Brake proportion/bias thingy?

Discussion

joe-motion said:

What is the original off? Or is it TVR designed and now not available?

Can't find a picture of one fitted in a Sierra but my guess is it's a TVR special?Did find a picture of one being fitted in a kit car, could be a Ford bracket, there looks to be a little strengthening kink where the metal is bent? Not the sort of thing you'd get with a homemade bracket

These were described as Escort Mk4, looks they it had a pair?

Edited by phillpot on Saturday 2nd February 12:39

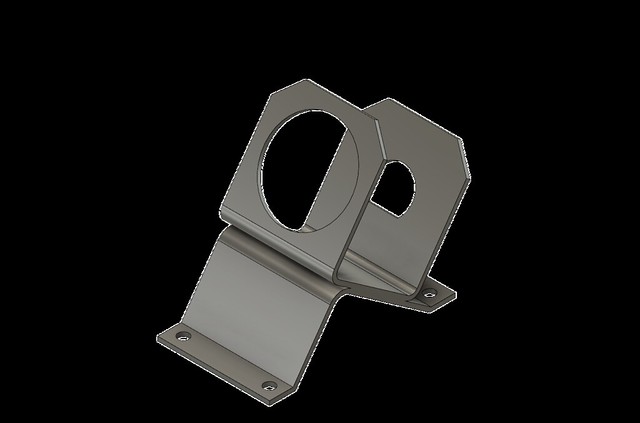

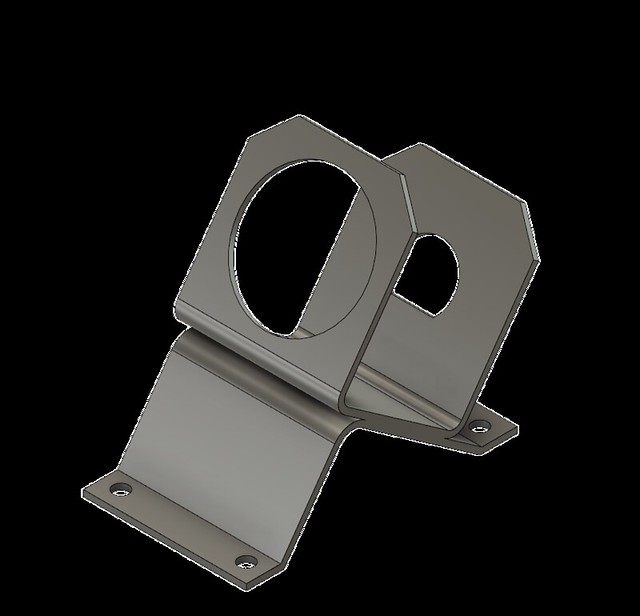

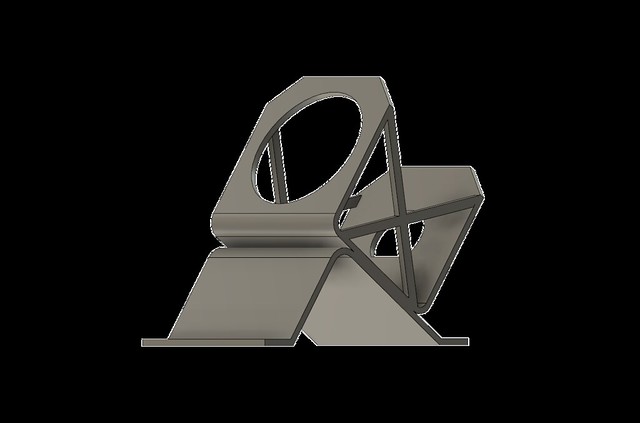

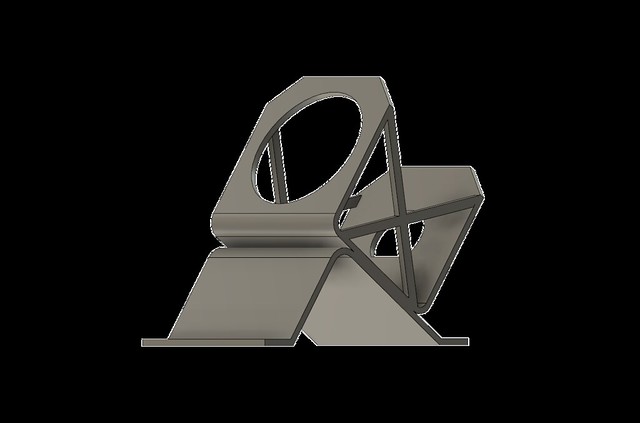

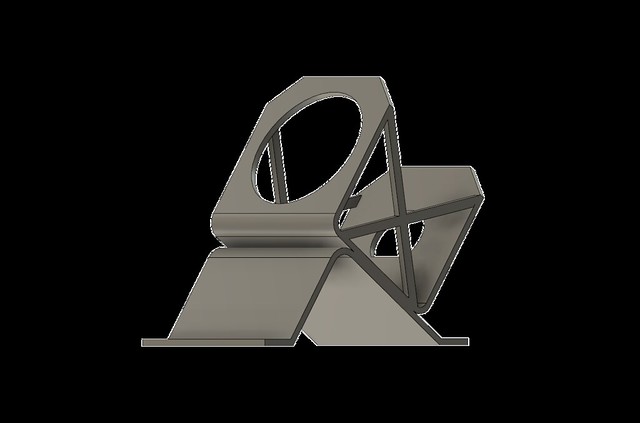

I don't know if this idea will be any good but as the bracket isn't subject to mechanical forces I can make them in plastic by 3D printing. I would use PETG (Polyethylene Terephthalate Glycol) its quite strong in itself but would obviously be subject to vibration and heat under the bonnet. Hopefully the added cross bracing would help with the vibration and PETG is only effected if the temperature is higher than 75 degrees. Does anyone know the under bonnet temperature?

Happy to send one to anyone just for postage who would like to experiment and let me know of outcome.

TVR Brake Bias Device 1 v1 by nfarmer1, on Flickr

TVR Brake Bias Device 1 v1 by nfarmer1, on Flickr

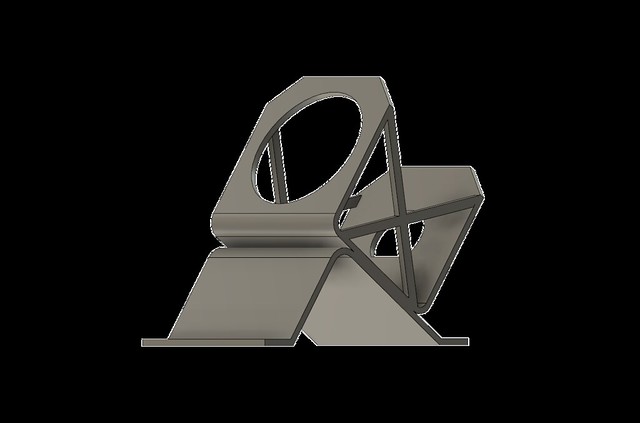

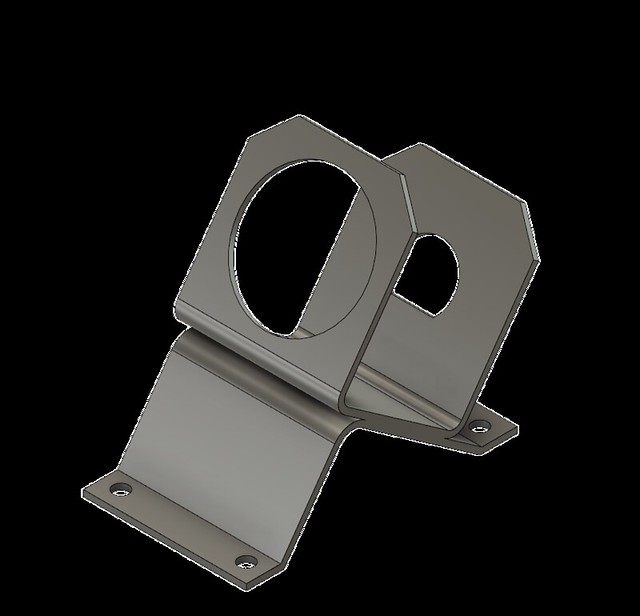

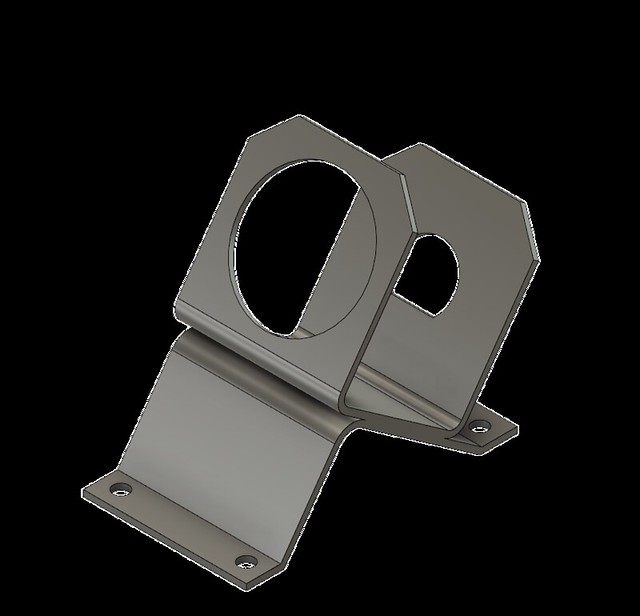

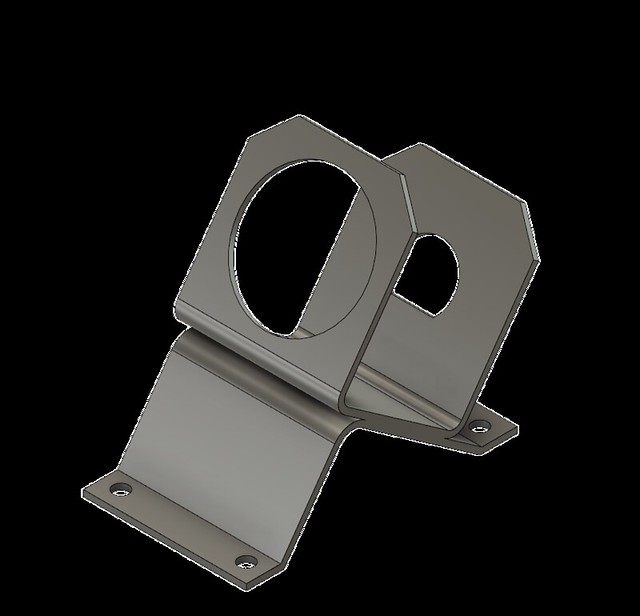

TVR Brake Bias Device v2 by nfarmer1, on Flickr

TVR Brake Bias Device v2 by nfarmer1, on Flickr

Norman

Happy to send one to anyone just for postage who would like to experiment and let me know of outcome.

TVR Brake Bias Device 1 v1 by nfarmer1, on Flickr

TVR Brake Bias Device 1 v1 by nfarmer1, on Flickr TVR Brake Bias Device v2 by nfarmer1, on Flickr

TVR Brake Bias Device v2 by nfarmer1, on FlickrNorman

None of my business, but those diagonals don't look at all substantial and in plastic I can imagine them getting broken. That valve is quite heavy and is in an area where it's going to get clonked from time to time. A side panel, even with a low fill ratio, would give me more confidence. Better still would be to fill the space around the valve. Again, probably doesn't need to be a high fill ratio.

I'm also using 3D printers. I've got one at home. I don't know PETG filament, but I always use ABS. I don't have any problem with this material under 100°C... even more. No problem under the bonnet.

Sure you can use an ABS 3D printed part to retain the valve, it's far heavy enough, but you will have to re-design the bracket. You don't design a part in the same way if you want to bend a steel sheet bracket or use 3D print.

The main drawback is the Lego aspect not as clean as a stainless steel bracket

not as clean as a stainless steel bracket

Sure you can use an ABS 3D printed part to retain the valve, it's far heavy enough, but you will have to re-design the bracket. You don't design a part in the same way if you want to bend a steel sheet bracket or use 3D print.

The main drawback is the Lego aspect

not as clean as a stainless steel bracket

not as clean as a stainless steel bracketI use a cheap Chinese RepRap at home. At work, I have a semi-professional printer, far more expensive. In fact the more expensive is just easier to use, and quicker, but with time and practice, you can obtain the same result with the cheaper one.

PA6 (nylon) is really hard to print. The melting temperature is high (240°C-260°C) and there is a lot of wrapping effect (top layers pulls on previous ones and remove first layers from the bed. You also need to dehumidify the material before each print session (4 hours in a dryer).

The problem is always the same with 3D printer. Printed parts don't resist to high temperature. PLA is really easy to print but water-sensitive and has low mechanical properties. ABS is little bit harder to print (needs a heated bed and a box around the printer to stabilize the temperature. Carbon filament is stronger at ambient temperature than a classical filament, but is not better at high temperature.

PA6 (nylon) is really hard to print. The melting temperature is high (240°C-260°C) and there is a lot of wrapping effect (top layers pulls on previous ones and remove first layers from the bed. You also need to dehumidify the material before each print session (4 hours in a dryer).

The problem is always the same with 3D printer. Printed parts don't resist to high temperature. PLA is really easy to print but water-sensitive and has low mechanical properties. ABS is little bit harder to print (needs a heated bed and a box around the printer to stabilize the temperature. Carbon filament is stronger at ambient temperature than a classical filament, but is not better at high temperature.

Gerald-TVR said:

I don't know if this idea will be any good but as the bracket isn't subject to mechanical forces I can make them in plastic by 3D printing. I would use PETG (Polyethylene Terephthalate Glycol) its quite strong in itself but would obviously be subject to vibration and heat under the bonnet. Hopefully the added cross bracing would help with the vibration and PETG is only effected if the temperature is higher than 75 degrees. Does anyone know the under bonnet temperature?

Happy to send one to anyone just for postage who would like to experiment and let me know of outcome.

TVR Brake Bias Device 1 v1 by nfarmer1, on Flickr

TVR Brake Bias Device 1 v1 by nfarmer1, on Flickr

TVR Brake Bias Device v2 by nfarmer1, on Flickr

TVR Brake Bias Device v2 by nfarmer1, on Flickr

Norman

I think i would print a solid wedge shape with bolt down clamps for this valve.Happy to send one to anyone just for postage who would like to experiment and let me know of outcome.

TVR Brake Bias Device 1 v1 by nfarmer1, on Flickr

TVR Brake Bias Device 1 v1 by nfarmer1, on Flickr TVR Brake Bias Device v2 by nfarmer1, on Flickr

TVR Brake Bias Device v2 by nfarmer1, on FlickrNorman

If i get tine i might draw it.

Damian S3

Cheers for the help on this guys, think the l shape bracket option is the way to go for ease and so i can at least get my brakes working again. Will have a rummage to see what i have, obviously if anyone has a nice stainless one knocking about that they can spare for beer tokens please shout up. 😀

Gassing Station | S Series | Top of Page | What's New | My Stuff