Caterham 6 to Sadev Anyone done it?

Discussion

As per earlier posts, I'm using Geartronics for the barrel position, driving the MBE powershift. It's initiated with the Sadev switch on the gearbox. I ran various strategies on the rolling road at Northampton Motorsport, and we concluded that simple ignition cut was the best. But there are many options, not all of which we had time to test, so I might revisit that at some stage.

It's half way through the season now and I can't really imagine driving the car without the Sadev or flatshift. So with no real issues to contend with, I've decided to crack on with the long term goals of the project and purchased a full paddleshift set-up from Geartronics.

As the car is used mainly for sprint events, I've opted for a high pressure bottle supply. This simplifies the installation and saves significant weight, but could be changed to a compressor relatively simply. The main challenge will be clutchless downshifts using a the throttle blipper. Having studied the software, it is clear that some clever stuff goes on. Looking forward to getting stuck in to the installation over the next few months.

As the car is used mainly for sprint events, I've opted for a high pressure bottle supply. This simplifies the installation and saves significant weight, but could be changed to a compressor relatively simply. The main challenge will be clutchless downshifts using a the throttle blipper. Having studied the software, it is clear that some clever stuff goes on. Looking forward to getting stuck in to the installation over the next few months.

k20erham said:

What does appear to be missing from your kit though is an extension that fits on the Sadev gear selector arm extends about 30mm and the shift cylinder to selector lever rod,mine was made by MOG in Germany, compliments the beautiful Sadev CNC work, it makes Quaife look like exactly what it is.... agricultural in comparison I dont run a gear lever and be careful about moisture in the air tank as mine does get it and I drain it out regularly.

That's interesting thanks for the info. I know the actuator is the long stroke version and I've got a figure for the travel I need to achieve (and the instructions suggest extending the lever if necessary). SWR do a fitting a kit but I didn't order that (yet) as I wanted to explore a few ideas of my own first. Because it is a bottle supply, it needs to be charged to 4500 psi with a source of dry high pressure air, Geartronics suggest a SCUBA tank, but several industrial product are available too.Kiltie said:

Do you have a feel for how frequently you'll have to charge the tank? ... say, in terms of KH laps?

I've been told 500+ shifts on a full charge, but if it's charged from another bottle, then I'm unlikely to be able to fully charge it, so so perhaps 300+ shifts, or 30 KH laps. I suspect it'll be a case of refilling it every time I put fuel in it. If it runs out, I'll still have the gear stick and flatshift backup.Wow! A lot going on there! Is that NOS in there too?

Thanks for posting the picture - the layout is very similar to the way my project seems to be going.

My Car is used for sprints, so every gram counts. The bottle is very light (carbon fibre) and it saves about 3 KG. That's over 6 BHP on the power to weight ratio, so worth doing. But I understand what you're saying. I could retrofit one if I change my mind.

Thanks for posting the picture - the layout is very similar to the way my project seems to be going.

My Car is used for sprints, so every gram counts. The bottle is very light (carbon fibre) and it saves about 3 KG. That's over 6 BHP on the power to weight ratio, so worth doing. But I understand what you're saying. I could retrofit one if I change my mind.

After too long a wait really, I managed to get back to the Geartronics paddle shift installation after the rebuild of the engine.

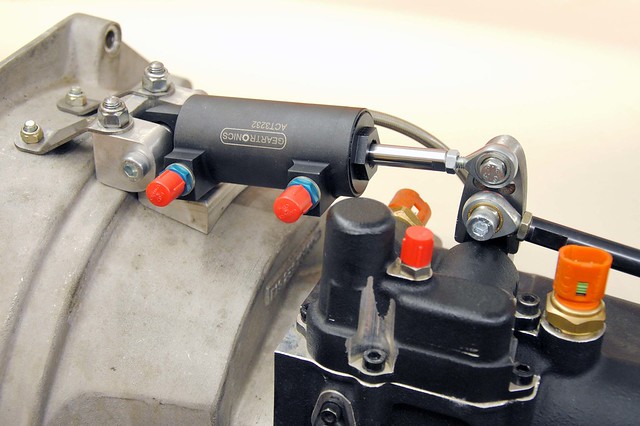

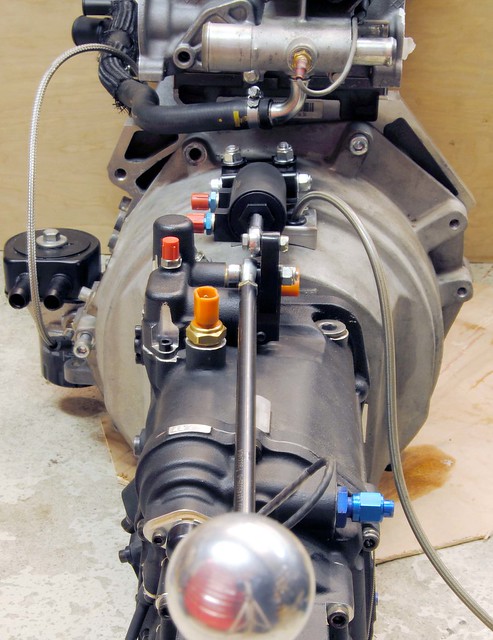

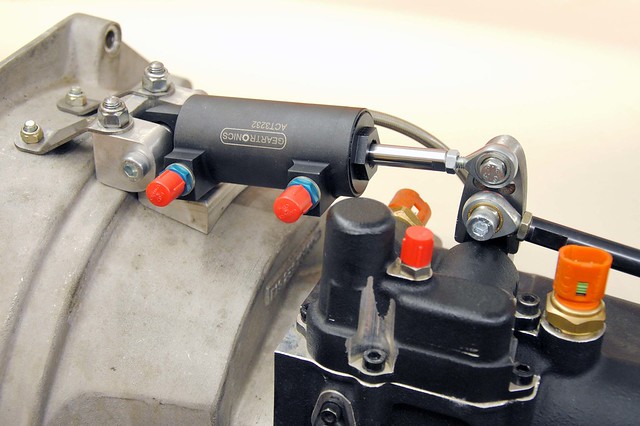

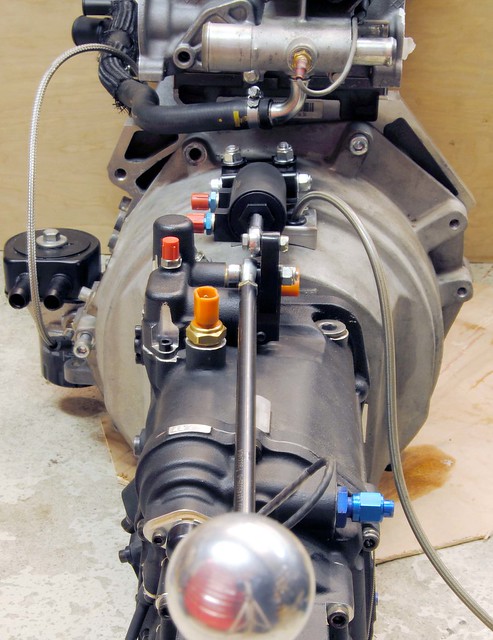

I’m really enjoy fabricating bits, and I was in my element fitting the gearshift actuator. I wanted to retain the gearstick as the air bottle set-up was a bit of an unknown in terms of duration. Many designs later, I finally settled on mounting it on the bell housing. This was the simplest and most robust solution. Here’s a picture of the prototype, which is essentially the same as the finished item.

The actuator travel needed to be at least +-22mm and not more than +-24 mm so the lever had to be extended to give this. A simple design made of 12mm steel plate that sat over the Sadev lever.

The whole assembly worked really well although given more time and money I would have commission a CNC version of the bell housing mount. But the handmade version looked OK when it was painted black and fitted to the engine.

Next stage will be fitting the engine and gearbox in the car and installing all the other bit and throttle blipper.

I’m really enjoy fabricating bits, and I was in my element fitting the gearshift actuator. I wanted to retain the gearstick as the air bottle set-up was a bit of an unknown in terms of duration. Many designs later, I finally settled on mounting it on the bell housing. This was the simplest and most robust solution. Here’s a picture of the prototype, which is essentially the same as the finished item.

The actuator travel needed to be at least +-22mm and not more than +-24 mm so the lever had to be extended to give this. A simple design made of 12mm steel plate that sat over the Sadev lever.

The whole assembly worked really well although given more time and money I would have commission a CNC version of the bell housing mount. But the handmade version looked OK when it was painted black and fitted to the engine.

Next stage will be fitting the engine and gearbox in the car and installing all the other bit and throttle blipper.

Edited by DCL on Thursday 28th January 17:53

Time for an update

Fitting the engine and gearbox back in the car is pretty routine these days so nothing to report there. It started OK and was given a few minutes at 2000 rpm to settle in the new camshaft then a quick balance of the throttle bodies and that was that until the rolling road session to run it in. With the engine done, it was back to the paddle shift.

My original idea had been to fit the paddle-shift kit on the passenger floor but that was soon dismissed as the length of the hoses posed a problem. So, after a brainstorming session, the plan was to replace the battery with a smaller lithium one. That gave the require space for the air bottle and it all worked out well in the end with the hoses nice and short - a significant performance factor for the actuators. The added bonus was the battery saved around 8 KG.

The custom loom made by Geartronics was a delight to install and fitted perfectly, the only significant job was opening up the ECU plug to add some wires. After powering it up, the main task was to calibrate barrel position. This was straightforward as I had already set the one half of the dual hall effect sensor to work with the 'easy shift' and gear display (a long trial and error process, but got there in the end). Next was to calibrate the throttle position, again straight forward, and then check the Tacho signal. That's were things started to go wrong. I just couldn't get it to work.

Discussing the matter with Geartronics resulted in some component level diagnostics, and I was all set to send the GCU back, when we realised that the ECU signal was just not of a high enough frequency for the GCU. Caterham use a very low frequency of one pulse per cycle (2 revolutions) for their tachometer. In the end this turned out to be of no real consequence as the RPM (and frequency) in the gear changing band was high enough.

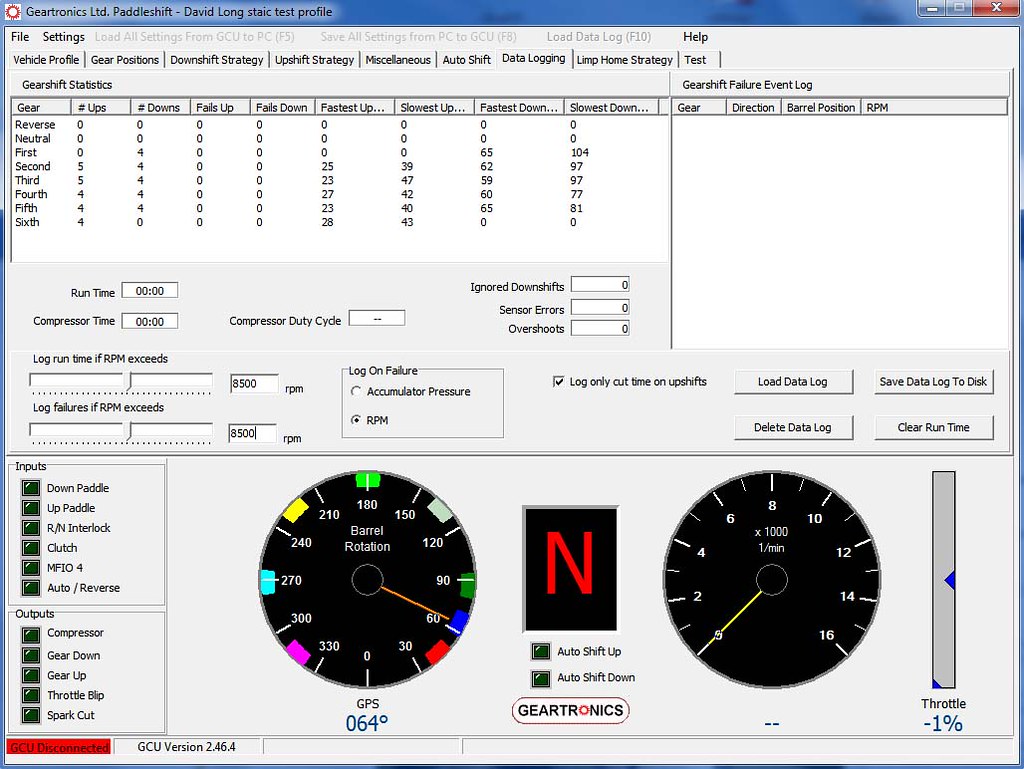

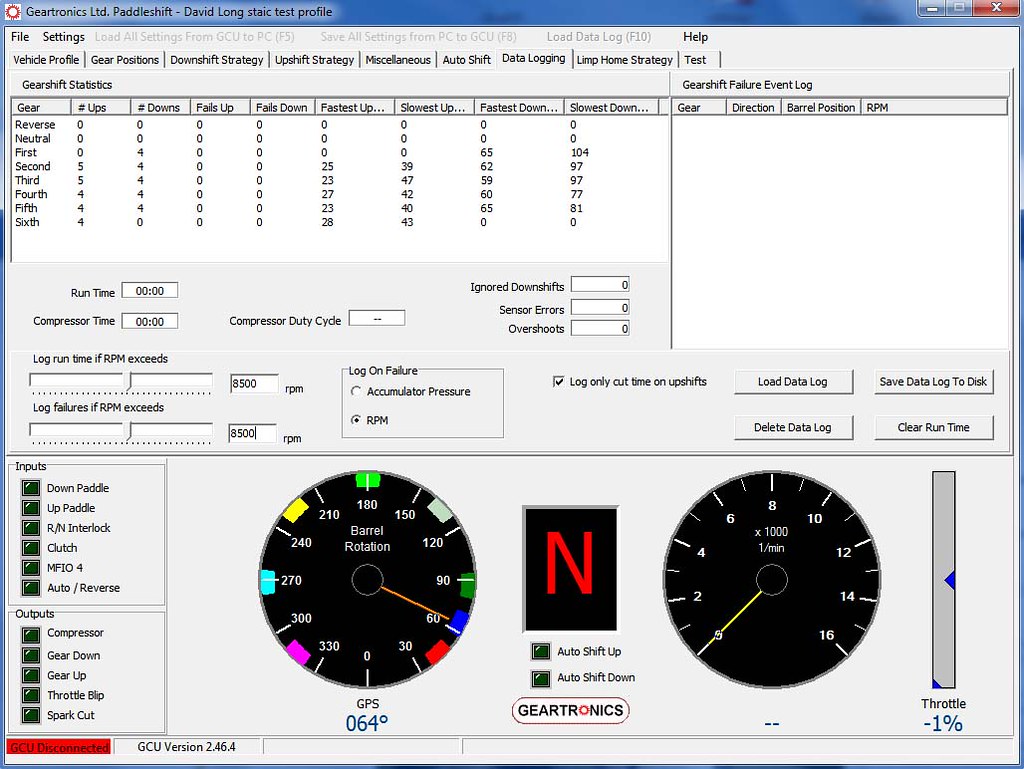

The MBE Easimap software and the Geartronic software in the set up and testing phase . . .

The steering wheel was straightforward too, and just needed to be bolted together. The neutral button was placed out of the way of my normal hand position, on a slightly recessed a carbon tab. I may change this after some use, but didn't want to drill hole in the spokes without some use on track first.

It was then just down to turning on the air bottle and testing it.

https://www.youtube.com/watch?v=NajxtwruUH8

The test logged the time of each change, the target up-shift time being between 20-60 ms, mine came in around 20 ms which was on the fast side, so we reduced the the pressure to provide less stress to the mechanics and save some air usage too. The down-shift time includes time for the engine to respond, so is much longer - typically 60-150 ms.

The test was then repeated with the engine running (no video I'm afraid) and it all worked as it should. No missed or failed shift since testing began, so I'm happy so far. The first track test will be later this month

Fitting the engine and gearbox back in the car is pretty routine these days so nothing to report there. It started OK and was given a few minutes at 2000 rpm to settle in the new camshaft then a quick balance of the throttle bodies and that was that until the rolling road session to run it in. With the engine done, it was back to the paddle shift.

My original idea had been to fit the paddle-shift kit on the passenger floor but that was soon dismissed as the length of the hoses posed a problem. So, after a brainstorming session, the plan was to replace the battery with a smaller lithium one. That gave the require space for the air bottle and it all worked out well in the end with the hoses nice and short - a significant performance factor for the actuators. The added bonus was the battery saved around 8 KG.

The custom loom made by Geartronics was a delight to install and fitted perfectly, the only significant job was opening up the ECU plug to add some wires. After powering it up, the main task was to calibrate barrel position. This was straightforward as I had already set the one half of the dual hall effect sensor to work with the 'easy shift' and gear display (a long trial and error process, but got there in the end). Next was to calibrate the throttle position, again straight forward, and then check the Tacho signal. That's were things started to go wrong. I just couldn't get it to work.

Discussing the matter with Geartronics resulted in some component level diagnostics, and I was all set to send the GCU back, when we realised that the ECU signal was just not of a high enough frequency for the GCU. Caterham use a very low frequency of one pulse per cycle (2 revolutions) for their tachometer. In the end this turned out to be of no real consequence as the RPM (and frequency) in the gear changing band was high enough.

The MBE Easimap software and the Geartronic software in the set up and testing phase . . .

The steering wheel was straightforward too, and just needed to be bolted together. The neutral button was placed out of the way of my normal hand position, on a slightly recessed a carbon tab. I may change this after some use, but didn't want to drill hole in the spokes without some use on track first.

It was then just down to turning on the air bottle and testing it.

https://www.youtube.com/watch?v=NajxtwruUH8

The test logged the time of each change, the target up-shift time being between 20-60 ms, mine came in around 20 ms which was on the fast side, so we reduced the the pressure to provide less stress to the mechanics and save some air usage too. The down-shift time includes time for the engine to respond, so is much longer - typically 60-150 ms.

The test was then repeated with the engine running (no video I'm afraid) and it all worked as it should. No missed or failed shift since testing began, so I'm happy so far. The first track test will be later this month

harry b said:

Just out of interest, how many running hours do you expect or is given for a Sadev before rebuilt is required? It is a dog cog shifting I presume?

And can this be done in your own workshop or does it require specialist because parts for service can't be bought like the quaife's.

Those are things yet holding me back to go for a sequential from Sadev, Quaife, Drenth etc. yet.

For track use, every season is recommended. I had planned to do it this winter but I ran out of time, but once the paddle shift is working smoothly (there are some risks of damaging it while testing) I may rebuild. Talking to the supplier, it seems only the serious racers rebuild them every year. Sadev upped the oil grade recently to help with boxes that are stretching overhaul periods and there doesn't seem to be any issues relating to extending overhaul, provided oil changes are regular. Oil temperature need to be monitored if used for long sessions at high power, and a cooler fitted is necessary.And can this be done in your own workshop or does it require specialist because parts for service can't be bought like the quaife's.

Those are things yet holding me back to go for a sequential from Sadev, Quaife, Drenth etc. yet.

For road use I think the consensus of opinion is that it can be used as any other box. But, as you say, its a dog box and will need regular oil changes as wear debris is a bigger problem than in a synchro box.

The gearbox is intended for racing and is therefore designed to be dismantled easily (for ratio changes etc). The only special tools are 'spline holding' sockets that are more about saving time than show stoppers. There's a comprehensive manual and parts seem readily available, and off the shelf, from SWR in my experience.

Edited by DCL on Wednesday 16th March 10:01

bdev said:

Nooo - you've got the paddles the wrong way round ! ;-)

Right has to be up a gear and left down... that's just natural no?

Right has to be up a gear and left down... that's just natural no?

It's the Geartronicts default and can be changed in the software. I believe in some professional racing circles, and in LHD cars, that is the preferred sides. But my son has grown up on Xbox, so it will be changed.

It's the Geartronicts default and can be changed in the software. I believe in some professional racing circles, and in LHD cars, that is the preferred sides. But my son has grown up on Xbox, so it will be changed.c9cwn said:

What oil grade have Sadev changed to??

I am currently using CRX 75w140 NT as supplied by Caterham with the gearbox.

Are you using the twin plate AP clutch set up? and how do you find it regarding clutch rattle noise at high idle 4,000 rpm and above.

I am currently using CRX 75w140 NT as supplied by Caterham with the gearbox.

Are you using the twin plate AP clutch set up? and how do you find it regarding clutch rattle noise at high idle 4,000 rpm and above.

That's the right oil, they did originally recommend 75W90, but that was intended to be used with an oil cooler. The story I was told was that the 620 Caterhams don't have an oil cooler so they now recommend a 75W140 to add some extra protection at high temperature.

Edit: I'm using the twin plate 7.5 inch Superclutch, and yes, it does rattle with the clutch in. But so does the gearbox off load.

Edited by DCL on Wednesday 16th March 12:44

tankplanker said:

Looks an awesome setup!

I've yet to try playing with the config on my paddleshift setup, is it easy to do so?

Where did you get the carbon shift paddles from, mine are metal and I fancy swapping them?

It's all Geartronics bits. They pitch themselves at the top end, and all the bits are superb quality - but the price reflects that. They will only sell complete systems so it's unlikely you'd get individual components from them.I've yet to try playing with the config on my paddleshift setup, is it easy to do so?

Where did you get the carbon shift paddles from, mine are metal and I fancy swapping them?

Edited by DCL on Thursday 17th March 12:02

First track test today . . .

https://www.youtube.com/watch?v=VQDOCv7UVnU

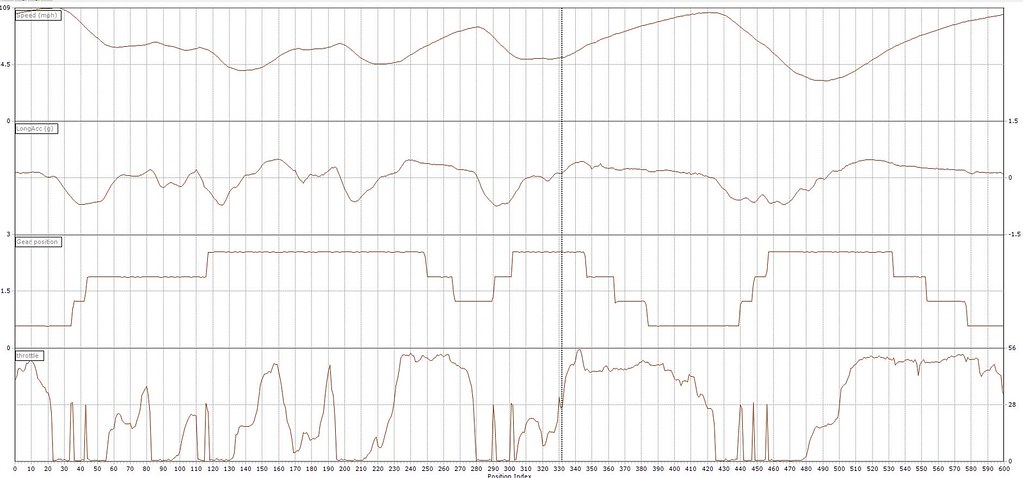

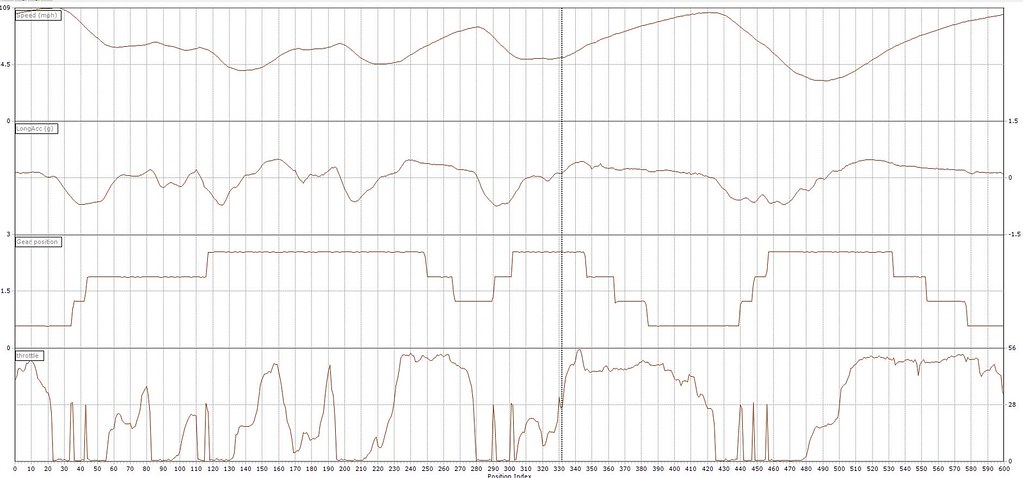

It all seemed to work as intended, the CT data showing it all to be smooth and consistent.

https://www.youtube.com/watch?v=VQDOCv7UVnU

It all seemed to work as intended, the CT data showing it all to be smooth and consistent.

Gassing Station | Caterham | Top of Page | What's New | My Stuff