Unusual job on the bench today

Discussion

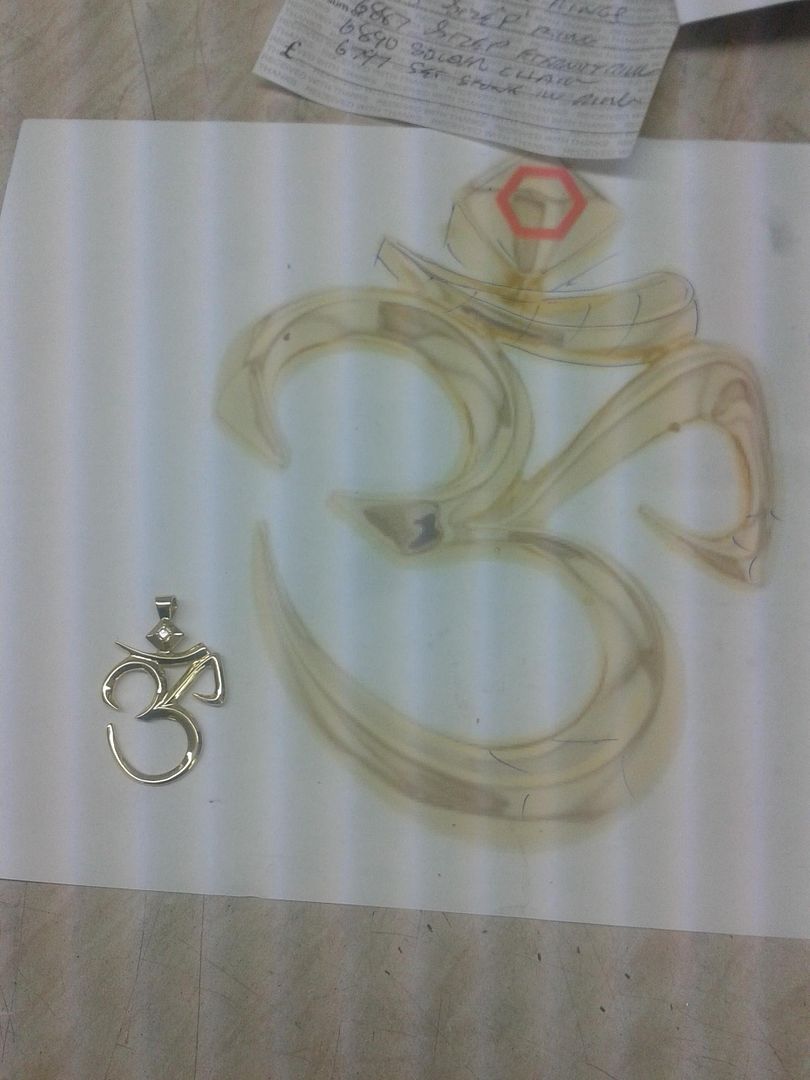

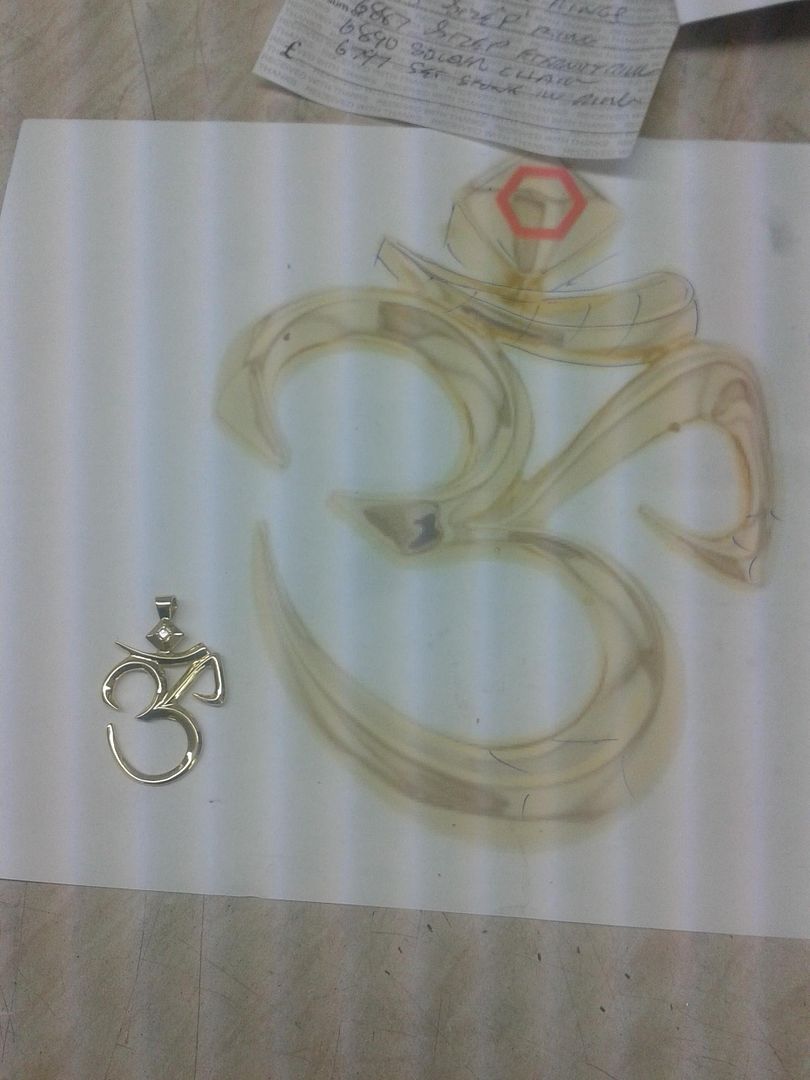

Ok, so here's one I've got on the go currently for a PHer.

Request: 18ct yellow gold, diamond set in the top (where red hexagon is), 30mm x 30mm or there abouts. Bale fitted to the top so a chain can run through.

The idea:

Initially I was going to CAD it, build a resin model and then cast it. That would have been easy, but being Xmas season the CAD and casting wing is choc-a-block so it's back to basics and I'm doing things using man-draulics.

So, I rolled out a plate of silver and scratched in the Tibetan Om design. And then got cracking with the hand saw (many blades broken!)

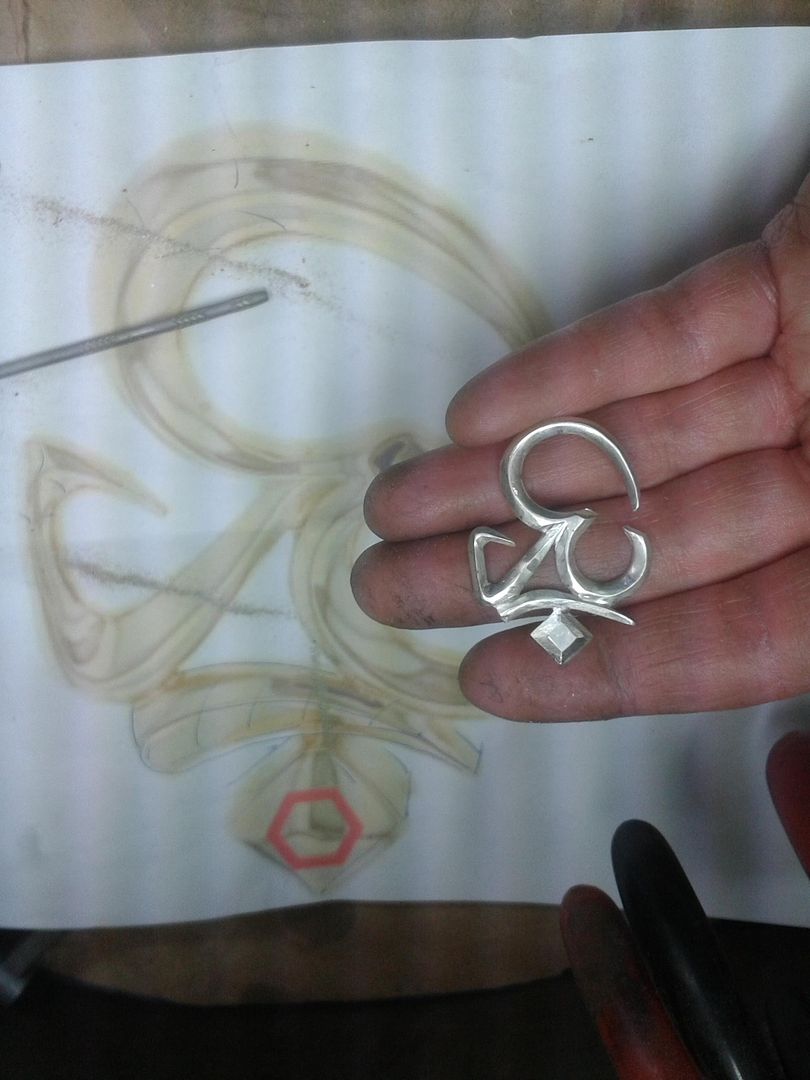

Rough design cut out:

The Om is not a square design, it has angles and cambers all round. Lots of grinding and filing follows!

With that done I get busy with the finer details and a little bit of adjusting of the shape. Looks good as it is!!

Tomorrow the plan is to take the silver example and fine-clay cast it in 18ct yellow gold. More to follow!

Request: 18ct yellow gold, diamond set in the top (where red hexagon is), 30mm x 30mm or there abouts. Bale fitted to the top so a chain can run through.

The idea:

Initially I was going to CAD it, build a resin model and then cast it. That would have been easy, but being Xmas season the CAD and casting wing is choc-a-block so it's back to basics and I'm doing things using man-draulics.

So, I rolled out a plate of silver and scratched in the Tibetan Om design. And then got cracking with the hand saw (many blades broken!)

Rough design cut out:

The Om is not a square design, it has angles and cambers all round. Lots of grinding and filing follows!

With that done I get busy with the finer details and a little bit of adjusting of the shape. Looks good as it is!!

Tomorrow the plan is to take the silver example and fine-clay cast it in 18ct yellow gold. More to follow!

Silver Smudger said:

There's some lovely stuff on this thread - Amazing how much is involved that I would not imagine looking at a finished piece.

Are the drawings as seen in the post above your work as well?

Thanks mate. Yeah it's often overlooked how much work goes into even the simplest of items. Drawings are customers own although I do often sketch if the customer is a bit poor with a pencil. Are the drawings as seen in the post above your work as well?

Today is casting day. So... "how do you do that then?" I hear you cry. Let the pictures tell the story.........

We use a clay which looks a bit like plaster-cine, but is a bit dryer.

The casting pots are 2 piece titanium items. They interlock to give a 2 piece press mold:

We start by chucking an amount of loose clay into the bottom half of the casting pot:

Then beat the crap out of it with a hammer until it's compressed down and level:

Then we chuck some more in.......

And batter it again:

The top of the pot is levelled off to give a nice flat surface to make the lower impression with:

The silver item is then pressed on to the top of the clay:

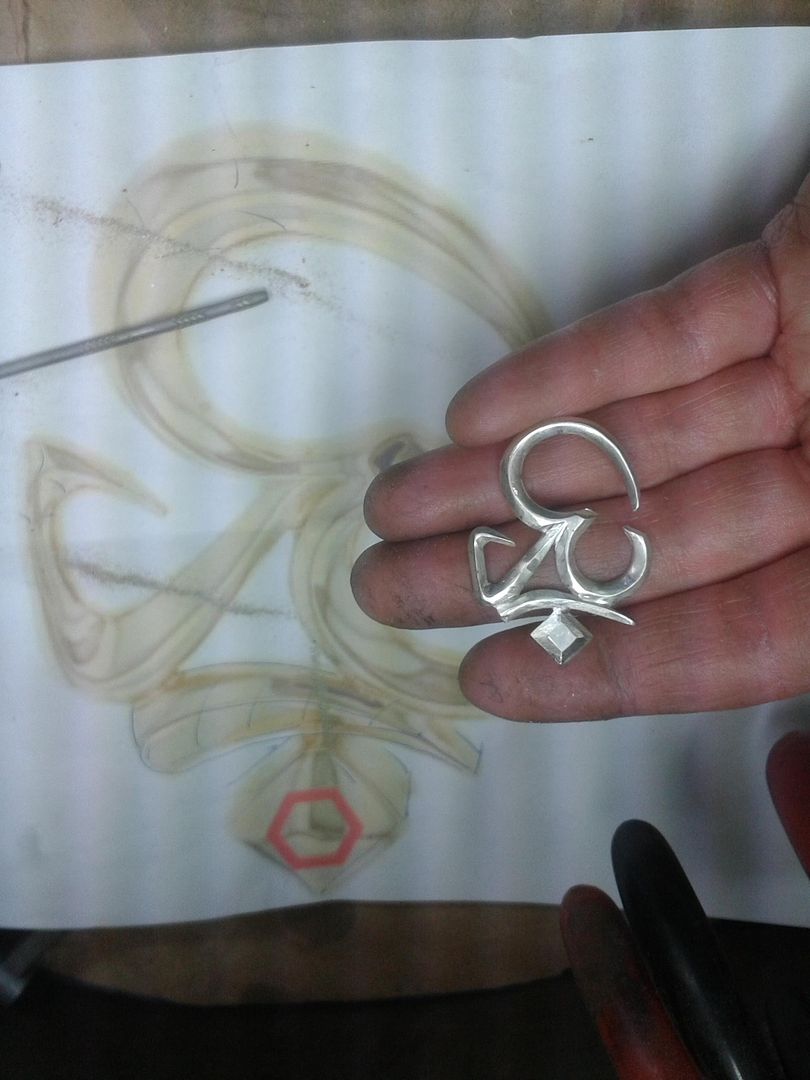

An impression has been made:

I pressed it on again to make the impression a bit deeper:

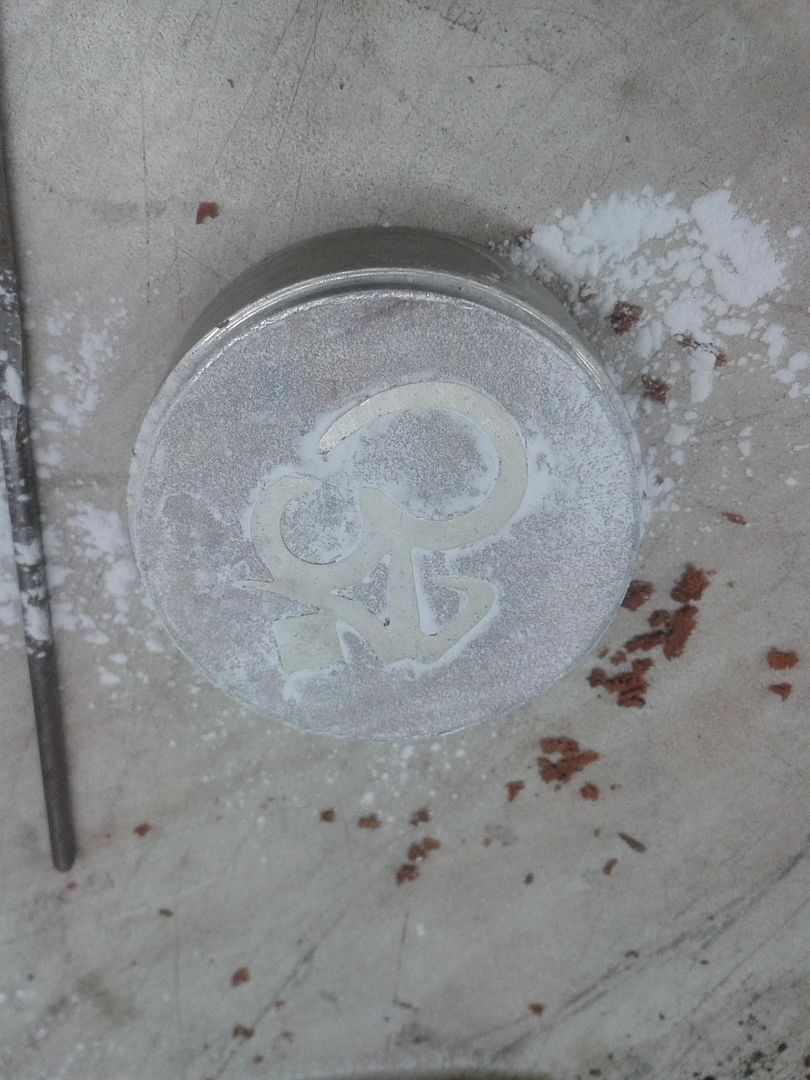

The silver item is then put back in to the clay and the top surface is covered with talcum powder. This is to stop the top half sticking to the lower half.

Top half of the pot is placed on top of the lower half. Note there are 2 notches at the mid point that need to be lined up. This allows me to make sure the impressions line up when i separate and realign:

More clay is chucked in and some more hammering follows:

Other side of the cast impression:

The silver item is carefully removed and the impressions are ready for the next stage:

The top half of the cast needs to have a hole cut from it. This is where the gold will be poured and is the most important hole of all:

Other side of the hole is bored out to create a funnel:

Some smaller holes are pushed into the arms of the impression. These allow the air to escape as it expands due to the heat. Without it the gold would not run properly:

Top half replaced and notches lined up: We are now ready for the the casting to start:

The customer wants the Om to be made in 18ct yellow gold. So, we fire up this bad boy!

And use it to melt some 18ct:

The melted gold:

Using constant applied heat from the torch the gold is poured into the hole: This is how it looks once cooled.

Now, what should have happened next is this: The gold is left to cool and the pots are separated. The cast metal inside will be perfectly formed and will have a sprue on the back where the funnel is (thats the lump you could see on the top of the clay). The sprue gets cut off and lots of filing and grinding takes place to tidy it up. Trouble is, my phone had a melt down and only rebooted once i'd got to the roughly ground stage:

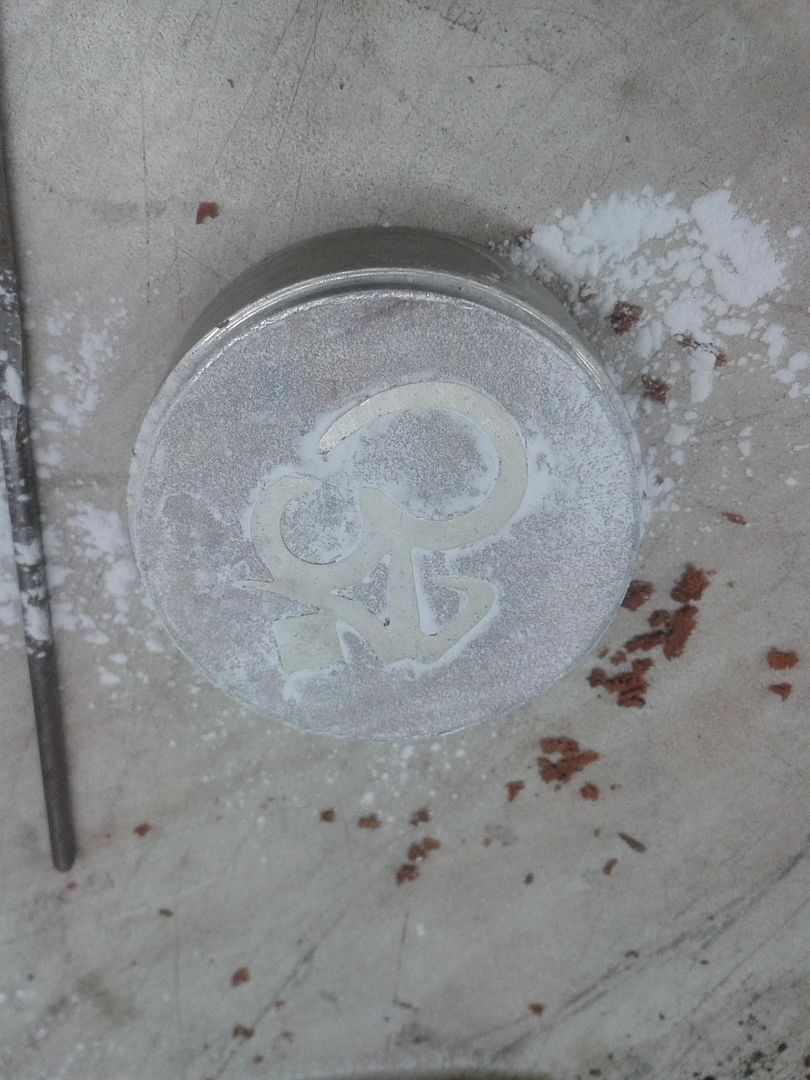

Gold on the left and silver on the right:

Some more grinding, buffing and a bit of polishing later:

The customer wants a princess cut diamond set in the square at the top. So i cut a square from the top of the Om in prep for setting later:

It also needs a bale in which to allow a chain to run through:

Bale soldered on:

Diamond set and all finished:

Eddie

We use a clay which looks a bit like plaster-cine, but is a bit dryer.

The casting pots are 2 piece titanium items. They interlock to give a 2 piece press mold:

We start by chucking an amount of loose clay into the bottom half of the casting pot:

Then beat the crap out of it with a hammer until it's compressed down and level:

Then we chuck some more in.......

And batter it again:

The top of the pot is levelled off to give a nice flat surface to make the lower impression with:

The silver item is then pressed on to the top of the clay:

An impression has been made:

I pressed it on again to make the impression a bit deeper:

The silver item is then put back in to the clay and the top surface is covered with talcum powder. This is to stop the top half sticking to the lower half.

Top half of the pot is placed on top of the lower half. Note there are 2 notches at the mid point that need to be lined up. This allows me to make sure the impressions line up when i separate and realign:

More clay is chucked in and some more hammering follows:

Other side of the cast impression:

The silver item is carefully removed and the impressions are ready for the next stage:

The top half of the cast needs to have a hole cut from it. This is where the gold will be poured and is the most important hole of all:

Other side of the hole is bored out to create a funnel:

Some smaller holes are pushed into the arms of the impression. These allow the air to escape as it expands due to the heat. Without it the gold would not run properly:

Top half replaced and notches lined up: We are now ready for the the casting to start:

The customer wants the Om to be made in 18ct yellow gold. So, we fire up this bad boy!

And use it to melt some 18ct:

The melted gold:

Using constant applied heat from the torch the gold is poured into the hole: This is how it looks once cooled.

Now, what should have happened next is this: The gold is left to cool and the pots are separated. The cast metal inside will be perfectly formed and will have a sprue on the back where the funnel is (thats the lump you could see on the top of the clay). The sprue gets cut off and lots of filing and grinding takes place to tidy it up. Trouble is, my phone had a melt down and only rebooted once i'd got to the roughly ground stage:

Gold on the left and silver on the right:

Some more grinding, buffing and a bit of polishing later:

The customer wants a princess cut diamond set in the square at the top. So i cut a square from the top of the Om in prep for setting later:

It also needs a bale in which to allow a chain to run through:

Bale soldered on:

Diamond set and all finished:

Eddie

longshot said:

I wondered that too.

Silver is cheap as chips and can be reused over and over. The myth that silver is a precious metal is just that. .... a myth. Compare to gold which is sold in grams, silver is sold by the kilo.A little story about silver and the myth:

About 2 years ago I had a customer come to me with a silver bangle which she had bought from Pandora (first mistake). It was one of those '1 of 500' limited run items that they were punting for Xmas. The window price was £800, and she paid it (mistake number 2). Over Xmas she dropped it and dented it in an area that was quite obvious. She tried to tale it back to Pandora to see if they'd fix it, to which they said 'No, but if you go and see Eddie at J&R he may be able to do something'.

She came straight up and asked if i could fix it. I said i could do my best but silver 'fire stains' and the area will always show. Also silver solder has nickel and other stuff mixed in with the silver so you never get a good finish like you do with gold or platinum solder. She decided that she would rather sell it so asked if I'd buy it from her at scrap value. Explaining that she'd only recently spunked £800 on the item she expected that she may have got a few hundred quid back and take the hit on the rest, like you would on a diamond ring maybe. I weighed the bangle at just over 100g and at a buying value of around 50p a gram at the time she went into a fit of rage. Could have been worse, today's price is circa 30p a gram!!!!

Don't be fooled by silver folks. Save your money and buy a Rolex or diamonds!!

Edited by ecain63 on Saturday 13th December 22:00

One of the last UJOTB posts for 2015, but one that my wife will like. Today she gets a diamond upgrade:

Original 1.31ct European cut diamond from our engagement in 2006. The new 2.34ct European cut as a well earned upgrade.

The old stone is out and the difference is clear. The new stone is VVS quality too.

The job spec is that we retain the original setting which means i have to modify the claws,

The original claws are filed off and made ready for the new ones.

The inner surface of the setting had to be ground out fractionally to accommodate the slightly wider keel of the new stone.

Ready to have new claws fitted.

They look rough now but these are the 6 new platinum claws that will be shaped to hide any evidence that any work was ever done.

The new stone is placed into the setting and the claws pushed over the girdle. They are then trimmed to length and filed to shape.

The sides get tidied up...

The claws rounded....

A polish and rhodium later and back on the wife's hand. Merry Christmas Mrs xx

Original 1.31ct European cut diamond from our engagement in 2006. The new 2.34ct European cut as a well earned upgrade.

The old stone is out and the difference is clear. The new stone is VVS quality too.

The job spec is that we retain the original setting which means i have to modify the claws,

The original claws are filed off and made ready for the new ones.

The inner surface of the setting had to be ground out fractionally to accommodate the slightly wider keel of the new stone.

Ready to have new claws fitted.

They look rough now but these are the 6 new platinum claws that will be shaped to hide any evidence that any work was ever done.

The new stone is placed into the setting and the claws pushed over the girdle. They are then trimmed to length and filed to shape.

The sides get tidied up...

The claws rounded....

A polish and rhodium later and back on the wife's hand. Merry Christmas Mrs xx

ecain63 said:

longshot said:

I wondered that too.

Silver is cheap as chips and can be reused over and over. The myth that silver is a precious metal is just that. .... a myth. Compare to gold which is sold in grams, silver is sold by the kilo.A little story about silver and the myth:

About 2 years ago I had a customer come to me with a silver bangle which she had bought from Pandora (first mistake). It was one of those '1 of 500' limited run items that they were punting for Xmas. The window price was £800, and she paid it (mistake number 2). Over Xmas she dropped it and dented it in an area that was quite obvious. She tried to tale it back to Pandora to see if they'd fix it, to which they said 'No, but if you go and see Eddie at J&R he may be able to do something'.

She came straight up and asked if i could fix it. I said i could do my best but silver 'fire stains' and the area will always show. Also silver solder has nickel and other stuff mixed in with the silver so you never get a good finish like you do with gold or platinum solder. She decided that she would rather sell it so asked if I'd buy it from her at scrap value. Explaining that she'd only recently spunked £800 on the item she expected that she may have got a few hundred quid back and take the hit on the rest, like you would on a diamond ring maybe. I weighed the bangle at just over 100g and at a buying value of around 50p a gram at the time she went into a fit of rage. Could have been worse, today's price is circa 30p a gram!!!!

Don't be fooled by silver folks. Save your money and buy a Rolex or diamonds!!

Edited by ecain63 on Saturday 13th December 22:00

It's that time again:

On Monday a good friend of mine came to see me at work. He's recently been diagnosed with terminal cancer and has had his focus directed toward sorting out his life affairs etc. One of the things he's got on his list is to have his wedding blessed. He's married to an Indian lady and with both of them on their second marriage they weren't allowed to get married in a church when they first got together 32 years ago. Now things have changed in the church and with everything that's going on they have decided to get it sorted before his condition deteriorates. She has worn her original 18ct and 0.05ct diamond engagement ring and 18ct wedding ring since they married in '83. Along side that she's worn a gold plated brass 1/2 eternity ring set with CZ's which she bought in France a few years back.

So, what was my tasking?

Job spec: Replace 0.05ct diamond in engagement ring with 0.10ct diamond. Clean up and polish engagement and wedding ring. Make a replacement matching 1/2 eternity ring in 18ct gold set with 7 x 0.10ct diamonds. The wedding and engagement ring jobs don't really warrant pics but I was quite chuffed with the eternity ring so here you go:

We started with a piece of 18ct yellow gold bar:

I then cut a section of 3mm x 3mm square bar to match the dimensions of the brass original:

Excuse the lack of pic of the original, it's coming in a minute. Here I have marked and started filing out the shapes of the settings:

Brass original and roughly filed new 18ct head:

Top part of the setting filed:

Underside of the top setting marked out and grooved:

Underside of the top setting rounded off to match brass original:

I then took a 0.75mm x 3mm sheet of 18ct yellow gold:

Shaped it to match the inner of the setting:

And soldered it to the top setting:

Lightly cleaned up and cut to length:

I then took some more 18ct yellow gold and rolled it to a 3mm x 1.75mm D-shaped bar:

Turned a shank and soldered on:

With the ring now in one piece it was time to get around the setting work. Here I've started to grove the claws:

And then drilled out the pilot holes where the keel of the diamonds will sit:

Then a bore drill is used to shape the holes where the diamonds sit:

Ready for setting:

And set. 7 x 0.10ct brilliant cut diamonds:

Old vs new:

And after a polish it's all good to go:

A very happy Mrs Smith and her husband / my mate Mr Smith:

That's the part of the job I enjoy!!

On Monday a good friend of mine came to see me at work. He's recently been diagnosed with terminal cancer and has had his focus directed toward sorting out his life affairs etc. One of the things he's got on his list is to have his wedding blessed. He's married to an Indian lady and with both of them on their second marriage they weren't allowed to get married in a church when they first got together 32 years ago. Now things have changed in the church and with everything that's going on they have decided to get it sorted before his condition deteriorates. She has worn her original 18ct and 0.05ct diamond engagement ring and 18ct wedding ring since they married in '83. Along side that she's worn a gold plated brass 1/2 eternity ring set with CZ's which she bought in France a few years back.

So, what was my tasking?

Job spec: Replace 0.05ct diamond in engagement ring with 0.10ct diamond. Clean up and polish engagement and wedding ring. Make a replacement matching 1/2 eternity ring in 18ct gold set with 7 x 0.10ct diamonds. The wedding and engagement ring jobs don't really warrant pics but I was quite chuffed with the eternity ring so here you go:

We started with a piece of 18ct yellow gold bar:

I then cut a section of 3mm x 3mm square bar to match the dimensions of the brass original:

Excuse the lack of pic of the original, it's coming in a minute. Here I have marked and started filing out the shapes of the settings:

Brass original and roughly filed new 18ct head:

Top part of the setting filed:

Underside of the top setting marked out and grooved:

Underside of the top setting rounded off to match brass original:

I then took a 0.75mm x 3mm sheet of 18ct yellow gold:

Shaped it to match the inner of the setting:

And soldered it to the top setting:

Lightly cleaned up and cut to length:

I then took some more 18ct yellow gold and rolled it to a 3mm x 1.75mm D-shaped bar:

Turned a shank and soldered on:

With the ring now in one piece it was time to get around the setting work. Here I've started to grove the claws:

And then drilled out the pilot holes where the keel of the diamonds will sit:

Then a bore drill is used to shape the holes where the diamonds sit:

Ready for setting:

And set. 7 x 0.10ct brilliant cut diamonds:

Old vs new:

And after a polish it's all good to go:

A very happy Mrs Smith and her husband / my mate Mr Smith:

That's the part of the job I enjoy!!

Butter Face said:

Great job and and a great story!

I'd love to have a ring made by you, but I really don't think I could afford it! Lol.

Got my first child on the way in July and I've been told an eternity ring is traditionally given by a man to his wife on the birth of a child? IDK!

Yeah. 1st child or 1st anniversary usually.I'd love to have a ring made by you, but I really don't think I could afford it! Lol.

Got my first child on the way in July and I've been told an eternity ring is traditionally given by a man to his wife on the birth of a child? IDK!

ali_kat said:

Beautiful ring & nice story

Did your late clients missing ring turn up?

Actually, yes it did. The coroners assistant called her family just before the funeral (4 weeks after she passed) to tell them she was wearing a gold band. Turned out to be the missing ring. Given she'd been passed from place to place in those 4 weeks I find it hard to believe the ring was on her finger the whole time. The coroner removed her jewellery when first called out so it's odd he missed it given the size of the ring.

Did your late clients missing ring turn up?

Gassing Station | Watches | Top of Page | What's New | My Stuff