauze filter and oil filter (which I cut open to check). I now know where they most likely came from. Their size probably doesn't present any risk to the engine as they are likely to be caught in the filters. But oil can bypass the filter when cold so I'd rather not find out.

The main bearings are graded in the same way as the big end shells but this time their are 13 combined sizes This is a yellow top and brown + brown bottom which represents one grade each side of the nominal size - all the shells where similar sizes. The top bearings are groved and the bottom is plain. I will reuse these bearings as they are new and VP2 upgraded bearings are not available.

The thrust bearing is the middle bearing of the five. The thrust sections are welded to the main bearing and are a snug fit to the crank case bearing web. They are not a precision bearing by any means and have a healthy clearance to the crank. I shall check the spec on assembly. The photo shows them sitting on the cradle with its opposite number - one is a brown + brown, and the other brown.

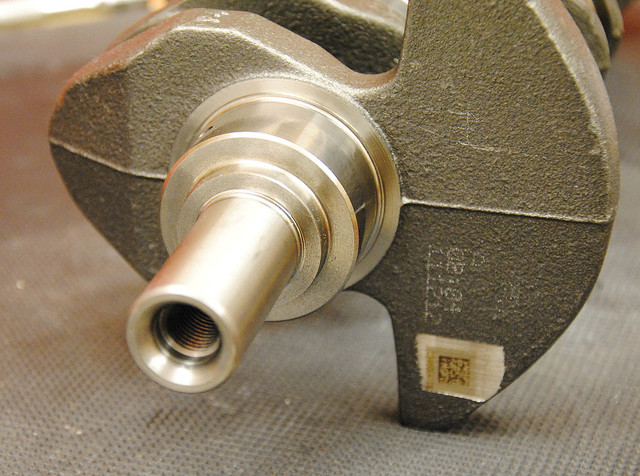

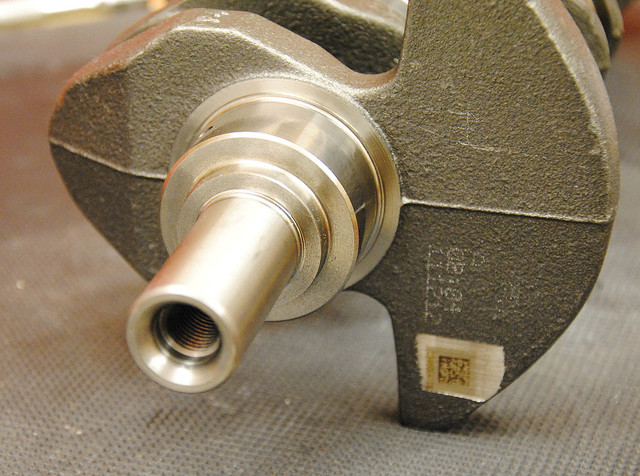

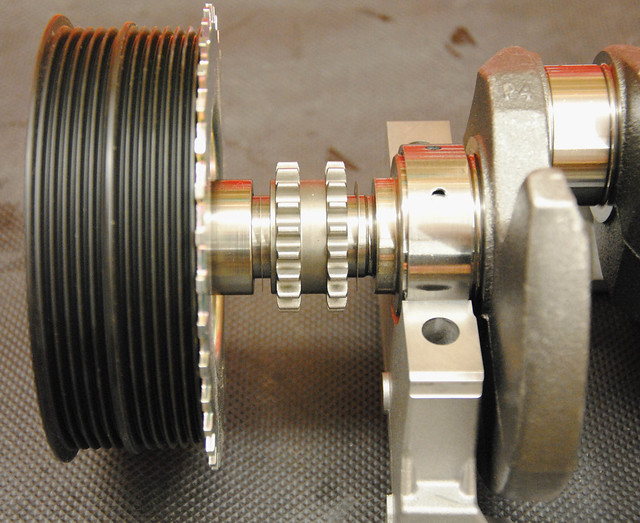

On of the first jobs will be to send off the crank to have a key cut in the crank. The standard friction washers are OK to 8000 rpm, but once above that, the risk of it slipping is real. That would undoubtedly be a dramatic and costly end to the engine.

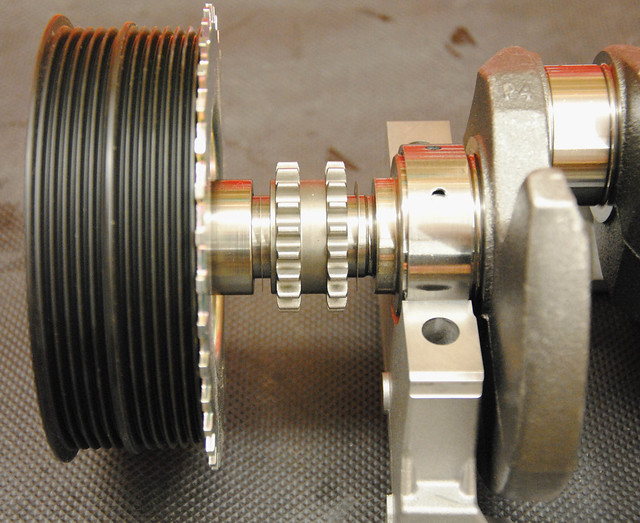

This is a slightly exploded view of the crank pulley. On the standard engine they all get clamped up with two 'friction' washers which can be seen both sides of the sprocket.

The crank shaft sprocket drives the camshafts from outer teeth, and the oil pump from the inner teeth. The chains are of different sizes.

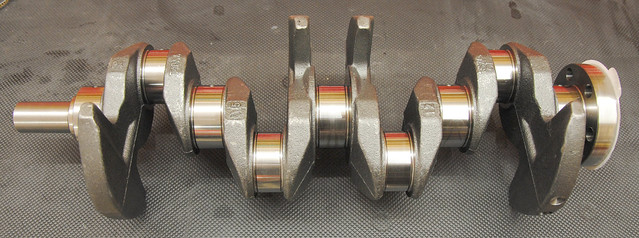

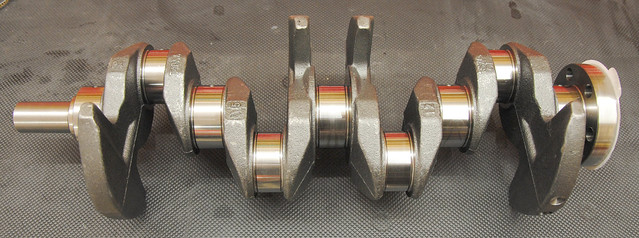

I suppose the crank is pretty ordinary and safe to 9000 rpm I’ve been told when keyed. I'm confident a that a steel crank would not add anything, and would not be worth the money.

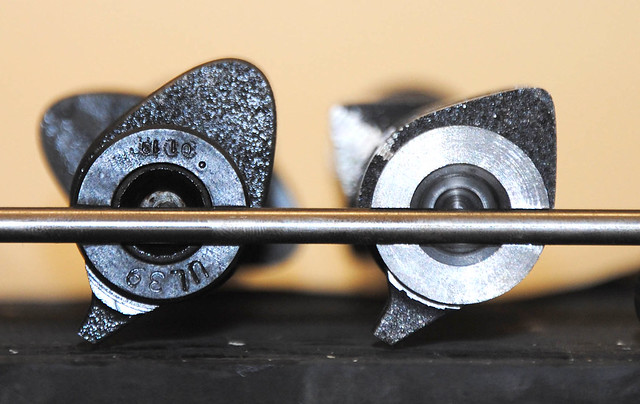

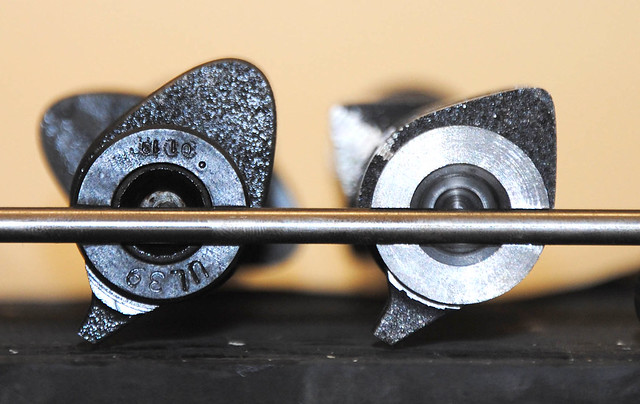

Comparing the camshafts: on the right is the standard (145BHP) camshaft and on the left is the UL39 (the bar through the center is just to align the two). The standard is just clamped to its sprocket with a bolt, although a friction washer can be added to 'upgrade' this arrangement. The UL39 is located with a pin (not shown) and has a vernier type sprocket to allow for adjustment.

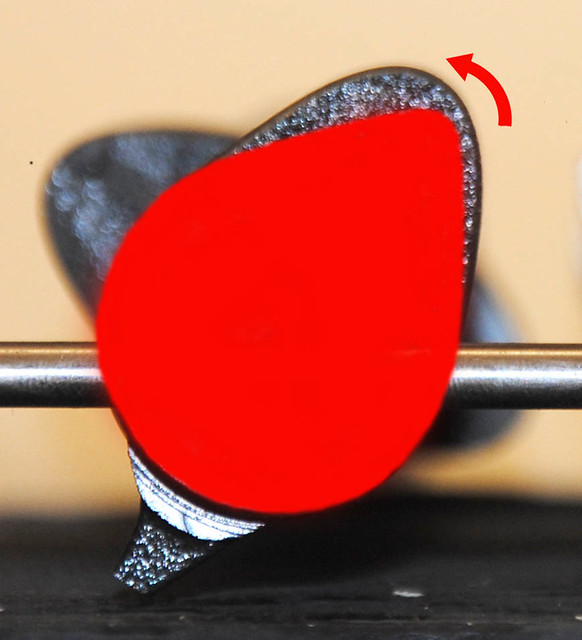

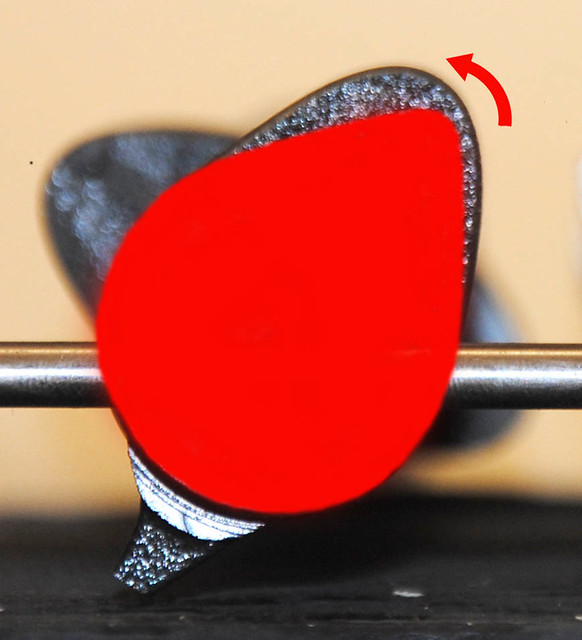

Superimposing the standard inlet cam over the UL39 inlet shows the different profile. The UL39 has a 12.5 mm lift (9 mm std) and is clearly opening earlier and longer.

The pulley bolt first - this proved to be exceptionally tight. I've done a few now, but this one was the tightest I've come across. But the holding tool fabricated on my last rebuild and the 3/4'' socket with the 3 foot breaker bar wasn't going to be defeated.

I've never worked on a zero hour engine before so when I opened it up I was surprised to find it bone dry - no assembly lubricant to be seen anywhere! Even a hint of corrosion on the lifters. Those first few seconds on a new engine must be a tough time.

Another good hour this afternoon saw the strip down completed. It has clearly been built by a different operator from the head as it was swimming in oil

Bores where honed to a higher finish than I expected and I am delighted with the quality of the bits that will be the basis of the new engine. More photos and details tomorrow.

Bores where honed to a higher finish than I expected and I am delighted with the quality of the bits that will be the basis of the new engine. More photos and details tomorrow.Duratec Strip

http://www.youtube.com/watch?v=He76ogDVqDw

With the engine stripped down, I could compare the bits that need replaced. Supertech pistons and Carillo rods (right) will replace the cast Ford items (left), both are forged items and apart from being stronger and better quality, they are 100 grams lighter.

An interesting feature on the Ford rods are the sheared bearing caps. The rods are cast in one piece and then 'broken'. I guess it makes them cheaper to manufacture and provides a nice 'keyed' joint

Heat management in pistons is something that you don't necessarily think about but there are some interesting books on the subject. Here the Supertec piston uses the traditional method of oil hole position to help create a thermal break to the skirt, while Ford seem to have inlaid a different material, the oil drains being notches at the side - presumably to keep the strength of the weaker cast piston.

The ring height appears to be slightly lower on the Carillo piston - I guess to allow it to run in a worn bore. Something that had worried me and one of the reasons I went for a new engine. You live and learn!

The standard shells come in three grades (sizes) red, blue and green. They mix and match the grades to get the optimum clearance to compensate for manufacturing tolerances - this big end uses one blue and one red. All the others where fitted with blue which is the nominal size. The up-rated VP2 bearings that I will use come in just the nominal size. The increased tolerances appear to be acceptable on a rebuilt performance engine.

The grading system is not just confined to bearings shells. The pistons are also made in three grades 1, 2, & 3 to give optimum fit to the bore. All four piston on this engine seem to be grade 2. The Supertech is a 12.5:1 CR so has a proud crown and pockets for the value as both the lift and timing would otherwise cause contact. Again the replacement Supertech Pistons all come in the nominal size.

One thing I noted on the casting was a number of flakes and decided to de-burred the block casting. This photo shows the finish - clearly Ford think it is acceptable. It probably is in most cases, but bits could break away and this 'bit' would not do the oil pump much good.

I spent an hour or so de-burring the casting - and I'm glad I did. Lots of pieces were found loosely attached, the biggest bit being pictured below. Because of the number of bits coming off, I decided to extend the de-burring to all areas that I could see. The oil galleries seemed particularly bad. I remember when my R400 was new I found bits in the gauze filter and oil filter (which I cut open to check). I now know where they most likely came from. Their size probably doesn't present any risk to the engine as they are likely to be caught in the filters. But oil can bypass the filter when cold so I'd rather not find out.

The main bearings are graded in the same way as the big end shells but this time their are 13 combined sizes This is a yellow top and brown + brown bottom which represents one grade each side of the nominal size - all the shells where similar sizes. The top bearings are groved and the bottom is plain. I will reuse these bearings as they are new and VP2 upgraded bearings are not available.

The thrust bearing is the middle bearing of the five. The thrust sections are welded to the main bearing and are a snug fit to the crank case bearing web. They are not a precision bearing by any means and have a healthy clearance to the crank. I shall check the spec on assembly. The photo shows them sitting on the cradle with its opposite number - one is a brown + brown, and the other brown.

On of the first jobs will be to send off the crank to have a key cut in the crank. The standard friction washers are OK to 8000 rpm, but once above that, the risk of it slipping is real. That would undoubtedly be a dramatic and costly end to the engine.

This is a slightly exploded view of the crank pulley. On the standard engine they all get clamped up with two 'friction' washers which can be seen both sides of the sprocket.

The crank shaft sprocket drives the camshafts from outer teeth, and the oil pump from the inner teeth. The chains are of different sizes.

I suppose the crank is pretty ordinary and safe to 9000 rpm I’ve been told when keyed. I'm confident a that a steel crank would not add anything, and would not be worth the money.

Comparing the camshafts: on the right is the standard (145BHP) camshaft and on the left is the UL39 (the bar through the center is just to align the two). The standard is just clamped to its sprocket with a bolt, although a friction washer can be added to 'upgrade' this arrangement. The UL39 is located with a pin (not shown) and has a vernier type sprocket to allow for adjustment.

Superimposing the standard inlet cam over the UL39 inlet shows the different profile. The UL39 has a 12.5 mm lift (9 mm std) and is clearly opening earlier and longer.

Edited by DCL on Friday 20th December 19:48

Gassing Station | Caterham | Top of Page | What's New | My Stuff