Unusual job on the bench today

Discussion

Hi Eddie, first time poster long time reader.

I wondered if you could give me some guidance on the best way to polish my ring (not bog roll related)

I think from memory it's 23.5 karat gold and thus quite soft, it just picks up scratches here and there and I would like to clean it without rubbing all the gold away.

I wondered if you could give me some guidance on the best way to polish my ring (not bog roll related)

I think from memory it's 23.5 karat gold and thus quite soft, it just picks up scratches here and there and I would like to clean it without rubbing all the gold away.

[quote=_MIKE_]Hi Eddie, first time poster long time reader.

I wondered if you could give me some guidance on the best way to polish my ring (not bog roll related)

I think from memory it's 23.5 karat gold and thus quite soft, it just picks up scratches here and there and I would like to clean it without rubbing all the gold away.

[/quote]

Unfortunately, unless you have a high speed polishing wheel and the correct wax / cutting agent you will never get a mirror shine. Especially with higher carat metals. Although soft, they are very dense. Platinum is the same. It too picks up every scratch but is a proper pain to polish properly.

The only suggestion I have is the one that involves you sending me the ring, which will be cheaper than buying the tools to do it yourself. PM me if that works for you. I'll do my best to retain at least 25% of the original metal

I wondered if you could give me some guidance on the best way to polish my ring (not bog roll related)

I think from memory it's 23.5 karat gold and thus quite soft, it just picks up scratches here and there and I would like to clean it without rubbing all the gold away.

[/quote]

Unfortunately, unless you have a high speed polishing wheel and the correct wax / cutting agent you will never get a mirror shine. Especially with higher carat metals. Although soft, they are very dense. Platinum is the same. It too picks up every scratch but is a proper pain to polish properly.

The only suggestion I have is the one that involves you sending me the ring, which will be cheaper than buying the tools to do it yourself. PM me if that works for you. I'll do my best to retain at least 25% of the original metal

As promised I got the mystery job finished today. Here's a brief summary of what I did....

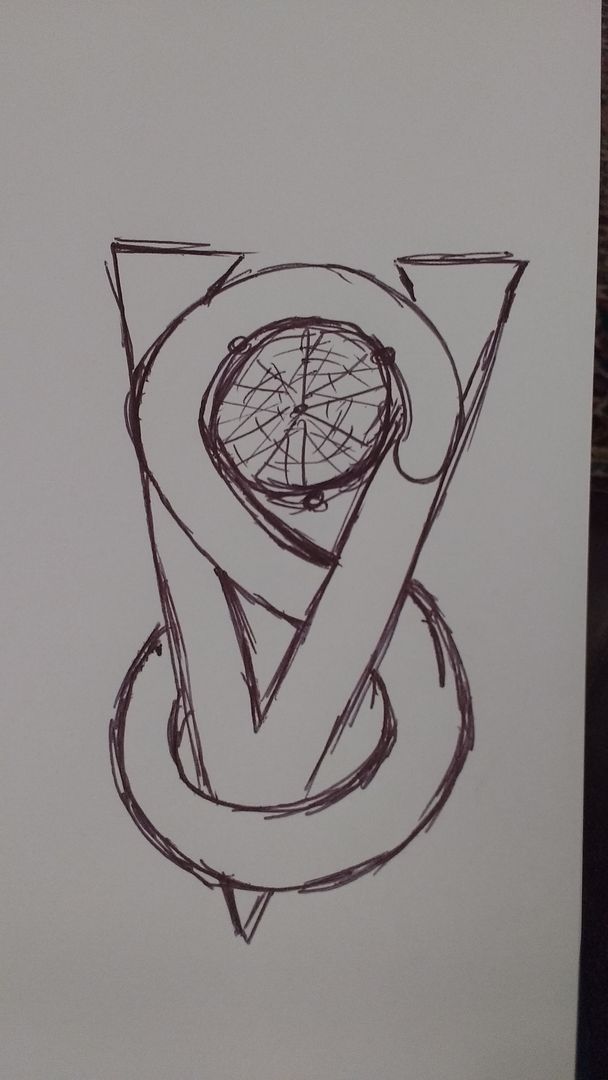

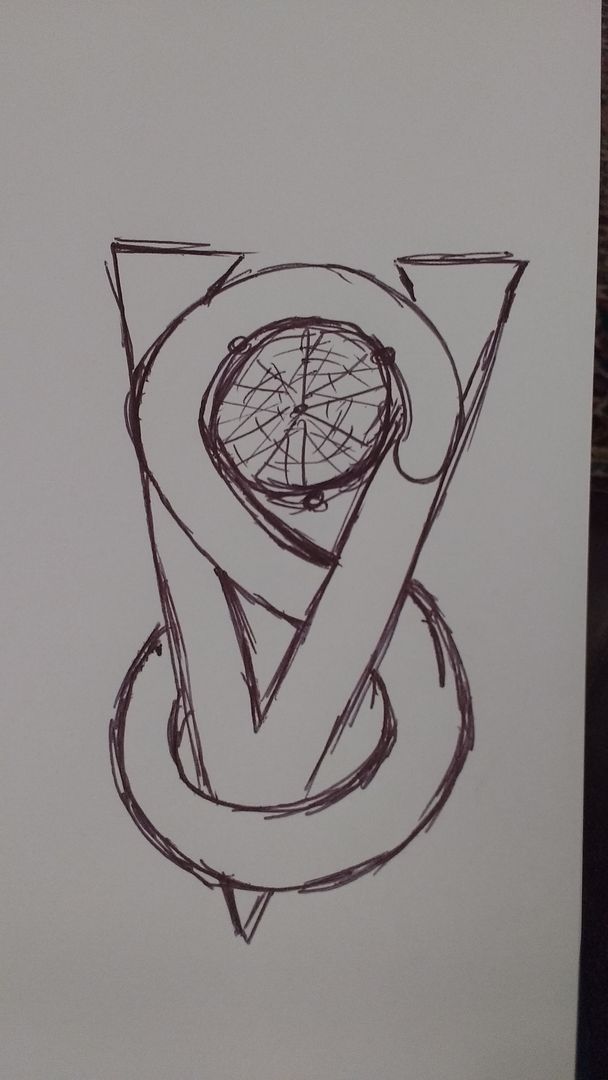

A customer contacted me with a request to make a pendent that incorporated the initials of his two daughters. He also originally wanted a diamond set in it but that was canned to be added another day. This is the rough guide for what we decided on:

The item is to be made in 18ct white gold. This is a plate of 18ct white gold rolled down from 6x6mm wire:

Onto the plate I stick a piece of paper that I have drawn a rough sketch on. This is the rough template to cut around (with a hand saw):

Roughly cut around:

Tidied up a little:

I try to do these jobs by eye rather than by ruler or gauge. Getting them perfect takes away some of the charm but I try to get it as close as possible with endless fiddling lol:

There were a couple of bits that I needed to add by soldering bits of 18ct white gold in the right places. If you look you can see them:

Getting there. Just needs some final touches toward the end:

With the initals / pendent nearly done it's time to get the chain fittings sorted. I fit a loop first:

Then take a bit more 18ct white gold plate:

This is rolled out, turned and shaped to make the bale that the chain runs through:

A hole is drilled though:

And the hole rivetted and soldered:

A polish and rhodium plate and it's done:

Eddie

A customer contacted me with a request to make a pendent that incorporated the initials of his two daughters. He also originally wanted a diamond set in it but that was canned to be added another day. This is the rough guide for what we decided on:

The item is to be made in 18ct white gold. This is a plate of 18ct white gold rolled down from 6x6mm wire:

Onto the plate I stick a piece of paper that I have drawn a rough sketch on. This is the rough template to cut around (with a hand saw):

Roughly cut around:

Tidied up a little:

I try to do these jobs by eye rather than by ruler or gauge. Getting them perfect takes away some of the charm but I try to get it as close as possible with endless fiddling lol:

There were a couple of bits that I needed to add by soldering bits of 18ct white gold in the right places. If you look you can see them:

Getting there. Just needs some final touches toward the end:

With the initals / pendent nearly done it's time to get the chain fittings sorted. I fit a loop first:

Then take a bit more 18ct white gold plate:

This is rolled out, turned and shaped to make the bale that the chain runs through:

A hole is drilled though:

And the hole rivetted and soldered:

A polish and rhodium plate and it's done:

Eddie

ecain63 said:

I'd normally do it over 2 or 3 days, between other jobs (did 185 this week) but I could do the whole thing in 3 or 4 hours.

One question if I may.When doing jobs like this, do you ever get lost in it or are you always conscious of the time and the list of jobs to do next?

RevsPerMinute said:

ecain63 said:

I'd normally do it over 2 or 3 days, between other jobs (did 185 this week) but I could do the whole thing in 3 or 4 hours.

One question if I may.When doing jobs like this, do you ever get lost in it or are you always conscious of the time and the list of jobs to do next?

It's a product of our own success so I won't complain but this is my average day as it stood this week. I currently work solo on the bench due to my employee being off sick. My wife comes in to take care of the shop front:

6.45am - open up.

6.45am to 7.30am - set up and book out previous days work. I cover the repair work for a dozen shops across England so there is always book work.

7.30 - Shop opens (we do mainly trade jobs so other shop owners come to collect and drop off before they open themselves)

7.30 to 13.45 - On the bench doing as much work as is physically possible without compromising quality. I personally average around 55 jobs a day myself Monday to Wednesday but sometimes I can do up to 80 if I stay on the bench until 3.30 due to massive workload. On a Thursday and Friday I'll do 15 to 30 bigger jobs as most of the bulk is already bagged and tagged. There is no lunch hour for me, much like many business owners. An hour out would create hassle so I have my lunch on the bench at 12 noon and just work through.

13.45 to around 16.00 / 16.30 - Polishing and plating the days work. This is as busy as the morning session as it's simply reprocessing the work already done.

16.00 - Shop closes to the public. Although we get plenty of people knocking anyway because they expect us to be open regardless. I close at 16.00 to allow me to securely process the next stage of the work as it's far more desirable at that point should anyone want to break in.

16.30 approx to lock up (18.00 often) - Quality control, adjustments and packing.

This is on top of telephone, email and shop front distraction. It's a busy day but we have to cover ground at a pace to satisfy valuable customers. If we cock up or can't produce the goods week in, week out then they go elsewhere. I've got half a dozen shops that have used us for over 20 years now. That says enough about the way we do things to satisfy the bank manager

That said, I did decide 3 years ago when I got ill that I'd change things and take more time to enjoy the work / enjoy my life. I am ashamed to say that I still continue to work under high stress but on the upside I don't take it overly seriously where possible. The work needs doing obviously but I try to skim off or price-out jobs that I can foresee problems in. The quality of work is now much cleaner despite the volume but it's a means to an end. At some point I'll stop. I'll sell and I'll move to be mortgage and worry free.

In 2 months, or less if things go smoothly, we will be moving premises to my home town of Ringwood. This will give us more public attention and so long as retail and higher margin stuff increases then I will be able to reduce the trade stuff by a percentage. If that works then just maybe I'll be able to get lost in the odd job or two. I plan to give that 5 to 10 years and then that should set me up to do private commissions in a home workshop. Low volume, low stress and lots of family time. That's the plan anyway

Eddie

Well, I suppose it's been about a month now.......

Final update of September:

One of our very own PHers better halves wanted some work doing and albeit with a little communication issue we set about making a platinum ring and some charms. She had a 5 stone, 18ct yellow gold 1/2 Eternity ring that she really didn't get on with and wanted it remodelled to a more likeable style. This is a pic from today, but it gives you an idea of what it looked like originally.

And as it stands now:

You've all seen me make rings before so I won't give you another today. The other 2 jobs she wanted me to do involved making a couple of charms from the remaining 18ct gold in the old ring and a scrap chain. The 18ct would make a 'nugget' charm which will go onto a Pandora style bracelet. The 9ct chain, if there is enough of it, will become a heart charm which will be engraved along with the Platinum ring.

So, nugget charm. How?......

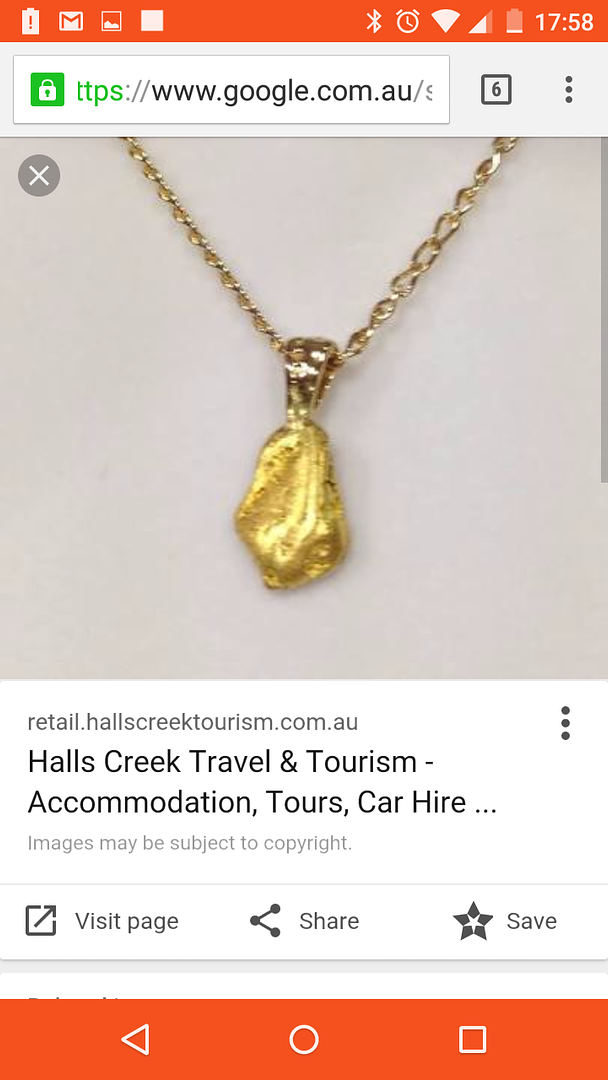

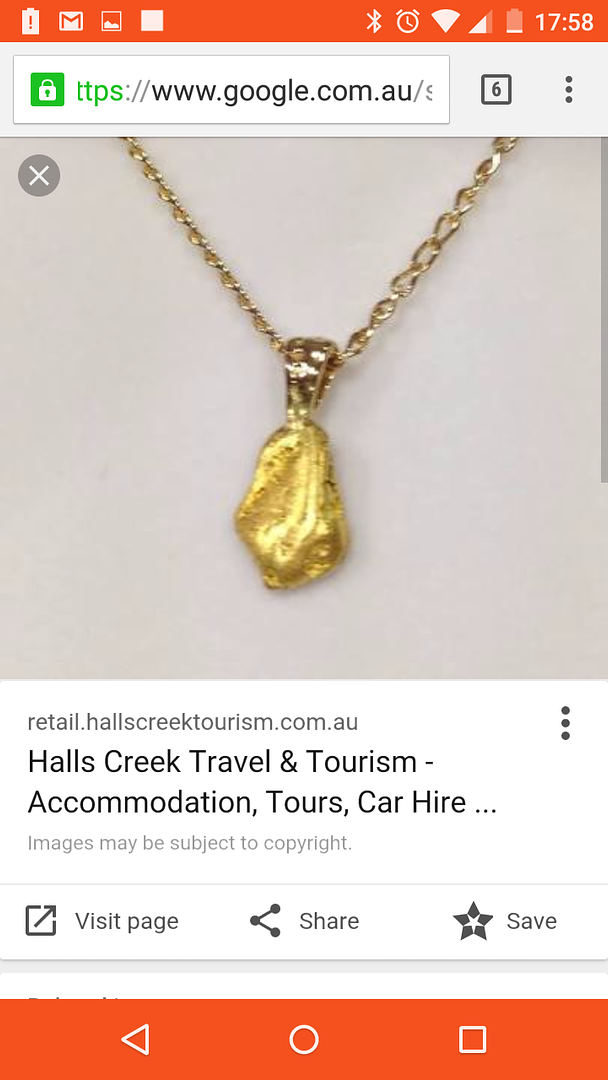

Basically, I am to melt the remainder of the 18ct yellow gold and make a nugget with the function of a charm. This is the nugget example:

I take the old ring:

Dismember it to remove the platinum claws:

Melt the shank section to make the nugget:

The rest of the 18ct will be used to make the fittings. Here is that gold melted and rolled into wire:

The hole needs to be 4.15mm wide so that the bracelet ends will fit through. I make a rough loop with the wire:

It is then soldered and compressed to the correct dimensions:

It gets a little tidy up:

It now needs fittings to attach the nugget:

Hey presto:

We'll come back to that later when it gets polished.

Next, the heart charm:

Here is the spec:

The charm will not have the paw print pattern applied but will be engraved along with the ring.

9ct chain:

Melted into a rough heart(ish) shape:

I use a bit of additional heat and some tools to try to tease it into as close a shape as possible. We are limited by a couple of factors with this job. Firstly the amount of gold that the chain will yield. Secondly, it needs to be thick enough and deep enough to allow a 4.15mm hole to be drilled through its length. Too narrow and it's a wasted job. This is it after a bit of hot pokery:

The V in the top is exaggerated with a file to start with. Again, we need to be careful about how deep we go with the details:

Before I file any more away I begin the long process of drilling the 4.15mm hole. The first hole is always the most difficult because it's being done by hand. Drill bits easily break and also they are difficult to keep on the straight and narrow. Amazingly this one went fine first time:

Slightly bigger. Oh, and it gets bloody hot:

At 4.15mm the hole is pushing the boundaries of what we can achieve with the supplied materials. With the gold I have drilled out so far I make some extensions for the holes in order to build the ends up a bit. This will help keep the shape better:

Trimmed down and ready for final polishing and later engraving:

Remember this is all being done by eye and hand (other than the internal dimensions of the hole):

The nugget charm will get a clean and polish now too:

Heart polished:

And it's mate:

Hope you like. See you in October

Final update of September:

One of our very own PHers better halves wanted some work doing and albeit with a little communication issue we set about making a platinum ring and some charms. She had a 5 stone, 18ct yellow gold 1/2 Eternity ring that she really didn't get on with and wanted it remodelled to a more likeable style. This is a pic from today, but it gives you an idea of what it looked like originally.

And as it stands now:

You've all seen me make rings before so I won't give you another today. The other 2 jobs she wanted me to do involved making a couple of charms from the remaining 18ct gold in the old ring and a scrap chain. The 18ct would make a 'nugget' charm which will go onto a Pandora style bracelet. The 9ct chain, if there is enough of it, will become a heart charm which will be engraved along with the Platinum ring.

So, nugget charm. How?......

Basically, I am to melt the remainder of the 18ct yellow gold and make a nugget with the function of a charm. This is the nugget example:

I take the old ring:

Dismember it to remove the platinum claws:

Melt the shank section to make the nugget:

The rest of the 18ct will be used to make the fittings. Here is that gold melted and rolled into wire:

The hole needs to be 4.15mm wide so that the bracelet ends will fit through. I make a rough loop with the wire:

It is then soldered and compressed to the correct dimensions:

It gets a little tidy up:

It now needs fittings to attach the nugget:

Hey presto:

We'll come back to that later when it gets polished.

Next, the heart charm:

Here is the spec:

The charm will not have the paw print pattern applied but will be engraved along with the ring.

9ct chain:

Melted into a rough heart(ish) shape:

I use a bit of additional heat and some tools to try to tease it into as close a shape as possible. We are limited by a couple of factors with this job. Firstly the amount of gold that the chain will yield. Secondly, it needs to be thick enough and deep enough to allow a 4.15mm hole to be drilled through its length. Too narrow and it's a wasted job. This is it after a bit of hot pokery:

The V in the top is exaggerated with a file to start with. Again, we need to be careful about how deep we go with the details:

Before I file any more away I begin the long process of drilling the 4.15mm hole. The first hole is always the most difficult because it's being done by hand. Drill bits easily break and also they are difficult to keep on the straight and narrow. Amazingly this one went fine first time:

Slightly bigger. Oh, and it gets bloody hot:

At 4.15mm the hole is pushing the boundaries of what we can achieve with the supplied materials. With the gold I have drilled out so far I make some extensions for the holes in order to build the ends up a bit. This will help keep the shape better:

Trimmed down and ready for final polishing and later engraving:

Remember this is all being done by eye and hand (other than the internal dimensions of the hole):

The nugget charm will get a clean and polish now too:

Heart polished:

And it's mate:

Hope you like. See you in October

Gassing Station | Watches | Top of Page | What's New | My Stuff