Repairable? Or am I looking for a donor body?

Discussion

I have now taken off everything I need to before the lift. Struggling to find front lift points due to splintered fibreglass which extends through the offside wheel arch (pic). Lifting from anywhere in front of the centre of front wheel arch could end up causing more damage I think.

Thinking of slipping two sections of L angle under the inner edges of the engine bay (indicated by white lines in next pic) and lifting from there. This would mean some drill holes through the 'glass probably.

Also, not thrilled to find the air filter box has a big crack in it and a thumbnail sized hole in it.

Fun and games....

Thinking of slipping two sections of L angle under the inner edges of the engine bay (indicated by white lines in next pic) and lifting from there. This would mean some drill holes through the 'glass probably.

Also, not thrilled to find the air filter box has a big crack in it and a thumbnail sized hole in it.

Fun and games....

Body lift this weekend. Tried a partial lift and everything works fine, up she went. Ended up using wheel arches and boot holes as lift points.

Anyone got any advice/pics of best way to support the body once off the car please? Ideally I want to be able the slide the chassis out from underneath whenever I am working on it and the slide it back afterwards. Don't really want it hanging from the roof indefinitely..

Thanks, Toby

Anyone got any advice/pics of best way to support the body once off the car please? Ideally I want to be able the slide the chassis out from underneath whenever I am working on it and the slide it back afterwards. Don't really want it hanging from the roof indefinitely..

Thanks, Toby

Mike "Brap_brap" had a lot of pictures on this thread:

http://www.pistonheads.com/gassing/topic.asp?h=0&a...

However Imageshack has dropped them so we can't see - there was some dodgy-looking propping-up going on though!

You could make up some stout wooden trestles to lower it onto, although I would retain all the lifting chains etc connected to the roof as an insurance.

http://www.pistonheads.com/gassing/topic.asp?h=0&a...

However Imageshack has dropped them so we can't see - there was some dodgy-looking propping-up going on though!

You could make up some stout wooden trestles to lower it onto, although I would retain all the lifting chains etc connected to the roof as an insurance.

I put mine up like this with a scissor jack and blocks of wood, would not advise anyone to do the same it was ridiculously dangerous, young thick and stupid and all that haa ,

the jig was safe enough it sat like that a year or 2 no problems , just make sure you support the middle of the car once the chasis is out it will more than likely bow otherwise

I used 6 x 3 lenth on the front and some home made axle stands and supports , the rear was just a few blocks of wood and some normal axle stands due to the slope on my drive

An idea of what will hold it , I will be doing it again soon and I think I will be welding a steel jig up this time out of some box and some wheels on the bottom or something like that

Good luck

Zack

[url]

[url]

|http://thumbsnap.com/gKf4ajuC[/url]

|http://thumbsnap.com/gKf4ajuC[/url]

the jig was safe enough it sat like that a year or 2 no problems , just make sure you support the middle of the car once the chasis is out it will more than likely bow otherwise

I used 6 x 3 lenth on the front and some home made axle stands and supports , the rear was just a few blocks of wood and some normal axle stands due to the slope on my drive

An idea of what will hold it , I will be doing it again soon and I think I will be welding a steel jig up this time out of some box and some wheels on the bottom or something like that

Good luck

Zack

[url]

[url] |http://thumbsnap.com/gKf4ajuC[/url]

|http://thumbsnap.com/gKf4ajuC[/url]Maybe nothing!

- Can I assume you are talking "left hooker" offside - that being the left hand side?

- Did you get any damage at all to the rear wheel - even a scuff?

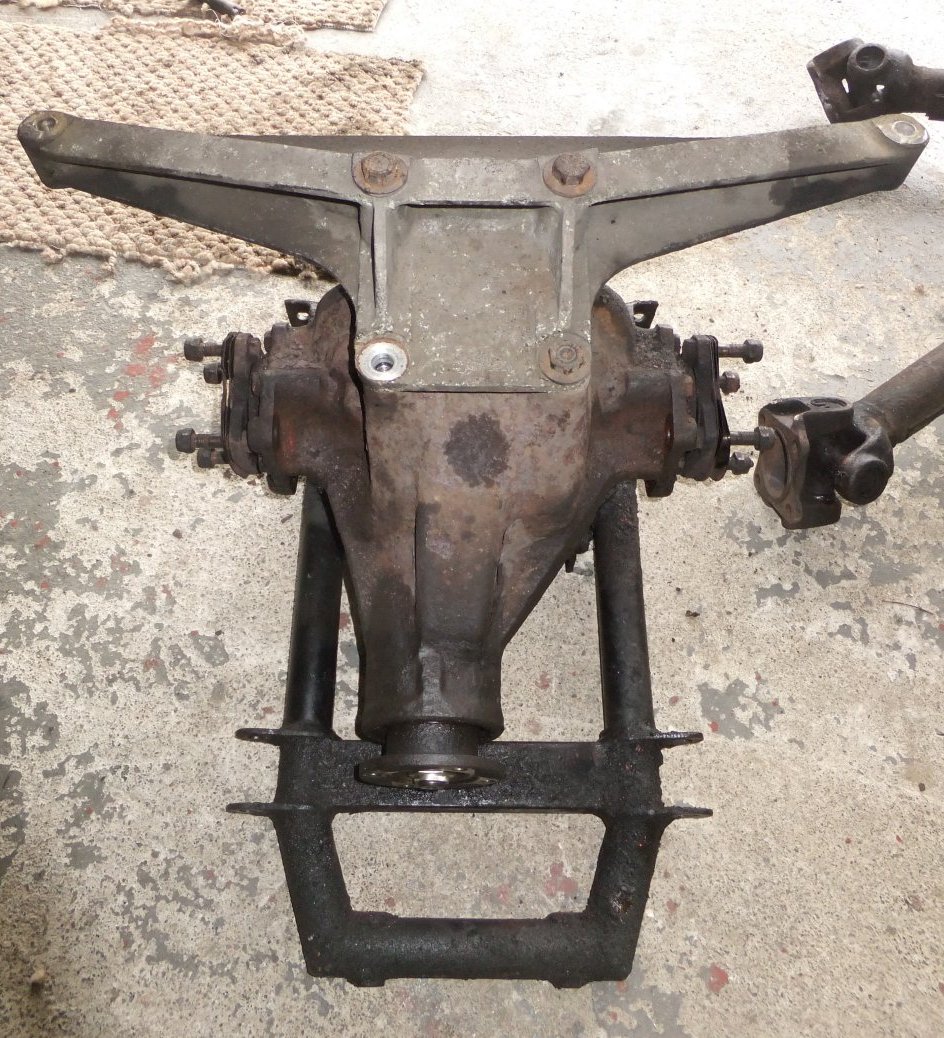

Looking at the driveshaft yes it does look a bit odd, but on the other hand the bolts for the diff hanget look symmetrical about the centre line, and it's the input shaft of the diff that might be offset? It's no often we get to look at them from above so this might be normal? Perhaps someone else with a body off can take some pics?

If you didn't get a knock on the wheel it's unlikely there's any further damage but if want to check, vulnerable places are the bracket at the front of the trailing arm, and the bottom link which is at the rear of the suspension. These tend to buckle first (from experience!)

- Can I assume you are talking "left hooker" offside - that being the left hand side?

- Did you get any damage at all to the rear wheel - even a scuff?

Looking at the driveshaft yes it does look a bit odd, but on the other hand the bolts for the diff hanget look symmetrical about the centre line, and it's the input shaft of the diff that might be offset? It's no often we get to look at them from above so this might be normal? Perhaps someone else with a body off can take some pics?

If you didn't get a knock on the wheel it's unlikely there's any further damage but if want to check, vulnerable places are the bracket at the front of the trailing arm, and the bottom link which is at the rear of the suspension. These tend to buckle first (from experience!)

Diff looks fine Adam, however clock the gearbox casting, its defo not a central exit, hence maybe it's supposed to be that way?

Whooops.....reverse that statement, not a central entry into the diff casting!.......looking upside down got my bearings (no pun) wrong.

Whooops.....reverse that statement, not a central entry into the diff casting!.......looking upside down got my bearings (no pun) wrong.

Edited by Llanelli-Rob on Tuesday 14th October 19:31

Mine was exactly the same mate ,

the diff is slightly offset to the offside just like that

Nothing to worry about looking at the pictures

Just make sure the shafts are straight

But to be honest you would need a hell of a shunt to push the diff over like that

And would be very noticeable marks on the chassis

Hope this helps,

Zack

the diff is slightly offset to the offside just like that

Nothing to worry about looking at the pictures

Just make sure the shafts are straight

But to be honest you would need a hell of a shunt to push the diff over like that

And would be very noticeable marks on the chassis

Hope this helps,

Zack

Fibreglass is very flexible and takes a lot out of the impact..Also as the chassis is low it may not of been damaged ..Check all the mounts..Diff..Trailing arms and pins...Engine...Did the exhaust get hit..If so then check the manifolds as they can crack being cast..In fact check everything over meticulously but you may be lucky and just have a damaged shell which even in the state its in is repairable...Putting another shell on may be a solution but i would be surprised if it goes straight on without any fettling...Remember these cars were hand built..

The diff input shaft is offset relative to the centre line of the car chassis and it's meant to be that way. In the diff housing the actual differential gears are central , this puts the crown wheel and pinion (and hence input shaft) off to one side a little making the prop seem pi55ed

Try googling some images (can't seem to get them to copy onto here - maybe iPhone issues) of diffs and you'll See what I mean.

Try googling some images (can't seem to get them to copy onto here - maybe iPhone issues) of diffs and you'll See what I mean.

Edited by Rockettvr on Tuesday 14th October 21:12

Gents, thanks. Big relief re the diff. Thought the project might be a non-starter.

Adam thanks, spot on. The bottom link has a ripple in it, guessing they're impossible to find so will need to get current one repaired. Bracket looks okay. yes car is RND and damage is to passenger side.

Left rear wheel could have been hit but no marks or anything obvious. Appears the fibreglass took almost all of the impact.

Zacky, I don't know how hard to find these airboxes are? If you have a good one it would be a great help. If you come across it would you mind p.m.ing me please?

Need to do a proper measure on the weekend, but distance (at outrigger height) between tyres on LHS is circa 1770mm and circa 1790 on the RHS. Somthing ain't quite straight.

Really appreciate your help guys.

Adam thanks, spot on. The bottom link has a ripple in it, guessing they're impossible to find so will need to get current one repaired. Bracket looks okay. yes car is RND and damage is to passenger side.

Left rear wheel could have been hit but no marks or anything obvious. Appears the fibreglass took almost all of the impact.

Zacky, I don't know how hard to find these airboxes are? If you have a good one it would be a great help. If you come across it would you mind p.m.ing me please?

Need to do a proper measure on the weekend, but distance (at outrigger height) between tyres on LHS is circa 1770mm and circa 1790 on the RHS. Somthing ain't quite straight.

Really appreciate your help guys.

adam quantrill said:

Take off the good bottom link from the other side, and have someone make a replica. It's only 3 bits of pipe welded together and the bushes pressed in.

'Only'...  you sound like my boss: his favourite word is 'just'.

you sound like my boss: his favourite word is 'just'.'Just' drive to the ends of the earth, 'just' do this job, 'just' do that...

Ah yes bushes.... Superflex? RT?

Thanks Zack, no screaming hurry as you can imagine...

Adam, thanks, should be a doddle.... (actually it might not be too hard, will get a matching set made).

Can't go ahead with ordering the nose and bumpers spoiler etc from Trevor until I know a bit more though.

Thanks Zack, no screaming hurry as you can imagine...

Adam, thanks, should be a doddle.... (actually it might not be too hard, will get a matching set made).

Can't go ahead with ordering the nose and bumpers spoiler etc from Trevor until I know a bit more though.

Wedg1e said:

adam quantrill said:

Take off the good bottom link from the other side, and have someone make a replica. It's only a measly 3 bits of pipe welded together and the bushes pressed in.

'Only'...  you sound like my boss: his favourite word is 'just'.

you sound like my boss: his favourite word is 'just'.'Just' drive to the ends of the earth, 'just' do this job, 'just' do that...

Gassing Station | Wedges | Top of Page | What's New | My Stuff