Unusual job on the bench today

Discussion

Hello Eddie

Are you able to do tin smith type repairs.?

I have a rare Lambretta embellisher that is a bit battered. Chrome plated Brass. Needs knocked back into shape and plated again.

This type of thing , but smaller. Mine sits over a bumper bar that fits onto the front of the Lambretta mudguard.

http://picssr.com/search/vigano+clamshell

Are you able to do tin smith type repairs.?

I have a rare Lambretta embellisher that is a bit battered. Chrome plated Brass. Needs knocked back into shape and plated again.

This type of thing , but smaller. Mine sits over a bumper bar that fits onto the front of the Lambretta mudguard.

http://picssr.com/search/vigano+clamshell

Brads67 said:

Hello Eddie

Are you able to do tin smith type repairs.?

I have a rare Lambretta embellisher that is a bit battered. Chrome plated Brass. Needs knocked back into shape and plated again.

This type of thing , but smaller. Mine sits over a bumper bar that fits onto the front of the Lambretta mudguard.

http://picssr.com/search/vigano+clamshell

Sorry mate, I don't delve into that side of things. Small objects maybe but not big stuff like that. I could diamond encrust a headlight if you wanted??? lolAre you able to do tin smith type repairs.?

I have a rare Lambretta embellisher that is a bit battered. Chrome plated Brass. Needs knocked back into shape and plated again.

This type of thing , but smaller. Mine sits over a bumper bar that fits onto the front of the Lambretta mudguard.

http://picssr.com/search/vigano+clamshell

Here's a good update for you........ A job that may or may not go as I hope. And I've got no "one i made earlier" to hide behind. I'll update is as I do it to keep it honest. Here's todays progress:

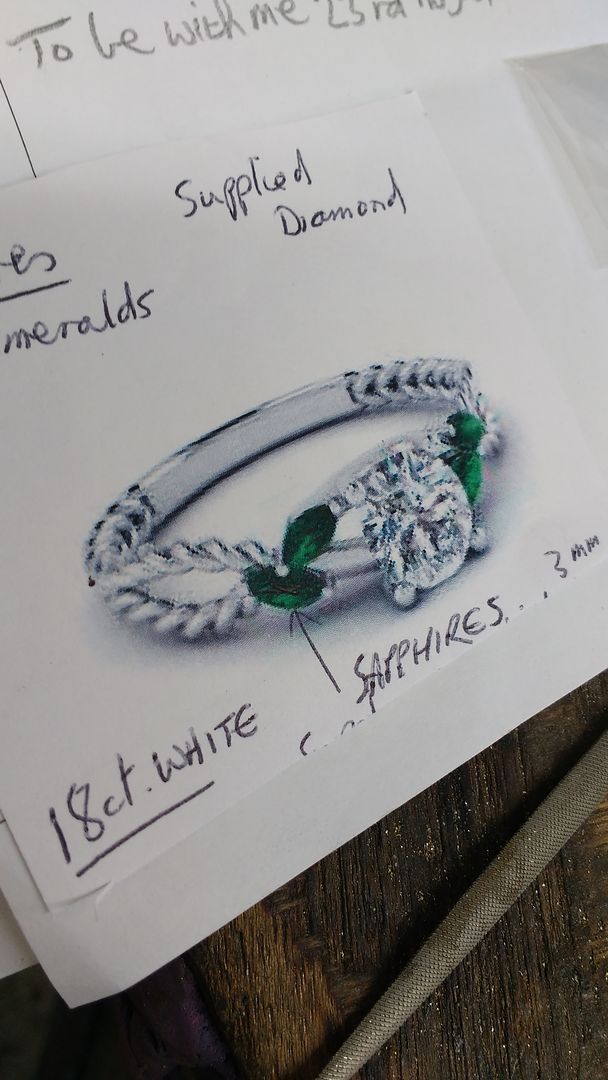

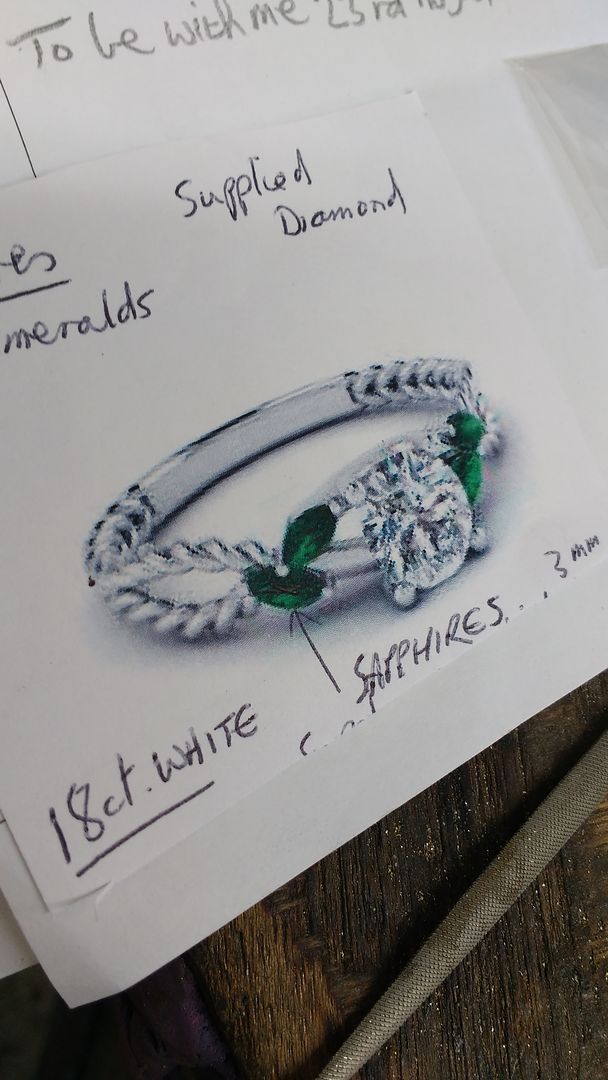

The customer wants this, but with blue sapphires and the twist bits only on the shoulders:

I decided to make the middle bit first...... 'bit' is not a technical term. I'm being casual with this as I have no idea if it's going to look good working with the materials provided.

18ct white gold wire:

With that done I turn my attention to the laborious job of the shoulder wires. I take some more 18ct white wire and cut a spiral into it with a fine saw. It is then filed to the correct shape with a triangle file. Not a quick job despite the small dimensions:

More to come tomorrow

The customer wants this, but with blue sapphires and the twist bits only on the shoulders:

I decided to make the middle bit first...... 'bit' is not a technical term. I'm being casual with this as I have no idea if it's going to look good working with the materials provided.

18ct white gold wire:

With that done I turn my attention to the laborious job of the shoulder wires. I take some more 18ct white wire and cut a spiral into it with a fine saw. It is then filed to the correct shape with a triangle file. Not a quick job despite the small dimensions:

More to come tomorrow

Ok. here is todays update: It's actually working!

So, yesterday I made a good dent in the twist wire production. A bit more filing and cutting later and I've got the point where I can make the shoulders:

Once I've made 2 the same I tack them on to the middle section:

The next step is to make a shank for the ring:

To prove I do make mistakes, see the wonky end:

Shank cut and shaped:

Tacked on one end:

And the other:

First look at where the centre stone will sit. It's not the best of diamonds..... I didn't supply it!

Give it a quick clean up before we start the next bit.....

Bore out the middle section to receive a tube to create the setting:

Tube is then placed in position and soldered from behind:

And then trimmed on top:

The tube is then bored out also and 4 claws soldered in place to hold the diamond:

Diamond is placed into the setting:

And set!

One last polish before I 'attempt' to add th sapphires tomorrow :S

So, yesterday I made a good dent in the twist wire production. A bit more filing and cutting later and I've got the point where I can make the shoulders:

Once I've made 2 the same I tack them on to the middle section:

The next step is to make a shank for the ring:

To prove I do make mistakes, see the wonky end:

Shank cut and shaped:

Tacked on one end:

And the other:

First look at where the centre stone will sit. It's not the best of diamonds..... I didn't supply it!

Give it a quick clean up before we start the next bit.....

Bore out the middle section to receive a tube to create the setting:

Tube is then placed in position and soldered from behind:

And then trimmed on top:

The tube is then bored out also and 4 claws soldered in place to hold the diamond:

Diamond is placed into the setting:

And set!

One last polish before I 'attempt' to add th sapphires tomorrow :S

The Spruce goose said:

When you set diamonds do you use a special glue or the force of the gold holding it.

if the Gold, it is very pliable so how so you stop the stone dropping out over time.

if the Gold, it is very pliable so how so you stop the stone dropping out over time.

Glue isn't used lol

The claw material (18ct white gold) is more than sufficient for holding stones in. So long as the material is thick enough and not too long it's actually pretty strong. You can manipulate it a bit obviously, but it will take normal wear quite easily. Just don't expect it to survive a building site or being driven over.

On the topic of longevity: the older generation are far better at looking after jewellery than today's throw away culture / cheaper is better generation. Insurance policies are routinely being used for bailing people out when an item becomes worn beyond recognition. The good thing is insurance companies are asking us as goldsmiths for evaluations of items in order to make a decision on whether to pay out or not.

Also. Many policies now have a clause where jewellery needs to be checked annually by a registered goldsmith for signs if wear and tear / manufacturer error.

Sorry to go off topic a little there but I thought it useful info.

Beachbum said:

"It's not the best of diamonds..... I didn't supply it!"

Can you go into the details of why its not ? Assuming the owner won't mind

Looks OK from the pics, but I assume the issues are in the detail

Colour is pretty poor for something so small. About an L. Clarity is not too bad. Maybe VS2 if it's lucky.Can you go into the details of why its not ? Assuming the owner won't mind

Looks OK from the pics, but I assume the issues are in the detail

I've just finished the job nw so I'll upload the pics to the host and update here in a little while.

Ok, it's done. Amazingly it pretty much all came together 1st time.

Sapphires ready to be set:

We need to make settings for these and to do that I solder 2 plates for each stone, which will be cut and notched to suit. Here's the first 2 in place:

The claws are then split and if necessary strengthened:

The first stone goes in to test the water:

The first is secured and then the second goes in:

The plates for the third and fourth stones are then soldered in place:

And split:

Stone 3 laid in:

And 4!

The ring is then polished and riven a bit of rhodium plating and it's good to go!

Have a nice weekend,

Eddie

Sapphires ready to be set:

We need to make settings for these and to do that I solder 2 plates for each stone, which will be cut and notched to suit. Here's the first 2 in place:

The claws are then split and if necessary strengthened:

The first stone goes in to test the water:

The first is secured and then the second goes in:

The plates for the third and fourth stones are then soldered in place:

And split:

Stone 3 laid in:

And 4!

The ring is then polished and riven a bit of rhodium plating and it's good to go!

Have a nice weekend,

Eddie

Yex 450 said:

Cracking write-up as always

Thing that really intrigues me with your jewellery threads is that the build process always looks like there is a load of extra metal used and then you magically work that away and polish it up to the beautiful finished article.

Because it's a soft metal it's always better to start with an excess. The process of finishing and polishing takes away a percentage of the product so it's worth having more meat on the bone early on. Any filings can be recovered later using a professional service. Also, cutting a single piece of material like the claws means you have less joints to worry about when soldering in the area. If you have lots of individual bits it can end up like a very vulnerable jigsaw.

Thing that really intrigues me with your jewellery threads is that the build process always looks like there is a load of extra metal used and then you magically work that away and polish it up to the beautiful finished article.

Glad you liked it

Eddie

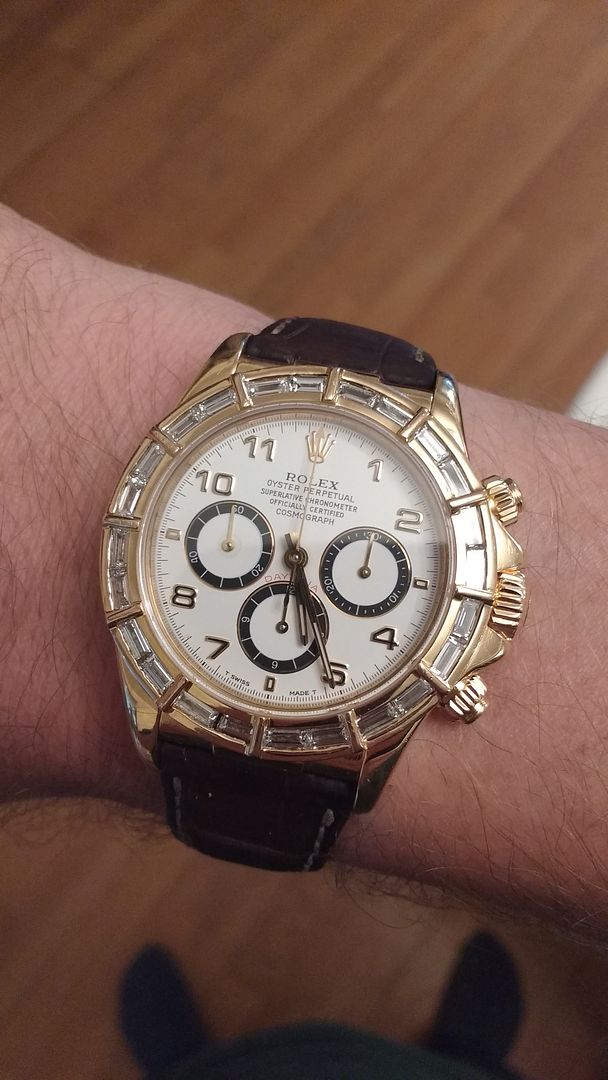

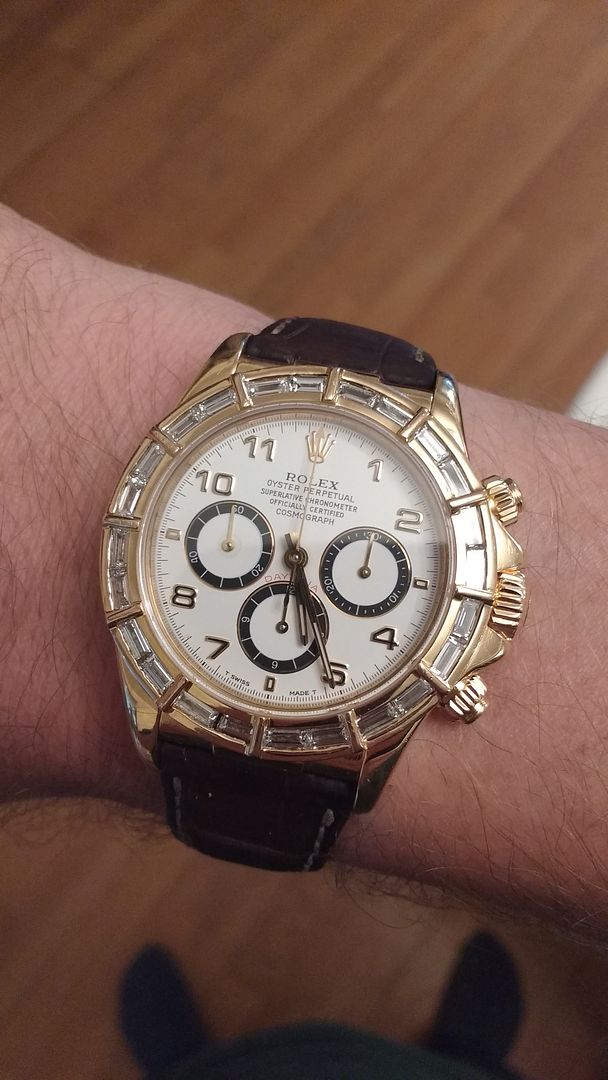

Had this come in yesterday for a refurb and service. Refurb wise there is no issue, as you'll see in the pics. The watch appears to have a very close copy of the Rolex branded diamond bezel fitted so servicing it may be an issue. We'll try to get around it somehow.

As you can see, the diamonds at the 33 min point and 57 min point don't quite line up.

A bit of work later and the stones are aligned:

Without giving away my secrets ha! the case gets a full overhall and is polished and dried. You can see the stones now all line up:

Buckle refurbished as far as possible without replacing parts:

And all back together:

As you can see, the diamonds at the 33 min point and 57 min point don't quite line up.

A bit of work later and the stones are aligned:

Without giving away my secrets ha! the case gets a full overhall and is polished and dried. You can see the stones now all line up:

Buckle refurbished as far as possible without replacing parts:

And all back together:

NeMiSiS said:

One of my dads sayings sums up that Daytona -

"You can't make a silk purse out of a sows ear."

Agreed. It's not very nice' Looks good in the box, .........in the safe, ........with the door closed!"You can't make a silk purse out of a sows ear."

It's got a new deployment strap coming next week so bar the service it's all singing, all dancing.

Gassing Station | Watches | Top of Page | What's New | My Stuff