GT86 HKS Version 2 Supercharger Install

Discussion

I’ve started this thread which will probably be like a small Mods blog as i’ve never really set one up for my car.

I’ve always thought about boosting my GT86 but never really decided on a route or if it would be viable. But after driving Maz’s car a fair bit on the road and once on track it made sense to go the Centrifugal Supercharged route.

For the style of driving and type of roads I drive it made sense. The HKS supercharger to me just feels like a bigger block NA car. You don’t get that sudden rush of power in one peak. It just keeps climbing and climbing. Over 6.5krpm is just awesome!

Being hands on and quite technical and capable I decided i’d fit the kit myself as a sense of achievement and a little personal project with the help from Maz at HKS Europe. We picked this weekend as it gives me the extra bank holiday day and fitted in best with Adrian mapping it at Fensport this week.

We started the install at about 5:30 Friday evening with the plan to get all the prep work and old bits off the car so that Saturday morning we could start fitting the go-faster bits.

The Manual is relatively easy to understand although at times the Japanese to English translation is a little poor. But luckily with having Maz to help he could read the Japanese ones and it all made sense!

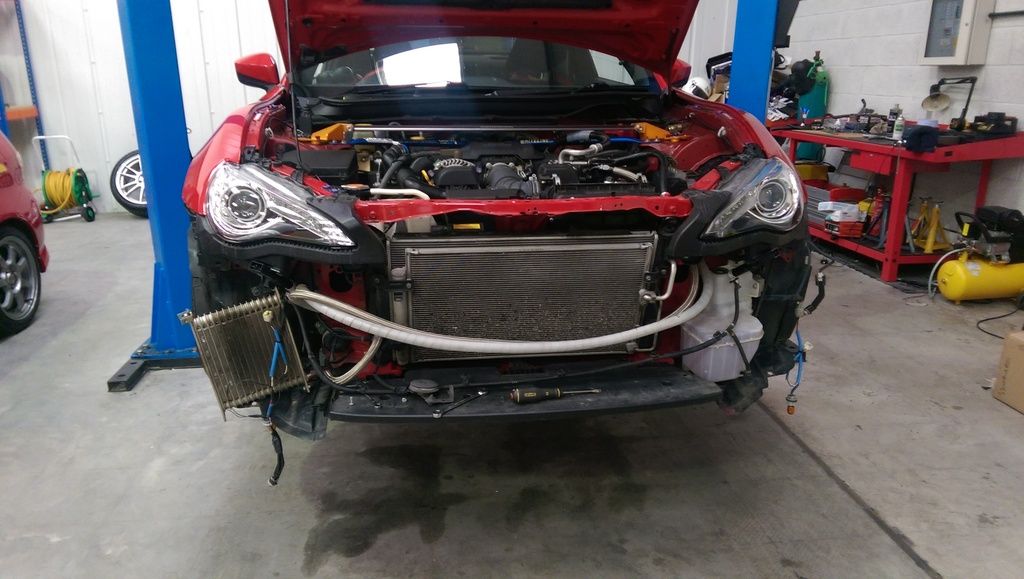

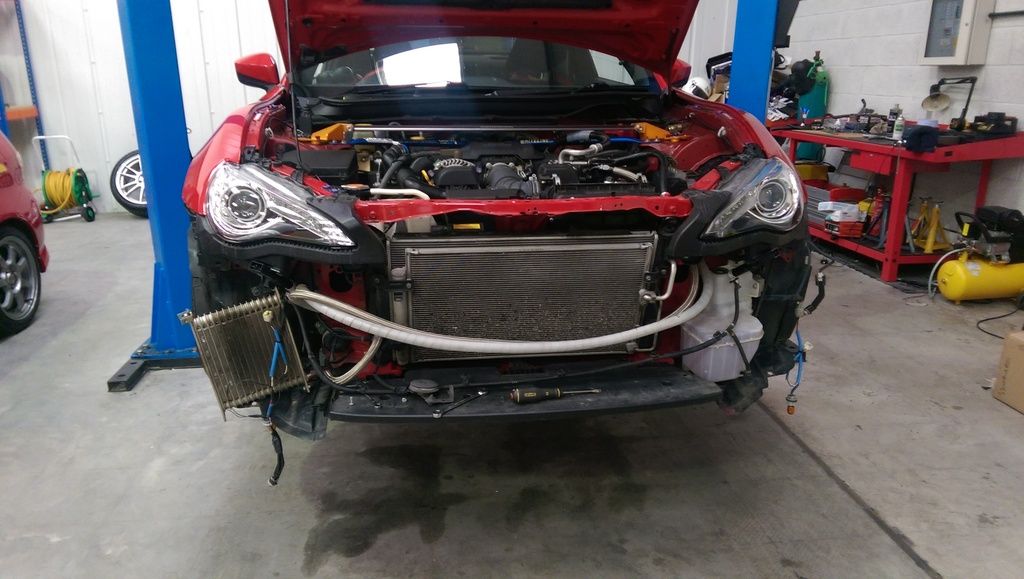

First thing is to get the Bumper off and expose the front of the car. Along with unbolting the crash bar as we fit some brackets to this for the Intercooler.

We also remove the bonnet catch and top bonnet support for later.

Also free’d up the Oil cooler and made sure this was out the way temporarily whilst fitting the new parts.

What’s impressive with the HKS kit is the amount of dedication and precision gone into planning the kits. We spent a fair couple of hours adding clips to existing hoses and supporting stock parts for the preparation of them receiving positive boost. Parts like the canister can under the manifold. Usually the hoses are just pushed on loosely. But now they’ll see positive pressure HKS actually supply clips to add to these hoses to make sure they don’t pop off! It would be a real PITA if one popped after install! It just gives a little bit of piece of mind that you’re adding reliability.

Interestingly Version 1 of the supercharger didn’t have these extras! But they added them for Version 2.

Once this was all done and the fiddly bits out of the way we had the car ready to receive boost! We have to add a bracket to the underside of the Crash beam which will be used to support the intercooler so we got this added and in place. This is fiddly as you’ve got to get a nut on the bolt which is half way along from an opening at the end! We got there in the end!

Also had to cut a little channel in the upper bonnet support for the charge pipe to come back into the engine bay.

Next up was fitting the actual compressor to the car. The bracket is very substantial and quality is outstanding. Everything just fitting into place lined up and went perfectly. The bracket basically fits into the existing holes in the Alternator and fits in really well. After a few bolts, belt on and tensioner released we had the unit in place!

We then went ahead and mounted the intercooler in place. It looks as though it sits on the bottom shelf. But it actually hanging from 2 bracket. Its a very good fit and the HKS kit hasn’t failed to impress regarding quality and fitment!

This charger uses a traction fluid system with it’s own oil cooler to lubricate the charger components. A tank is mounted just beside the airbox, using two existing holes in the support just below the bonnet release. After cutting the supplied hoses to length, adding an inline filter and clipping it all on. The traction fluid system was in place along with the cooler, bottle, lines and filter. It's important to get the traction fluid cool and ensure everything is working correctly. As this can seriously damage the compressor if the fluid isn't there as expected!

Now to put the stock airbox back into it’s location ready for the intake suction pipe.

Any airbox or induction that uses the stock intake pipe location should fit with this kit.

Here we put a restrictor plate between the supercharger and the intake air box. The restrictor is a simple plate which sandwiches between the intake pipe and the charger with two gaskets. It restricts the power from the capable 400hp to about 300hp to use on a stock engine block! The restrictor is great as it keeps all the available torque and power low and and just clips the peak power towards the top end. You can of course run it without a restrictor if you dare on a stock engine!

The great thing with this unit is if you do decide to go for a forged engine you can simply remove the restrictor, tweak the map and you’ll be able to produce around 400hp comfortably with the same kit.

We then plumbed in the intercooler which is a fiddly job as there isn’t much room, especially if you have the oil cooler installed too! This kit was obviously designed, tested and fitted in Japan where they do not have HID headlights also meaning they haven't got the headlight washers! Which actually get in the way a fair bit on the UK cars as the headlight washers sit just where the pipe wants to naturally sit. But after some persuasion and careful positioning it does all go back in and the headlight washer still works.

Moving on by connecting up the throttle body intake pipe from the intercooler. This bit was straight forward. The pipe sits in the neat hole that was cut earlier on in the process. All connecting up and on the throttle body. We have a completed plumbed in Supercharger.

We have to take a vacuum line from the vacuum brake line so that the Recirc valve can work. For this we simply take a T-Piece in the original vacuum line and connect it to the valve.

At this point the install is done! We topped up the traction fluid tank. Fired it up and ensured there are no air leaks and fluid is circulating ok.

Starts first time and the sound is just fantastic. A real rushing of air and breathing sound!

One with the final bits like the bumper, and side indicators etc. And it’s finished!

All together it took us around 12 hours with two of us working on it. What helped was Maz’s ability to know stuff as he’d already done it on his car. Little tips and tricks to make things easier and the knowledge of knowing what we we’re un-doing was correct! The manual makes it easy as the install is split up into smaller chunks of work. So you’re only ever aiming for one goal at a time. Such as ‘Fit the intercooler’ - ‘For this you will need’. Rather than tackling the entire project with all the bits in one go.

What a difference it makes!

I’ve always thought about boosting my GT86 but never really decided on a route or if it would be viable. But after driving Maz’s car a fair bit on the road and once on track it made sense to go the Centrifugal Supercharged route.

For the style of driving and type of roads I drive it made sense. The HKS supercharger to me just feels like a bigger block NA car. You don’t get that sudden rush of power in one peak. It just keeps climbing and climbing. Over 6.5krpm is just awesome!

Being hands on and quite technical and capable I decided i’d fit the kit myself as a sense of achievement and a little personal project with the help from Maz at HKS Europe. We picked this weekend as it gives me the extra bank holiday day and fitted in best with Adrian mapping it at Fensport this week.

We started the install at about 5:30 Friday evening with the plan to get all the prep work and old bits off the car so that Saturday morning we could start fitting the go-faster bits.

The Manual is relatively easy to understand although at times the Japanese to English translation is a little poor. But luckily with having Maz to help he could read the Japanese ones and it all made sense!

First thing is to get the Bumper off and expose the front of the car. Along with unbolting the crash bar as we fit some brackets to this for the Intercooler.

We also remove the bonnet catch and top bonnet support for later.

Also free’d up the Oil cooler and made sure this was out the way temporarily whilst fitting the new parts.

What’s impressive with the HKS kit is the amount of dedication and precision gone into planning the kits. We spent a fair couple of hours adding clips to existing hoses and supporting stock parts for the preparation of them receiving positive boost. Parts like the canister can under the manifold. Usually the hoses are just pushed on loosely. But now they’ll see positive pressure HKS actually supply clips to add to these hoses to make sure they don’t pop off! It would be a real PITA if one popped after install! It just gives a little bit of piece of mind that you’re adding reliability.

Interestingly Version 1 of the supercharger didn’t have these extras! But they added them for Version 2.

Once this was all done and the fiddly bits out of the way we had the car ready to receive boost! We have to add a bracket to the underside of the Crash beam which will be used to support the intercooler so we got this added and in place. This is fiddly as you’ve got to get a nut on the bolt which is half way along from an opening at the end! We got there in the end!

Also had to cut a little channel in the upper bonnet support for the charge pipe to come back into the engine bay.

Next up was fitting the actual compressor to the car. The bracket is very substantial and quality is outstanding. Everything just fitting into place lined up and went perfectly. The bracket basically fits into the existing holes in the Alternator and fits in really well. After a few bolts, belt on and tensioner released we had the unit in place!

We then went ahead and mounted the intercooler in place. It looks as though it sits on the bottom shelf. But it actually hanging from 2 bracket. Its a very good fit and the HKS kit hasn’t failed to impress regarding quality and fitment!

This charger uses a traction fluid system with it’s own oil cooler to lubricate the charger components. A tank is mounted just beside the airbox, using two existing holes in the support just below the bonnet release. After cutting the supplied hoses to length, adding an inline filter and clipping it all on. The traction fluid system was in place along with the cooler, bottle, lines and filter. It's important to get the traction fluid cool and ensure everything is working correctly. As this can seriously damage the compressor if the fluid isn't there as expected!

Now to put the stock airbox back into it’s location ready for the intake suction pipe.

Any airbox or induction that uses the stock intake pipe location should fit with this kit.

Here we put a restrictor plate between the supercharger and the intake air box. The restrictor is a simple plate which sandwiches between the intake pipe and the charger with two gaskets. It restricts the power from the capable 400hp to about 300hp to use on a stock engine block! The restrictor is great as it keeps all the available torque and power low and and just clips the peak power towards the top end. You can of course run it without a restrictor if you dare on a stock engine!

The great thing with this unit is if you do decide to go for a forged engine you can simply remove the restrictor, tweak the map and you’ll be able to produce around 400hp comfortably with the same kit.

We then plumbed in the intercooler which is a fiddly job as there isn’t much room, especially if you have the oil cooler installed too! This kit was obviously designed, tested and fitted in Japan where they do not have HID headlights also meaning they haven't got the headlight washers! Which actually get in the way a fair bit on the UK cars as the headlight washers sit just where the pipe wants to naturally sit. But after some persuasion and careful positioning it does all go back in and the headlight washer still works.

Moving on by connecting up the throttle body intake pipe from the intercooler. This bit was straight forward. The pipe sits in the neat hole that was cut earlier on in the process. All connecting up and on the throttle body. We have a completed plumbed in Supercharger.

We have to take a vacuum line from the vacuum brake line so that the Recirc valve can work. For this we simply take a T-Piece in the original vacuum line and connect it to the valve.

At this point the install is done! We topped up the traction fluid tank. Fired it up and ensured there are no air leaks and fluid is circulating ok.

Starts first time and the sound is just fantastic. A real rushing of air and breathing sound!

One with the final bits like the bumper, and side indicators etc. And it’s finished!

All together it took us around 12 hours with two of us working on it. What helped was Maz’s ability to know stuff as he’d already done it on his car. Little tips and tricks to make things easier and the knowledge of knowing what we we’re un-doing was correct! The manual makes it easy as the install is split up into smaller chunks of work. So you’re only ever aiming for one goal at a time. Such as ‘Fit the intercooler’ - ‘For this you will need’. Rather than tackling the entire project with all the bits in one go.

What a difference it makes!

Nicely hidden away in a regional forum.

Great job a nice writeup.

Would you mind if I asked mods to move this to Readers' Cars where it'll get more views?

Great job a nice writeup.

Would you mind if I asked mods to move this to Readers' Cars where it'll get more views?

Gassing Station | East Anglia | Top of Page | What's New | My Stuff