R400D to R500D Anyone done it?

Discussion

Great thread. Love the detail. Makes me want to do the upgrade on the sogma myself. The super clutch is the same as I fitted to my VX. They are 'heavy' and very on/off to use. Not good for hill starts :-) In saying that, I did do lemans and back with mine. No issues, other than a really big left calf at the end :-)

RGambo said:

Great thread. Love the detail. Makes me want to do the upgrade on the sogma myself. The super clutch is the same as I fitted to my VX. They are 'heavy' and very on/off to use. Not good for hill starts :-) In saying that, I did do lemans and back with mine. No issues, other than a really big left calf at the end :-)

That's an interesting comment. Since buying the Superclutch I've had some negative feedback about them, basically saying the solid plate requires an un-achievable tolerance to give any sort of long term durability. Failure of splines and bearings (engine and gearbox) being listed. How many miles has yours done? Any problems? I have a 7.5" twin plate Super Clutch in conjunction with a sequential box , I have been using this set up for a year now and my car spends all of its life on track, These Clutches put more strain on the Transmission etc with the shear nature of how they operate, As for using then on the road i cant imagine them lasting very long at all.

DCL said:

RGambo said:

Great thread. Love the detail. Makes me want to do the upgrade on the sogma myself. The super clutch is the same as I fitted to my VX. They are 'heavy' and very on/off to use. Not good for hill starts :-) In saying that, I did do lemans and back with mine. No issues, other than a really big left calf at the end :-)

That's an interesting comment. Since buying the Superclutch I've had some negative feedback about them, basically saying the solid plate requires an un-achievable tolerance to give any sort of long term durability. Failure of splines and bearings (engine and gearbox) being listed. How many miles has yours done? Any problems? Hi I run 250BHP and 180 ft/lb at the hubs from a K20 honda through a Sadev with paddle shift and very tall 3.19 diff, 50/50 road track 2000 miles since the box went in and never had an issue with an AP ceramic button spring damped friction plate and a Greedy (Honda tuning part) pressure plate, both on thier limits torque wise and concentric bearing operation.I think folk get more issues than they deserve when they fit non Damped (IE Sprung) friction plates IE competion plate leaving all the shock loadings and torque to just carry on through the box into the prop and diff. Obiviously my flat upshifts and down shifts are near seamless (Geartronics)so as they say a proper paddle/flatshift setup protects the drive train very well.Before that I had AP organic with the same Greedy pressure plate and the Caterham 6 speed same engine and diff and no problems either.

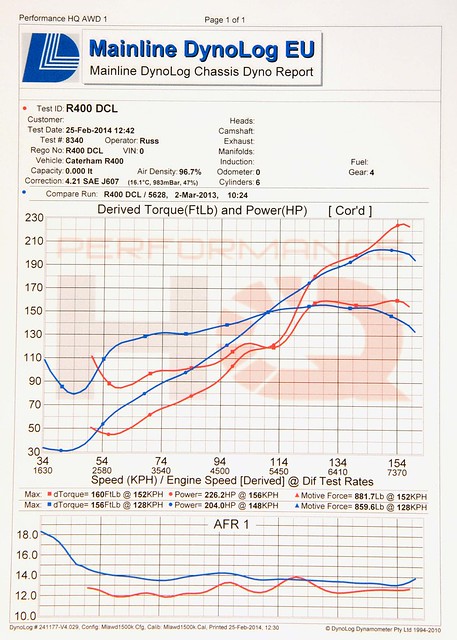

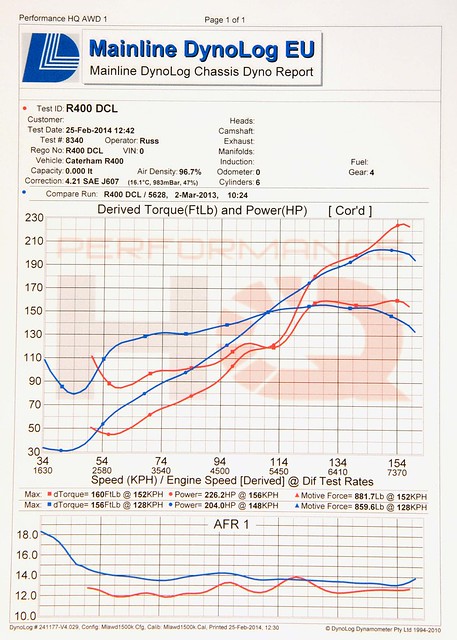

Yesterday was spent on the rolling road running-in and putting together a safe map to allow some track time. The running-in was an alternating pattern between various stages of throttle and full vacuum (closed throttle). The idea (I'm told) is to allow the rings to be pushed out followed by all the debris being sucked out. This went on for about an hours or so as we watched and listened for any thing out of the ordinary. The operator wore a stethoscope bolted to the knock sensor bolt just to give us early warning of any issues. The Supertech pistons, apparently, were heard slapping about a bit - typical of the short skirt design, but it ran smoothly with less vibration than the predecessor.

Once this was completed, we moved on to mapping. The objective at this stage was not to get a headline BHP figure, but to get something safe to build a bit of track time. We therefore set a rev limit of 7600 RPM and mapped with an eye on the budget. The detailed tweaking is still to come, but we did a few power runs at the end which gave 226BHP at the wheels - which was better than I expected.

What did become clear is that the cams are really intended for high RPM. It really came alive at 6000 RPM and, in the words of the operator, 'about to go ballistic' when the rev limiter cut in. I know the 4:1 exhaust is not ideal for low torque and also the Cosworth barrels have limitations too, so this was good news and spot on what Simon at Ultimate had predicted.

http://www.youtube.com/watch?v=fU6U_N9_mPc

There was an induction noise at around 3000 rpm that sounds horrible, but is probably the large overlap on the cams. All in all a good day

Once this was completed, we moved on to mapping. The objective at this stage was not to get a headline BHP figure, but to get something safe to build a bit of track time. We therefore set a rev limit of 7600 RPM and mapped with an eye on the budget. The detailed tweaking is still to come, but we did a few power runs at the end which gave 226BHP at the wheels - which was better than I expected.

What did become clear is that the cams are really intended for high RPM. It really came alive at 6000 RPM and, in the words of the operator, 'about to go ballistic' when the rev limiter cut in. I know the 4:1 exhaust is not ideal for low torque and also the Cosworth barrels have limitations too, so this was good news and spot on what Simon at Ultimate had predicted.

http://www.youtube.com/watch?v=fU6U_N9_mPc

There was an induction noise at around 3000 rpm that sounds horrible, but is probably the large overlap on the cams. All in all a good day

An update:

226 BHP at the wheels at only 7600 RPM was more impressive than I was expecting, but, I must confess, the torque curve was a little disappointing - particularly when comparing it to the old engine (blue)

I knew, with the 4-1 exhaust, things would not be great, but feel the skill required to keep it 'on cam' may be beyond both me and the gear ratios. So the decision has been made to bring forward 'phase two' of the project and get a proper 4-2-1 made for this season. So, BTB have been commissioned to make an exhaust to Ultimate performance's spec. It will be a real challenge to package it in the S3 chassis without compromise but thanks to purespeed for prototyping it for me , I've only got three weeks to my first event, so this will be fun.

, I've only got three weeks to my first event, so this will be fun.

226 BHP at the wheels at only 7600 RPM was more impressive than I was expecting, but, I must confess, the torque curve was a little disappointing - particularly when comparing it to the old engine (blue)

I knew, with the 4-1 exhaust, things would not be great, but feel the skill required to keep it 'on cam' may be beyond both me and the gear ratios. So the decision has been made to bring forward 'phase two' of the project and get a proper 4-2-1 made for this season. So, BTB have been commissioned to make an exhaust to Ultimate performance's spec. It will be a real challenge to package it in the S3 chassis without compromise but thanks to purespeed for prototyping it for me

, I've only got three weeks to my first event, so this will be fun.

, I've only got three weeks to my first event, so this will be fun.

DCL said:

What did become clear is that the cams are really intended for high RPM. It really came alive at 6000 RPM and, in the words of the operator, 'about to go ballistic' when the rev limiter cut in. I know the 4:1 exhaust is not ideal for low torque and also the Cosworth barrels have limitations too, so this was good news and spot on what Simon at Ultimate had predicted.

I would have thought with that spec higher peak figures as looking at the graph is the power starting to tail off and it does seem to be quite a drop off in the middle? regarding the torque figure ,mine runs 45mm dth ITB"s and a raceco 4-1 system and the torque low down is unreal its like a big diesel , just as a comparison my original Raceco R400 engine had 160lbs feet, on my new engine the torque stays above 170lbs ft from 5000rpm to 8,000rpm peaking at 190lbs feet at 6500rpm , when I specced the engine I didnt want a screamer so wasnt looking for peak power but more of a useable engine as I wanted it as a road car not race so we didnt go for slipper pistons or the biggest cams and the result to drive is incredible, power peaks on mine at 8,100rpm but the way it delivers I rarely rev it that high.another thing worth mentioning is I was curious about the c400 Carbon air filter cover as I felt it zapped power (due to the major noise reduction) so I got the car back on a rolling road to do some back to back testing and found that with it fitted I only lost 2bhp right at the top end but removing it actually reduced torque and we also noticed that with it fitted it filled in a hole in the mid range curve. Interesting on the day I also found that I was lacking air volume in the airbox as by doing a run with the filter and box removed the power shot up considerably so by increasing the distance from the end of the trumpets to the filter by fitting an extended back plate I found 8bhp at the top end , one of the cheapest power upgrades I have done

Have you road tested it yet? pretty sure will be impressive on the road !

Ps. great write up I have followed with interest on Fb.

Edited by JeffC on Saturday 8th March 08:39

Thanks, that's some good information. The car is purely a track car, so I was intending to go a bit hotter on the cams than I would have done for a road car. But I think I may have overdone done it for the current exhaust and perhaps milder cams may have produced more cost effective results - there's still work to be done!(and I haven't ruled out a cam change).

A couple of things about the graphs - there is a lot of smoothing on the graph and, when you look at the raw dyno data, the power is still going up at the limiter. We think it is going to peak in another 5-600 RPM. Also the derived rpm is a little off due to differing degrees of wheel slip on the runs, so the derived torque is also off as it is defined by the 5252 cross over point - meaning the back to back comparison with the original engine, and figures, shouldn't be taken too literally.

I'm very much in a learning curve at the moment. Most people I have talked to think the exhaust needs to be a bigger diameter, and 4-2-1, so that's the way this project is heading at the moment. I like your comment about induction clearance and will certainly look at that next.

A couple of things about the graphs - there is a lot of smoothing on the graph and, when you look at the raw dyno data, the power is still going up at the limiter. We think it is going to peak in another 5-600 RPM. Also the derived rpm is a little off due to differing degrees of wheel slip on the runs, so the derived torque is also off as it is defined by the 5252 cross over point - meaning the back to back comparison with the original engine, and figures, shouldn't be taken too literally.

I'm very much in a learning curve at the moment. Most people I have talked to think the exhaust needs to be a bigger diameter, and 4-2-1, so that's the way this project is heading at the moment. I like your comment about induction clearance and will certainly look at that next.

Edited by DCL on Saturday 8th March 11:17

I think I said right at the beginning of this project that there was going to be more than one phase - the idea in my head was to build the engine and then upgrade the exhaust and inductions over the following year. But what I have learnt is that the more you push the limits, the less tolerant the engine becomes to minor deficiencies.

So I have decided to accelerate exhaust phase of the project in the hope of a less peaky power delivery.

Today the exhaust was finished. It is basically a bigger diameter and a 4-2-1 design. The dimensions are Ultimate's and are specifically for the CNC head and cams I'm using. There are other headers and exhausts on the market that are similar (and may have worked) but I decided the additional cost of one fabricated to the exact dimensions was not that high and would be worth it. So, this is a one is a one-off made by BTB and, I believe, a first for a metric S3 chassis.

Dyno next week! Talk about putting your money where your mouth is - hope it works

So I have decided to accelerate exhaust phase of the project in the hope of a less peaky power delivery.

Today the exhaust was finished. It is basically a bigger diameter and a 4-2-1 design. The dimensions are Ultimate's and are specifically for the CNC head and cams I'm using. There are other headers and exhausts on the market that are similar (and may have worked) but I decided the additional cost of one fabricated to the exact dimensions was not that high and would be worth it. So, this is a one is a one-off made by BTB and, I believe, a first for a metric S3 chassis.

Dyno next week! Talk about putting your money where your mouth is - hope it works

k20erham said:

Hi your about 2 years late for the 1st btb in a s3, Joe did a wonderful job on mine, again spot on with how it performs, although had to repack the can twice so far but its not a drama.

Joe said it's the first metric chassis they've done - maybe he's mistaken, but they were measuring templates from it yesterday for future reference. The main difference from an imperial S3 is the cross member on the metric chassis allows no.4 header on the other side of the steering tube and reduce the otherwise tight radius. [edit: as seen on Jason's car photograph in the post above]

Edited by DCL on Saturday 22 March 22:28

Mostly when I hit a problem I try and think it through, come up with a plan, and start again when my solution doesn't work. But every now and then it all comes together - the last couple of days have been like that. BTB delivered on time, Ulitimate's exhaust spec was spot on, and Northampton Motorsport did their stuff.

I am still digesting the data and will comment more later, but at last got a torque curve, and BHP figures, that put a smile on my face.

I am still digesting the data and will comment more later, but at last got a torque curve, and BHP figures, that put a smile on my face.

Edited by DCL on Thursday 27th March 12:01

Edited by DCL on Tuesday 15th April 11:15

Gassing Station | Caterham | Top of Page | What's New | My Stuff