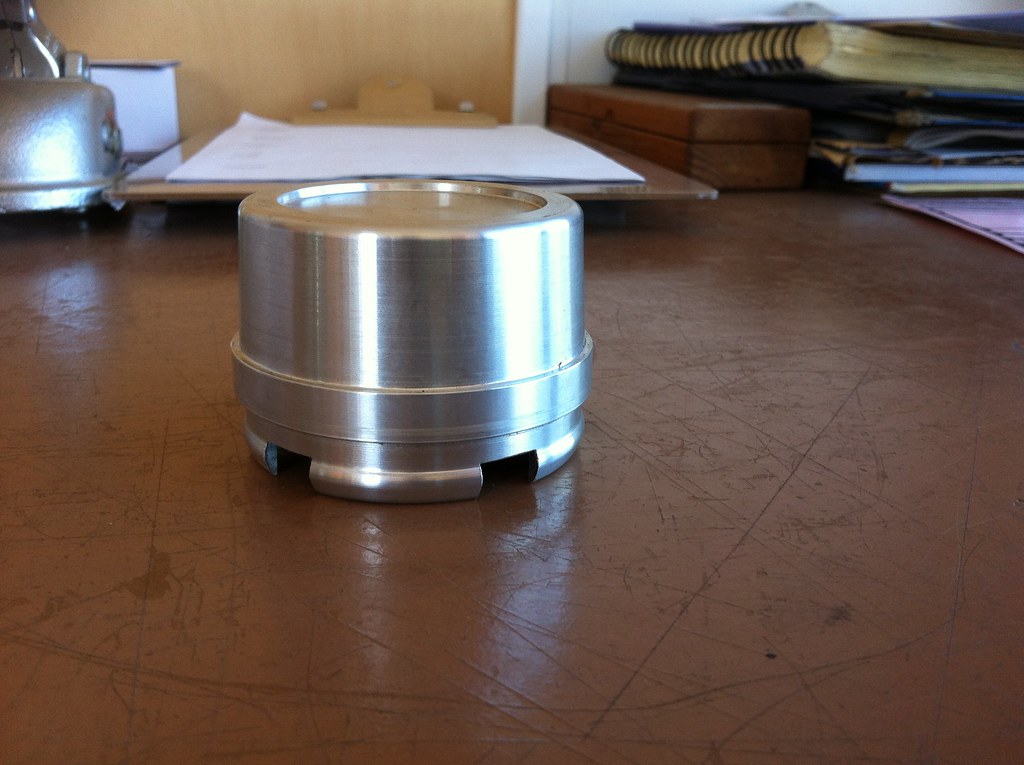

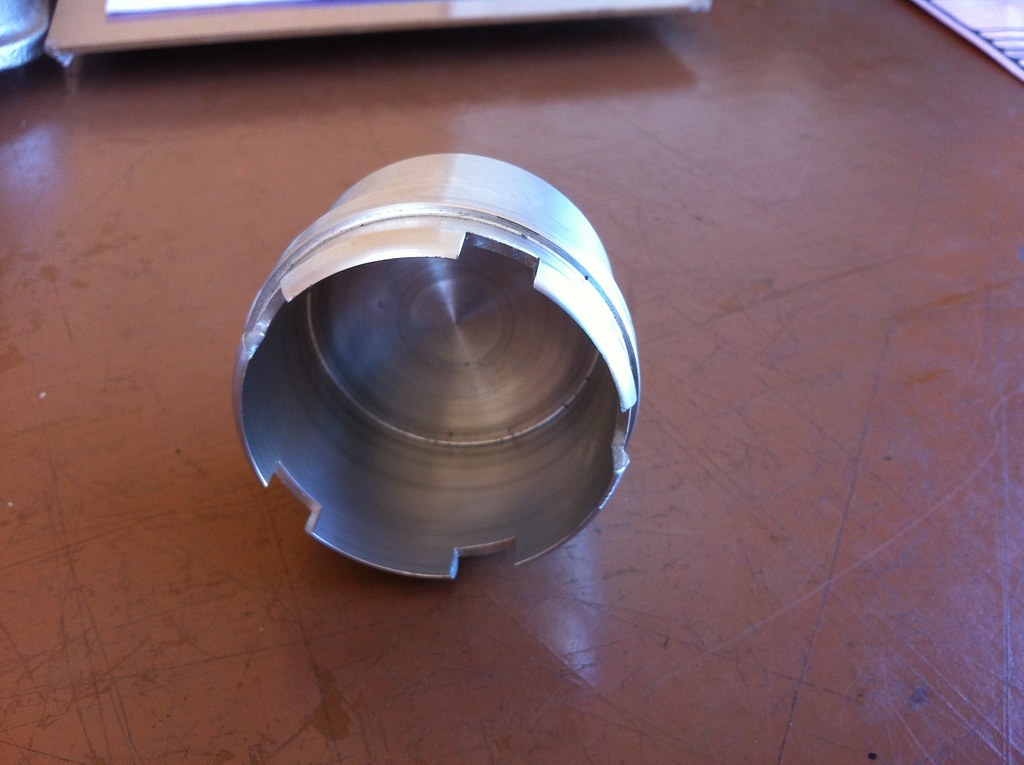

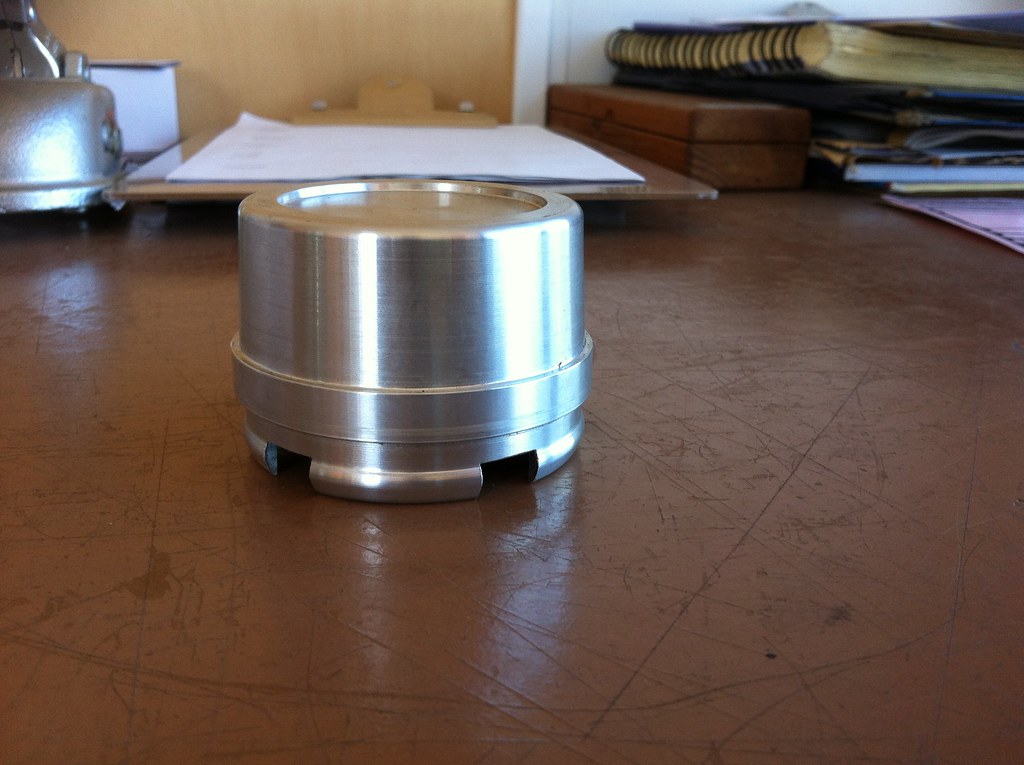

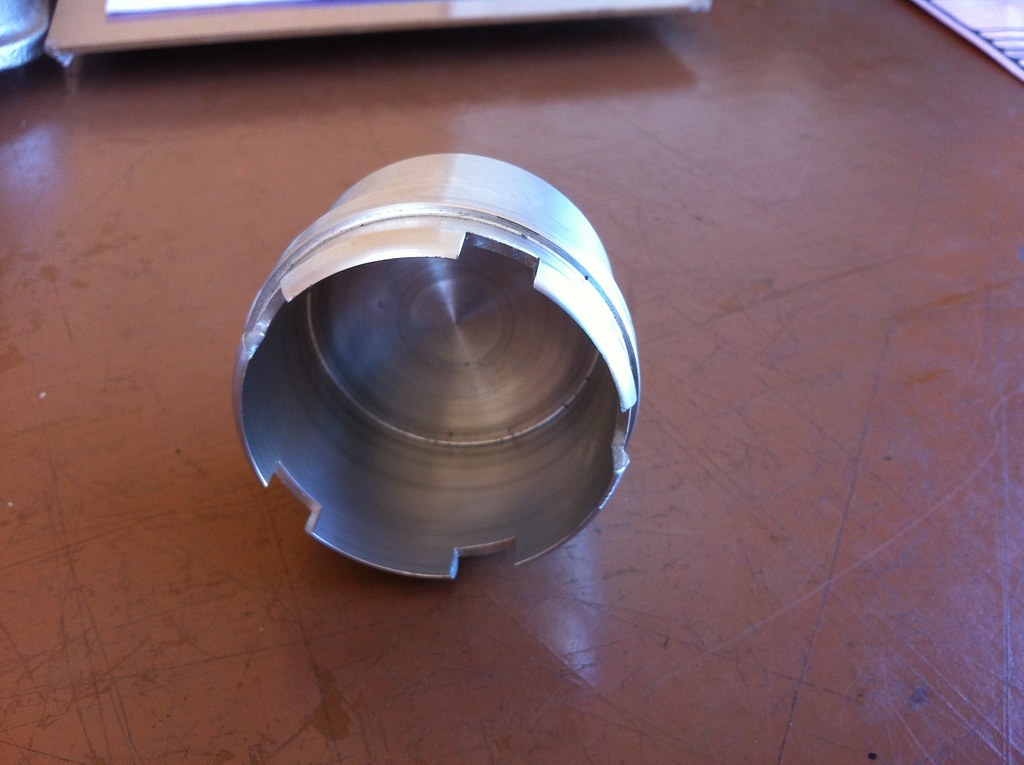

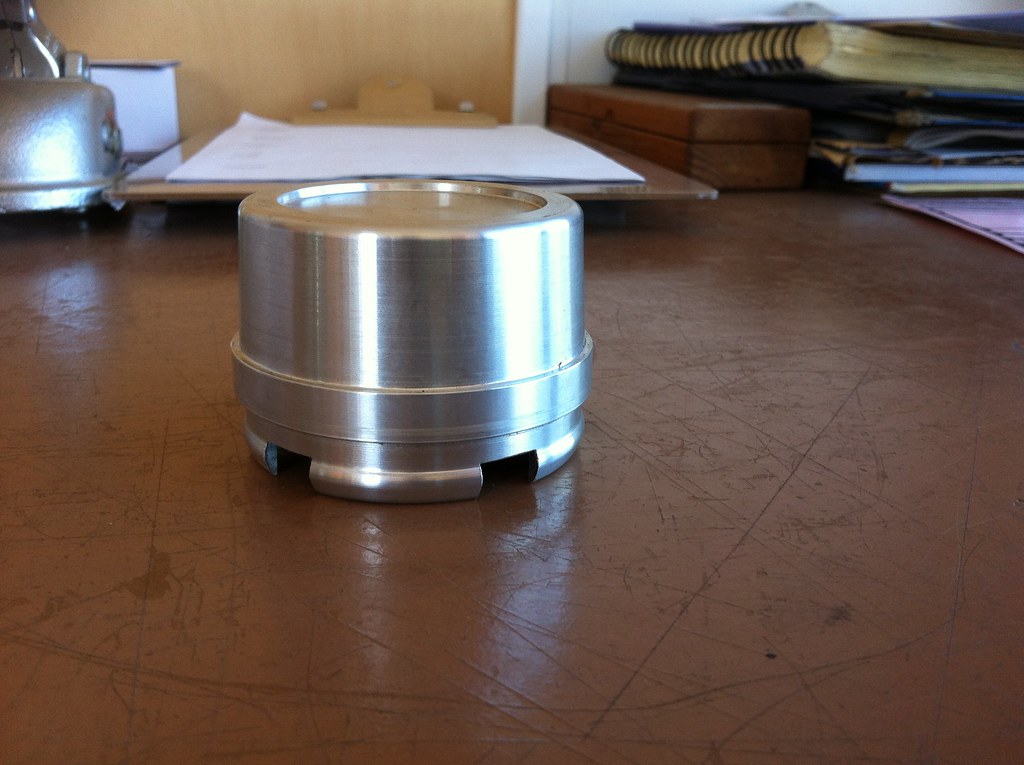

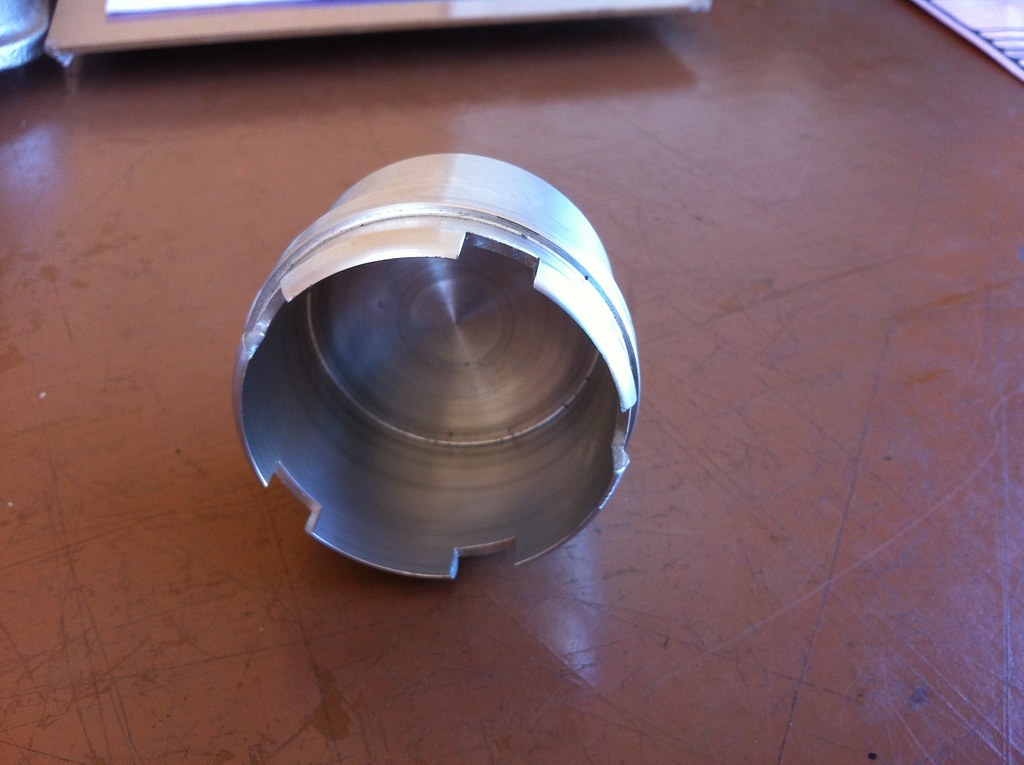

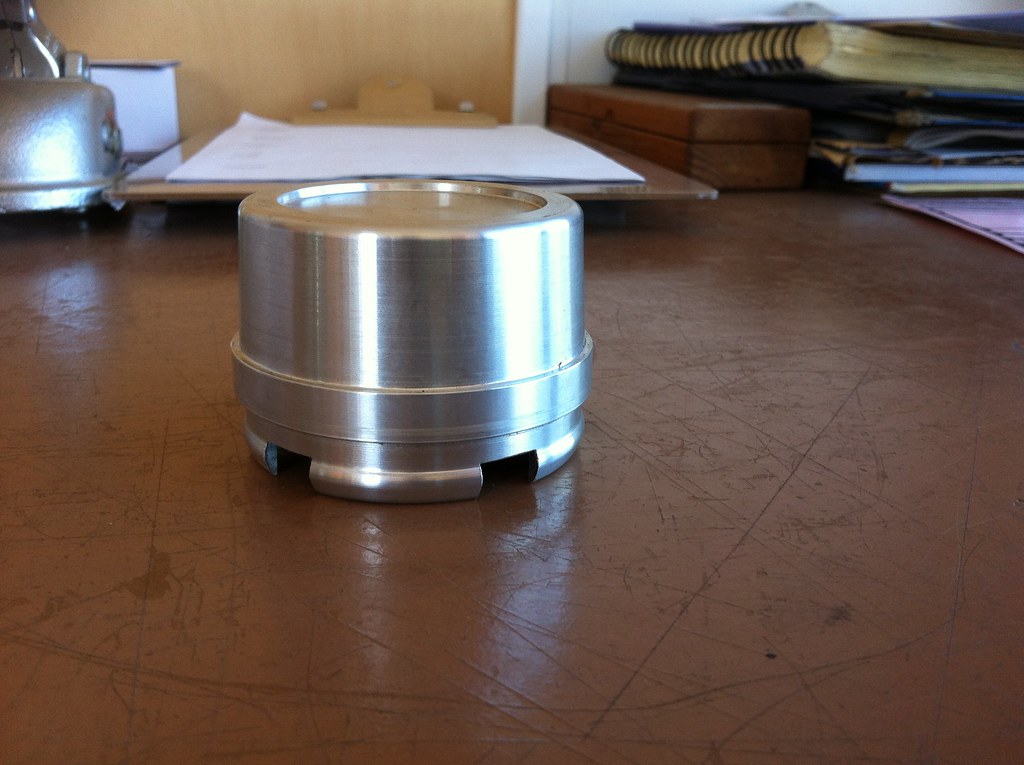

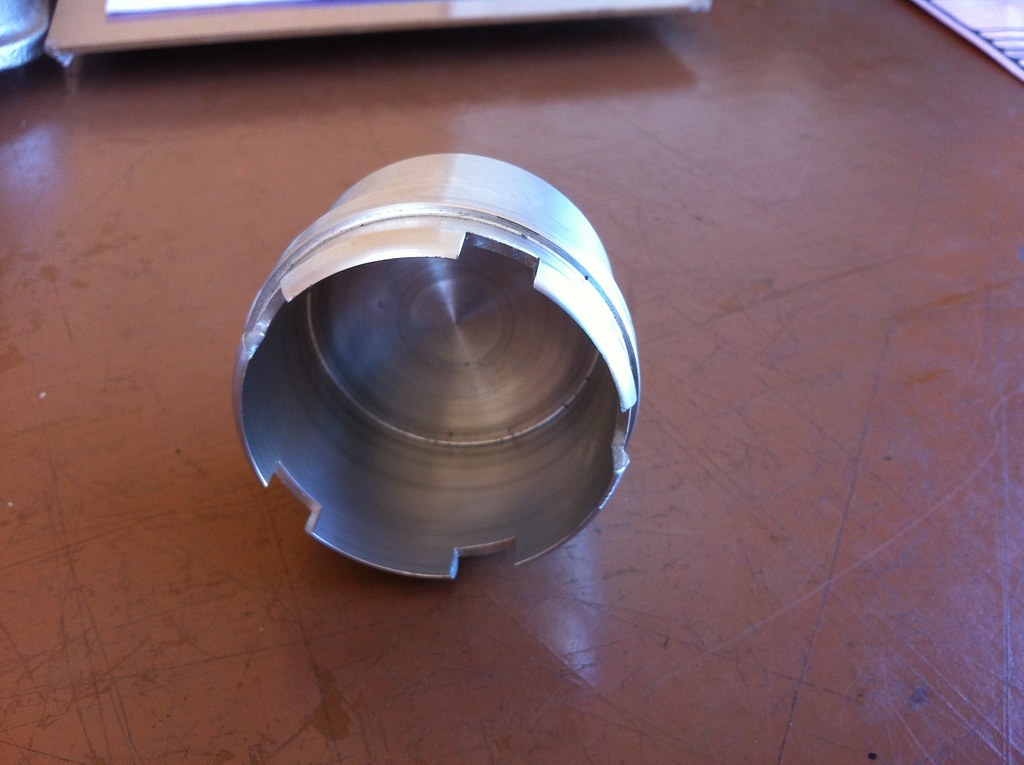

wheel centres in ally

Discussion

just finished the prototype centre in ally needs a little adjustment to the measurements to the holding bump its good from a fitment point but is slightly loose once in the wheel so next one should be perfect the picture makes it look parallel sided but it is tapered as per the original,the finish is just off the tool so easily polished anodised what you want.

john

Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr

john

Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickrjust finished the prototype centre in ally needs a little adjustment to the measurements to the holding bump its good from a fitment point but is slightly loose once in the wheel so next one should be perfect the picture makes it look parallel sided but it is tapered as per the original,the finish is just off the tool so easily polished anodised what you want.

john

Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr

john

Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr Untitled by hmstvr, on Flickr

Untitled by hmstvr, on Flickr Untitled by hmstvr, on Flickr

Untitled by hmstvr, on FlickrHell, if I had the wheels they need I would be beating a path to your door. Looks good.

Something that always bugged me though, they were just a push fit.

Edit. PS. There is one in a hedge outside Nuneaton. Pretty sure I know roughly where though I could not find it at the time.....

Something that always bugged me though, they were just a push fit.

Edit. PS. There is one in a hedge outside Nuneaton. Pretty sure I know roughly where though I could not find it at the time.....

Edited by jmorgan on Tuesday 17th June 08:58

Hi John...Fantastic bit of workmanship as always...I will definitely have a set, However as mentioned would the lugs be flexible enough?...I did look into this a while back and that was the challenge..Could a small thread be applicable with an O ring?....Also every time i have had tyres fitted the caps have had to be knocked out from behind with the handle of a screwdriver..Again would this cause damage to the lugs?...Oxidisation may prove to be a bit of a pain, Especially if they are left for long periods of time.

Looking forward to the finished item....Ziga

Looking forward to the finished item....Ziga

mrzigazaga said:

Im really glad that someone has taken the time to actually make them...I guess the OZ wheel centres could be next...Lovely bit of polish alloy...Who could resist... ..

..

PS: Any luck with the catch tank...I take it you received the plastic one?...Cheers...Ziga

Oz centres have already hit the shops zig, some time ago mind. ..

..PS: Any luck with the catch tank...I take it you received the plastic one?...Cheers...Ziga

adam quantrill said:

Corrosion can be a problem with polished aly. When I put my 400SE style ones on that someone had made from turned aly, they looked great for a couple of years, but now need polishing again. Perhaps they can be chromed?

Hi Adam, I think I have a set of those and they did polish up really well, however I have never had them on the car other than to see what they look like and make them fit. I have wondered if they would fade after extended use and pit there is anyway to coat them?

adam quantrill said:

Corrosion can be a problem with polished aly. When I put my 400SE style ones on that someone had made from turned aly, they looked great for a couple of years, but now need polishing again. Perhaps they can be chromed?

Chrome can be applied to any surface but with alloy you are better off polishing it and then either keeping it clean with a periodical application of autosol or liquid metal polish..You can use WD40 on polished alloy and it will keep the oxidisation down for quite a while or there are alloy wheel waxes that you can buy...Chroming alloy is a waste..Most chroming is over cheap metal.I was thinking about having some CNC or injection moulded which can be expensive due to set up costs..I could actually make a two part mould to cast some in resin and then have them chrome plated..Its a bit messy, Especially as i would have to do it indoors...I used to help a friend years ago making skulls..ashtray's...Candle holders, Mad statues and garden ornaments and learnt the lost wax process..Two part moulding and cold casting..However the garage that we used was covered in plaster dust...Rubber and resin dust particles..Not to mention the inhalation of thinners and resin activators...I always used a mask but because he was a bit of a lad he never..Subsequently he sadly passed away due to lung cancer, I stopped doing it and haven't done so for over 20 years....R.I.P Gary you mad bastid...Ziga

adam quantrill said:

Corrosion can be a problem with polished aly. When I put my 400SE style ones on that someone had made from turned aly, they looked great for a couple of years, but now need polishing again. Perhaps they can be chromed?

Anodising is probably better for ali and will stop the corrosion.Phil

420 SEAC

Gassing Station | Wedges | Top of Page | What's New | My Stuff

- would take bloody ages on a manual lathe though...

- would take bloody ages on a manual lathe though...