3" Scale Marshall Traction Engine

Discussion

NOW UPDATED ON PAGE 3

Due to popular demand I've finally got around to making this, the first of my vehicle writeups and a glimpse into the smoky world of steam power:

This is my 3" to the foot (1/4 Scale) miniature of the 1910 Marshall 10-Ton traction engine No.54587 "Pride of the Road", which I bought during the Christmas holidays. It is 56" long and weighs approximately 300kg dry.

This is the full-size engine:

As with many miniatures, the engine was built over a number of years from a commercially available kit of castings and a scale boiler.

The heart of any steam engine is the boiler/firebox assembly, especially on a traction engine where in lieu of a separate frame the boiler forms a chassis to which everything else mounts. According to the logbook that came with the engine, the steel boiler vessel was built in 1994, but due to other delays in completing the engine it was not steamed until 2008/9.

This is a relief, as a boiler normally has a lifespan or 10-15 years of weekly steaming until it needs major work or even total replacement to rectify internal corrosion and metal thinning rendering it unsafe for further use. At the same time, it means the boiler is early enough to sidestep more stringent paperwork on post-2002 builds. With use of modern tannin-based corrosion inhibiting water treatment, and the fact that being at uni cuts off a fair chunk of the show season, with luck this boiler will last a decent while longer than average.

The rest of the engine started life as a kit of raw foundry castings from Brunel Models of Lancashire. It was expertly machined and assembled by a very talented engineer called John in his home workshop. Machining one of these kits of no mean feat, calling for precision drilling, boring, honing, milling and turning with only very vague instructions and scaled-down blueprints of the real thing to work from! Other panelwork such as the tender (the coal and water storage compartment that extends backward from between the rear wheels) was hand-formed and riveted from sheet brass.

After 2 or 3 seasons of rallying the engine, John decided to sell it on to finance the building of another miniature in a larger scale. Noting my wanted advert on a traction engine forum, he got in touch. Although the engine was nearly a foot longer than the miniature Burrell I was after (more on why this is a problem later), at the price he offered it to me the opportunity was far too good to pass up - it was mechanically perfect but in need of some cosmetic TLC. Some dosh changed hands and I was now an engine owner!

So, in my Christmas holidays work commenced. An insulated storage area was constructed (letting lots of delicate pipework freeze on winter nights is a very bad and expensive idea). The next week we pinched a van from Dad's office and set off to Lancashire for a crash course in engine driving before loading up and bringing it home.

Driving a traction engine is not quite as simple as driving a car!

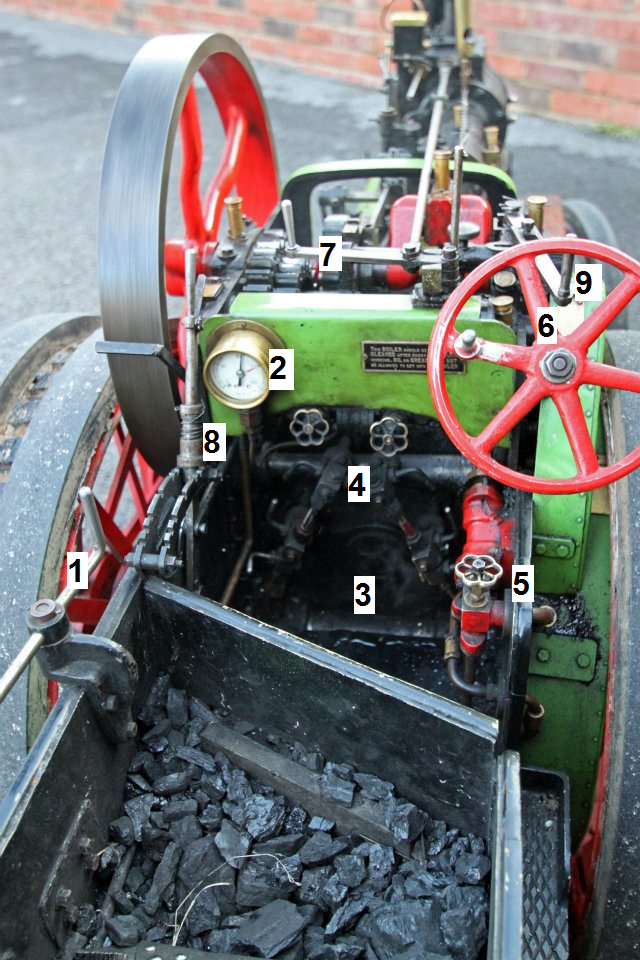

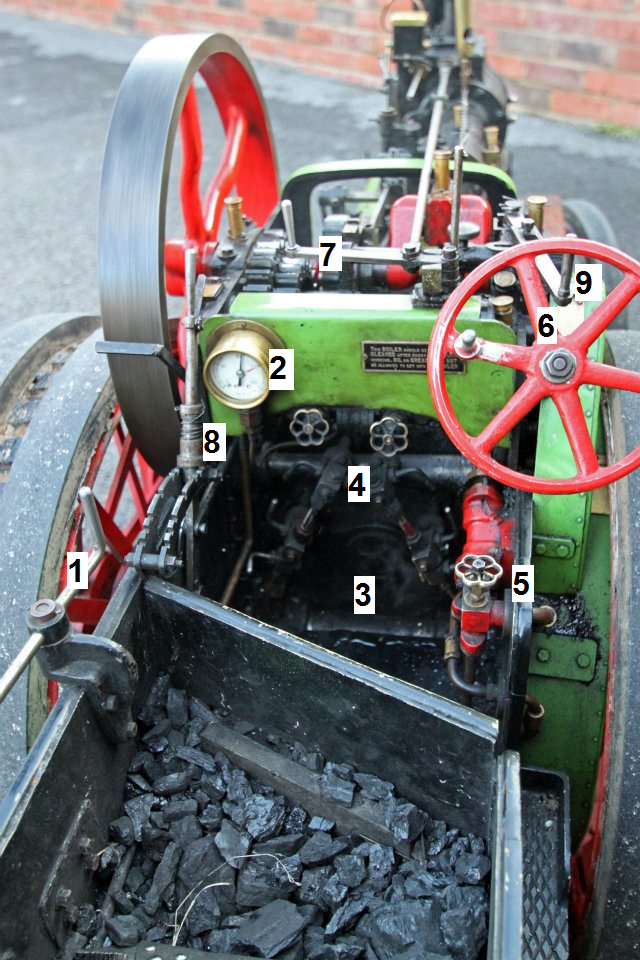

1 - Handbrake winding lever.

2 - Boiler pressure gauge. Sort of like the BHP dial on a Veyron. Anything from 10psi gives enough to lug the driver about, the redline (120psi) will suffice to tow a car - powerful stuff, steam!

3 - Firebox door. Put coal in here and set fire to it. At anything other than ticking over stationary, it needs a good feeding every few minutes

4 - Water level gauges (the glass tubes). The trick is to keep the level right by balancing use with replenishment. Let it run too low and you melt an emergency stopper in the boiler that lets all the steam out to prevent an explosion. Let it run too high, and water is drawn into the cylinder with similar effects to hydraulic-ing a car engine.

5 - Water pump valve - screw this in to replenish the boiler water level (see 4.)

6 - Steering wheel. If you can't identify one of these then you shouldnt be allowed out in public unsupervised.

7 - Regulator - pulling this open allows steam into the cylinder in the same fashion as a throttle

8 - Reversing lever - this is an additional method of throttle control by determining how far the valves open. In the middle they dont open at all - like a neutral gear. the further from the centre it is, the more the vales open, increasing the power of each stroke but also the amount of steam used so reducing coal and water economy (So you could say that traction engines pioneered variable valve timing!!). Which side of the centre it is determines the direction of piston motion.

9 - Gear selector - moving this engages the gearshaft with the crankshaft. To the left = low gear (~1mph), right = high gear (~5mph). Some engines have a third extra-long road gear that gives 15mph. It doesnt sound much but on a traction engine its a positively scary speed!

After getting the engine home I invited round a local owner/builder of the same model for a day's steaming. We had a great afternoon trundling up and down my drive and I learnt the finer points of raising a fire and driving the engine, as well as the post-driving maintenance such as polishing away the oil dribbles and sweeping the soot out of the firebox heat exchanging tubes (this ensures heat transfers easily from the fire to the water in the boiler).

Alas, bad news was to follow. 2 years ago, the safety rules changed for miniature engines to require not 1 but 2 methods of getting water into the boiler whilst in steam. In an emergency situation the last thing you want to find is that the part responsible for replenishing boiler the water level has broken or you will therefore be sitting on a mobile bomb. This is why full-size engines have both a mechanical pump driven from the crankshaft, and a steam-powered water injector that uses dark science to do with pressure and temperature differentials. As it stood, my engine had just the mechanical pump and would therefore no longer be capable of passing the relevant checks to gain certification for display at public shows.

With much to-ing and fro-ing of emails, the engine went back to John to have an injector retrofitted and tested and was now show-ready.... almost

The only thing preventing me now was the imminent expiry of the boiler test certificates. these are like a 2-tier MOT system for steam engines, without which they cannot legally be steamed anywhere where the general public is in attendance. There is an annual steam test, during which the boiler is steamed up to its red line to check the the safety valves operate correctly and prevent pressure rising any higher:

There is also a 2-yearly hydraulic test. this is the main structural integrity test of the boiler, during which it is filled with water and pressurised to 1.5x the maximum working pressure - 180PSI in my case!!!

Pressure is held whilst the inspector checks for any leaks or weeping - and no sign of either was found on mine

I was lucky enough to have both of these tests done last week for free, due to joining the extremely helpful and friendly Handforth Model Engineering Society, a group based near Cheadle that caters for both Traction engines and miniature railway locomotives. I would have some photos to show you but due to fact it pissed with horizontal rain for the duration of the test I refrained from doing anything except seeking shelter!

So, I now have the engine back home, and ready to take to shows - once I have finished recommissioning and modifying the motorbike trailer I had to buy to accomodate it! (I told you its extra length was a problem - a Burrell would just about have fitted neatly in the back of the Land Rover!)

The next step I want to take is to get the engine road-resigtered. Being steam powered, it is tax and mot exempt, and all it needs to be road legal is a set of registration plates (whether you get given yearly or q plates seems to depend on your local DVLA office). Many people do register and use their miniatures on the road, though it is a tad exposed so they often tuck into convoys of full-size engines for protection!

Anyway, here's a few more pictures for you, and if you see me at a show in the Cheshire area over the summer then do come and say hi!

Due to popular demand I've finally got around to making this, the first of my vehicle writeups and a glimpse into the smoky world of steam power:

This is my 3" to the foot (1/4 Scale) miniature of the 1910 Marshall 10-Ton traction engine No.54587 "Pride of the Road", which I bought during the Christmas holidays. It is 56" long and weighs approximately 300kg dry.

This is the full-size engine:

As with many miniatures, the engine was built over a number of years from a commercially available kit of castings and a scale boiler.

The heart of any steam engine is the boiler/firebox assembly, especially on a traction engine where in lieu of a separate frame the boiler forms a chassis to which everything else mounts. According to the logbook that came with the engine, the steel boiler vessel was built in 1994, but due to other delays in completing the engine it was not steamed until 2008/9.

This is a relief, as a boiler normally has a lifespan or 10-15 years of weekly steaming until it needs major work or even total replacement to rectify internal corrosion and metal thinning rendering it unsafe for further use. At the same time, it means the boiler is early enough to sidestep more stringent paperwork on post-2002 builds. With use of modern tannin-based corrosion inhibiting water treatment, and the fact that being at uni cuts off a fair chunk of the show season, with luck this boiler will last a decent while longer than average.

The rest of the engine started life as a kit of raw foundry castings from Brunel Models of Lancashire. It was expertly machined and assembled by a very talented engineer called John in his home workshop. Machining one of these kits of no mean feat, calling for precision drilling, boring, honing, milling and turning with only very vague instructions and scaled-down blueprints of the real thing to work from! Other panelwork such as the tender (the coal and water storage compartment that extends backward from between the rear wheels) was hand-formed and riveted from sheet brass.

After 2 or 3 seasons of rallying the engine, John decided to sell it on to finance the building of another miniature in a larger scale. Noting my wanted advert on a traction engine forum, he got in touch. Although the engine was nearly a foot longer than the miniature Burrell I was after (more on why this is a problem later), at the price he offered it to me the opportunity was far too good to pass up - it was mechanically perfect but in need of some cosmetic TLC. Some dosh changed hands and I was now an engine owner!

So, in my Christmas holidays work commenced. An insulated storage area was constructed (letting lots of delicate pipework freeze on winter nights is a very bad and expensive idea). The next week we pinched a van from Dad's office and set off to Lancashire for a crash course in engine driving before loading up and bringing it home.

Driving a traction engine is not quite as simple as driving a car!

1 - Handbrake winding lever.

2 - Boiler pressure gauge. Sort of like the BHP dial on a Veyron. Anything from 10psi gives enough to lug the driver about, the redline (120psi) will suffice to tow a car - powerful stuff, steam!

3 - Firebox door. Put coal in here and set fire to it. At anything other than ticking over stationary, it needs a good feeding every few minutes

4 - Water level gauges (the glass tubes). The trick is to keep the level right by balancing use with replenishment. Let it run too low and you melt an emergency stopper in the boiler that lets all the steam out to prevent an explosion. Let it run too high, and water is drawn into the cylinder with similar effects to hydraulic-ing a car engine.

5 - Water pump valve - screw this in to replenish the boiler water level (see 4.)

6 - Steering wheel. If you can't identify one of these then you shouldnt be allowed out in public unsupervised.

7 - Regulator - pulling this open allows steam into the cylinder in the same fashion as a throttle

8 - Reversing lever - this is an additional method of throttle control by determining how far the valves open. In the middle they dont open at all - like a neutral gear. the further from the centre it is, the more the vales open, increasing the power of each stroke but also the amount of steam used so reducing coal and water economy (So you could say that traction engines pioneered variable valve timing!!). Which side of the centre it is determines the direction of piston motion.

9 - Gear selector - moving this engages the gearshaft with the crankshaft. To the left = low gear (~1mph), right = high gear (~5mph). Some engines have a third extra-long road gear that gives 15mph. It doesnt sound much but on a traction engine its a positively scary speed!

After getting the engine home I invited round a local owner/builder of the same model for a day's steaming. We had a great afternoon trundling up and down my drive and I learnt the finer points of raising a fire and driving the engine, as well as the post-driving maintenance such as polishing away the oil dribbles and sweeping the soot out of the firebox heat exchanging tubes (this ensures heat transfers easily from the fire to the water in the boiler).

Alas, bad news was to follow. 2 years ago, the safety rules changed for miniature engines to require not 1 but 2 methods of getting water into the boiler whilst in steam. In an emergency situation the last thing you want to find is that the part responsible for replenishing boiler the water level has broken or you will therefore be sitting on a mobile bomb. This is why full-size engines have both a mechanical pump driven from the crankshaft, and a steam-powered water injector that uses dark science to do with pressure and temperature differentials. As it stood, my engine had just the mechanical pump and would therefore no longer be capable of passing the relevant checks to gain certification for display at public shows.

With much to-ing and fro-ing of emails, the engine went back to John to have an injector retrofitted and tested and was now show-ready.... almost

The only thing preventing me now was the imminent expiry of the boiler test certificates. these are like a 2-tier MOT system for steam engines, without which they cannot legally be steamed anywhere where the general public is in attendance. There is an annual steam test, during which the boiler is steamed up to its red line to check the the safety valves operate correctly and prevent pressure rising any higher:

There is also a 2-yearly hydraulic test. this is the main structural integrity test of the boiler, during which it is filled with water and pressurised to 1.5x the maximum working pressure - 180PSI in my case!!!

Pressure is held whilst the inspector checks for any leaks or weeping - and no sign of either was found on mine

I was lucky enough to have both of these tests done last week for free, due to joining the extremely helpful and friendly Handforth Model Engineering Society, a group based near Cheadle that caters for both Traction engines and miniature railway locomotives. I would have some photos to show you but due to fact it pissed with horizontal rain for the duration of the test I refrained from doing anything except seeking shelter!

So, I now have the engine back home, and ready to take to shows - once I have finished recommissioning and modifying the motorbike trailer I had to buy to accomodate it! (I told you its extra length was a problem - a Burrell would just about have fitted neatly in the back of the Land Rover!)

The next step I want to take is to get the engine road-resigtered. Being steam powered, it is tax and mot exempt, and all it needs to be road legal is a set of registration plates (whether you get given yearly or q plates seems to depend on your local DVLA office). Many people do register and use their miniatures on the road, though it is a tad exposed so they often tuck into convoys of full-size engines for protection!

Anyway, here's a few more pictures for you, and if you see me at a show in the Cheshire area over the summer then do come and say hi!

Edited by ChemicalChaos on Saturday 26th March 22:56

Not something I'd ever take up as a hobby but I'm a real nerd for the mechanical engineering side of things so that was a really good read, I particularly enjoyed the diagram of all the parts you need to drive it. I can imagine myself coming unstuck and losing control of it, a 300kg engine at 5mpg would be like a battering ram if you lost it and it trundled into a building or something.

That is simply fantastic. A couple of years ago I took my young kids to a couple of steam rallies in Worcestershire and Herefordshire. These little engines were in attendance, although there were only a few, but my (now) 7yo son is determined that we should have one, one day.

In the meantime I've consoled him with playing with my late father's mamod train and my own mamod steam lorry (from my 10th birthday - I'm now 43).

I would like to say "great toy" but that almost sounds condescending.

In the meantime I've consoled him with playing with my late father's mamod train and my own mamod steam lorry (from my 10th birthday - I'm now 43).

I would like to say "great toy" but that almost sounds condescending.

Thanks for all the comments everyone!

I am indeed mad! And you certainly cannot beat the smell of burning coal mingled with hot steam oil

I've yet to get smilies for any of my vehicles, if I do then a small one may appear on the back of the tender.

Wizardskills - is that a big 1" or a small 2" engine? It looks very nice, is it static or steam-able? What engine is it a model of? Your dad sounds like he'd enjoy the TractionTalk forum (http://www.tractiontalkforum.com), if he's not already on it.

Mastodon - I'd imagine it would do a bit of damage but being made mainly of cast iron, lots of the fittings are very brittle and would probably just snap. It's already lost a little bit off the side of a cast valve-driving eccentric rod that normally holds an lubrication flap shut, and you do have to be surprisingly careful with them.

Watchman - we need more young people like him involved in the hobby as too many of them see it as an old man's pastime. If he is really serious, then a good start is to enrol in the NTET's Steam Apprentice Club:

http://www.ntet.co.uk/sac/

That way he will get to help out with other people's engines at shows whilst he works towards getting his own, as well as befriending experts to call on for help. It will take a bit of saving - one the size of mine is normally £7-10k (plus a van/big mpv/trailer you dont mind getting filthy to transport it, coal, accessories etc etc), but they are very rewarding machines to own and will certainly keep you busy!

Dont worry about sounding condescending - it is after all just a big boy's toy!

A sort of update:

Today has seen me doing some jobs and prep work on the engine and accessories. First job was to drop the grate from the firebox and rake out the half-burnt coals from the last steaming. The hard bit is getting it back on as it is secured on pegs by 4 small circlips

After that, a quick sweep of the boiler tubes and a good all-over polish was all it needed. if you've ever wondered why owners are continually polishing at shows, its because the total-loss lubrication of every pivot and joint in the "motion work" (all the bits between the cylinder and the flywheel) drips all over the boiler cladding leaving it streaked in thick, dirty oil.

Attention then turned to the trailer I'd bought, an old motorbike carrier:

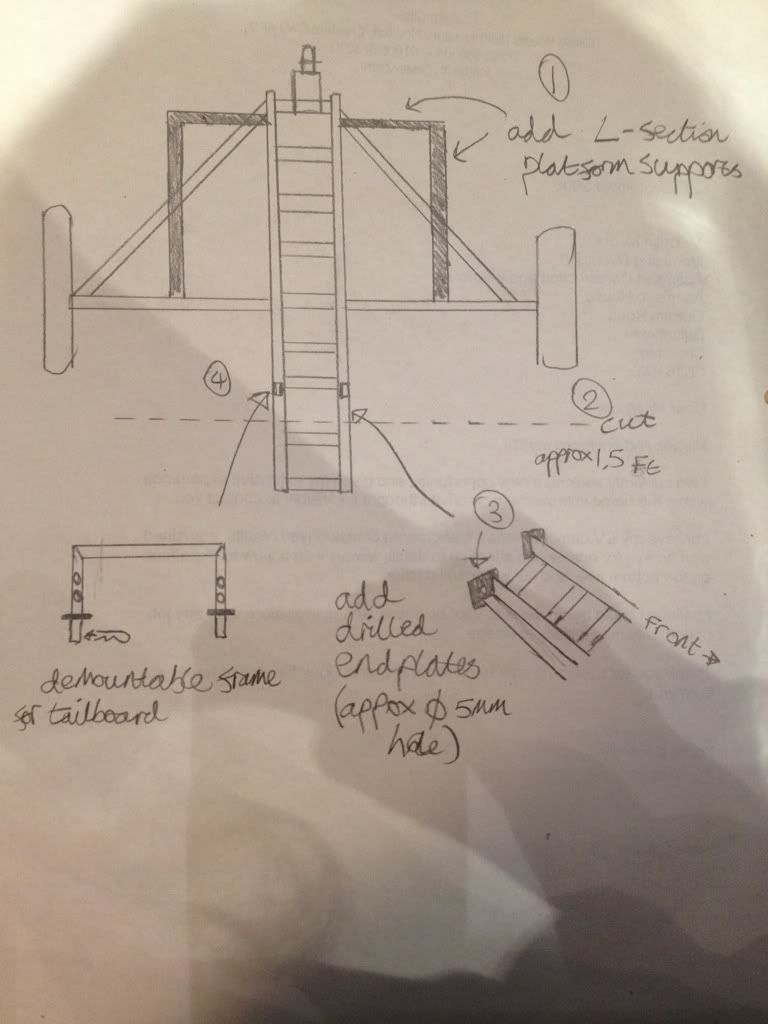

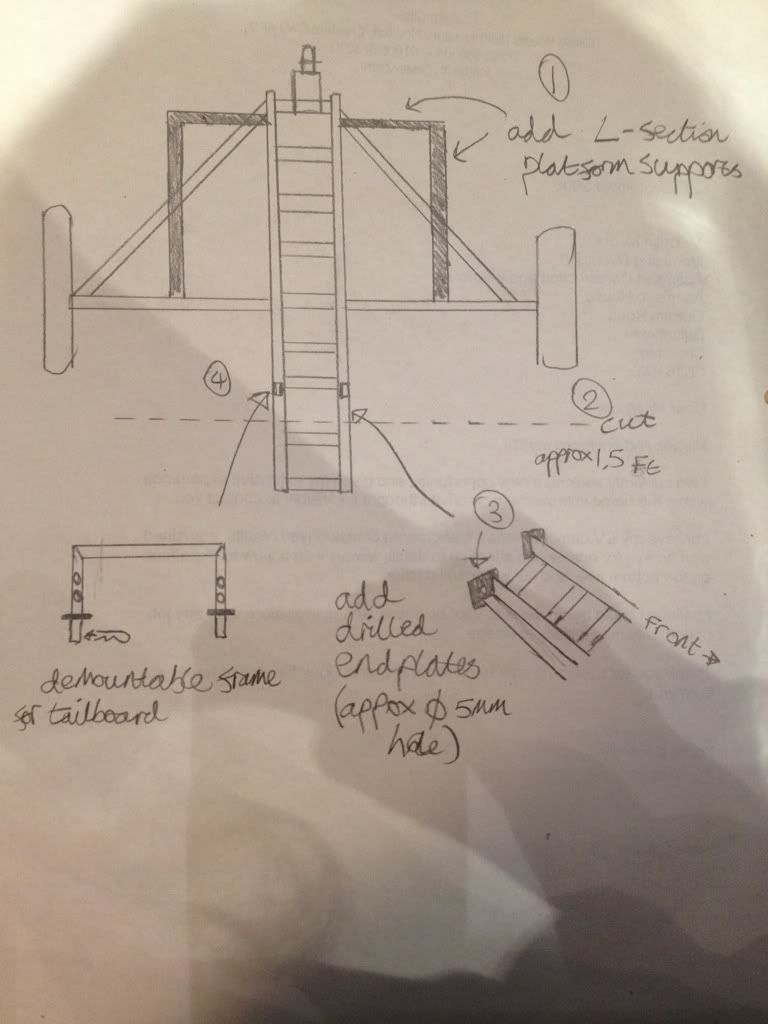

The plan is to square off the a-frame and board it with some spare 12mm ply I have left over from another job, along with some other jobs to make it ready to carry the engine. Exam revision was procrastinated to doodle the plans for a handyman friend to chop'n'weld it:

In the meantime, it needs some new tyres!

(yes, I puled it 15 miles home like that, full of tyre sealant )

)

After a half hour fight with a tyre lever and some rather nice lavender scented fairy liquid, I had a set of bare rims ready to send for shotblasting and priming as a favour from yet another mate - you soon end up well-connected in the steam world, everyone is incredibly helpful and friendly!

the trailer is then going to be painted to match the new colour scheme the engine will be getting in a year or 2 when I'm familiar enough with it to strip off all the wheels, boiler classing and other tinwork. Eventually it should end up painted something like the Fowler Showman's road loco "Renown", in deep blue with gold (or possibly off white) piping:

Another little project is to make a chimney blower. On an engine, the flow of air goes into the bottom of the firebox, up through the grate, through the boiler tubes and out the chimney. On a full-size engine there is plenty of flow even when cold with a just-lit fire. However, as the size of the engine decreases, the airflow ratio does not decrease proportionally, and thus on smaller scale engines such as mine it can be a challenge to get the fie going. The normal solution is therefore to place an electric blower on top of the chimney to pull air through until the fire is going and able to create its own draft.

The problem is, it's very hard to find an impellor fan these days that is all-metal - plastic ones dont like the exhaust of a roaring coal fire!

Step forward a military surplus website, and the cooling fan from a 1970s Army valve radio set (amazing what one can buy on the internet these days!)

Having established it wont run off a piddly house battery, I found that once connected to the man-sized Land Rover battery it shifts a surprising amount of air for its size. thus, more doodling ensued (but this time using my technical drawing skills), and I have some plans for an adaptor to get fabbed up:

For now though, its back in the garage with everything until mid-june, when uni exams finish and I can go out and play again!

I am indeed mad! And you certainly cannot beat the smell of burning coal mingled with hot steam oil

I've yet to get smilies for any of my vehicles, if I do then a small one may appear on the back of the tender.

Wizardskills - is that a big 1" or a small 2" engine? It looks very nice, is it static or steam-able? What engine is it a model of? Your dad sounds like he'd enjoy the TractionTalk forum (http://www.tractiontalkforum.com), if he's not already on it.

Mastodon - I'd imagine it would do a bit of damage but being made mainly of cast iron, lots of the fittings are very brittle and would probably just snap. It's already lost a little bit off the side of a cast valve-driving eccentric rod that normally holds an lubrication flap shut, and you do have to be surprisingly careful with them.

Watchman - we need more young people like him involved in the hobby as too many of them see it as an old man's pastime. If he is really serious, then a good start is to enrol in the NTET's Steam Apprentice Club:

http://www.ntet.co.uk/sac/

That way he will get to help out with other people's engines at shows whilst he works towards getting his own, as well as befriending experts to call on for help. It will take a bit of saving - one the size of mine is normally £7-10k (plus a van/big mpv/trailer you dont mind getting filthy to transport it, coal, accessories etc etc), but they are very rewarding machines to own and will certainly keep you busy!

Dont worry about sounding condescending - it is after all just a big boy's toy!

A sort of update:

Today has seen me doing some jobs and prep work on the engine and accessories. First job was to drop the grate from the firebox and rake out the half-burnt coals from the last steaming. The hard bit is getting it back on as it is secured on pegs by 4 small circlips

After that, a quick sweep of the boiler tubes and a good all-over polish was all it needed. if you've ever wondered why owners are continually polishing at shows, its because the total-loss lubrication of every pivot and joint in the "motion work" (all the bits between the cylinder and the flywheel) drips all over the boiler cladding leaving it streaked in thick, dirty oil.

Attention then turned to the trailer I'd bought, an old motorbike carrier:

The plan is to square off the a-frame and board it with some spare 12mm ply I have left over from another job, along with some other jobs to make it ready to carry the engine. Exam revision was procrastinated to doodle the plans for a handyman friend to chop'n'weld it:

In the meantime, it needs some new tyres!

(yes, I puled it 15 miles home like that, full of tyre sealant

)

)After a half hour fight with a tyre lever and some rather nice lavender scented fairy liquid, I had a set of bare rims ready to send for shotblasting and priming as a favour from yet another mate - you soon end up well-connected in the steam world, everyone is incredibly helpful and friendly!

the trailer is then going to be painted to match the new colour scheme the engine will be getting in a year or 2 when I'm familiar enough with it to strip off all the wheels, boiler classing and other tinwork. Eventually it should end up painted something like the Fowler Showman's road loco "Renown", in deep blue with gold (or possibly off white) piping:

Another little project is to make a chimney blower. On an engine, the flow of air goes into the bottom of the firebox, up through the grate, through the boiler tubes and out the chimney. On a full-size engine there is plenty of flow even when cold with a just-lit fire. However, as the size of the engine decreases, the airflow ratio does not decrease proportionally, and thus on smaller scale engines such as mine it can be a challenge to get the fie going. The normal solution is therefore to place an electric blower on top of the chimney to pull air through until the fire is going and able to create its own draft.

The problem is, it's very hard to find an impellor fan these days that is all-metal - plastic ones dont like the exhaust of a roaring coal fire!

Step forward a military surplus website, and the cooling fan from a 1970s Army valve radio set (amazing what one can buy on the internet these days!)

Having established it wont run off a piddly house battery, I found that once connected to the man-sized Land Rover battery it shifts a surprising amount of air for its size. thus, more doodling ensued (but this time using my technical drawing skills), and I have some plans for an adaptor to get fabbed up:

For now though, its back in the garage with everything until mid-june, when uni exams finish and I can go out and play again!

Edited by mat777 on Monday 16th April 01:51

Gassing Station | Scale Models | Top of Page | What's New | My Stuff