3" Scale Marshall Traction Engine

Discussion

buzzy bee said:

"Handyman Friend" He sounds an interesting chap!

I am trying to do a very simmilar thing, just based as An Agricultural Engineer/Steam Engineer, lol

See you later!

LOL hello Dave, if I'd known you were on PH I'd have written a much more glowing description of your engineering skills I am trying to do a very simmilar thing, just based as An Agricultural Engineer/Steam Engineer, lol

See you later!

Edited by mat777 on Tuesday 17th April 17:24

Edited by mat777 on Tuesday 17th April 17:25

My wife's Grandad used to be into traction engines and one of his son's bought him one for his 70th birthday!

Used to keep it in a huge shed behind his house in Louth.

Another son ran a haulage business so used to take it on a low loader to shows on a weekend.

Think he had to sell it when he got too old to climb onboard.

Used to keep it in a huge shed behind his house in Louth.

Another son ran a haulage business so used to take it on a low loader to shows on a weekend.

Think he had to sell it when he got too old to climb onboard.

MEGA UPDATE! Warning - extremely technical explanations ahead to satisfy the fellow engineering geeks!

Well, its been a fun and eventful season!

After much grinding, chopping, bashing and welding by PHer Buzzy Bee, the motorbike trailer in my previous post was now sporting the addition of some nice "wings" to carry the decking for the engine (and I ordered some new tyres too!):

After a few arguments on colour, we decided to paint it to match the Series Landy rather than any current or future colour scheme of the engine. This was mainly due to the available colours of rust-proof paint!

Some loading ramps were fashioned from 1" marine ply, with some seriously beefy metal hooks bolted to one end to keep them in place on the back of the trailer when taking the strain

The trailer was finished off with a piece of scrap curtainsider lorry canvas nailed to the bottom to cover the bloody bigbike rung hole down the centre. On the shiny (and visible) top side, some spare offcuts of 3/4" ply liberally coated in yacht varnish, gave a lovely period look

And voila, one beautiful Land Rover, traction engine and trailer combo:

So, I was all set for my first outing of the season (in fact my very first outing full stop) - the Lancashire and Morecambe Model Engineering Society's annual open day. One problem - it was 11pm the night before, and the weather had been awful all day The roads were soaking wet, and the £5 tarp from ebay didnt fit in any way shape or form (its not easy to wrap something traction engine shaped in a square tarp!). This called for some lateral thinking, which led to an SAS-style raid on the kitchen cupboard for some clingfilm when mum wasn't looking

In the end, we got to Lancs without incident, and had a brilliant day despite discovering a few teething troubles!

The first problem I soon discovered was with the cheap Chinese garden trolley I bought and built to act as a supply trailer to keep my coal, water and oil in when roaming the rally field arenas away from base pitch. It was rated at 300kg, and worked brilliantly for, ooh, 20 yards loaded with a 20kg sack of coal and a bloke sat on it. Then this happened:

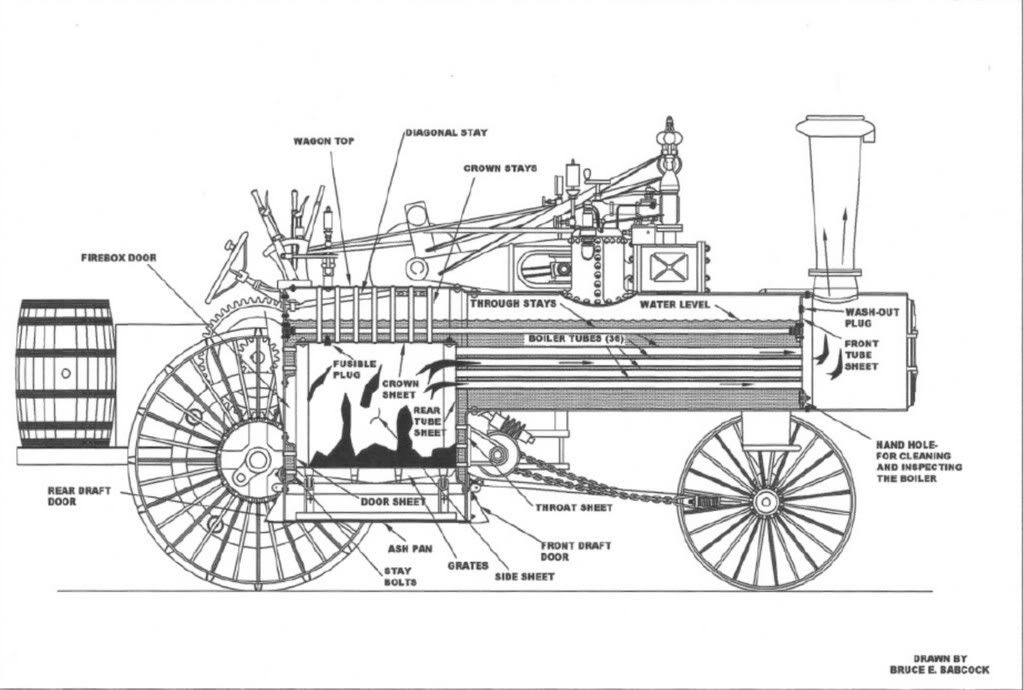

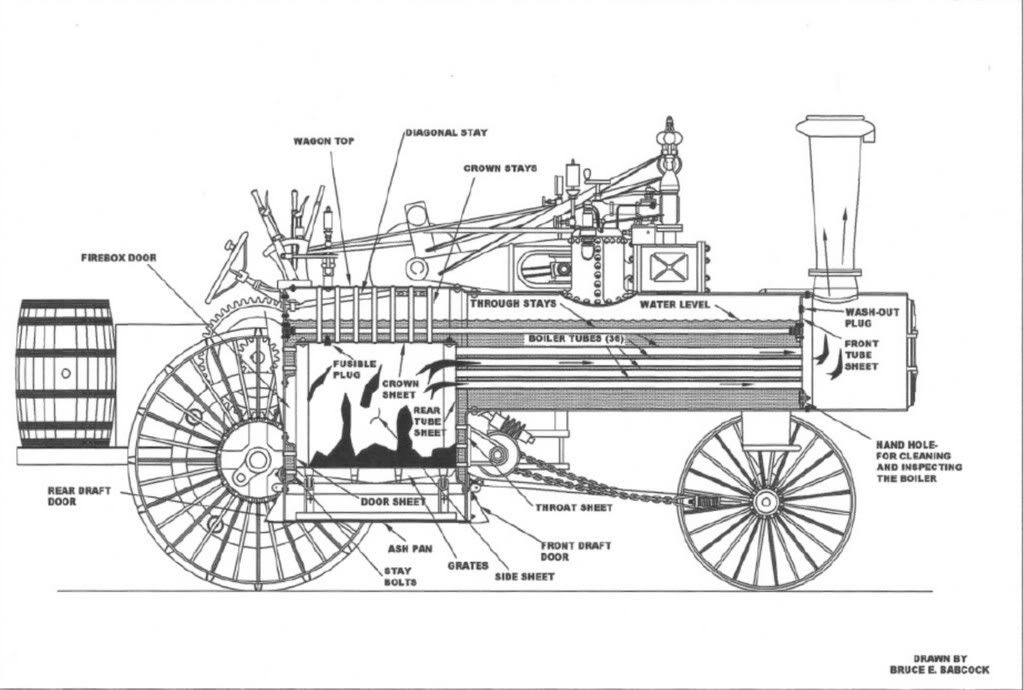

Undeterred, I unhitched it and carried on roaming at a reduced radius. A cracking couple of hours ensued as I learnt the finer points of managing fire and water - with the added complication of slopes. As explained in the opening post, the amount of water in the boiler has to be just right. The boiler itself is essentially a big cylinder with a square box on one end. Because of this, the structurally weakest part of it is the "crown", ie the flat (or sometimes "m" shaped) sheet covering the top of the firebox and blending into the main tube. This diagram skanked off t'interweb explains it better than I can with words:

Let the water level run too low and the crown is the first part of the boiler to be uncovered - and this will soon overheat, soften and rupture causing a catastrophic explosion. Luckily, there is an emergency stopper called a fusible plug to prevent this - a hollow brass bolt with a tin solder core that melts at a far lower temperature than it takes to soften steel. If the crown is uncovered, this melts and lets all the steam and water out of the boiler, dousing the fire in the process. Oh, and its an utter sod to get at to replace!!! Let the water level run too high on the other hand, and water is drawn into the cylinder with similar effects to hydraulic-ing a car engine.

So what does this have to go with gradients, you might ask? Well, keeping the water level correct is child's play on the flat, but on a gradient all the water sloshes to one end of the boiler! So, when going downhill, the water all goes to the front of the boiler and leaves the fusible plug uncovered. Going uphill, it all sloshes to the crown, which would be great if not for the fact that this is where the steam inlet for the cylinder usually is - hydraulic time!

As such, driving an engine calls for great vigilance of what the road or terrain ahead is like - if its going downhill, get that water pumping in as fast as possible to "overfill" the boiler as it begins to nose down. For going uphill, run the level as low as possible as you approach the hill.

On a full-size engine, it takes a fairly large slope to cause this kind of frantic level-fiddling, but in a miniature scale every slight incline is a potential hazard!

Anyway - back to teething troubles

After a few hours of playing, I got off to tend to something else and noticed a suspiciously redundant looking actuator on the motion-work (all the moving linkages you can see on the top between the cylinder and the driver's footplate). To my horror, a little bit of linkage for the cylinder lubricator had worked loose, come undone and fallen off. This was slightly alarming as it meant that, for an undetermined amount of time, no lubrication had been reaching the cylinder

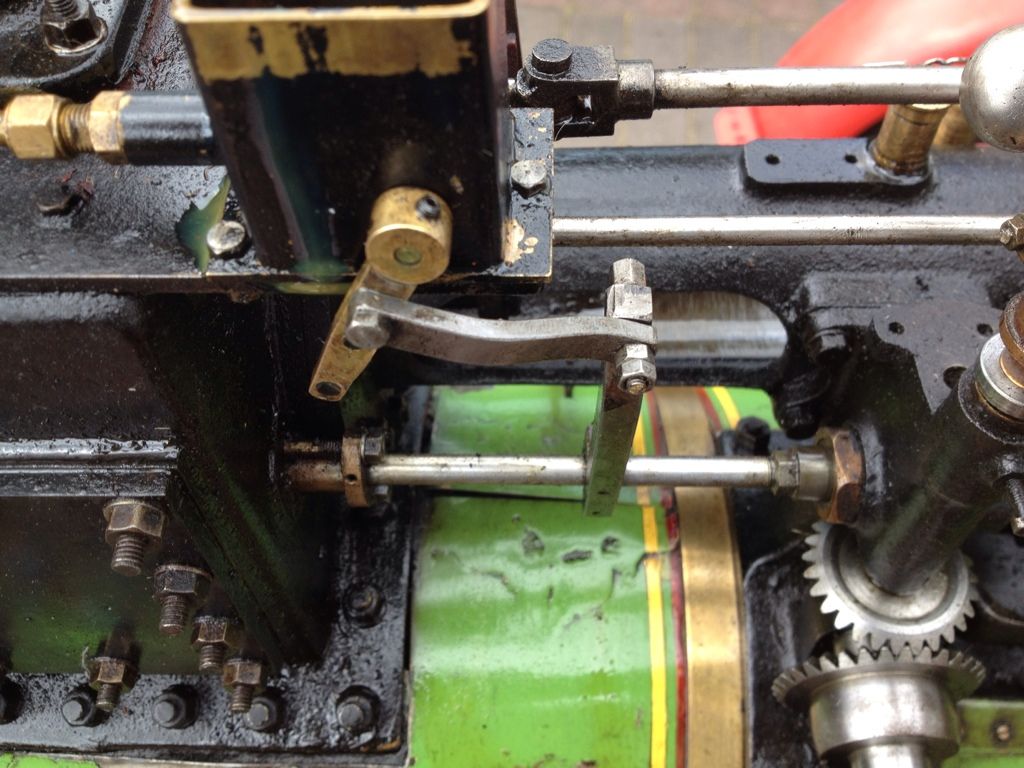

So how does the cylinder lubricator work? Well:

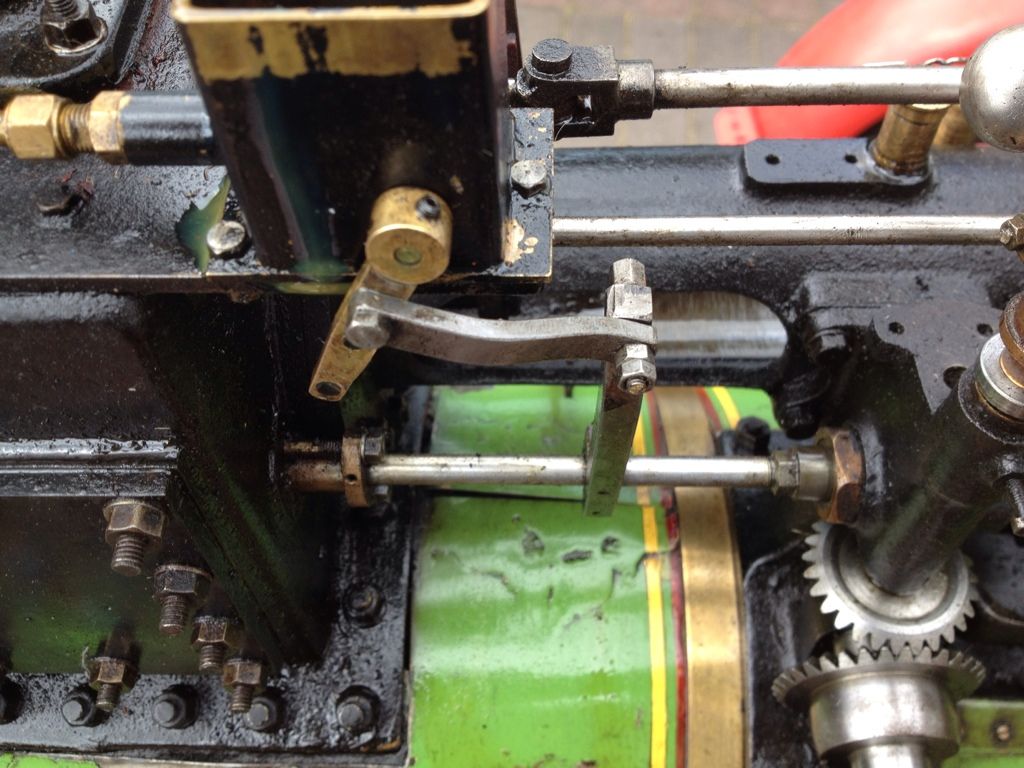

The cylindrical bar at the bottom of the below picture is linked to the crankshaft by an eccentric bearing shell, and moves back and forth as the crank rotates (kind of like a pushrod). The vertical post is clamped to this, so moves back and forth, moving the linkage at the top of it. This causes the brass connecting rod to move back and forth, rotating the shaft in the middle of it about a quarter or a turn either way.

As the shaft turns, it causes the cam inside the box here to force down the spring-loaded plunger on its way up and again on its way down. Now, this little box is usually full of 650 grade (yes, 650 weight - none of your poncy 10w30 here!) oil, so as the plunger is depressed by the cam a small amount of the oil is forced out, down a tube, through a pair of non-return valves and into the cylinder during each stroke. Here, it atomises into the steam charge and condenses on the cylinder bore, providing essential lubrication in possibly the worst environment for a precision-machined metal surface - constantly being steam cleaned!

This is a total loss lubrication system as each fresh charge of steam washes the oil out of the bore again and up the chimney with the steam exhaust - hence the constant supply of oil. And hence why it was rather a worry to realise it wasnt working!!!

Lacking the supply of incredibly tiny spanners and allen keys to fix it at the event, that rather put the kibosh on activities for the day..

Oh well, it meant I got to have a go on a 4" (1/3 scale) Burrell - I think I know what I'll be looking to upgrade to in a few years time!

All went quiet then for a few weeks, until I was able to get the engine over to the house of the friendly local enthusiast mentioned in the original post. Knowing much more than me on how to re-setup the linkage so the cam was in the right position relative to the push rod and linkage, he soon had it sorted.

The next rally was to be Cheshire Steam Fair (in Warrington). Well, it was supposed to be until the weather turned the showground into this:

Doesnt look bad on the truck, but that equates to about half way up the wheels on an engine my size!! having been pre-warned by a friend already there, I left the engine at home and thumbed my nose at all the other exhibitors by driving the Landy straight through the deepest bit of the mud right to my pitch, as they all waited for a tractor tow

In the meantime, the engine had broken again.

Steaming it up at a local village show, I soon discovered the water pump wasnt quite working to its full extent - ie. it couldnt put water in the boiler as fast as it was being used for the hardly demanding task of sitting ticking over. Something obviously wasn't quite right here!

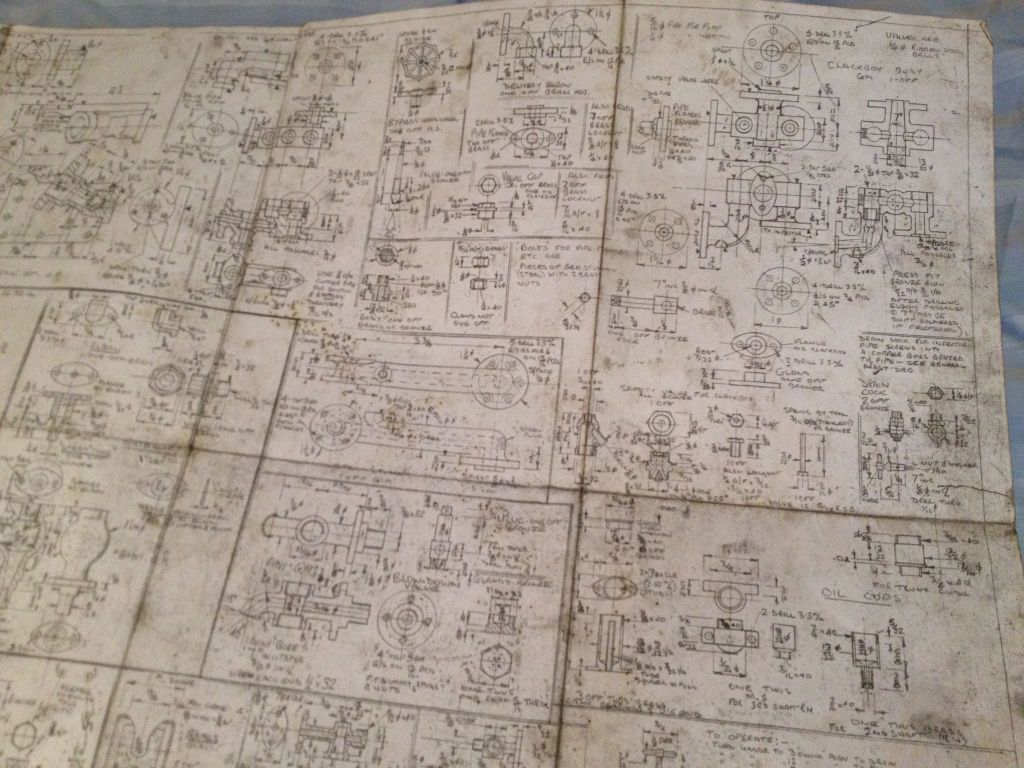

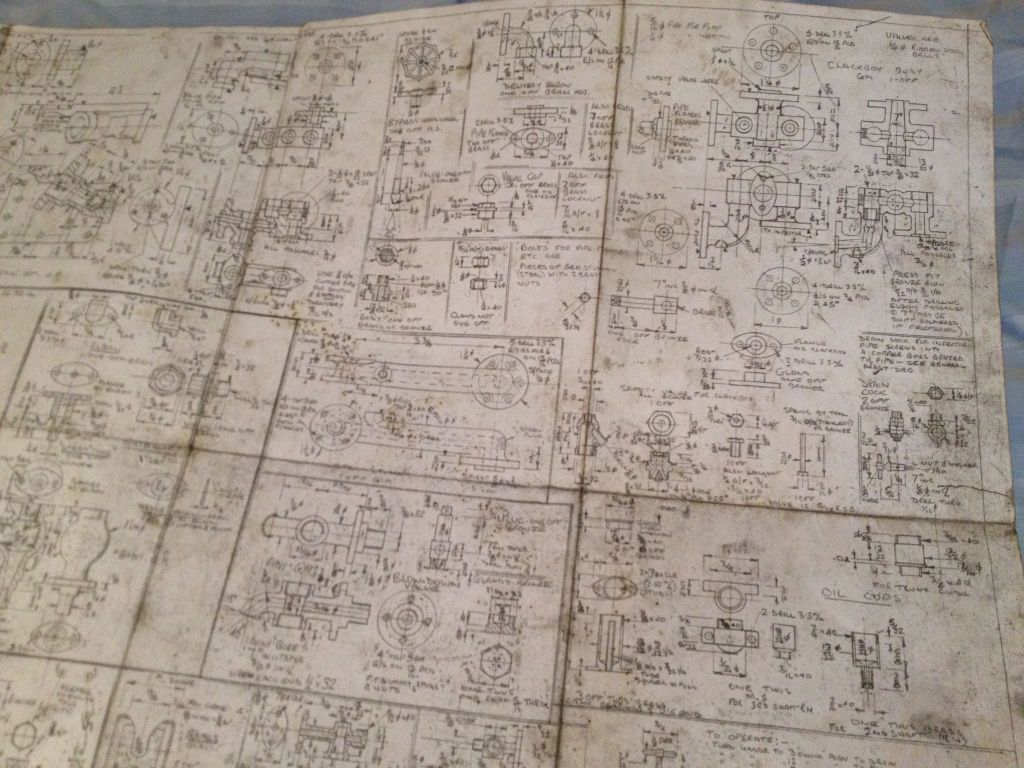

After putting out the fire and packing up then fuming a bit, I got out the plans that came with the engine to see exactly what was supposed to be happening in there, and thus try and work out what had gone wrong. I was suddenly very very glad I had paid attention in engineering drawing classes!

The pump uses another eccentric bearing shell from the crank (eccentric crank-driven bearings are a steam engineer's favourite way of generating linear motion from the crank) to drive a plunger-type pumping cylinder that is in constant operation. This lifts water from the tender into the bypass valve, where normally it is directed back into the tender. When the valve is wound down, this exit is blocked and the water is forced down a pipe into the clack on the side of the boiler. The clack valve is basically a ball bearing wedged in the flared end of a pipe, screwed into the pressurised part of the boiler. The steam pressure holds the ball bearing tight into the pipe normally, but, when pumping, the incompressible nature of water forces the ball out just enough to get past and into the boiler.

Having taken all the aforementioned to pieces and confirmed it was all working properly, the problem of course turned out to be something annoyingly simple that I could have fixed at the show! The hand wheel on the bypass valve had loosened, moved down on its shaft and tightened again, meaning that when it felt like the valve was full wound down (ie maximum pumping), it wasnt - meaning most of the water was still bypassing back into the tender. Grrrrrr

All too soon, however, it was time for my last show of the season as an exhibitor - Astle Park. This was my first "proper" grass field large-scale show. It was also my first time keeping the engine in steam all day from 9.30 to 4.30 - and let me tell you it is bloody knackering!! On a full-size engine you can top up the boiler to max, stick a few lumps of coal on the fire then leave it ticking over for an hour or 2. No such luck with a miniature though - the smaller an engine is, the quicker things happen. 5 minutes for a sandwich or toilet break is all you're likely to get before either fire, water or one of the various lubrication points needs attention, typically requiring you to get on your hands and knees just for extra aches and pains by the end of the day...

However, no pain no gain! Astle park is a mobile show, ie. the engines are allowed to move around as they please within reason, rather than some shows where they are roped off and forced to sit stationary all day. So I took the opportunity to tour the entire showground on the engine!

The highlight of the day was the miniatures contingent mixing it with the full size boys in the parade arena

And yep, that's Fred Dibnah's roller in the background, rallied these days by his sons Roger and Jack.

Astle Park over, it was time to ready the engine for its winter bedtime. Steaming up once last time, the fire was built up nicely dropped out the grate whilst burning fiercely (rather than letting it die off naturally and go out by itself), so that I could open the boiler drain tap whilst still hot and pressurised to 10-15psi (dont try this at home kids!). This is the equivalent of draining a car's engine oil whilst hot - most of the crap such as silt comes out in suspension with the water, negating the need for it to be pressure-washed through an inspection hatch later on. If you leave it over winter it dries and hardnes to a cement-like substance with similar effects to scaling up a kettle. The latent heat of the boiler also means that, once the steam and water has emptied and other inspection plugs are opened up, it dries itself off inside. This stops moisture and condensation remaining in the boiler so the risk of internal corrosion is at a minimum.

A few other menial jobs include sweeping the soot out of the boiler tubes - as the smoke and hot air is drawn through the tubes and out the chimney, a helluvalot of soot goes with it too! Once again, this builds up and reduces the efficiency of heat transfer from the hot gas to the water its supposed to be boiling.

Pro Tip - everything within a 10 foot radius will get covered in a very fine layer of soot dust. I turned the shower basin black after that little job!

And so the engine is now hibernating for the winter somewhere insulated and heated, to prevent any chance of frost damage (a very major risk to full-size engines kept outside under sheeting during their working lives) and I eagerly away the start of next year's show season!

Phew, my fingers are knackered now!

TL;DR version - I did some steam rallies. It broke, I fixed it. I did some more rallies then put it away for winter. The end

Well, its been a fun and eventful season!

After much grinding, chopping, bashing and welding by PHer Buzzy Bee, the motorbike trailer in my previous post was now sporting the addition of some nice "wings" to carry the decking for the engine (and I ordered some new tyres too!):

After a few arguments on colour, we decided to paint it to match the Series Landy rather than any current or future colour scheme of the engine. This was mainly due to the available colours of rust-proof paint!

Some loading ramps were fashioned from 1" marine ply, with some seriously beefy metal hooks bolted to one end to keep them in place on the back of the trailer when taking the strain

The trailer was finished off with a piece of scrap curtainsider lorry canvas nailed to the bottom to cover the bloody big

And voila, one beautiful Land Rover, traction engine and trailer combo:

So, I was all set for my first outing of the season (in fact my very first outing full stop) - the Lancashire and Morecambe Model Engineering Society's annual open day. One problem - it was 11pm the night before, and the weather had been awful all day The roads were soaking wet, and the £5 tarp from ebay didnt fit in any way shape or form (its not easy to wrap something traction engine shaped in a square tarp!). This called for some lateral thinking, which led to an SAS-style raid on the kitchen cupboard for some clingfilm when mum wasn't looking

In the end, we got to Lancs without incident, and had a brilliant day despite discovering a few teething troubles!

The first problem I soon discovered was with the cheap Chinese garden trolley I bought and built to act as a supply trailer to keep my coal, water and oil in when roaming the rally field arenas away from base pitch. It was rated at 300kg, and worked brilliantly for, ooh, 20 yards loaded with a 20kg sack of coal and a bloke sat on it. Then this happened:

Undeterred, I unhitched it and carried on roaming at a reduced radius. A cracking couple of hours ensued as I learnt the finer points of managing fire and water - with the added complication of slopes. As explained in the opening post, the amount of water in the boiler has to be just right. The boiler itself is essentially a big cylinder with a square box on one end. Because of this, the structurally weakest part of it is the "crown", ie the flat (or sometimes "m" shaped) sheet covering the top of the firebox and blending into the main tube. This diagram skanked off t'interweb explains it better than I can with words:

Let the water level run too low and the crown is the first part of the boiler to be uncovered - and this will soon overheat, soften and rupture causing a catastrophic explosion. Luckily, there is an emergency stopper called a fusible plug to prevent this - a hollow brass bolt with a tin solder core that melts at a far lower temperature than it takes to soften steel. If the crown is uncovered, this melts and lets all the steam and water out of the boiler, dousing the fire in the process. Oh, and its an utter sod to get at to replace!!! Let the water level run too high on the other hand, and water is drawn into the cylinder with similar effects to hydraulic-ing a car engine.

So what does this have to go with gradients, you might ask? Well, keeping the water level correct is child's play on the flat, but on a gradient all the water sloshes to one end of the boiler! So, when going downhill, the water all goes to the front of the boiler and leaves the fusible plug uncovered. Going uphill, it all sloshes to the crown, which would be great if not for the fact that this is where the steam inlet for the cylinder usually is - hydraulic time!

As such, driving an engine calls for great vigilance of what the road or terrain ahead is like - if its going downhill, get that water pumping in as fast as possible to "overfill" the boiler as it begins to nose down. For going uphill, run the level as low as possible as you approach the hill.

On a full-size engine, it takes a fairly large slope to cause this kind of frantic level-fiddling, but in a miniature scale every slight incline is a potential hazard!

Anyway - back to teething troubles

After a few hours of playing, I got off to tend to something else and noticed a suspiciously redundant looking actuator on the motion-work (all the moving linkages you can see on the top between the cylinder and the driver's footplate). To my horror, a little bit of linkage for the cylinder lubricator had worked loose, come undone and fallen off. This was slightly alarming as it meant that, for an undetermined amount of time, no lubrication had been reaching the cylinder

So how does the cylinder lubricator work? Well:

The cylindrical bar at the bottom of the below picture is linked to the crankshaft by an eccentric bearing shell, and moves back and forth as the crank rotates (kind of like a pushrod). The vertical post is clamped to this, so moves back and forth, moving the linkage at the top of it. This causes the brass connecting rod to move back and forth, rotating the shaft in the middle of it about a quarter or a turn either way.

As the shaft turns, it causes the cam inside the box here to force down the spring-loaded plunger on its way up and again on its way down. Now, this little box is usually full of 650 grade (yes, 650 weight - none of your poncy 10w30 here!) oil, so as the plunger is depressed by the cam a small amount of the oil is forced out, down a tube, through a pair of non-return valves and into the cylinder during each stroke. Here, it atomises into the steam charge and condenses on the cylinder bore, providing essential lubrication in possibly the worst environment for a precision-machined metal surface - constantly being steam cleaned!

This is a total loss lubrication system as each fresh charge of steam washes the oil out of the bore again and up the chimney with the steam exhaust - hence the constant supply of oil. And hence why it was rather a worry to realise it wasnt working!!!

Lacking the supply of incredibly tiny spanners and allen keys to fix it at the event, that rather put the kibosh on activities for the day..

Oh well, it meant I got to have a go on a 4" (1/3 scale) Burrell - I think I know what I'll be looking to upgrade to in a few years time!

All went quiet then for a few weeks, until I was able to get the engine over to the house of the friendly local enthusiast mentioned in the original post. Knowing much more than me on how to re-setup the linkage so the cam was in the right position relative to the push rod and linkage, he soon had it sorted.

The next rally was to be Cheshire Steam Fair (in Warrington). Well, it was supposed to be until the weather turned the showground into this:

Doesnt look bad on the truck, but that equates to about half way up the wheels on an engine my size!! having been pre-warned by a friend already there, I left the engine at home and thumbed my nose at all the other exhibitors by driving the Landy straight through the deepest bit of the mud right to my pitch, as they all waited for a tractor tow

In the meantime, the engine had broken again.

Steaming it up at a local village show, I soon discovered the water pump wasnt quite working to its full extent - ie. it couldnt put water in the boiler as fast as it was being used for the hardly demanding task of sitting ticking over. Something obviously wasn't quite right here!

After putting out the fire and packing up then fuming a bit, I got out the plans that came with the engine to see exactly what was supposed to be happening in there, and thus try and work out what had gone wrong. I was suddenly very very glad I had paid attention in engineering drawing classes!

The pump uses another eccentric bearing shell from the crank (eccentric crank-driven bearings are a steam engineer's favourite way of generating linear motion from the crank) to drive a plunger-type pumping cylinder that is in constant operation. This lifts water from the tender into the bypass valve, where normally it is directed back into the tender. When the valve is wound down, this exit is blocked and the water is forced down a pipe into the clack on the side of the boiler. The clack valve is basically a ball bearing wedged in the flared end of a pipe, screwed into the pressurised part of the boiler. The steam pressure holds the ball bearing tight into the pipe normally, but, when pumping, the incompressible nature of water forces the ball out just enough to get past and into the boiler.

Having taken all the aforementioned to pieces and confirmed it was all working properly, the problem of course turned out to be something annoyingly simple that I could have fixed at the show! The hand wheel on the bypass valve had loosened, moved down on its shaft and tightened again, meaning that when it felt like the valve was full wound down (ie maximum pumping), it wasnt - meaning most of the water was still bypassing back into the tender. Grrrrrr

All too soon, however, it was time for my last show of the season as an exhibitor - Astle Park. This was my first "proper" grass field large-scale show. It was also my first time keeping the engine in steam all day from 9.30 to 4.30 - and let me tell you it is bloody knackering!! On a full-size engine you can top up the boiler to max, stick a few lumps of coal on the fire then leave it ticking over for an hour or 2. No such luck with a miniature though - the smaller an engine is, the quicker things happen. 5 minutes for a sandwich or toilet break is all you're likely to get before either fire, water or one of the various lubrication points needs attention, typically requiring you to get on your hands and knees just for extra aches and pains by the end of the day...

However, no pain no gain! Astle park is a mobile show, ie. the engines are allowed to move around as they please within reason, rather than some shows where they are roped off and forced to sit stationary all day. So I took the opportunity to tour the entire showground on the engine!

The highlight of the day was the miniatures contingent mixing it with the full size boys in the parade arena

And yep, that's Fred Dibnah's roller in the background, rallied these days by his sons Roger and Jack.

Astle Park over, it was time to ready the engine for its winter bedtime. Steaming up once last time, the fire was built up nicely dropped out the grate whilst burning fiercely (rather than letting it die off naturally and go out by itself), so that I could open the boiler drain tap whilst still hot and pressurised to 10-15psi (dont try this at home kids!). This is the equivalent of draining a car's engine oil whilst hot - most of the crap such as silt comes out in suspension with the water, negating the need for it to be pressure-washed through an inspection hatch later on. If you leave it over winter it dries and hardnes to a cement-like substance with similar effects to scaling up a kettle. The latent heat of the boiler also means that, once the steam and water has emptied and other inspection plugs are opened up, it dries itself off inside. This stops moisture and condensation remaining in the boiler so the risk of internal corrosion is at a minimum.

A few other menial jobs include sweeping the soot out of the boiler tubes - as the smoke and hot air is drawn through the tubes and out the chimney, a helluvalot of soot goes with it too! Once again, this builds up and reduces the efficiency of heat transfer from the hot gas to the water its supposed to be boiling.

Pro Tip - everything within a 10 foot radius will get covered in a very fine layer of soot dust. I turned the shower basin black after that little job!

And so the engine is now hibernating for the winter somewhere insulated and heated, to prevent any chance of frost damage (a very major risk to full-size engines kept outside under sheeting during their working lives) and I eagerly away the start of next year's show season!

Phew, my fingers are knackered now!

TL;DR version - I did some steam rallies. It broke, I fixed it. I did some more rallies then put it away for winter. The end

Edited by mat777 on Sunday 16th September 02:20

Nice to read. Building 5 inch gauge B17 at the moment. long slog but worth it. Getting the axleboxes just right is a bit of swine, building more jigs than would thought necessary, but if it works without the rods binding it will be worth it.

Might kick start me into doing a thread on it from the railway point of view.

Might kick start me into doing a thread on it from the railway point of view.

Thanks for all the appreciative comments everyone. It gives me a lot of satisfaction in cheering up and fascinating other people with machinery they dont often see and explaining to them how it works to spread the joy of steam

Silverfoxcc - jigs are key to everything! The chap who built my engine has a very long build thread on a steam forum (unfortunately it is members only, or I would paste a link across) and I am simply in awe at the engineering and machining skill needed to build up a steam engine from castings!

For those of you asking for a video, here is a little something I uploaded from the first time I steamed the engine up in my ownership

http://www.youtube.com/watch?v=oz5y4ez0vgk

Silverfoxcc - jigs are key to everything! The chap who built my engine has a very long build thread on a steam forum (unfortunately it is members only, or I would paste a link across) and I am simply in awe at the engineering and machining skill needed to build up a steam engine from castings!

For those of you asking for a video, here is a little something I uploaded from the first time I steamed the engine up in my ownership

http://www.youtube.com/watch?v=oz5y4ez0vgk

Yeehaw!

I live in Wylam, Northumberland, birth place of George Stephenson, so there is a bit of a theme of railways and steam engines locally. All the tourists coming to see his house etc etc. There is a steam engine club nearby, I think, where people get up to this sort of thing. Nice project, have fun with it!

Gassing Station | Scale Models | Top of Page | What's New | My Stuff

Fantastic! Passed a full-size steam engine trundling up the A127 last week near Basildon. We went into Wickford, got what we needed to from where we were going, had a bite to eat, set off home and passed it not much further, mad things in today's world but it's all the better for it

Fantastic! Passed a full-size steam engine trundling up the A127 last week near Basildon. We went into Wickford, got what we needed to from where we were going, had a bite to eat, set off home and passed it not much further, mad things in today's world but it's all the better for it

t they dig these old traction engines out to get stuff done.

t they dig these old traction engines out to get stuff done.