Hard to get parts

Discussion

mrzigazaga said:

BODGE!... Sorry mate but that word is forbidden near my Wedge <snip>

Sorry mate but that word is forbidden near my Wedge <snip>

I understand completely - I was thinking more of a 'get you home' emergency repair, or fixing up your old one and carrying it in the boot as a spare.....that kind of thing. Sorry mate but that word is forbidden near my Wedge <snip>

Sorry mate but that word is forbidden near my Wedge <snip>Also - having done kits etc - I wonder if one of the Triumph cables might fit - I think the 2000/2500 saloon and Spitfire had a very similar (carb) end, but no idea if pedal end is useable in a TVR or if it's long enough.

I do know that actually quite a bit of BL stuff like cables was more interchangeable than they let on, especially for an emergency.

3D stuff - all looks neat - would be great if some of that could be printed....

Edited by RCK974X on Tuesday 25th November 22:21

ed_crouch said:

I could machine the roof lugs out of Aluminium and anodise them if you want, although I'd also be interested to see how they come out of the 3d printer. "Additive Manufacture" as the corporates call it is really catching on. Powder metallurgy (another buzzword) conrods have been about for years. All has its origins in sintering.

The main tricky bit with the roof lugs is probably getting the screws out cleanly? Mine were a bit crumbly...

Anodised sound nice...Even brushed alloy would be equally as good...I know Adam H in Oz made some for himself and i did think about having a go at something similar, Also including a set of screws and a nitrile 0.05mm gasket.The main tricky bit with the roof lugs is probably getting the screws out cleanly? Mine were a bit crumbly...

Like you say the screws seem to chew up the fibreglass so maybe when replacing them its a good idea to bond in a small rawlplug, Maybe metal with some polyurethane filler.

Thinking about it they would probably be easier to cast in cold metal casting...

RCK974X said:

I understand completely - I was thinking more of a 'get you home' emergency repair, or fixing up your old one and carrying it in the boot as a spare.....that kind of thing.

Also - having done kits etc - I wonder if one of the Triumph cables might fit - I think the 2000/2500 saloon and Spitfire had a very similar (carb) end, but no idea if pedal end is useable in a TVR or if it's long enough.

I do know that actually quite a bit of BL stuff like cables was more interchangeable than they let on, especially for an emergency.

3D stuff - all looks neat - would be great if some of that could be printed....

Yeah it would seem strange if TVR actually manufactured a cable..Modified is more applicable i think...Sometimes i say to myself..."Why"...Am i alone in this thought...I wonder.Also - having done kits etc - I wonder if one of the Triumph cables might fit - I think the 2000/2500 saloon and Spitfire had a very similar (carb) end, but no idea if pedal end is useable in a TVR or if it's long enough.

I do know that actually quite a bit of BL stuff like cables was more interchangeable than they let on, especially for an emergency.

3D stuff - all looks neat - would be great if some of that could be printed....

All sounds good and hopefully something will emerge from it all...I can't wait either...

Cheers...Ziga

Sireatalot said:

how strong are parts that have been 3d printed ?? would the part strength compare to the same part made in fibreglass for example ?

Just had a conversation with the head of 3D printing at Warwick University. He mentioned "It’s an ingenious idea you have there – but – it may not be practical, the printer is not capable of using structural plastics that would be required for these wheel caps. 3D printing is only currently capable of soft-thermoset plastics,

I guess that answers the "strength" question

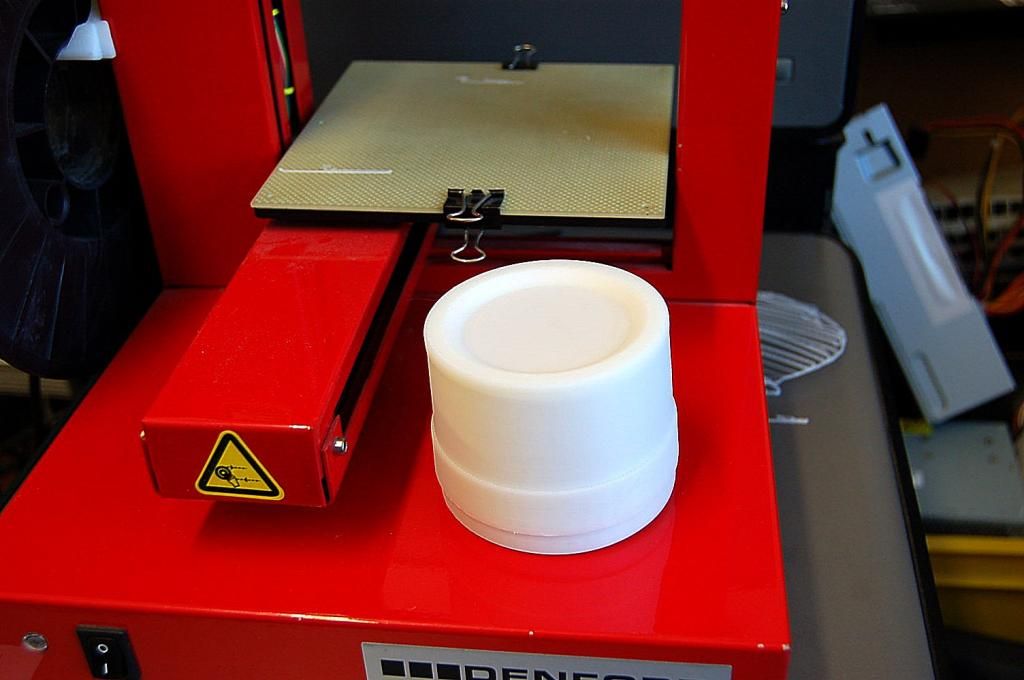

Looks like an industrial printer. Looks pretty strong stuff. After all things that we would look to print would just hang there in theory.

https://www.youtube.com/watch?v=WmDz7Q9_h6c

Rob

https://www.youtube.com/watch?v=WmDz7Q9_h6c

Rob

gmw9666 said:

Sireatalot said:

how strong are parts that have been 3d printed ?? would the part strength compare to the same part made in fibreglass for example ?

Just had a conversation with the head of 3D printing at Warwick University. He mentioned "It’s an ingenious idea you have there – but – it may not be practical, the printer is not capable of using structural plastics that would be required for these wheel caps. 3D printing is only currently capable of soft-thermoset plastics,

I guess that answers the "strength" question

however.. would it matter for the wheel caps though ?? They aren't structural components and as long as they grip the alloy effectively and are 'weatherproof', so wouldn't disintegrate in the rain and road muck.. they should be fine..

edit - Just had another thought... a little out of the box..

If the 3d parts weren't strong enough and suitable, could a mould be made instead from the 3d printer to then produce the parts from fibreglass etc...

Edited by Sireatalot on Wednesday 26th November 13:22

My Mate's father owns an engineering company and they have a super sized 3D printer (600mm x 600mm x 1000mm) His actually cures the polymer as it is printed, basically making the printed item as strong as a solid block of polymer. Ill have a chat about strength with him when I see him next.

pwd95 said:

Not a bad attempt. Although I think the 'Engineer 1949' solution looks the better option. This one will need some finishing and there's a question mark over the suitability of the material etc.

Glad to help though.

Wyn

Have to agree with you there mate..Although it does throw up numerous possibilities for other "Hard to get" Parts...De-mister vents..Roof lugs..Ashtrays...Glad to help though.

Wyn

It amazing how people band together to help everyone else out..Well done....

Mind you what would be the pro's and con's of both..

i:e Each cost of raw materials...Time taken to make...Setting up of equipment...Durability of finished product..Longevity....

How would the flanges...(ooo missus) be applied to the 3D printed version...I think this is a very exciting time...What with TVR being bought up and like a Phoenix rising from the ashes...It would be fantastic to create enough "Hard to get parts" for all the Wedges and a very small replacement of each stashed away for future Wedge enthusiast to fight over..... Or start making their own "Hard to get parts"...

i:e Each cost of raw materials...Time taken to make...Setting up of equipment...Durability of finished product..Longevity....

How would the flanges...(ooo missus) be applied to the 3D printed version...I think this is a very exciting time...What with TVR being bought up and like a Phoenix rising from the ashes...It would be fantastic to create enough "Hard to get parts" for all the Wedges and a very small replacement of each stashed away for future Wedge enthusiast to fight over..... Or start making their own "Hard to get parts"...

mrzigazaga said:

How would the flanges...(ooo missus) be applied to the 3D printed version...

well. couple of ways.. easiest would be to have the flanges modelled as part of the whole 3d model so when it prints, it is printed as a complete part. This is how I would have liked the model to be but I was having issues getting the flanges modelled properly.suppose they could also just be filed into the model but this would be time consuming and probably remove some of the inherent strength of the printed part.

Hi Dom...First I'm a little confused..Did you make it or create the image and then Wynn made it???....Where the flanges scanned in also?...Just wondering why a 3D plastic printer modeller is only printing in 2.98.04D instead of 3....Have you been fiddling....Actually don't let Mr Fiddle near it for f ksake ..Mind you we might get the worlds first multi-screwdriver that is just a screwdriver...Amazing...(Only kidding mate)...

ksake ..Mind you we might get the worlds first multi-screwdriver that is just a screwdriver...Amazing...(Only kidding mate)...

Who's machine is it?

ksake ..Mind you we might get the worlds first multi-screwdriver that is just a screwdriver...Amazing...(Only kidding mate)...

ksake ..Mind you we might get the worlds first multi-screwdriver that is just a screwdriver...Amazing...(Only kidding mate)...

Who's machine is it?

Hiya Mark

The worlds first mulitscrewdriver thats just a screwdriver.... interesting thought that. Sounds like a socket set with only one socket haha.

haha.

I created the 3d model on my pc and sent the file through to Wyn as he offered to 3d print on a printer he has access to.

Regarding the flanges.. I wasnt able to get the compound curves modelled correctly in so short time so sent through a model with out them. However, i did include enough material / depth / space within the model to 'cut' and create the flanges at a later date.

intention being to 1- see if the centre cap could be 3d printed as per Rob's original post. and 2- im still going to work on the centre cap model to include the flanges.

with hindsight, the centre cap may have been an ambishous 1st 3d model ( I havnt attempted anything like it for years..) but with a little work and practice, anything should be possible.

Keep the ideas coming though as I really enjoyed modelling it and would like to do more..

Hope i havnet caused more confusion..

Cool. I'm off now to draw up plans for single use multiscrewdriver

The worlds first mulitscrewdriver thats just a screwdriver.... interesting thought that. Sounds like a socket set with only one socket

haha.

haha.I created the 3d model on my pc and sent the file through to Wyn as he offered to 3d print on a printer he has access to.

Regarding the flanges.. I wasnt able to get the compound curves modelled correctly in so short time so sent through a model with out them. However, i did include enough material / depth / space within the model to 'cut' and create the flanges at a later date.

intention being to 1- see if the centre cap could be 3d printed as per Rob's original post. and 2- im still going to work on the centre cap model to include the flanges.

with hindsight, the centre cap may have been an ambishous 1st 3d model ( I havnt attempted anything like it for years..) but with a little work and practice, anything should be possible.

Keep the ideas coming though as I really enjoyed modelling it and would like to do more..

Hope i havnet caused more confusion..

Cool. I'm off now to draw up plans for single use multiscrewdriver

Cool..Ill have one...But leave off the "Buttery biscuit base"...(Im still laughing about that)...So as regards to the printing its down to the quality of the print...Im understanding how it works but never did any of that just old school resins and such...I was amazed when it was first shown possible..(Too many years ago now..) 30 or so...I remember thinking then that this technology will be swallowed up by massive corporate companies as its possibilities are incredible, I did think that eventually it will become affordable to the every day man..If there is such a thing...Strange...First they get rid of manual labour in manufacturing plants and replace them with robots...Then they find a machine that takes the place of the robot...Then they use the machine to make a humanoid who builds the machine...."Wait...STOP...This could be the start of the...."Wedge against the machine".....A REAL TERMINATOR...I just hope he's driving a Wedge.....

PS:...Bloody iMac

PS:...Bloody iMac

Edited by mrzigazaga on Thursday 27th November 23:13

Gassing Station | Wedges | Top of Page | What's New | My Stuff