Anodized alloy panels

Discussion

Has anyone ever anodized their aluminium panels, I think that could be a nice touch (depending on color)?

The panels could be drilled, deburred and then instead of riveting them to the chassis have them anodized prior to that. Sooner or later they`ll become dull anyway...any thoughts?

The panels could be drilled, deburred and then instead of riveting them to the chassis have them anodized prior to that. Sooner or later they`ll become dull anyway...any thoughts?

If any of the panels are to be folded or curved round to chassis tube then pre-anodised will not be good as the surface will crack.

Anodising after fabricating will be good.

If you are going to have them coloured then avoid black. The process is to anodise the panel then dip it in a colour dye. Black is a real pain as it can be patchy particularly if the panel has be handled after anodise or even if it was not cleaned well before anodise. If it does not come out well there is no second try.

Steve

Anodising after fabricating will be good.

If you are going to have them coloured then avoid black. The process is to anodise the panel then dip it in a colour dye. Black is a real pain as it can be patchy particularly if the panel has be handled after anodise or even if it was not cleaned well before anodise. If it does not come out well there is no second try.

Steve

another idea that might be a bit easier if you go on Hansen Rivets web site they produce a "cap" if you will, that is driven into the hole left be a 3/16 rivet. The Cap is made of aluminum. why not built the car with 3/16 rivets then anodize or powder coat the caps in whatever color you want. I left the real short cut, square weave, carpet panels short of the rivet lines by an inch or so on my car then trimmed the gray carpet with yellow leather on the edges with the rivet lines exposed. Everyone who has commented on it really likes the look. As opposed to those that have seen it thought it stunk and where polite enough not to say anything. Anyway I think this idea taken one step futher with the rivets in color would be very striking. Lee

ROWDYRENAULT said:

another idea that might be a bit easier if you go on Hansen Rivets web site they produce a "cap" if you will, that is driven into the hole left be a 3/16 rivet. The Cap is made of aluminum. why not built the car with 3/16 rivets then anodize or powder coat the caps in whatever color you want. I left the real short cut, square weave, carpet panels short of the rivet lines by an inch or so on my car then trimmed the gray carpet with yellow leather on the edges with the rivet lines exposed. Everyone who has commented on it really likes the look. As opposed to those that have seen it thought it stunk and where polite enough not to say anything. Anyway I think this idea taken one step futher with the rivets in color would be very striking. Lee

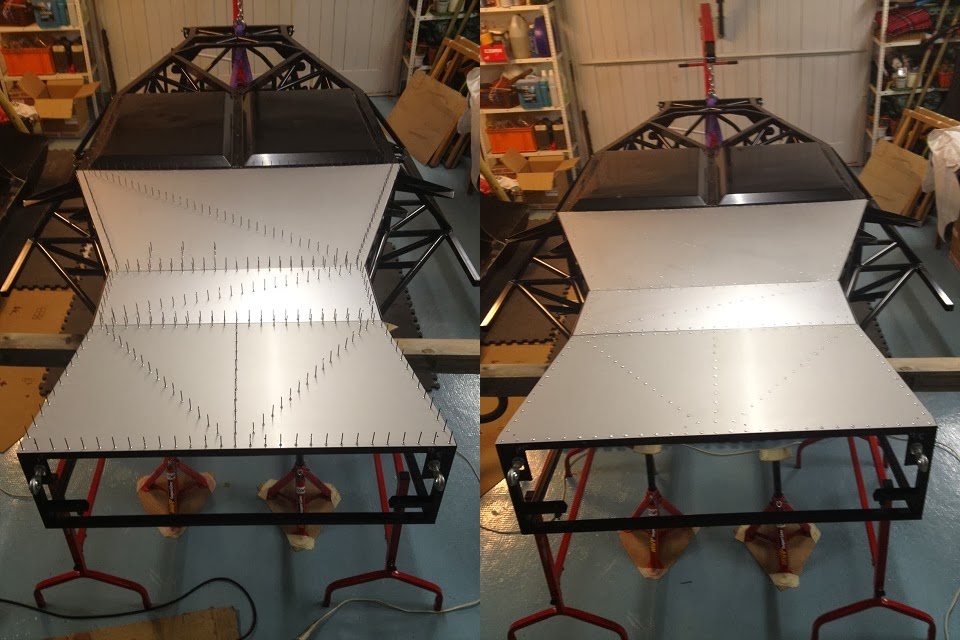

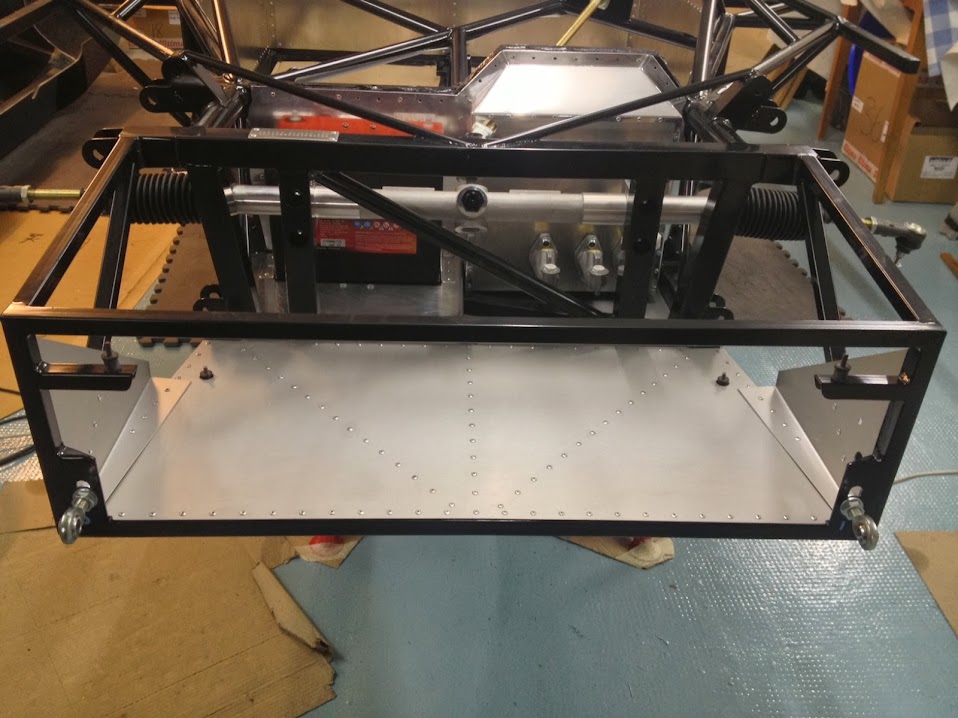

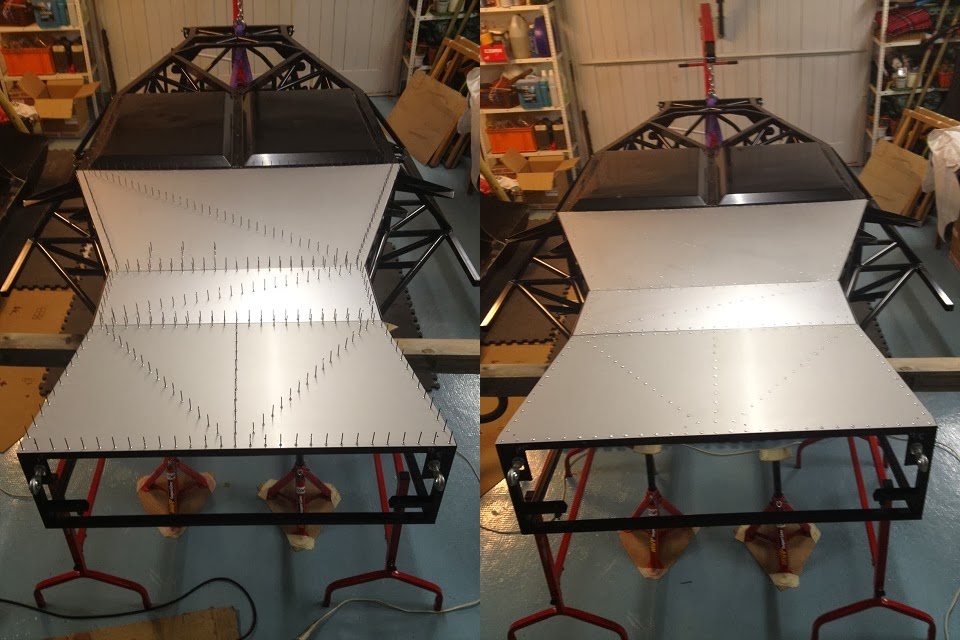

Are you talking about mushroom caps?Only part of my panels are anodized. The underside panel and the double skin of the radiator bay. I have choosen natural anodizing (no colour), it looks silver mat and the surface is perfectly homogeneous with no shadow like normal panels.

My anodising is limited to those panels, as I have another plan for the interior. As anodizing can't be repaired, I avoided cosmetic area with a lot of hand/foot contact.

The advantages/disadvantage:

+ Doesn't scratch if we simply touch it with ring or a watch as the standard panel. To scratch the surface, we need to push hard to deform the aluminium below.

+ Perfectly smooth surface

+ Natural anodizing leads to less visible scratches, as it will happen anyway with time.

- No possibility to repair

- Expensive (compare to the price of the panelling)

For the resistance against oxydation, it doesn't help a lot, as aluminium is anyway automatically passivated with the first layer of oxydation. Even with anodizing, it would still be eaten by oxydation through galvanised processes (salted water, caustic soda,...)

My anodising is limited to those panels, as I have another plan for the interior. As anodizing can't be repaired, I avoided cosmetic area with a lot of hand/foot contact.

The advantages/disadvantage:

+ Doesn't scratch if we simply touch it with ring or a watch as the standard panel. To scratch the surface, we need to push hard to deform the aluminium below.

+ Perfectly smooth surface

+ Natural anodizing leads to less visible scratches, as it will happen anyway with time.

- No possibility to repair

- Expensive (compare to the price of the panelling)

For the resistance against oxydation, it doesn't help a lot, as aluminium is anyway automatically passivated with the first layer of oxydation. Even with anodizing, it would still be eaten by oxydation through galvanised processes (salted water, caustic soda,...)

Alain, that looks very nice indeed

Are you going to do an extra panel at the rear of the radiator to avoid excess heat getting into the battery and master cylinder area? I strongly recommend you do, fastening with rivnuts. Mine is riveted but I don't think it will be necessary to remove.

Are you going to do an extra panel at the rear of the radiator to avoid excess heat getting into the battery and master cylinder area? I strongly recommend you do, fastening with rivnuts. Mine is riveted but I don't think it will be necessary to remove.

UltimaCH said:

Are you going to do an extra panel at the rear of the radiator to avoid excess heat getting into the battery and master cylinder area? I strongly recommend you do, fastening with rivnuts. Mine is riveted but I don't think it will be necessary to remove.

I don't know yet, as it can be added easily afterwards, I will check if temperature is really a problem despite the aircon. The problem that I see with the back plate is that the air can still go around it, mainly above. Wouldn't it be better to find a way to seal the gap with the front GRP body air extraction duct and the radiator?Gassing Station | Ultima | Top of Page | What's New | My Stuff

Wish mine looked like that...

Wish mine looked like that...