Unusual job on the bench today

Discussion

Today's job really is an 'unusual' one......

Customer has a husband who has everything. His birthday is coming up and his interests are: golf, cufflinks, gold, rubies, the number 7 and cars. He's got a new car, got more cufflinks than he can use but could maybe do with pimping out his golf kit. I bring you, the uber golf ball marker (apparently something you put on the green when you have to move your ball??).

The main body of the marker is to be made in silver. As it's going to be a bit large I opted to use specialist casting grains for the melt. This is a premium, clean metal that when melted should give a very workable and crack resistant finish. Here are thre grains:

The grains are melted and then rolled out to make a nice plate. The plate is pretty thick and weighs around 85g:

I spent a little time with the customer working out a design that incorporated the marker style as well as the gold, rubies and a number 7. We drew this on a piece of card and once underway I cut it out and glued it to the plate. The next job was to get the big (b.a.s.t.a.r.d) file out and burn some calories by filing away the excess. A clamp is essential if you want to save your fingers:

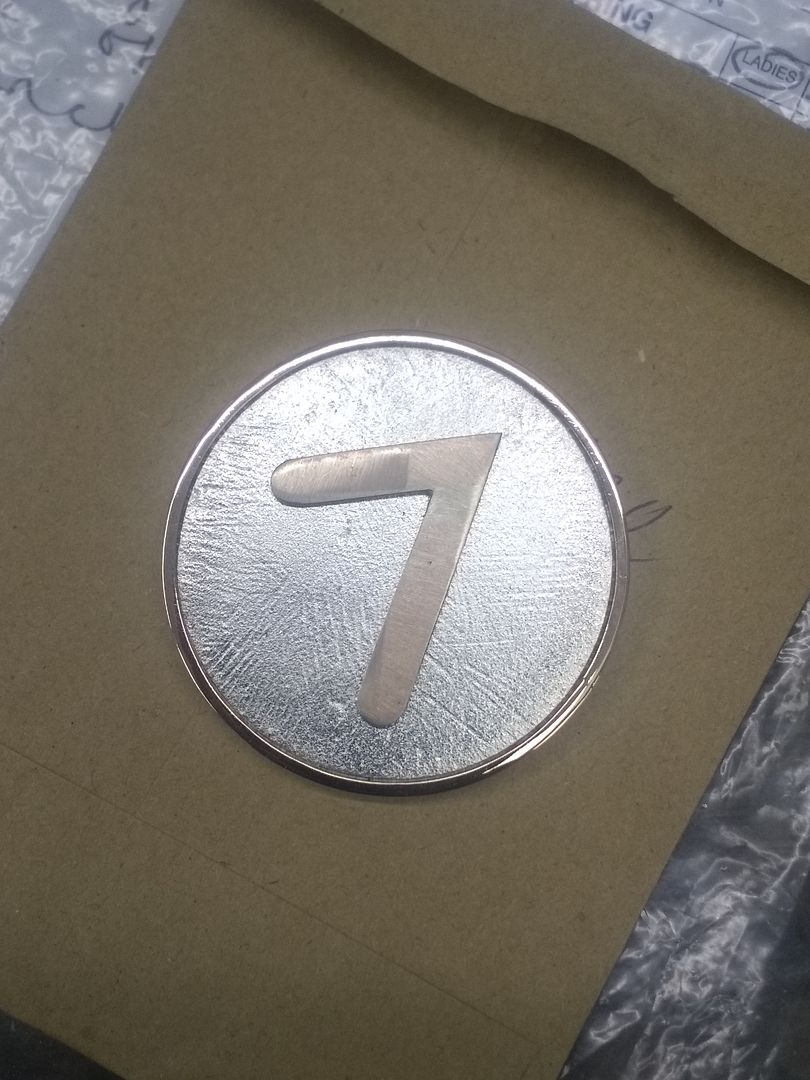

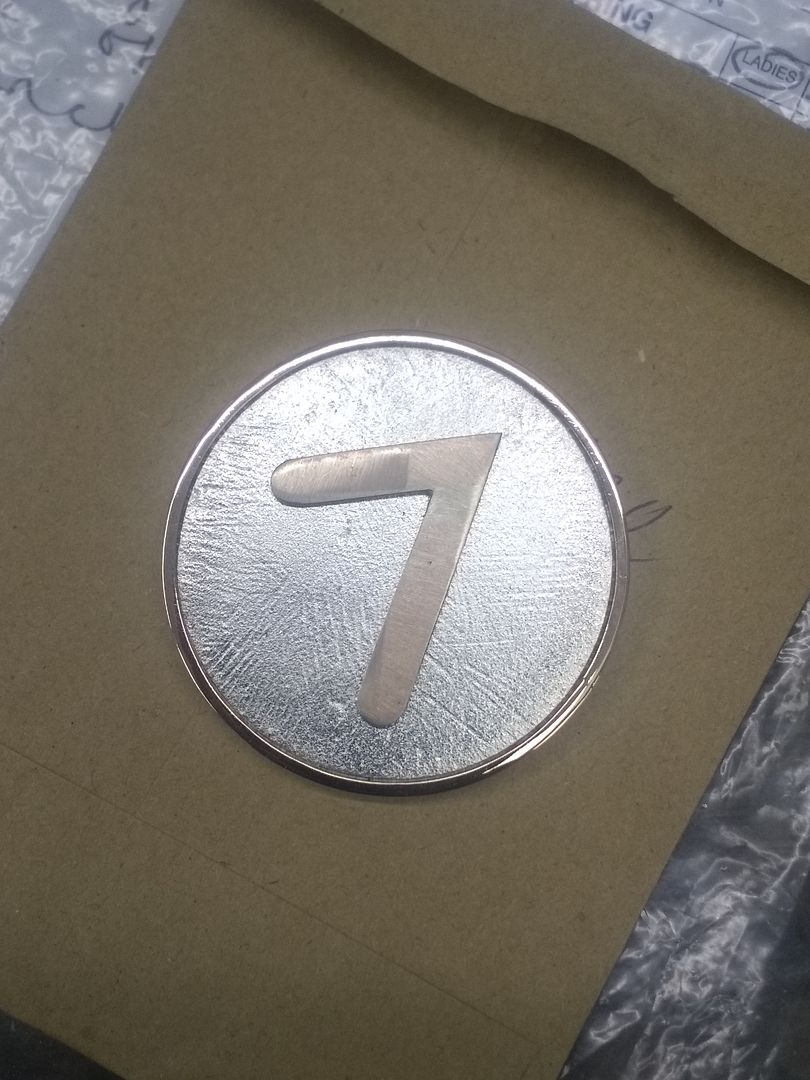

A good while later the disc is ready. My right shoulder is also whacked!

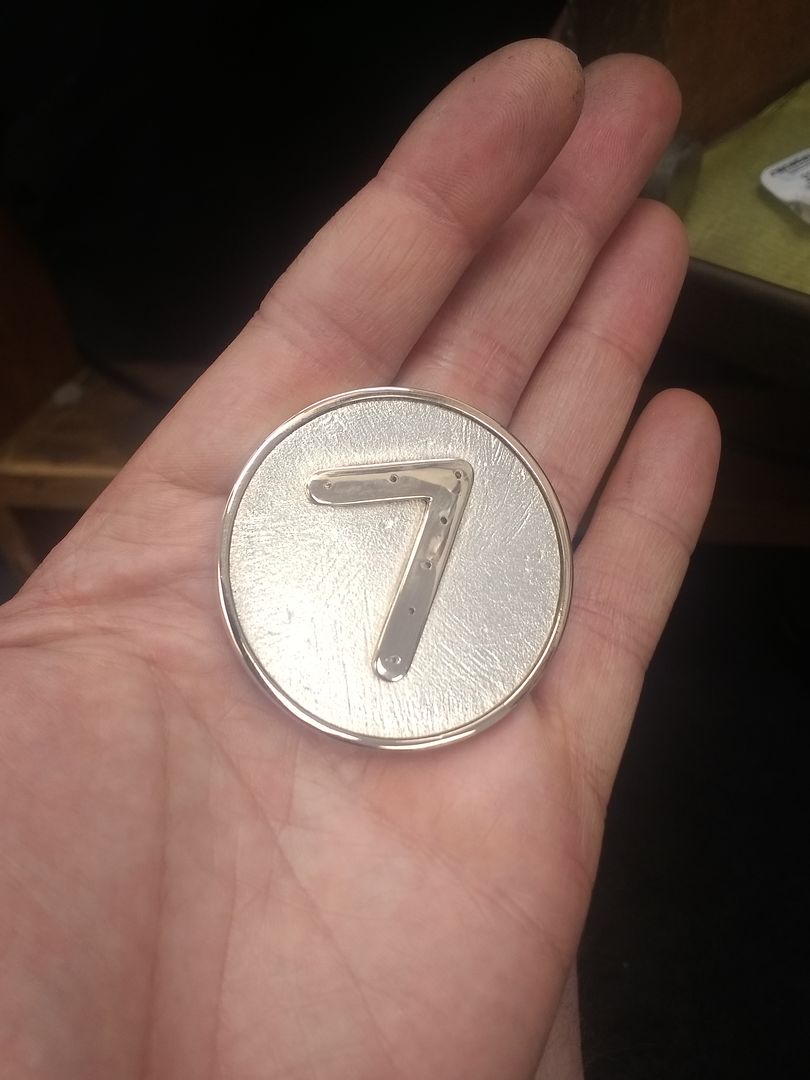

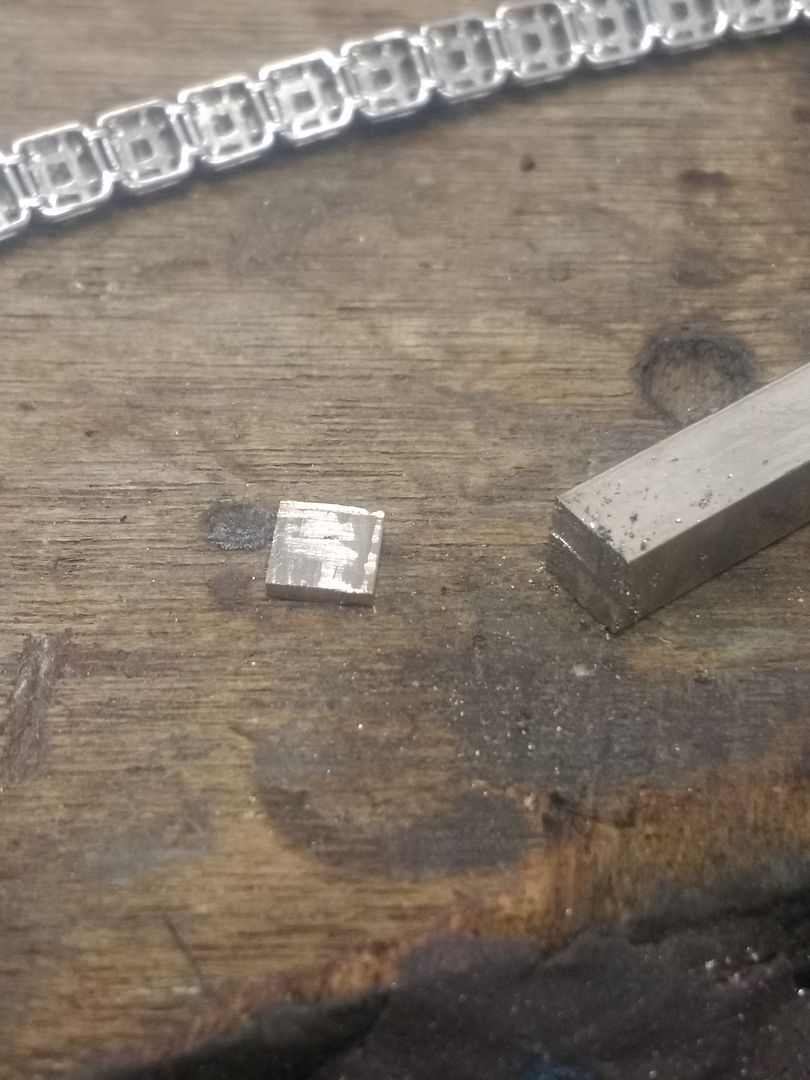

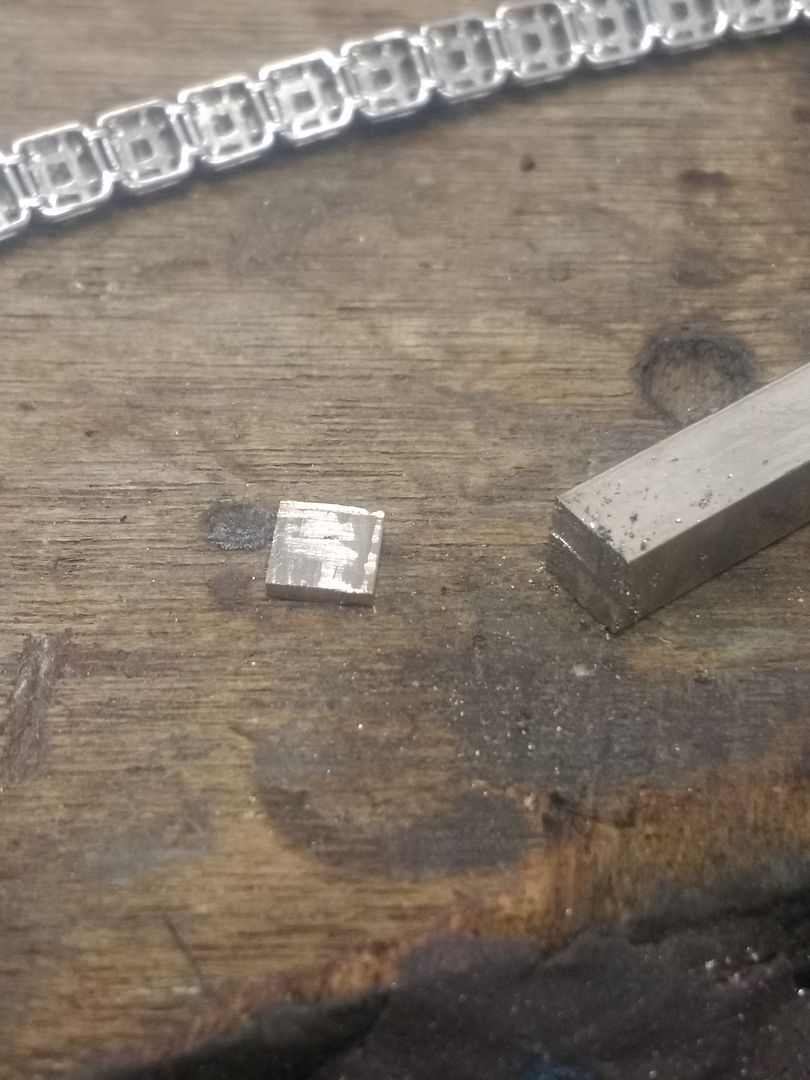

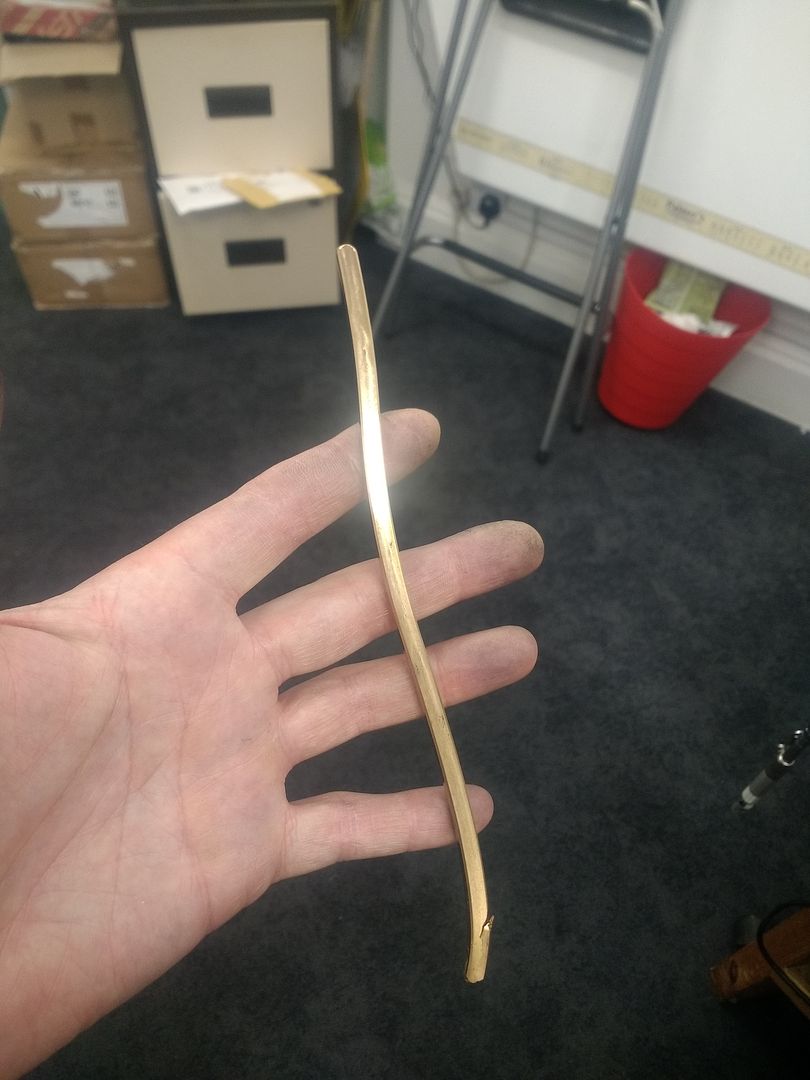

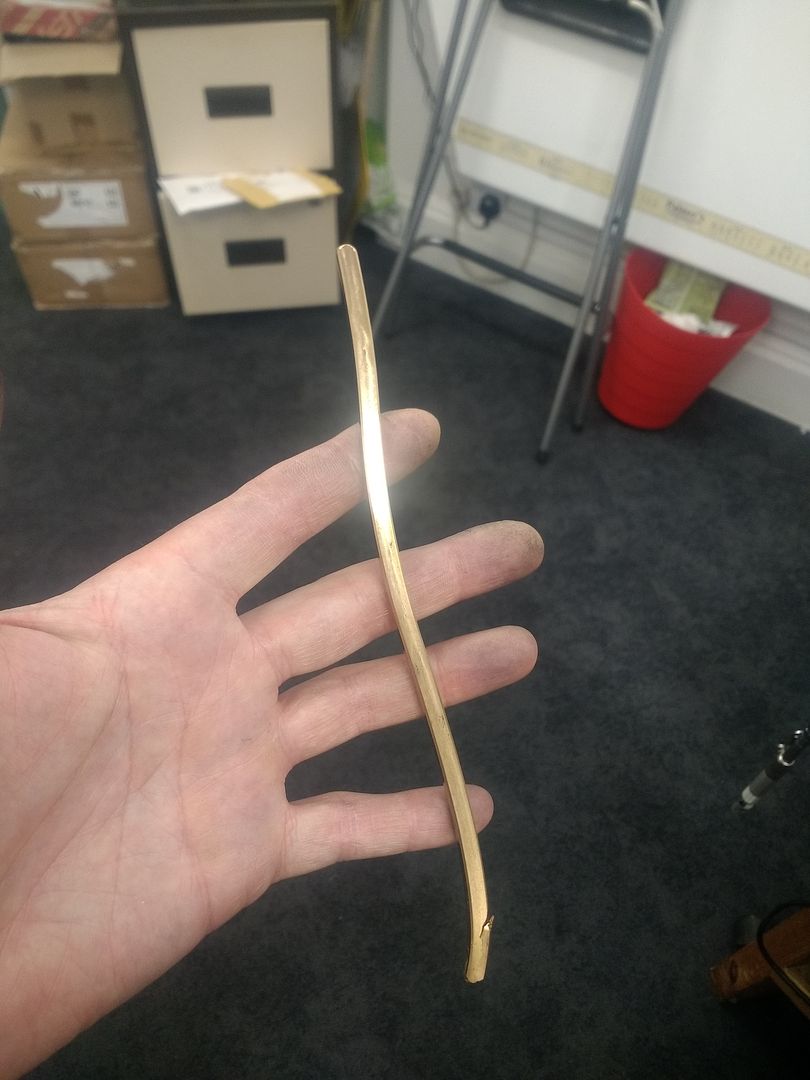

The gold part of the design is made using the customers own gold that we melted down. It is a mix if bits that range from 9ct to 18ct. This actually yielded a very nice metal that was not only soft but also a nice pinkish colour:

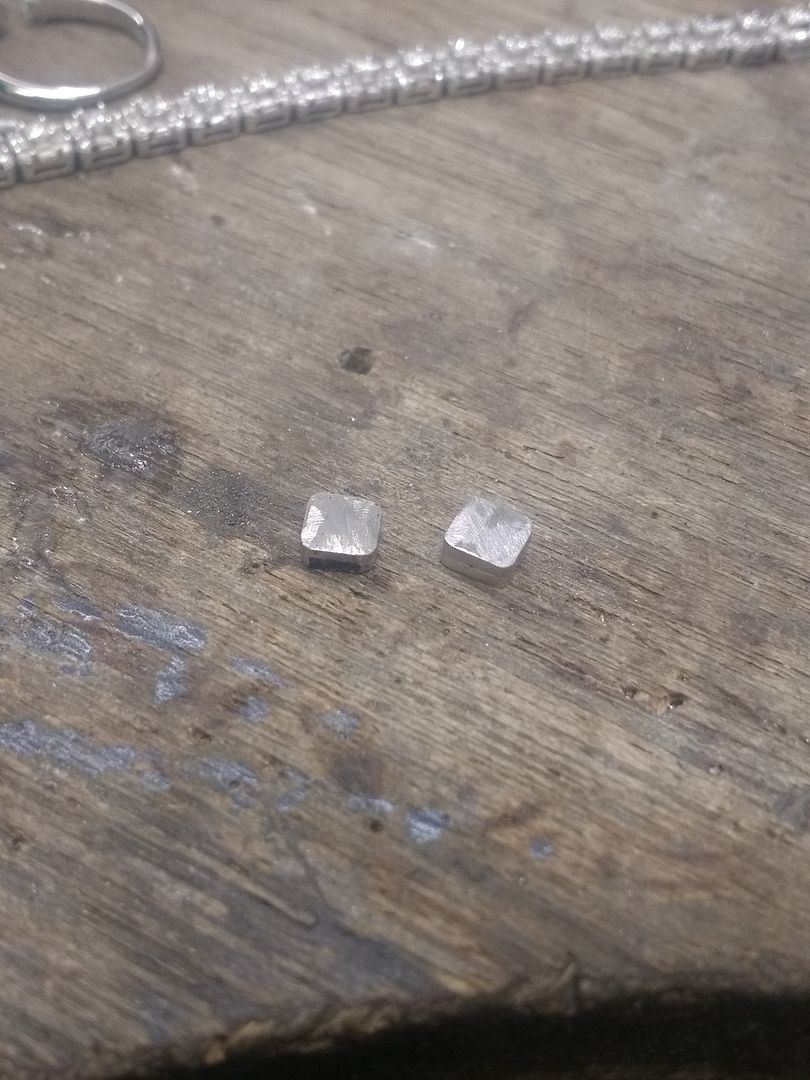

The metal is rolled out to the desired dimensions:

You'll notice the finish of the plate in that last pic too. Rather than polish it I decided to give it a sand blasted finish. We achieve this by putting it over a high speed wire brush. We have various weights to choose from but on this one we chose the heavy gauge.

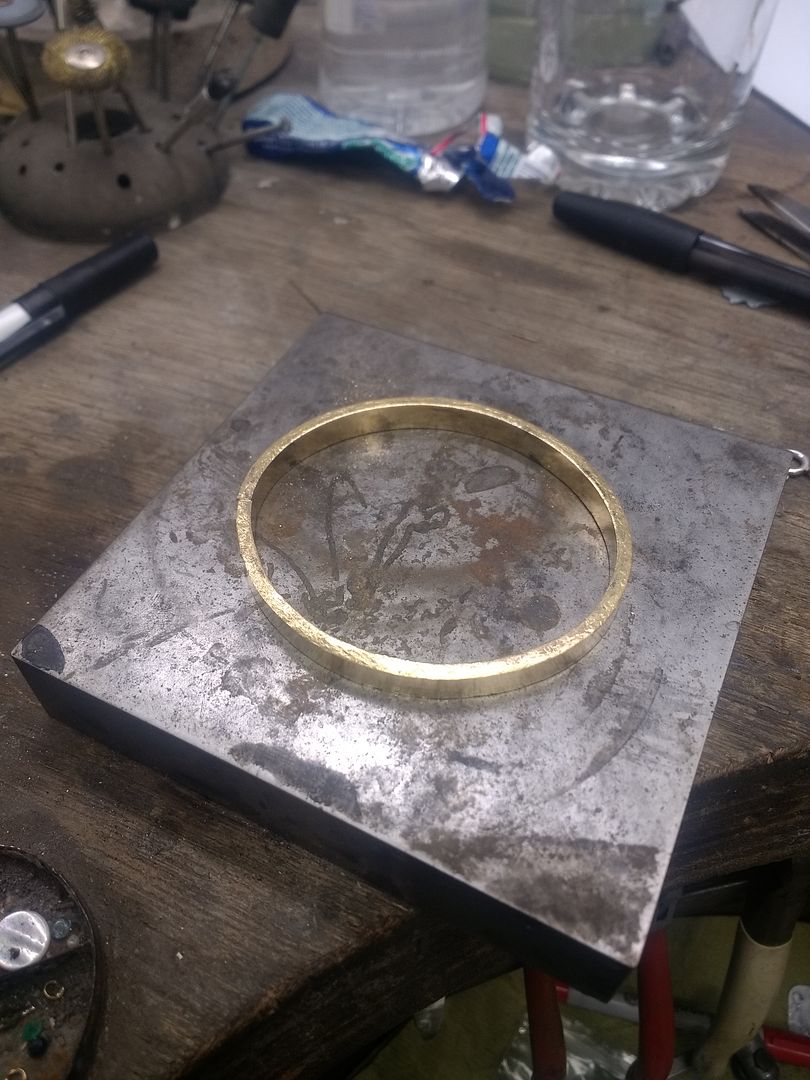

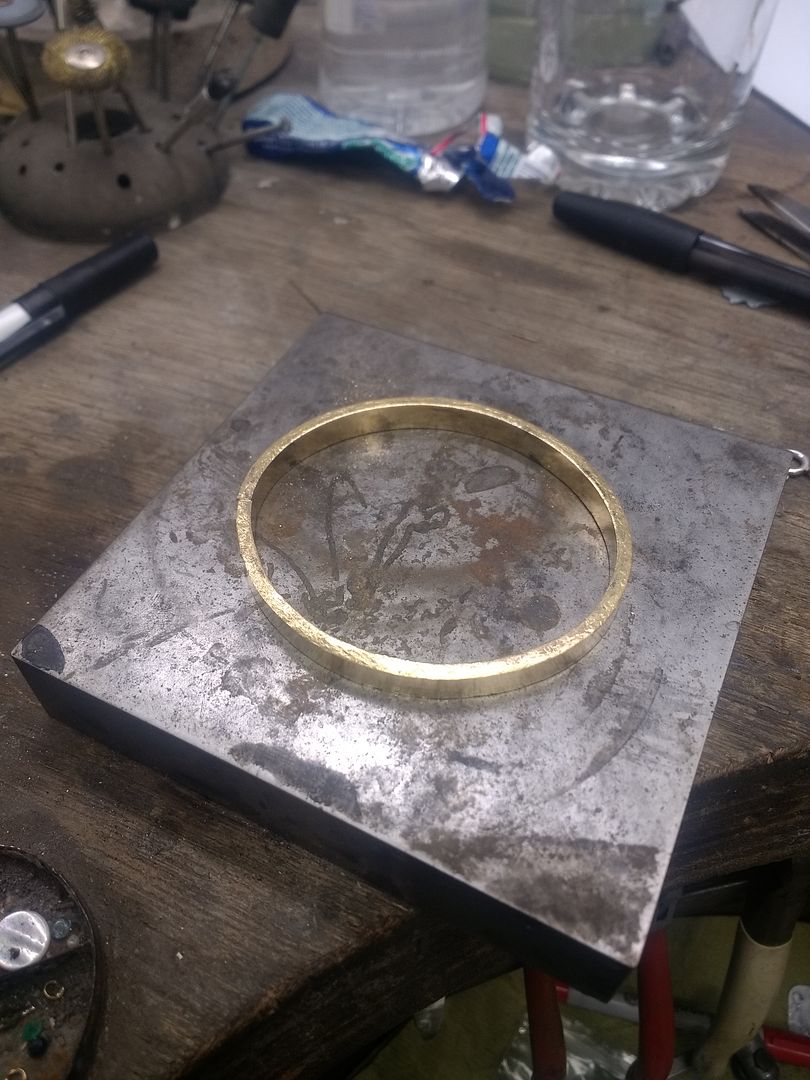

The metal is cut to length and then soldered in a rough circle:

Once soldered it's cleaned up and the circle hammered out a little to remove any lumps or bumps. I'm rather chuffed with myself at this point as I have measured nothing, yet the sizes are perfect. That's years of practice for you.

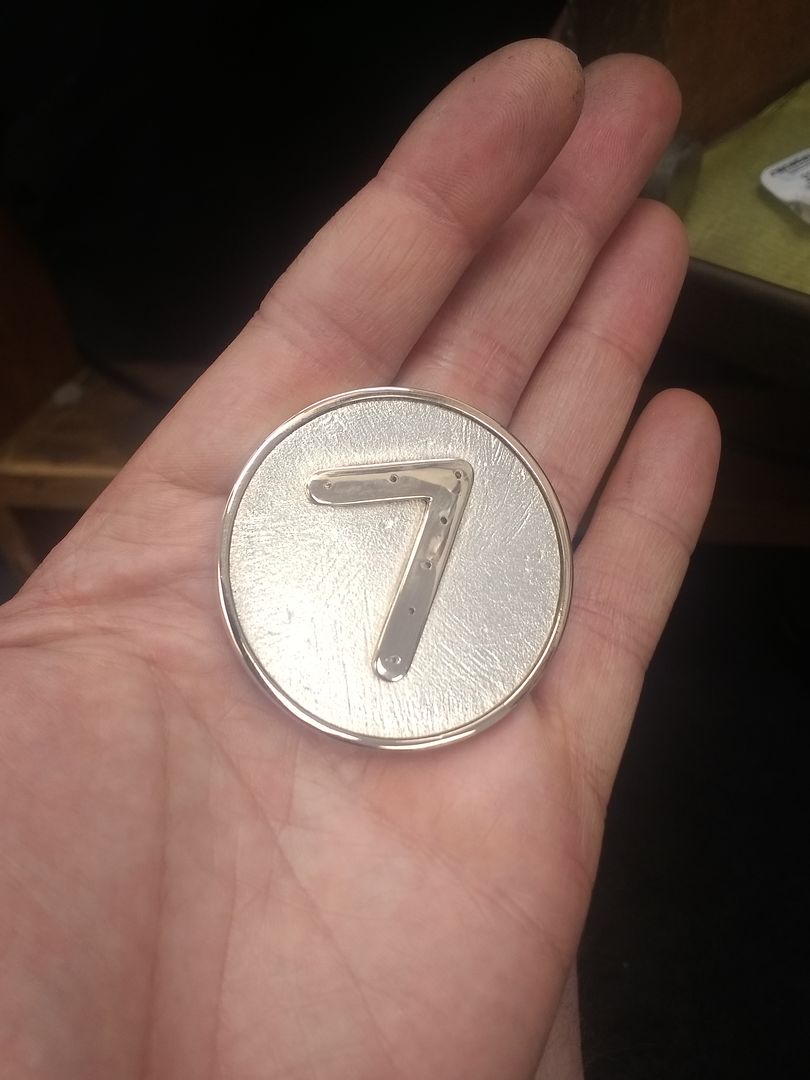

The disc is placed on the surround and with a little tap with a rubber mallet it slots in perfectly. I secured the disc to the surround with some low temperature gold solder before cleaning it up again:

The surround is polished up and then I stamped the reverse of the plate to show the materials used. 925 for silver and 375 for the 9ct grade of gold:

So, where does the rest of it come in?

The off-cuts from the surround are remelted and rolled out again:

The strip is then cut at the halfway point, at an angle. The pieces are aligned, soldered and a rough number 7 is formed:

A little bit of tidying up.......

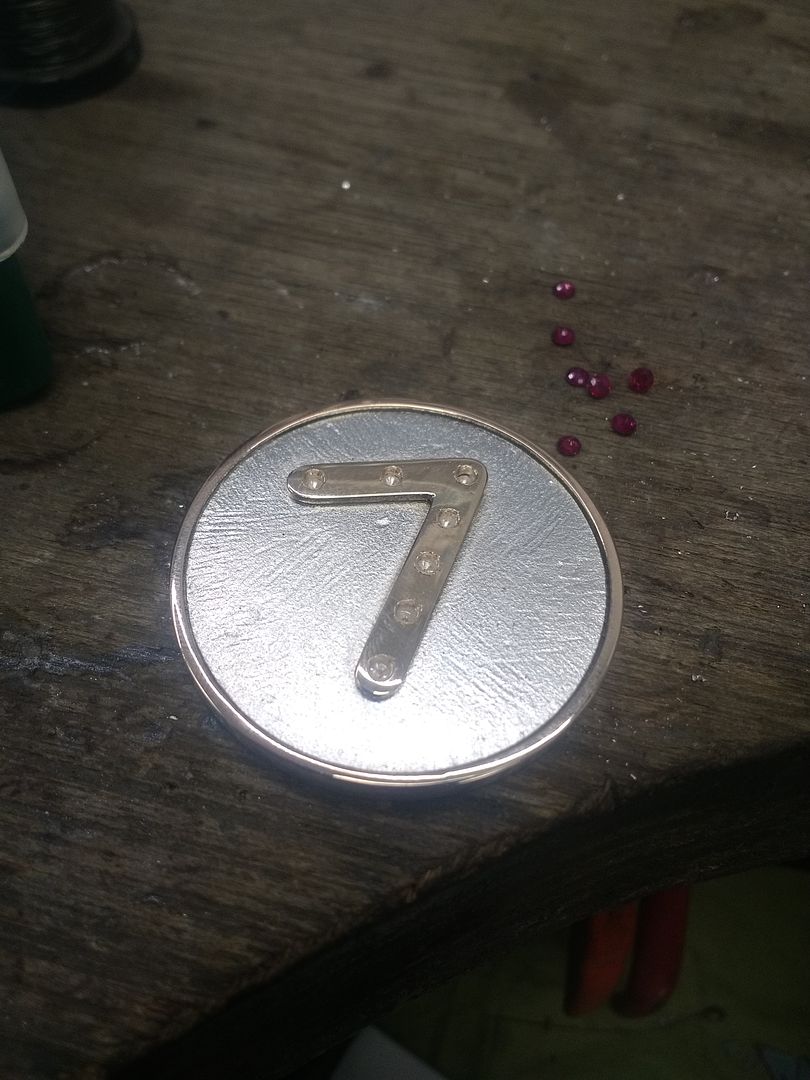

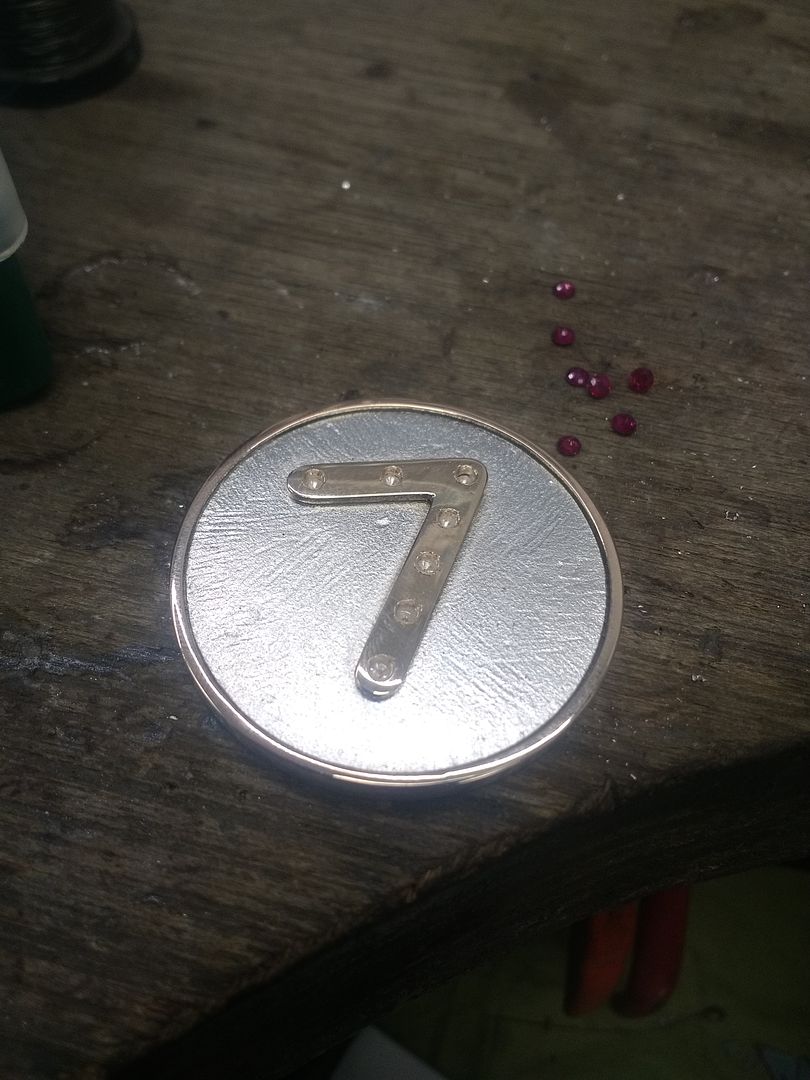

The design incorporates 7 rubies to be set in the number 7. Here I've marked out the centre lines:

And then the positions of the stones are punched in:

Pilot holes are drilled before the 7 is soldered to the middle of the disc:

In between this job I also managed to make a ring. The customer had her late parents wedding bands and she wanted them joining together somehow. My solution: Melt them down and draw out some wire. Take 4 lengths of the wire and twist. Turn to a circle and join the ends. Job jobbed!

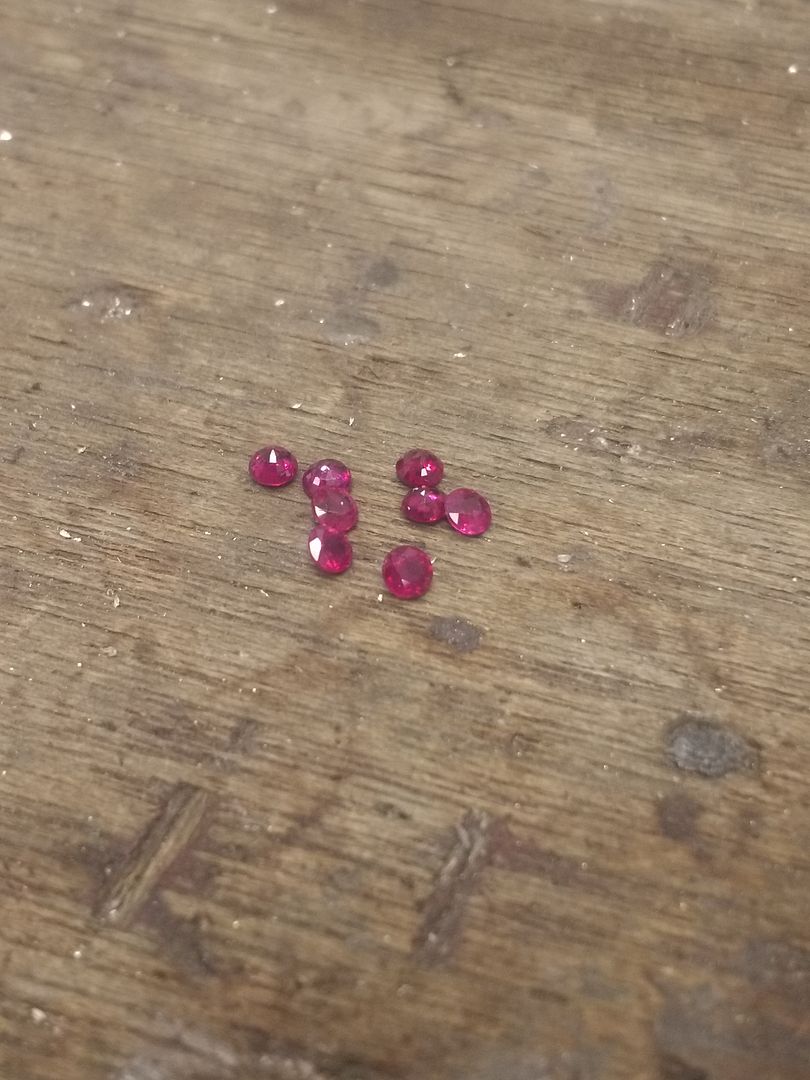

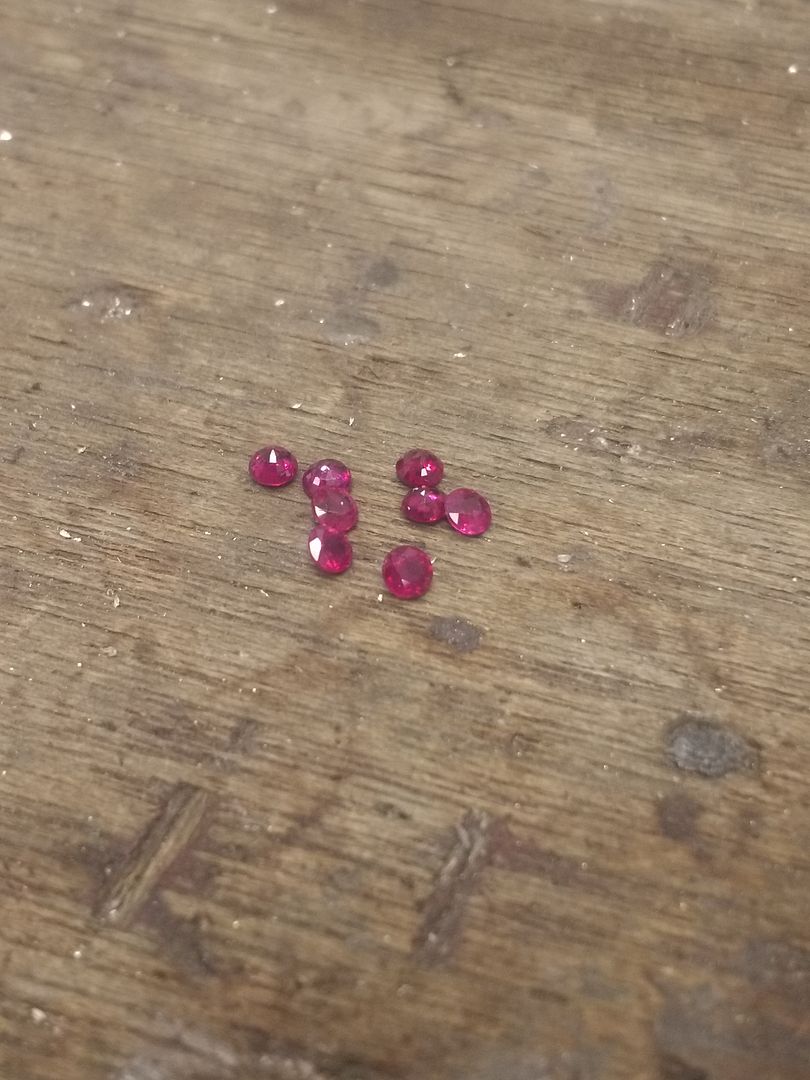

The postman arrived with some nice rubies. 3.1mm, nice and deep in colour:

The holes are then drilled to the correct size:

And the setting begins:

Job done, and the ring polished. Is the marker over the top? Hell yes!! But why not!!!

Customer has a husband who has everything. His birthday is coming up and his interests are: golf, cufflinks, gold, rubies, the number 7 and cars. He's got a new car, got more cufflinks than he can use but could maybe do with pimping out his golf kit. I bring you, the uber golf ball marker (apparently something you put on the green when you have to move your ball??).

The main body of the marker is to be made in silver. As it's going to be a bit large I opted to use specialist casting grains for the melt. This is a premium, clean metal that when melted should give a very workable and crack resistant finish. Here are thre grains:

The grains are melted and then rolled out to make a nice plate. The plate is pretty thick and weighs around 85g:

I spent a little time with the customer working out a design that incorporated the marker style as well as the gold, rubies and a number 7. We drew this on a piece of card and once underway I cut it out and glued it to the plate. The next job was to get the big (b.a.s.t.a.r.d) file out and burn some calories by filing away the excess. A clamp is essential if you want to save your fingers:

A good while later the disc is ready. My right shoulder is also whacked!

The gold part of the design is made using the customers own gold that we melted down. It is a mix if bits that range from 9ct to 18ct. This actually yielded a very nice metal that was not only soft but also a nice pinkish colour:

The metal is rolled out to the desired dimensions:

You'll notice the finish of the plate in that last pic too. Rather than polish it I decided to give it a sand blasted finish. We achieve this by putting it over a high speed wire brush. We have various weights to choose from but on this one we chose the heavy gauge.

The metal is cut to length and then soldered in a rough circle:

Once soldered it's cleaned up and the circle hammered out a little to remove any lumps or bumps. I'm rather chuffed with myself at this point as I have measured nothing, yet the sizes are perfect. That's years of practice for you.

The disc is placed on the surround and with a little tap with a rubber mallet it slots in perfectly. I secured the disc to the surround with some low temperature gold solder before cleaning it up again:

The surround is polished up and then I stamped the reverse of the plate to show the materials used. 925 for silver and 375 for the 9ct grade of gold:

So, where does the rest of it come in?

The off-cuts from the surround are remelted and rolled out again:

The strip is then cut at the halfway point, at an angle. The pieces are aligned, soldered and a rough number 7 is formed:

A little bit of tidying up.......

The design incorporates 7 rubies to be set in the number 7. Here I've marked out the centre lines:

And then the positions of the stones are punched in:

Pilot holes are drilled before the 7 is soldered to the middle of the disc:

In between this job I also managed to make a ring. The customer had her late parents wedding bands and she wanted them joining together somehow. My solution: Melt them down and draw out some wire. Take 4 lengths of the wire and twist. Turn to a circle and join the ends. Job jobbed!

The postman arrived with some nice rubies. 3.1mm, nice and deep in colour:

The holes are then drilled to the correct size:

And the setting begins:

Job done, and the ring polished. Is the marker over the top? Hell yes!! But why not!!!

Edited by ecain63 on Friday 21st July 21:03

Top work Eddie!

I have some questions, as I find it all fascinating.

The filing of the golf marker seems to have yielded quite a few 'dust' bits. I remember something about weighing in a cloth at the end of the year for a nice bonus...How does it work with clients paying for a certain weight and then you cashing in at the end? Or is it all factored in?

That bloody massive stone you talked about, do you sign an NDA? You've not posted photos, maybe as it'd link you. You also posted after the job was complete and off site. I imagine you were wanting to post, but held back.

I think that's it, but I'm very impressed, especially as you doing the gold bit by hand on the golf marker!

I have some questions, as I find it all fascinating.

The filing of the golf marker seems to have yielded quite a few 'dust' bits. I remember something about weighing in a cloth at the end of the year for a nice bonus...How does it work with clients paying for a certain weight and then you cashing in at the end? Or is it all factored in?

That bloody massive stone you talked about, do you sign an NDA? You've not posted photos, maybe as it'd link you. You also posted after the job was complete and off site. I imagine you were wanting to post, but held back.

I think that's it, but I'm very impressed, especially as you doing the gold bit by hand on the golf marker!

EJH said:

That's so cool! Words fail me when I see your work; it just continues to impress further!

What's the white stuff that's in with the metal when it goes to be melted?

The white stuff is Borax. It cleans the metal as it melts as well as lowering the melting point slightly. We also use it to protect diamonds and silver from burning on the surface. What's the white stuff that's in with the metal when it goes to be melted?

illmonkey said:

Top work Eddie!

I have some questions, as I find it all fascinating.

The filing of the golf marker seems to have yielded quite a few 'dust' bits. I remember something about weighing in a cloth at the end of the year for a nice bonus...How does it work with clients paying for a certain weight and then you cashing in at the end? Or is it all factored in?

That bloody massive stone you talked about, do you sign an NDA? You've not posted photos, maybe as it'd link you. You also posted after the job was complete and off site. I imagine you were wanting to post, but held back.

I think that's it, but I'm very impressed, especially as you doing the gold bit by hand on the golf marker!

The silver element of the marker is very low in value material wise. Maybe £15 or so if you were to scrap it. The filings maybe a couple of quid. For gold items there are 2 ways it can go: Most customers aren't interested in the filings unless there is lots of it. Even then they have to pay a refiners cost if they scrap it. Of course, they could use it in something else later. The stuff that is left is just a perk of the job, much like a garage will scrap metal left from car repairs. Sometimes however a customer will ask for the bits back or the piece out of the ring from a down sizing. They are welcome to have them. Win some / lose some. I have some questions, as I find it all fascinating.

The filing of the golf marker seems to have yielded quite a few 'dust' bits. I remember something about weighing in a cloth at the end of the year for a nice bonus...How does it work with clients paying for a certain weight and then you cashing in at the end? Or is it all factored in?

That bloody massive stone you talked about, do you sign an NDA? You've not posted photos, maybe as it'd link you. You also posted after the job was complete and off site. I imagine you were wanting to post, but held back.

I think that's it, but I'm very impressed, especially as you doing the gold bit by hand on the golf marker!

As for the big diamond... the customer supplied their own insurance in the end. We gave a quote of £750 for the 24hr period but it would involve lots of paperwork to prove its value and existence to our insurance company and for the customer it was just easier to supply their own extension of their existing policy. We only had to adhere to closing the shop for the period of its stay and to use recognised methods for the work. I did not post at the time for a couple of reasons. Photobucket wanted lots of cash for continued 3rd party hosting and I had not sorted it at that point so didn't see a need to post. Secondly, I did not have permission to post images as the stone is a very unique shape and would be easily linked to the customer and the agency delivering and collecting it. I am still under an agreement where I am forbidden to post images or share images with anyone. I have images for private use but none for social media or this blog. Lastly, as you spotted, the post was delayed well beyond the point where the stone was with us. Just better that way.

ecain63 said:

illmonkey said:

Top work Eddie!

I have some questions, as I find it all fascinating.

The filing of the golf marker seems to have yielded quite a few 'dust' bits. I remember something about weighing in a cloth at the end of the year for a nice bonus...How does it work with clients paying for a certain weight and then you cashing in at the end? Or is it all factored in?

That bloody massive stone you talked about, do you sign an NDA? You've not posted photos, maybe as it'd link you. You also posted after the job was complete and off site. I imagine you were wanting to post, but held back.

I think that's it, but I'm very impressed, especially as you doing the gold bit by hand on the golf marker!

The silver element of the marker is very low in value material wise. Maybe £15 or so if you were to scrap it. The filings maybe a couple of quid. For gold items there are 2 ways it can go: Most customers aren't interested in the filings unless there is lots of it. Even then they have to pay a refiners cost if they scrap it. Of course, they could use it in something else later. The stuff that is left is just a perk of the job, much like a garage will scrap metal left from car repairs. Sometimes however a customer will ask for the bits back or the piece out of the ring from a down sizing. They are welcome to have them. Win some / lose some. I have some questions, as I find it all fascinating.

The filing of the golf marker seems to have yielded quite a few 'dust' bits. I remember something about weighing in a cloth at the end of the year for a nice bonus...How does it work with clients paying for a certain weight and then you cashing in at the end? Or is it all factored in?

That bloody massive stone you talked about, do you sign an NDA? You've not posted photos, maybe as it'd link you. You also posted after the job was complete and off site. I imagine you were wanting to post, but held back.

I think that's it, but I'm very impressed, especially as you doing the gold bit by hand on the golf marker!

As for the big diamond... the customer supplied their own insurance in the end. We gave a quote of £750 for the 24hr period but it would involve lots of paperwork to prove its value and existence to our insurance company and for the customer it was just easier to supply their own extension of their existing policy. We only had to adhere to closing the shop for the period of its stay and to use recognised methods for the work. I did not post at the time for a couple of reasons. Photobucket wanted lots of cash for continued 3rd party hosting and I had not sorted it at that point so didn't see a need to post. Secondly, I did not have permission to post images as the stone is a very unique shape and would be easily linked to the customer and the agency delivering and collecting it. I am still under an agreement where I am forbidden to post images or share images with anyone. I have images for private use but none for social media or this blog. Lastly, as you spotted, the post was delayed well beyond the point where the stone was with us. Just better that way.

I suppose customers go into buying something not knowing true cost etc, so have to trust that you'll price is accordingly. It's great you get to mop up the filings for a bit of profit, and I imagine it's over 100's of jobs, so in reality pennies of the £100's. But not a bad side line!

illmonkey said:

ecain63 said:

illmonkey said:

Top work Eddie!

I have some questions, as I find it all fascinating.

The filing of the golf marker seems to have yielded quite a few 'dust' bits. I remember something about weighing in a cloth at the end of the year for a nice bonus...How does it work with clients paying for a certain weight and then you cashing in at the end? Or is it all factored in?

That bloody massive stone you talked about, do you sign an NDA? You've not posted photos, maybe as it'd link you. You also posted after the job was complete and off site. I imagine you were wanting to post, but held back.

I think that's it, but I'm very impressed, especially as you doing the gold bit by hand on the golf marker!

The silver element of the marker is very low in value material wise. Maybe £15 or so if you were to scrap it. The filings maybe a couple of quid. For gold items there are 2 ways it can go: Most customers aren't interested in the filings unless there is lots of it. Even then they have to pay a refiners cost if they scrap it. Of course, they could use it in something else later. The stuff that is left is just a perk of the job, much like a garage will scrap metal left from car repairs. Sometimes however a customer will ask for the bits back or the piece out of the ring from a down sizing. They are welcome to have them. Win some / lose some. I have some questions, as I find it all fascinating.

The filing of the golf marker seems to have yielded quite a few 'dust' bits. I remember something about weighing in a cloth at the end of the year for a nice bonus...How does it work with clients paying for a certain weight and then you cashing in at the end? Or is it all factored in?

That bloody massive stone you talked about, do you sign an NDA? You've not posted photos, maybe as it'd link you. You also posted after the job was complete and off site. I imagine you were wanting to post, but held back.

I think that's it, but I'm very impressed, especially as you doing the gold bit by hand on the golf marker!

As for the big diamond... the customer supplied their own insurance in the end. We gave a quote of £750 for the 24hr period but it would involve lots of paperwork to prove its value and existence to our insurance company and for the customer it was just easier to supply their own extension of their existing policy. We only had to adhere to closing the shop for the period of its stay and to use recognised methods for the work. I did not post at the time for a couple of reasons. Photobucket wanted lots of cash for continued 3rd party hosting and I had not sorted it at that point so didn't see a need to post. Secondly, I did not have permission to post images as the stone is a very unique shape and would be easily linked to the customer and the agency delivering and collecting it. I am still under an agreement where I am forbidden to post images or share images with anyone. I have images for private use but none for social media or this blog. Lastly, as you spotted, the post was delayed well beyond the point where the stone was with us. Just better that way.

I suppose customers go into buying something not knowing true cost etc, so have to trust that you'll price is accordingly. It's great you get to mop up the filings for a bit of profit, and I imagine it's over 100's of jobs, so in reality pennies of the £100's. But not a bad side line!

Back to the gold filings: It's a bonus, that's the bottom line. Jobs that are heavy on the waste would be priced to allow for the recovery later on. Smaller jobs are not. We do over 300 jobs a week so there will always be waste worthy of recovery. The amounts per job are tiny. A few pence worth an item i guess. Over the year it adds up for sure but that's the perks of the job. Every business has avenues that can yield extra benefits. Builders take left over materials for other jobs and home jobs. Plumbers the same. Customers could ask for the spare parts from an house extension but you have to ask what the average person could possibly do with them. Same thing goes for metal dusts. At £15+vat for a single burn you need to have a gram of 18ct to cover it. 1g of gold is not a tiny bit. It's way more than the piece out of a ring sizing or chain repair. It's only worth the effort in bulk.

ecain63 said:

It's double sided with regards to closing up for the day. As much as we won't allow customers in during that period we give a sound explanation and offer them to either pop back the next day or whenever suits. Most customers are pretty understanding. We are a small shop that does a unique thing and most of our customers would be than less happy going elsewhere just because we were shut for the day. The upside of it is that we gain a reputation with high end customers. There are very few jewellers in the UK that would touch such a stone beyond selling it and the smooth turnaround is a good footing for future work. It's not about the money with those jobs, its the appreciation of trust that is our payment. As much as we don't want to advertise the really expensive stuff we work on we do want the right people to know that we can do it.

Back to the gold filings: It's a bonus, that's the bottom line. Jobs that are heavy on the waste would be priced to allow for the recovery later on. Smaller jobs are not. We do over 300 jobs a week so there will always be waste worthy of recovery. The amounts per job are tiny. A few pence worth an item i guess. Over the year it adds up for sure but that's the perks of the job. Every business has avenues that can yield extra benefits. Builders take left over materials for other jobs and home jobs. Plumbers the same. Customers could ask for the spare parts from an house extension but you have to ask what the average person could possibly do with them. Same thing goes for metal dusts. At £15+vat for a single burn you need to have a gram of 18ct to cover it. 1g of gold is not a tiny bit. It's way more than the piece out of a ring sizing or chain repair. It's only worth the effort in bulk.

Thanks Eddie. Keep posting!Back to the gold filings: It's a bonus, that's the bottom line. Jobs that are heavy on the waste would be priced to allow for the recovery later on. Smaller jobs are not. We do over 300 jobs a week so there will always be waste worthy of recovery. The amounts per job are tiny. A few pence worth an item i guess. Over the year it adds up for sure but that's the perks of the job. Every business has avenues that can yield extra benefits. Builders take left over materials for other jobs and home jobs. Plumbers the same. Customers could ask for the spare parts from an house extension but you have to ask what the average person could possibly do with them. Same thing goes for metal dusts. At £15+vat for a single burn you need to have a gram of 18ct to cover it. 1g of gold is not a tiny bit. It's way more than the piece out of a ring sizing or chain repair. It's only worth the effort in bulk.

Two jobs in quick succession eh! You lucky people

I took this job in on Monday and to be honest I wasn't that keen. The customer has an 18ct white gold and diamond bracelet that needs lengthened by 2 links. It's had some work done on it before (see dark claws) but it's a sound enough item. The links are diamond set and the stones are a mix of princess cuts surrounded by round and baguette cuts. I wasn't keen because it's a faffy job, one that can take an age and may cause problems during the build. But the customer is a no-compromise type so I'm doing it. This morning I decided to get stuck in and actually, to this point it appears to be going ok.......

Here is the bracelet:

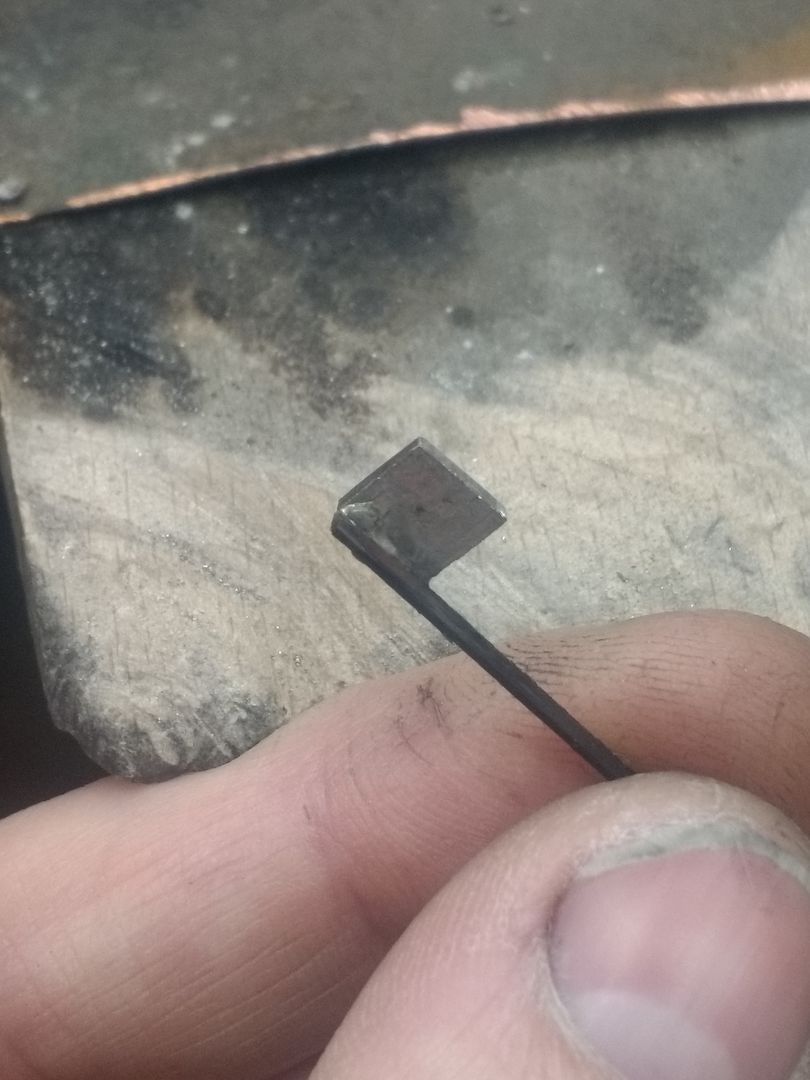

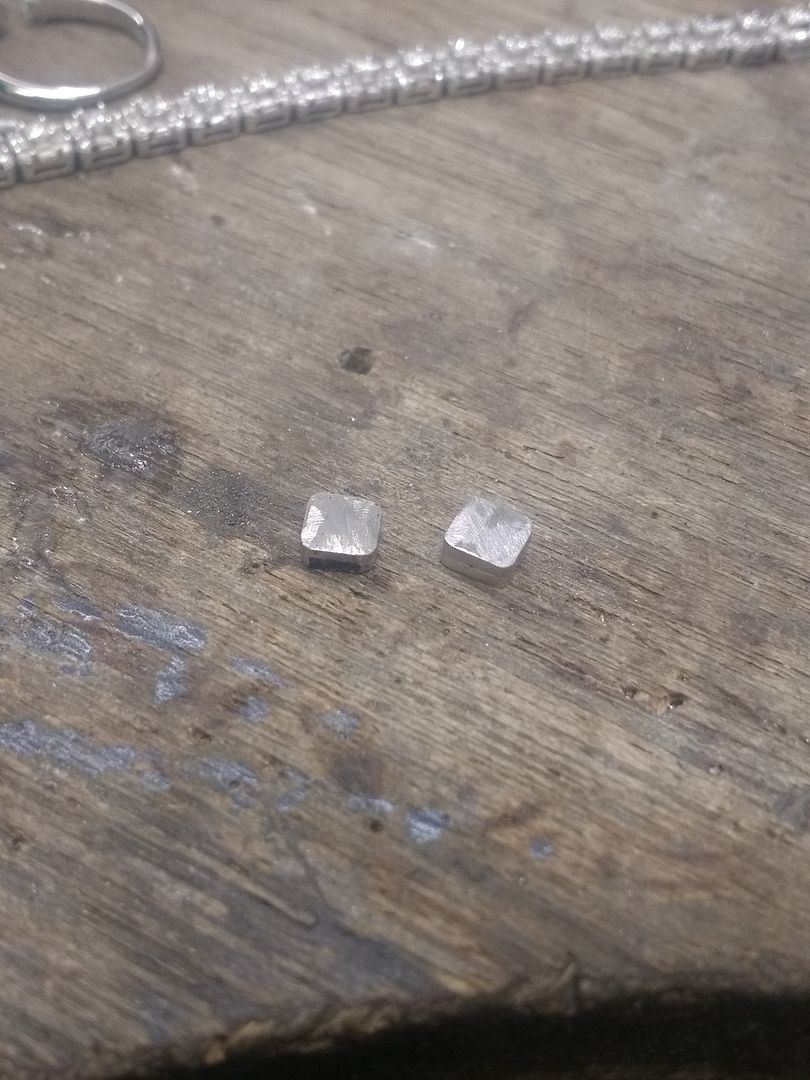

The first thing to do is roll out some metal to the same dimensions as the links:

Measure the depth of the top deck and score / cut. They don't have to be perfect at this point as there is much to do along the way:

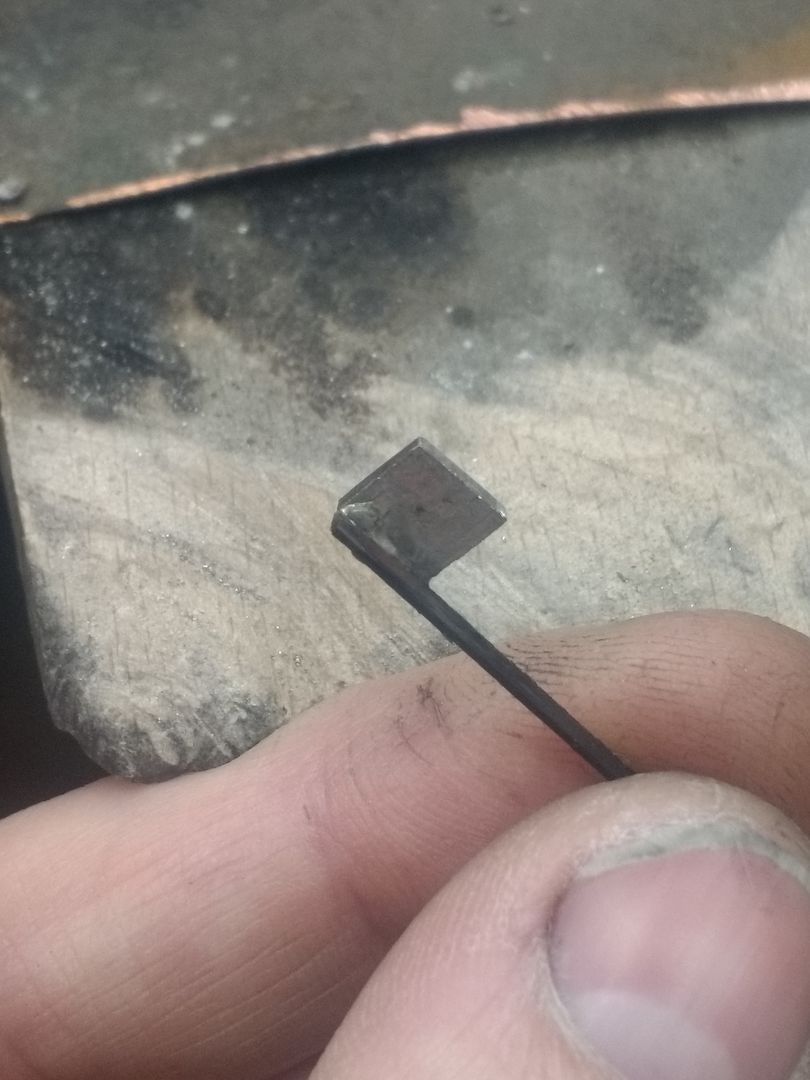

I then roll down some more to make the undersetting / underrails:

This is then tacked to one edge:

After some bending the underrails are soldered in place:

And tidied up:

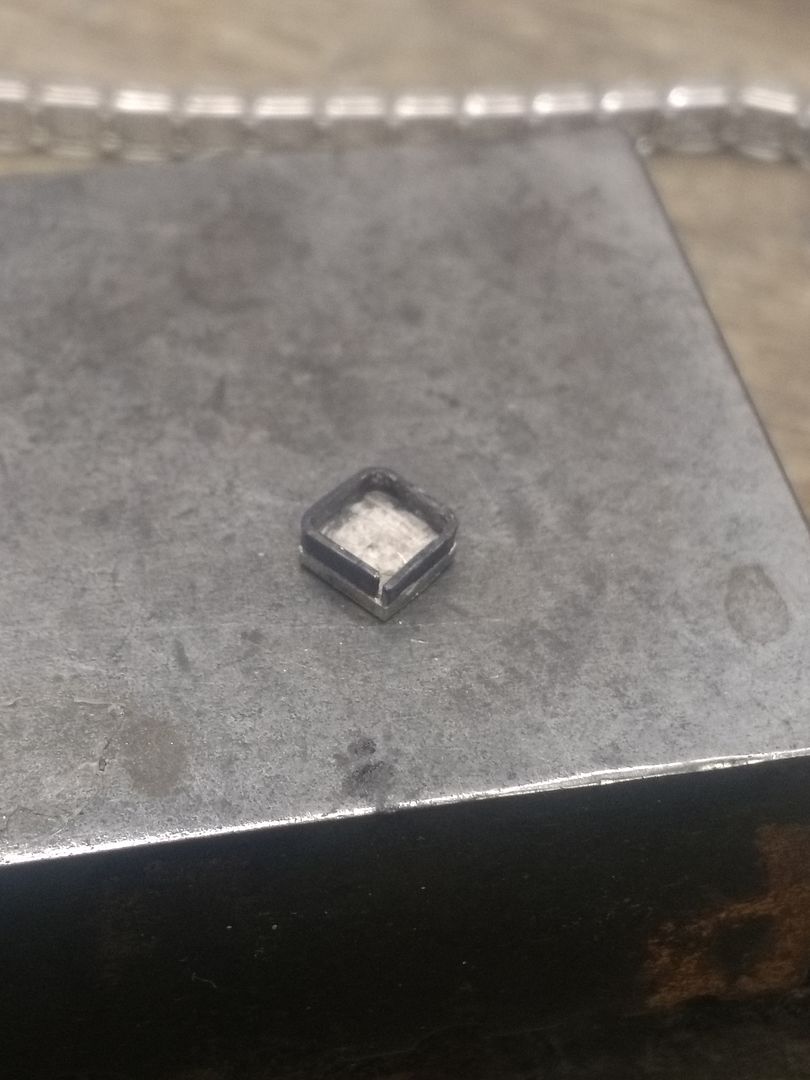

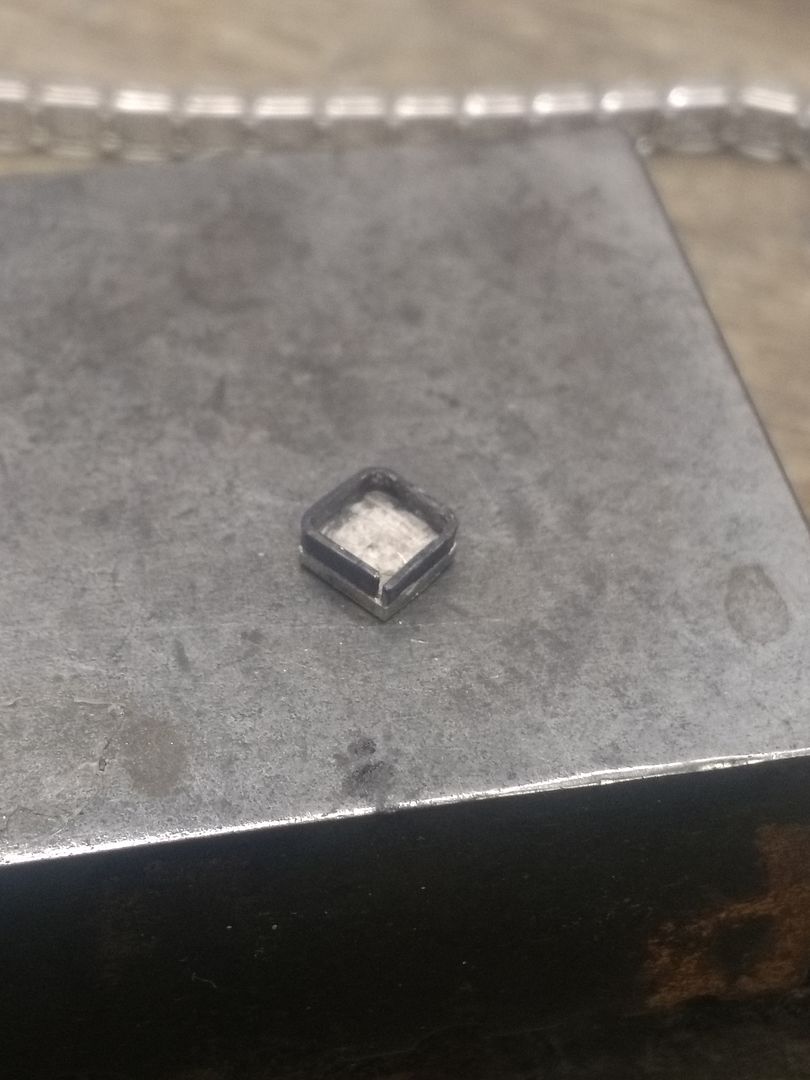

So that I can round off the corners I add some thickness on the inner edges:

Looking like a link..... almost:

The sides of the links are slotted so the next step is to drill and cut those in:

I got distracted at this pint so I'll apologise for not photographing the previous steps. It went like this..... The sides were cut in and once looking ok I then began to look at the connections between the links. The loops for the hinges are prongs that get bent in a loop. The prongs go through 2 holes which also need to be drilled. Once through the holes they are bent and they then sit in 2 grooves. Once shaped they are soldered in place. Looks like this:

And 2:

The end link is then refitted:

I could do the setting work with the links separated from the bracelet. For me personally I'd prefer to do it with them fitted. That way I can accurately gauge the height and depth of the stones at the time of setting. If it doesn't work out that way I can always remove them. I'll post the pics up when I get back to it. Possibly in a week or so as it's very much a spare time job rather than a rushed one.

Eddie

I took this job in on Monday and to be honest I wasn't that keen. The customer has an 18ct white gold and diamond bracelet that needs lengthened by 2 links. It's had some work done on it before (see dark claws) but it's a sound enough item. The links are diamond set and the stones are a mix of princess cuts surrounded by round and baguette cuts. I wasn't keen because it's a faffy job, one that can take an age and may cause problems during the build. But the customer is a no-compromise type so I'm doing it. This morning I decided to get stuck in and actually, to this point it appears to be going ok.......

Here is the bracelet:

The first thing to do is roll out some metal to the same dimensions as the links:

Measure the depth of the top deck and score / cut. They don't have to be perfect at this point as there is much to do along the way:

I then roll down some more to make the undersetting / underrails:

This is then tacked to one edge:

After some bending the underrails are soldered in place:

And tidied up:

So that I can round off the corners I add some thickness on the inner edges:

Looking like a link..... almost:

The sides of the links are slotted so the next step is to drill and cut those in:

I got distracted at this pint so I'll apologise for not photographing the previous steps. It went like this..... The sides were cut in and once looking ok I then began to look at the connections between the links. The loops for the hinges are prongs that get bent in a loop. The prongs go through 2 holes which also need to be drilled. Once through the holes they are bent and they then sit in 2 grooves. Once shaped they are soldered in place. Looks like this:

And 2:

The end link is then refitted:

I could do the setting work with the links separated from the bracelet. For me personally I'd prefer to do it with them fitted. That way I can accurately gauge the height and depth of the stones at the time of setting. If it doesn't work out that way I can always remove them. I'll post the pics up when I get back to it. Possibly in a week or so as it's very much a spare time job rather than a rushed one.

Eddie

Ranger 6 said:

Hi Eddie,

Apologies if I've missed it earlier in the thread - does your watch man do servicing? Looking to get my Steinhart done (ETA movement I think?)

Currently I'm directing people to Variomatic. I am without a watchmaker at the moment and finding a good one for decent money is getting harder with Rolex etc charging more for parts and qualified watchmakers charging more for the demand. My previous guy was good but he quickly found he could make a killing on his own and now does stuff at home. Lucrative business with the right tickets.Apologies if I've missed it earlier in the thread - does your watch man do servicing? Looking to get my Steinhart done (ETA movement I think?)

I got back on this badger today. Bit of a sod actually and after a major issue where I bent it the wrong way we are now getting toward the point where we start setting stones.

I marked out the mid point of each link (roughly):

And drilled a couple of pilot holes:

I then did the same for the corner stones:

The 4 centre posts are then marked as well as the outer claw locations:

The baguette locations are then drilled:

Centre posts are then fitted:

More to come

I marked out the mid point of each link (roughly):

And drilled a couple of pilot holes:

I then did the same for the corner stones:

The 4 centre posts are then marked as well as the outer claw locations:

The baguette locations are then drilled:

Centre posts are then fitted:

More to come

I've done nothing more on the bracelet this week, mostly because I've been digging with 2 shovels in my other work. It's madness currently. This is one I did yesterday morning:

A young lady with a bump on the way had a shaped platinum and diamond eternity ring that didn't do much for her. We sat down with a pen and paper and worked out a little plan that included her liking for 18ct rose gold and some loose diamonds she had from old jewellery. Here's how it went.......

1 x 18ct rose gold bar:

Warmed up and bent into a ring (ish) shape:

I modified an existing 4.5mm 18ct rose gold setting and manipulated the 18ct rose band to the desired shape. The intention was to make it look as off-centre as possible whilst keeping it looking like it was working with the platinum band:

After a little more bending I trimmed the edges to give it a more attractive finish:

The band then got a bit of a clean up:

The setting is then soldered in place. I did this with the platinum band along side so that it didn't need to be adjusted after:

The underside of the setting is now added. This was the bit that I modified as the standard undersetting didn't let the bands sit close enough together:

The customers diamonds:

The ring is polished and the stone laid in:

And the claws finished:

There were also 2 small diamonds in the eternity ring that needed replacing as well as it sizing up 2 sizes. This is all done before the next phase:

Ready for the next bit:

The 2 rings are laid together and soldered on the inside at the base:

The inside is cleaned up before a light buff and a trip to the acid bath:

The ring is now ready for polishing, which I do:

Nice fit too:

That's where we are now with the ring. The only thing to do is add some diamonds along the outer arm of the rose band. I'll do this later in the week:

A young lady with a bump on the way had a shaped platinum and diamond eternity ring that didn't do much for her. We sat down with a pen and paper and worked out a little plan that included her liking for 18ct rose gold and some loose diamonds she had from old jewellery. Here's how it went.......

1 x 18ct rose gold bar:

Warmed up and bent into a ring (ish) shape:

I modified an existing 4.5mm 18ct rose gold setting and manipulated the 18ct rose band to the desired shape. The intention was to make it look as off-centre as possible whilst keeping it looking like it was working with the platinum band:

After a little more bending I trimmed the edges to give it a more attractive finish:

The band then got a bit of a clean up:

The setting is then soldered in place. I did this with the platinum band along side so that it didn't need to be adjusted after:

The underside of the setting is now added. This was the bit that I modified as the standard undersetting didn't let the bands sit close enough together:

The customers diamonds:

The ring is polished and the stone laid in:

And the claws finished:

There were also 2 small diamonds in the eternity ring that needed replacing as well as it sizing up 2 sizes. This is all done before the next phase:

Ready for the next bit:

The 2 rings are laid together and soldered on the inside at the base:

The inside is cleaned up before a light buff and a trip to the acid bath:

The ring is now ready for polishing, which I do:

Nice fit too:

That's where we are now with the ring. The only thing to do is add some diamonds along the outer arm of the rose band. I'll do this later in the week:

The wife and I had agreed that for our 10th wedding anniversary that we wouldn't give presents. This was the result of a conversation about 2 months ago where we concluded that we would just book a decent holiday to celebrate the date and also the hopefully good results from my CT scan next week. Our anniversary is this Friday and up until yesterday the above plan was proving watertight.

Tuesday 11am: It would appear she has been watch shopping for me and a nice parcel arrived at work in her name. The senders address is a recognised one and now I only have 36hrs to get her something sorted before she comes into the office to do her 2 days of book work. I've known for a while that she also wants a watch but the model she wants is £8k and only available on special order. It's something that we will get round to, but not yet.

Deciding that today the public must wait for me for a change, this is my rushed (8hrs) recovery programme:

We handmade a heavy 18ct rose gold bracelet for a customer a couple of years ago. The short story is that he (con-man) never shown up to pay for it and it's been sat in stock ever since. At 120g it's a lot of cash tied up and a good 3 days on the bench in labour. Mrs ecain63 has hinted in the past that she'd like a rose gold Cartier bangle. Why the hell not!! I must admit, for the effort we put into producing it I was a bit sad to see it melted.

I chopped off an 80g (approx) length of link and kept aside the very well made clasp. That may come in handy one day.

And set about melting it:

Amazingly, I think thanks to the quality of the gold used, there was zero lost in the melt:

The aim was to produce a 6mm wide, approx 40g bangle set with 10 x 0.15ct diamonds. First thing to do is roll it out:

I know her wrist size already so marked out the position on the 'bangle basher' and bent the metal to suit:

The ends are tacked together and after a little hammering the bangle shape is formed:

Next job... making a hinge: Take a bit of 18ct rose and roll down:

And pull through a round draw plate:

The joint in the bangle is recut and the ends rounded to accept the wire:

The hinge is made in 3 parts. The rivet then added after:

With the 3 parts soldered in the next step is to drill it and add the rivet. You'll notice that I've not cut the other end of the bangle. This is to keep tension on the hinge parts, ensuring a good fit:

And the rivet:

And now we cut the other end to see if it works:

This next bit is where you either make or break the design. The clasp has to look in keeping and if it's too crude or bulky it'll look s t. I never measure anything and just let years and thousands of jobs worth of experience do the talking. It'll either work or it won't. This design I just blagged as I went. True story:

t. I never measure anything and just let years and thousands of jobs worth of experience do the talking. It'll either work or it won't. This design I just blagged as I went. True story:

It's basically the same gauge wire as the hinge but with a box cut out of it and sides added. The tongue is also a bit of the hinge wire that's been cut to be the female element. The two sit together nice and snug with plenty of tension in the metal to make safe:

With that little bit of design (fluke, jammy bloody luck) out of the way the bangle is polished up ready for the setting work:

The only bit I tend to measure is stone positioning. Here I've found the centre line and also measured the 10 points where the diamonds will go. These are drilled and setting begins:

With the stones set it's back to the polishing machine to finish off. Pretty much bang on 8hrs on from having a heavy gold bracelet in the window to a diamond set bangle and 80g of gold left for something else....... and hopefully a happy wife:

Not the wife's hands

Tuesday 11am: It would appear she has been watch shopping for me and a nice parcel arrived at work in her name. The senders address is a recognised one and now I only have 36hrs to get her something sorted before she comes into the office to do her 2 days of book work. I've known for a while that she also wants a watch but the model she wants is £8k and only available on special order. It's something that we will get round to, but not yet.

Deciding that today the public must wait for me for a change, this is my rushed (8hrs) recovery programme:

We handmade a heavy 18ct rose gold bracelet for a customer a couple of years ago. The short story is that he (con-man) never shown up to pay for it and it's been sat in stock ever since. At 120g it's a lot of cash tied up and a good 3 days on the bench in labour. Mrs ecain63 has hinted in the past that she'd like a rose gold Cartier bangle. Why the hell not!! I must admit, for the effort we put into producing it I was a bit sad to see it melted.

I chopped off an 80g (approx) length of link and kept aside the very well made clasp. That may come in handy one day.

And set about melting it:

Amazingly, I think thanks to the quality of the gold used, there was zero lost in the melt:

The aim was to produce a 6mm wide, approx 40g bangle set with 10 x 0.15ct diamonds. First thing to do is roll it out:

I know her wrist size already so marked out the position on the 'bangle basher' and bent the metal to suit:

The ends are tacked together and after a little hammering the bangle shape is formed:

Next job... making a hinge: Take a bit of 18ct rose and roll down:

And pull through a round draw plate:

The joint in the bangle is recut and the ends rounded to accept the wire:

The hinge is made in 3 parts. The rivet then added after:

With the 3 parts soldered in the next step is to drill it and add the rivet. You'll notice that I've not cut the other end of the bangle. This is to keep tension on the hinge parts, ensuring a good fit:

And the rivet:

And now we cut the other end to see if it works:

This next bit is where you either make or break the design. The clasp has to look in keeping and if it's too crude or bulky it'll look s

t. I never measure anything and just let years and thousands of jobs worth of experience do the talking. It'll either work or it won't. This design I just blagged as I went. True story:

t. I never measure anything and just let years and thousands of jobs worth of experience do the talking. It'll either work or it won't. This design I just blagged as I went. True story:

It's basically the same gauge wire as the hinge but with a box cut out of it and sides added. The tongue is also a bit of the hinge wire that's been cut to be the female element. The two sit together nice and snug with plenty of tension in the metal to make safe:

With that little bit of design (fluke, jammy bloody luck) out of the way the bangle is polished up ready for the setting work:

The only bit I tend to measure is stone positioning. Here I've found the centre line and also measured the 10 points where the diamonds will go. These are drilled and setting begins:

With the stones set it's back to the polishing machine to finish off. Pretty much bang on 8hrs on from having a heavy gold bracelet in the window to a diamond set bangle and 80g of gold left for something else....... and hopefully a happy wife:

Not the wife's hands

Edited by ecain63 on Wednesday 9th August 21:56

thebraketester said:

That is lovely. Can you explain how you set the diamonds in the holes? Are the just a press fit?

3.3mm diamonds. Holes drilled to 3.3mm and about 0.5mm deeper than the edge of the stone. Stone is pressed in then the gold around the edge is pressed over the lip of the hole onto the edge of the stone. Nice, neat and secure finish.Gassing Station | Watches | Top of Page | What's New | My Stuff