R400D to R500D Anyone done it?

Discussion

Just a little feedback on the BTB exhaust. I decided to have a look inside before the new season . . .

It has done some serious events but no indication of any distress.

I'm sure the packing would have gone on for many seasons with only slight discoulration at the silencing end. The cat looks like new but has must have been getting hot as the E-glass packing around it was beginning to break down. I've ordered some new packing as the the old stuff is really too fragile to slide back in. A quality item - one of the nicest things on the car

It has done some serious events but no indication of any distress.

I'm sure the packing would have gone on for many seasons with only slight discoulration at the silencing end. The cat looks like new but has must have been getting hot as the E-glass packing around it was beginning to break down. I've ordered some new packing as the the old stuff is really too fragile to slide back in. A quality item - one of the nicest things on the car

Edited by DCL on Wednesday 21st January 21:59

Just an update on this thread

The engine had been extremely reliable last year, so this year I was tempted to play around with thinner oil grades to see if any power was on offer. Certainly there was more power, but one event saw oil temperatures getting rather elevated. I got the feeling that perhaps I’d pushed my luck too far.

The oil filter check confirmed a higher particle count than normal, but returning to a thicker oil for the final event of the year seemed to settle it down. But I knew a rebuild was needed, if nothing else, to give me peace of mind.

To give some perspective to what follows, the engine has completed 13 sprint events, and a similar number of trackdays, 6 rolling road sessions, 120 hours on the ECU, and about 1000 miles on the speedo. Reving to 8600, and producing up to 270 BHP

First impressions, when opening the cam cover, was that it all looked rather nice. The spark plugs were text book (if anything getting a bit hot) and the only thing that caught my eye was two small scores on one cam lobe.

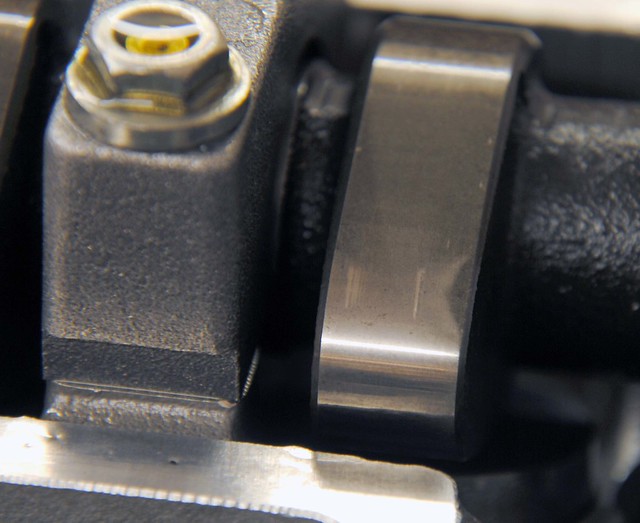

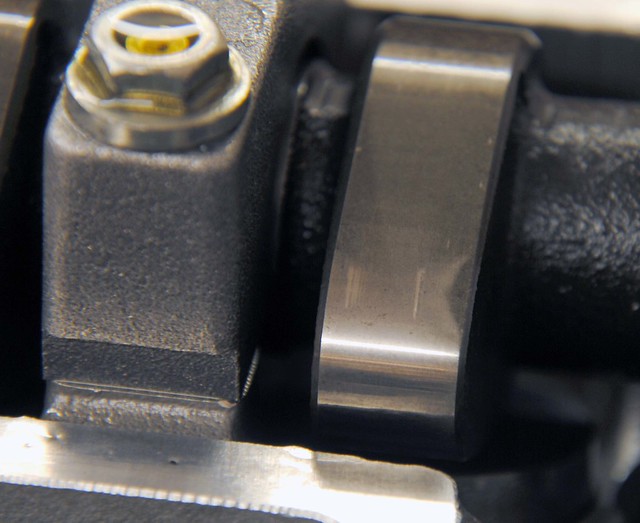

In hindsight, the two little scores where a clue to a more serious problem. And yes, the bearing next to that lobe was in trouble.

There was noticeable wear on the cam bearing and the cap looked a bit distressed too. Luckily the unloaded side (the head itself) seemed not to have suffered to the same degree.

Now the cause of this is difficult to say for sure. The cam had two little hammer marks on the bearing surface which were within the oil groove most likely caused by it ingesting something via the oil.

But the bearing cap also looked porous, so maybe a problem there. Anyone’s guess to be honest.

One issue that played on my mind was the length of time this engine had been at idle. It has spent most of its time idling away, warming up, and waiting for sprint starts, so maybe low oil pressure played a part too - or at least assisted the failure.

I say failure, but it hadn’t failed really - the measured clearance was still within an acceptable limit, but it was not what you want on your race engine. The jury is out on the fix, but I will give it some thought, and probably look at the rest of the engine first.

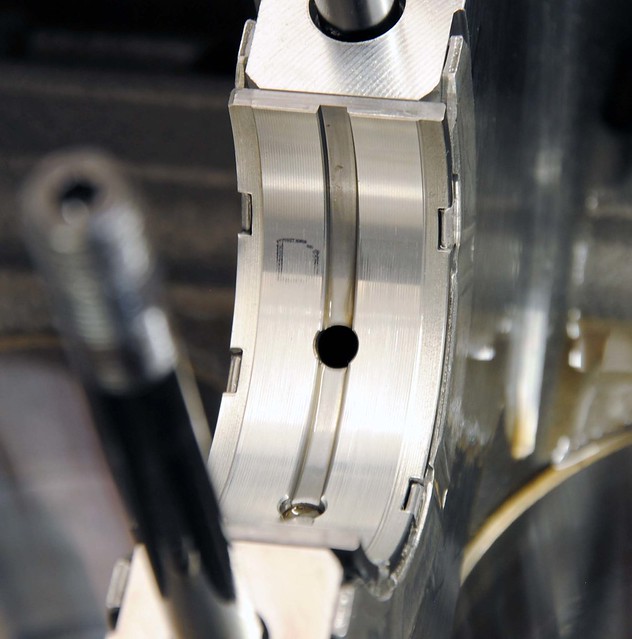

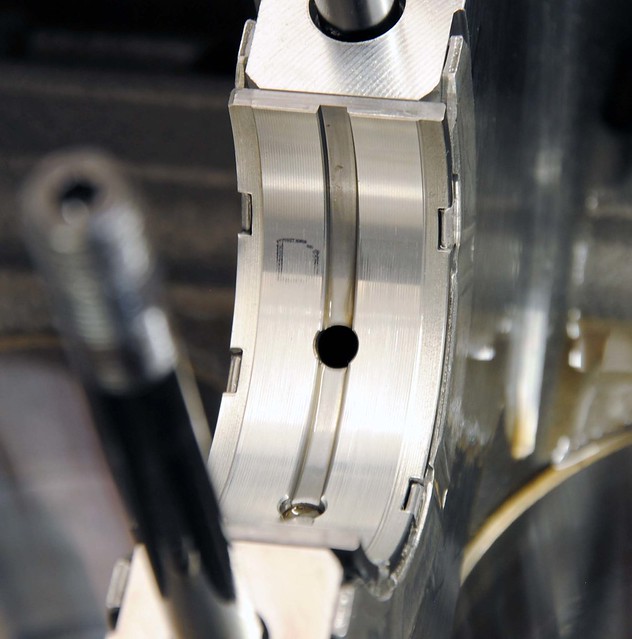

Moving on to the bottom end, things looked much as expected at first. Big end 1,2, & 3 where all running normally. But number 4 had clearly picked up something and was showing signs of distress and failure was not too far away.

Particles were causing little dents and disturbing the wear pattern. Speaking to various suppliers, it seems the VP2 tri metal bearings are designed to behave like this - absorbing any foreign matter (out of harm’s way) and buying you some extra time.

Having looked at many Duratec big end bearings now, I would recommend regular replacements if you are using high RPM on a frequent basis.

The mains looked like a totally different engine: the printing still present and not signs of wear whatsoever. That was a big relief as they are the one item that is difficult to replace due to the numerous grades.

All the journals should be serviceable after a polish, certainly not at a regrind stage yet.

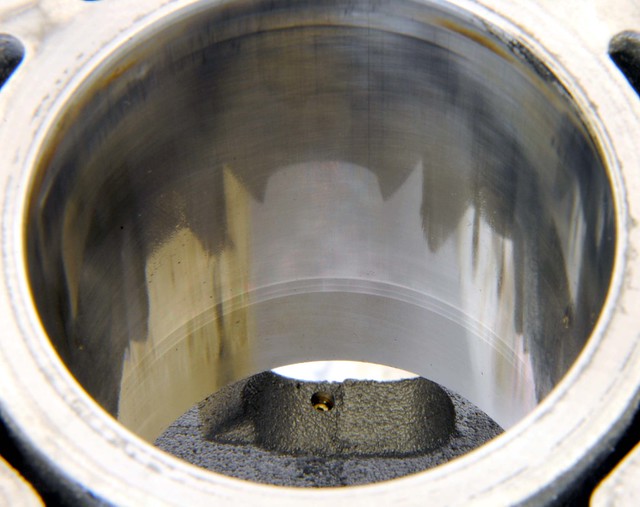

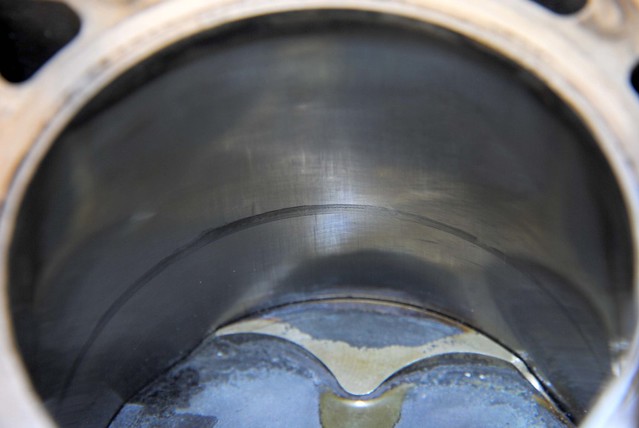

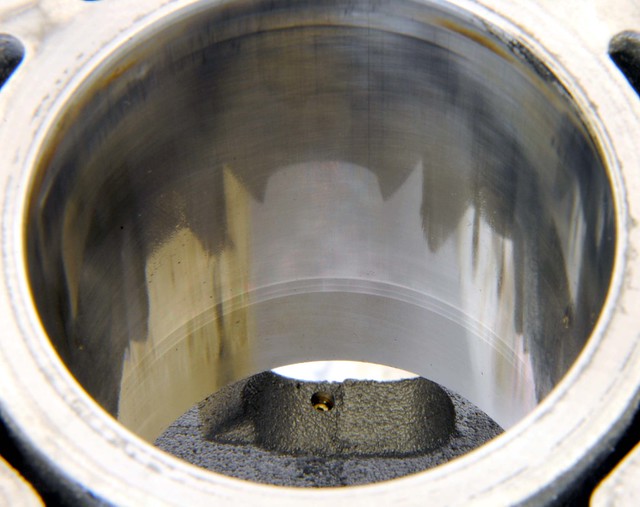

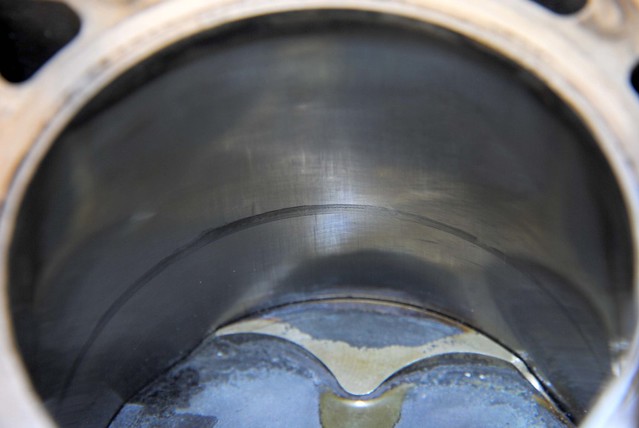

I was curious about the cylinder bores as this was the first engine I've run-in solely on the dyno. The initial results were outstanding on leak-down and BHP. But the second season did seem to take its toll and the last check suggested it had lost a little.

Clearly the bores have done some work, but I can't detect any measurable wear and all the ring gaps are the same as recorded in the build. There's no hint of any bore wash, and the honing marks are still visible, even through the heaviest of wear (more on that later). I'll give some thought as to whether to just lightly de-glaze the bores and rings, or do a full hone and replace the rings.

One unexpected surprise in cylinder 3 bore was a corrosion ring. The car is stored in the dry, and run on a regular basis so I was initially puzzled by it.

But thinking back, there was one occasion that I put the car to bed with a wet filter (it's a foam one). I guess the cylinder with the inlet valve open must have drawn in moist air as the engine cooled. It looks worse than it is, so hopefully it will come out with the de-glaze, or light hone.

But be warned if you have a foam filter - remove it from the air-box if it is wet!

There's not an awful lot to say about the Supertech pistons and Cosworth rods. They all came out with hardly a mark on them, just a hint of slap on the top edge.

But it's clear combustion temperatures were high as they were self cleaning around the exhaust valves. There's no alternative to forged pistons at this level of tune.

Duratecs don't have a reputation for cylinder head gasket problems, so I fitted the standard gasket on this engine. However, on close inspection, there's some evidence of movement and wear.

I think it would be fair to say that the standard gasket will do the job, but it probably has a limited lifespan at these sort of power levels.

Those with a good memory may recall the burr embedded in a cam bearing. When it was removed, it left a sizeable hole. Well, there seems to have been some healing going on, and it looks better now.

This is something I've noticed on aluminium bearings before - they seem to improve with age. The Bearing material seems able to move around to fill the imperfections.

The dismantling of the head concluded the strip-down. I'm pleased to say there were no problems with the valves or followers - nothing more than a light lapping of the valve seats and a clean and polish will be needed.

So what's the conclusion?

I Think I should have done it a year earlier! There's no doubt that once you go to 260+ BHP, the life reduces. At a guess, this engine is wearing out about 10 times faster than a road car engine. Possibly I encouraged the bearing issue with the thinner oil. This does release more power, but ALL your bearings do need to be in perfect condition. Probably something only for the race teams with big budgets, and plenty of spare engines.

The Duratec can be reliable at this state of tune, if not immune, from problems. But I would strongly recommend a seasonal rebuild/check/refresh if you are racing.

The engine had been extremely reliable last year, so this year I was tempted to play around with thinner oil grades to see if any power was on offer. Certainly there was more power, but one event saw oil temperatures getting rather elevated. I got the feeling that perhaps I’d pushed my luck too far.

The oil filter check confirmed a higher particle count than normal, but returning to a thicker oil for the final event of the year seemed to settle it down. But I knew a rebuild was needed, if nothing else, to give me peace of mind.

To give some perspective to what follows, the engine has completed 13 sprint events, and a similar number of trackdays, 6 rolling road sessions, 120 hours on the ECU, and about 1000 miles on the speedo. Reving to 8600, and producing up to 270 BHP

First impressions, when opening the cam cover, was that it all looked rather nice. The spark plugs were text book (if anything getting a bit hot) and the only thing that caught my eye was two small scores on one cam lobe.

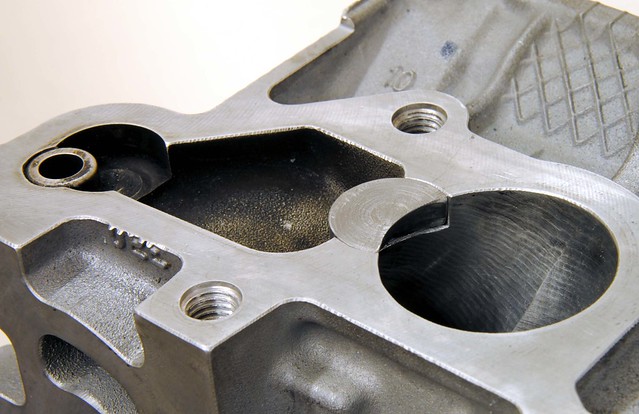

In hindsight, the two little scores where a clue to a more serious problem. And yes, the bearing next to that lobe was in trouble.

There was noticeable wear on the cam bearing and the cap looked a bit distressed too. Luckily the unloaded side (the head itself) seemed not to have suffered to the same degree.

Now the cause of this is difficult to say for sure. The cam had two little hammer marks on the bearing surface which were within the oil groove most likely caused by it ingesting something via the oil.

But the bearing cap also looked porous, so maybe a problem there. Anyone’s guess to be honest.

One issue that played on my mind was the length of time this engine had been at idle. It has spent most of its time idling away, warming up, and waiting for sprint starts, so maybe low oil pressure played a part too - or at least assisted the failure.

I say failure, but it hadn’t failed really - the measured clearance was still within an acceptable limit, but it was not what you want on your race engine. The jury is out on the fix, but I will give it some thought, and probably look at the rest of the engine first.

Moving on to the bottom end, things looked much as expected at first. Big end 1,2, & 3 where all running normally. But number 4 had clearly picked up something and was showing signs of distress and failure was not too far away.

Particles were causing little dents and disturbing the wear pattern. Speaking to various suppliers, it seems the VP2 tri metal bearings are designed to behave like this - absorbing any foreign matter (out of harm’s way) and buying you some extra time.

Having looked at many Duratec big end bearings now, I would recommend regular replacements if you are using high RPM on a frequent basis.

The mains looked like a totally different engine: the printing still present and not signs of wear whatsoever. That was a big relief as they are the one item that is difficult to replace due to the numerous grades.

All the journals should be serviceable after a polish, certainly not at a regrind stage yet.

I was curious about the cylinder bores as this was the first engine I've run-in solely on the dyno. The initial results were outstanding on leak-down and BHP. But the second season did seem to take its toll and the last check suggested it had lost a little.

Clearly the bores have done some work, but I can't detect any measurable wear and all the ring gaps are the same as recorded in the build. There's no hint of any bore wash, and the honing marks are still visible, even through the heaviest of wear (more on that later). I'll give some thought as to whether to just lightly de-glaze the bores and rings, or do a full hone and replace the rings.

One unexpected surprise in cylinder 3 bore was a corrosion ring. The car is stored in the dry, and run on a regular basis so I was initially puzzled by it.

But thinking back, there was one occasion that I put the car to bed with a wet filter (it's a foam one). I guess the cylinder with the inlet valve open must have drawn in moist air as the engine cooled. It looks worse than it is, so hopefully it will come out with the de-glaze, or light hone.

But be warned if you have a foam filter - remove it from the air-box if it is wet!

There's not an awful lot to say about the Supertech pistons and Cosworth rods. They all came out with hardly a mark on them, just a hint of slap on the top edge.

But it's clear combustion temperatures were high as they were self cleaning around the exhaust valves. There's no alternative to forged pistons at this level of tune.

Duratecs don't have a reputation for cylinder head gasket problems, so I fitted the standard gasket on this engine. However, on close inspection, there's some evidence of movement and wear.

I think it would be fair to say that the standard gasket will do the job, but it probably has a limited lifespan at these sort of power levels.

Those with a good memory may recall the burr embedded in a cam bearing. When it was removed, it left a sizeable hole. Well, there seems to have been some healing going on, and it looks better now.

This is something I've noticed on aluminium bearings before - they seem to improve with age. The Bearing material seems able to move around to fill the imperfections.

The dismantling of the head concluded the strip-down. I'm pleased to say there were no problems with the valves or followers - nothing more than a light lapping of the valve seats and a clean and polish will be needed.

So what's the conclusion?

I Think I should have done it a year earlier! There's no doubt that once you go to 260+ BHP, the life reduces. At a guess, this engine is wearing out about 10 times faster than a road car engine. Possibly I encouraged the bearing issue with the thinner oil. This does release more power, but ALL your bearings do need to be in perfect condition. Probably something only for the race teams with big budgets, and plenty of spare engines.

The Duratec can be reliable at this state of tune, if not immune, from problems. But I would strongly recommend a seasonal rebuild/check/refresh if you are racing.

Edited by DCL on Saturday 28th November 17:56

BertBert said:

Interesting to compare with a radical hyabusa that is 1500, 260bhp and is refreshed every 40 hours. The 40 hours is all running so a mix of on-load and idling or off-throttle. As a guess out of 40 probably 25-28 is on-load.

How did your 120 hours break down? For 1000 miles is that 15-20 hours on load? Not sure that computes!

Bert

At first those figures got me confused too, but when looking at the ECU histogram for RPM, only about 20% was above 4000 RPM (driving RPM) and by far the biggest amount was at idle. So you're right - about 25 hours at high RPM and on load. You could say that if you are more than 130 BHP per litre, then 20 hours track time (racing) is really all you are going to get between re-biulds (if you want to keep it in good condition). Fifty hours would probably guarantee a failure of some sort.How did your 120 hours break down? For 1000 miles is that 15-20 hours on load? Not sure that computes!

Bert

Edited by DCL on Monday 30th November 14:26

GreigM said:

So what do you reckon is causing the issues - is the the basic power output being asked of the enine, or is it the high-revving nature (i.e. will I fare better with a lower revving FI engine?)

It's the high RPM that does the harm. The oil feed to the big ends becomes problematic at high RPM. It has to pass through the main bearings and the center of the crank. The Duratec has some clever drilling of the crank, but this still results in the bearings suffering minor starvation and they get damaged over time. Eventually it will reach a point that the bearing will fail. Usually by getting very hot and melting the bearing material, followed rapidly by big end bolts, or rod. End of engine. The trick is to believe that a seemingly healthy engine will fail if use at high (above 8000) RPM for sustained periods.A supercharged 7800 RPM limited 310 BHP engine is really not stressed in the same way.

Edited by DCL on Monday 30th November 20:08

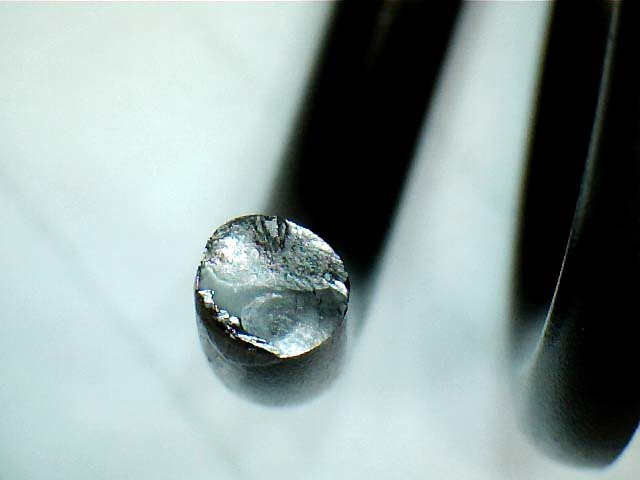

Going back to number 4 big end. I had assumed that it had picked up something from the oil, but a close examination of the crank showed that it was a knock on the edge of the oil way that seemed to be causing the damage. Although small it did protrude more than the photo suggests. That raised the question about whether this was something I had done, SBD when the machined it, a hard particle in the oil jamming while it was running, or simply a result of coming out of the factory like that. It was a new crate engine before I upgraded it, and I still had the original shells, and sure enough, number four has a scratch.

But it cleaned off and all the jounals polished up quite nicely so I'm confident it is a problem resolved. But it just goes to show that you can never take anything for granted. It probably happen very early and survived 2 seasons like that but it shows even new factory engines can have faults. In fact, rebuilding a good second hand engine is probably a better bet in terms of reliability.

But it cleaned off and all the jounals polished up quite nicely so I'm confident it is a problem resolved. But it just goes to show that you can never take anything for granted. It probably happen very early and survived 2 seasons like that but it shows even new factory engines can have faults. In fact, rebuilding a good second hand engine is probably a better bet in terms of reliability.

That's a tricky question! There's too many factors to answer simply but here goes (IMHO) . . .

Taking the standard engine first; it's designed to run on a 5w30. For a 2L engine that was quite ambitious, and was one of the factors that make the Duratec a it highly efficient engine. To achieve it, the factory engine uses graded bearings to keep tolerances within a very tight spec.

But when you tune the Duratec it is difficult, to maintain such tight tolerances with up-rated aftermarket bearings. In fact, it often desirable to increase clearance as the engine will tend flex and expand more as the level of tune increases.

So it tends leaks more oil from the bearings and it's normal to use a 5w50 oil once you raise RPM and power significantly. For racing a 10w50, or even a 10w60, is need to give a similar level of protection as a standard engine using 5w30. However, you can gain some power by using thinner oil and accepting a shorter engine life.

This year I used a 5w40, which is fine for sprint events, but maybe not for longer track sessions. it certainly added to the cost of this refresh and was probably not worth it - unless your budget is not a problem of course.

Taking the standard engine first; it's designed to run on a 5w30. For a 2L engine that was quite ambitious, and was one of the factors that make the Duratec a it highly efficient engine. To achieve it, the factory engine uses graded bearings to keep tolerances within a very tight spec.

But when you tune the Duratec it is difficult, to maintain such tight tolerances with up-rated aftermarket bearings. In fact, it often desirable to increase clearance as the engine will tend flex and expand more as the level of tune increases.

So it tends leaks more oil from the bearings and it's normal to use a 5w50 oil once you raise RPM and power significantly. For racing a 10w50, or even a 10w60, is need to give a similar level of protection as a standard engine using 5w30. However, you can gain some power by using thinner oil and accepting a shorter engine life.

This year I used a 5w40, which is fine for sprint events, but maybe not for longer track sessions. it certainly added to the cost of this refresh and was probably not worth it - unless your budget is not a problem of course.

k20erham said:

Hi not that you need the tip, but just look at all that lint/fibers on the crank casting from your clothes/rags, it's a bugger to get off, lovely analysis and reporting, look forward enjoying the next chapters, glad you managed to avoid any damage.

Don't worry  - still to go through the dishwasher when the wife's out.

- still to go through the dishwasher when the wife's out.

Edited by DCL on Tuesday 8th December 09:16

It always had good oil pressure, 60+ psi and 25-30 psi on idle. With the thinner oil, it didn't drop noticeably, but what I did notice was reduced endurance. With the thicker oil, t&p's seemed to plateau, but with the 5w40 the oil temp wanted to keep edging up until you needed and take action with a cool down lap. Had I been racing, and not sprinting, I suspect that would have been a bigger issue.

Edited by DCL on Tuesday 8th December 10:10

BertBert said:

So that's interesting, why is that?

Not because the engine produced more heat from the combustion process surely? Not because of poorer cooling? I can only think that the oil is not doing its job properly in the mains and big ends. Causing friction and thus more heat and oil temp? Sounds like very close to failure if that's right.

Bert

I'm not sure, but one theory, as you say, is that the oil film thickness was getting thinner and stresses on the oil were greater. But it could also be that the thinner oil is circulating faster and removing more heat to the point that the cooler was no longer adequate. Either way, I think when oil temps don't stabalise, your probably at the limits of the bearings and oil. Not because the engine produced more heat from the combustion process surely? Not because of poorer cooling? I can only think that the oil is not doing its job properly in the mains and big ends. Causing friction and thus more heat and oil temp? Sounds like very close to failure if that's right.

Bert

One for the oil professionals to answer really.

Interesting! That suggests that the engine may have been entering a 'mixed lubrication regime'. Certainly the cam journal fits that theory. But The dyno showed more power (less friction?) so it couldn't be too far into that regime. But it possibly did get to an unstable stage at some point.

There's no doubt other factors too, but it has been an interesting exercise to test these things in a relatively controlled way. The lesson learnt is that 5w40 is marginal on a 270 BHP Duratec.

There's no doubt other factors too, but it has been an interesting exercise to test these things in a relatively controlled way. The lesson learnt is that 5w40 is marginal on a 270 BHP Duratec.

Edited by DCL on Tuesday 8th December 19:31

Time for an update

The engine went back together without any unexpected problems. The only thing to report was that I replaced the inlet cam, rings, and re-honed the bores. I spent quite a while waiting for a specialist honing brush to plateau finish them, but that was really a waste of time as the finish was not any better than the stone.

I also made a little profiled blanking plug for the exhaust

So, with the engine finished, it was back to the paddle shift. I'll pick up on its own thread.

The engine went back together without any unexpected problems. The only thing to report was that I replaced the inlet cam, rings, and re-honed the bores. I spent quite a while waiting for a specialist honing brush to plateau finish them, but that was really a waste of time as the finish was not any better than the stone.

I also made a little profiled blanking plug for the exhaust

So, with the engine finished, it was back to the paddle shift. I'll pick up on its own thread.

Time for an update

Three years ago, at the start of this thread, there was some discussion about lap times at Knockhill and what improvements the up grade was likely to make. I was hoping for 56 second, maybe 55 second laps, but this project grew arms and legs and the car has evolved to something a little more special than I was expecting. The finishing touch was a set of Penske shocks from Meteor Motorsport.

Here's Rory Butcher driving the car on Friday . . .

https://youtu.be/vut8eOH9oPk

Three years ago, at the start of this thread, there was some discussion about lap times at Knockhill and what improvements the up grade was likely to make. I was hoping for 56 second, maybe 55 second laps, but this project grew arms and legs and the car has evolved to something a little more special than I was expecting. The finishing touch was a set of Penske shocks from Meteor Motorsport.

Here's Rory Butcher driving the car on Friday . . .

https://youtu.be/vut8eOH9oPk

This year I really felt this project had peaked. Not because there wasn’t more performance available from the 2L Duratec, but because I had become aware how stressed a 2L 8500+ rpm engine is. Three seasons was asking a lot - it was time to retire the engine to the spares corner in the garage.

Knowing that I was probably climbing out the reliability bathtub, I had commissioned a new head with the intention of building a new zero hour engine for 2017, and that arrived a couple of days before the SLS championship final. Perhaps that was tempting fate, but the engine must have known its time was up . . . and it didn't want to go quietly.

Picture courtesy of Richard Breakell

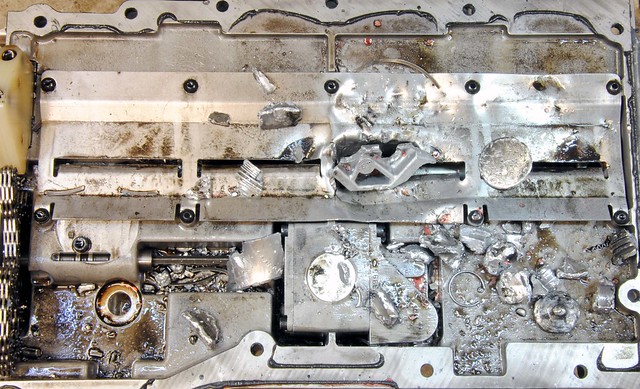

During the first hot lap in qualifying, I noticed a misfire going up Duffus (reverse direction). In hindsight, I should have abandoned the session at that point, but, with oil pressure and temps normal, I was keen to get a lap time. The misfire cleared for a while, but returned on the back straight and developed into a mechanical rattle as I approached the chicane. The throttle then would not close and the revving engine spectacularly ground itself to bits in a big cloud of smoke. I finally shut it down as I coasted to halt. I knew it was bad, but I was more upset about not finishing the event - my first time ever in the SLS.

https://www.youtube.com/watch?v=QTdeBj7h400

There was a fist size hole in the crank, but I sensed this was not a big end failure. The engine was rotating so freely, and with oil pressure normal throughout, it had to be a dropped valve, and that probably meant a valve spring failure.

Once home, this was was quickly confirmed . . .

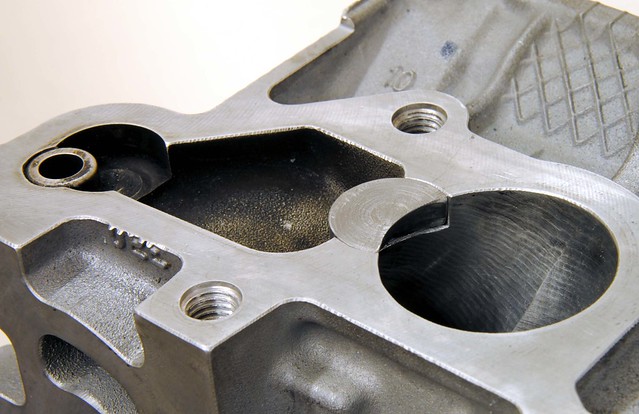

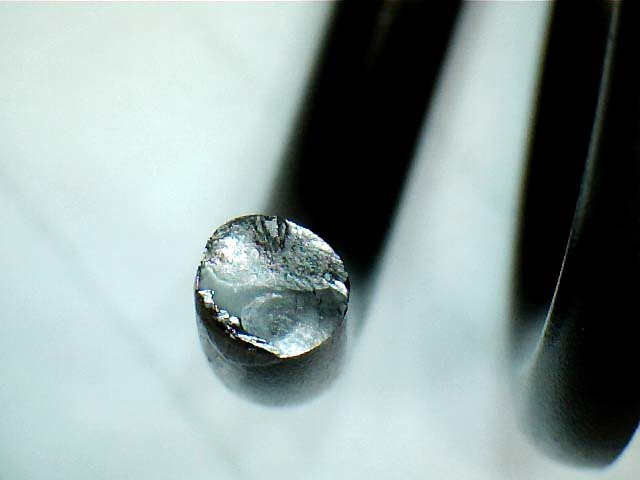

The spring showing a classic fatigue fracture . . .

It had logged 85 hours, all on track. That is on the lower end of what you might expect from a spring, but not outside the life expectancy with the cam lift and and RPM I was using. Kent Cams have offered to analyse the spring and I will take them up on that offer, but they initial response is that it was not a combination of cam profile they have tested. They say the spring was intended to be used as a duplex set. Strangely they supply seats and retainers to use it as single spring. The early R500 Duratecs do have a history of valve spring failures, but this one is a different spring. Personally, I suspect resonance played a part in the failure as the position of the break strongly suggest that.

The rest of the engine was essentially a write off, and I don’t intend to reuse any of the stressed parts in my new engine, but I’d be happy to run the crank, cams, drysump, remaining rods, pistons, valves, cams, in a ‘down rated’ engine.

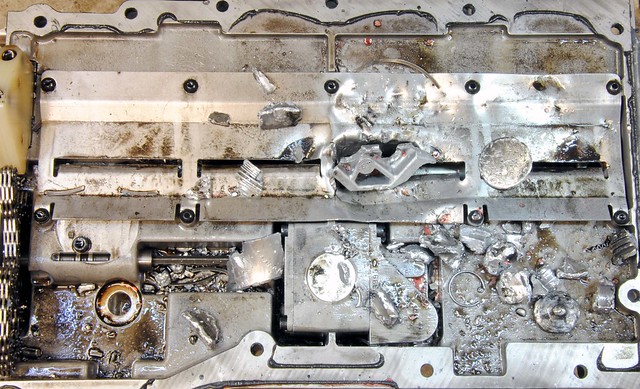

For your entertainment, here’s some photos of the carnage . . .

The dry sump damage to the windage tray, but otherwise intact

The gudgeon pin circlip that jammed the throttle open.

So what’s for next year?

As said, I’ve already got a new head, this time to an even higher spec (bigger valves and seats) with hotter cams - basically as far as you can go with the standard head. But what it will be matted with is still undecided . . . I may try a 2.5L just for the hell of it. I’ll keep you posted.

Knowing that I was probably climbing out the reliability bathtub, I had commissioned a new head with the intention of building a new zero hour engine for 2017, and that arrived a couple of days before the SLS championship final. Perhaps that was tempting fate, but the engine must have known its time was up . . . and it didn't want to go quietly.

Picture courtesy of Richard Breakell

During the first hot lap in qualifying, I noticed a misfire going up Duffus (reverse direction). In hindsight, I should have abandoned the session at that point, but, with oil pressure and temps normal, I was keen to get a lap time. The misfire cleared for a while, but returned on the back straight and developed into a mechanical rattle as I approached the chicane. The throttle then would not close and the revving engine spectacularly ground itself to bits in a big cloud of smoke. I finally shut it down as I coasted to halt. I knew it was bad, but I was more upset about not finishing the event - my first time ever in the SLS.

https://www.youtube.com/watch?v=QTdeBj7h400

There was a fist size hole in the crank, but I sensed this was not a big end failure. The engine was rotating so freely, and with oil pressure normal throughout, it had to be a dropped valve, and that probably meant a valve spring failure.

Once home, this was was quickly confirmed . . .

The spring showing a classic fatigue fracture . . .

It had logged 85 hours, all on track. That is on the lower end of what you might expect from a spring, but not outside the life expectancy with the cam lift and and RPM I was using. Kent Cams have offered to analyse the spring and I will take them up on that offer, but they initial response is that it was not a combination of cam profile they have tested. They say the spring was intended to be used as a duplex set. Strangely they supply seats and retainers to use it as single spring. The early R500 Duratecs do have a history of valve spring failures, but this one is a different spring. Personally, I suspect resonance played a part in the failure as the position of the break strongly suggest that.

The rest of the engine was essentially a write off, and I don’t intend to reuse any of the stressed parts in my new engine, but I’d be happy to run the crank, cams, drysump, remaining rods, pistons, valves, cams, in a ‘down rated’ engine.

For your entertainment, here’s some photos of the carnage . . .

The dry sump damage to the windage tray, but otherwise intact

The gudgeon pin circlip that jammed the throttle open.

So what’s for next year?

As said, I’ve already got a new head, this time to an even higher spec (bigger valves and seats) with hotter cams - basically as far as you can go with the standard head. But what it will be matted with is still undecided . . . I may try a 2.5L just for the hell of it. I’ll keep you posted.

Just a quick up date . . .

The engine was rebuilt to more or less an identical spec to the last one. It went on the rollers yesterday and performed faultlessly and returned an almost identical power graph. A little stronger towards the top due to a slightly different cam and head spec. Overall it's a little more responsive. Here's it on the rollers having the transient fueling checked for the blipper - something I wasn't able to do last time as it was before the paddle shift was fitted.

https://youtu.be/gzwnlsi5G1M

Attention is now going to the building of a 2.5L engine. Hopefully I will have something by the end of the season.

The engine was rebuilt to more or less an identical spec to the last one. It went on the rollers yesterday and performed faultlessly and returned an almost identical power graph. A little stronger towards the top due to a slightly different cam and head spec. Overall it's a little more responsive. Here's it on the rollers having the transient fueling checked for the blipper - something I wasn't able to do last time as it was before the paddle shift was fitted.

https://youtu.be/gzwnlsi5G1M

Attention is now going to the building of a 2.5L engine. Hopefully I will have something by the end of the season.

griggsy2 said:

Looks like I have JeffC's old car.

Can confirm the engine is a peach and just been remapped to get 265bhp by 7000 rpm as opposed to 8000+.

Yeah, that car has very similar spec of engine, but perhaps a slightly early incarnation of head and cams. A few years ago I would have been quite happy to quote figures, but I've been doing this long enough now to realise that rolling roads are not quite all what they seem. The inherent errors and particularly the human factors make quoting figures a little academic. But Simon's 2L engines will produce a real 260-270 BHP on a good day, but 265BHP at 7000 requires a volumetric efficiency that is unlikely.Can confirm the engine is a peach and just been remapped to get 265bhp by 7000 rpm as opposed to 8000+.

Edited by DCL on Saturday 18th March 13:57

This is worth a read. http://www.pistonheads.com/gassing/topic.asp?t=110...

I'm afraid 193 lbf-ft is verging on the theoretically impossibility from your spec of normally aspirated 2L. It would need full race with considerable pulse tuning to get the volumetric efficiency that this represents.

I'm afraid rolling roads are more than capable of producing errors this big, just surprised your guys who did this don't know there stuff well enough to realise something was wrong.

I'm afraid 193 lbf-ft is verging on the theoretically impossibility from your spec of normally aspirated 2L. It would need full race with considerable pulse tuning to get the volumetric efficiency that this represents.

I'm afraid rolling roads are more than capable of producing errors this big, just surprised your guys who did this don't know there stuff well enough to realise something was wrong.

Sorry, definitely some confusion as that engine spec is not the one I thought we were talking about. My point was that once you see over 95 lbf-ft per litre, you know there's likely to be something wrong with the run/calibration as it takes a VERY special engine to get that.

Out of interest, looking at the shape of your torque curve, my guess is that there been some early loss of traction on the rollers and the inertia has added back in mid range. But the overall figure is what I would expect.

Out of interest, looking at the shape of your torque curve, my guess is that there been some early loss of traction on the rollers and the inertia has added back in mid range. But the overall figure is what I would expect.

Edited by DCL on Sunday 19th March 08:30

Gassing Station | Caterham | Top of Page | What's New | My Stuff