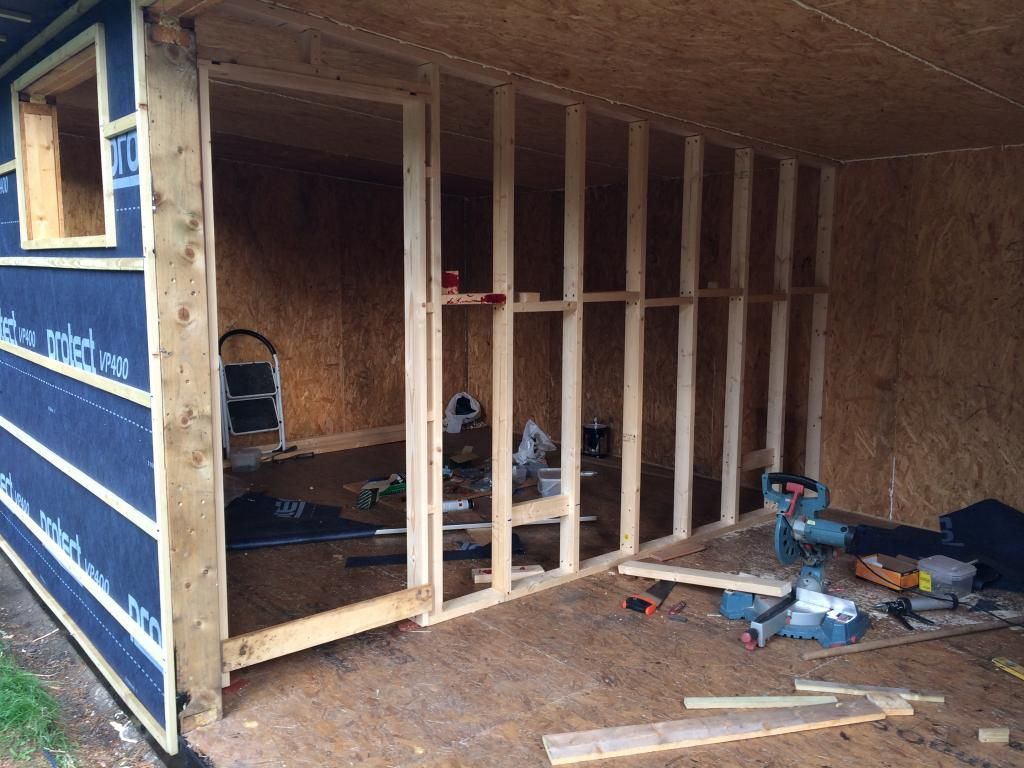

Posh Shed / Garden Room DIY Build

Discussion

V8RX7 said:

I guess it depends what you want but surely a SIPS panel is effectively 2 sheets of OSB and a sheet of Kingspan / Celotex.

Baring in mind you wouldn't want to look at either side - so have to clad it I can't see there is any saving in a shed build.

Absolutely - SIPS is not the cheap option for a shed. I was always going to clad the exterior and plasterboard the interior but at £80 for a 6100 x 1200 x 140mm sheet it works out cheaper than a wooden frame and Kingspan. Baring in mind you wouldn't want to look at either side - so have to clad it I can't see there is any saving in a shed build.

Total overkill for a posh shed/garden room however it should end up being very strong and thermally efficient. Supported one of the panels at each end and stood in the unsupported middle - very little deflection which was impressive.

Our place is a SIPs house. Here's a video of it going up: http://www.youtube.com/watch?v=bDw6Eh8wa0Q

The kingspan site has a load of technical drawings for wall construction. Basically, you need a ring beam that the panels sit on, and a post that runs up between each panel. The posts should be a good fit in the gap between the outer boards. Foam glue the posts in place then nail them.

Don't clad directly on to them or you trap moisture - cover them in breather membrane, held in place with vertical battens, then you can do the traditional horizontal shiplap boards to clad.

The kingspan site has a load of technical drawings for wall construction. Basically, you need a ring beam that the panels sit on, and a post that runs up between each panel. The posts should be a good fit in the gap between the outer boards. Foam glue the posts in place then nail them.

======= ======

###### ++ ##### <--- Two panels and a post, from above

###### ++ #####

======= ======

Nail

VV

=============

######++#####

######++#####

=============

^^

Nail

Don't clad directly on to them or you trap moisture - cover them in breather membrane, held in place with vertical battens, then you can do the traditional horizontal shiplap boards to clad.

Tuna said:

Our place is a SIPs house. Here's a video of it going up: http://www.youtube.com/watch?v=bDw6Eh8wa0Q

Great video - wish I'd done similar on my buildhowdo, believe it or no I stumbled on this site looking for advice on led lights, but it just so happens I am building a SIP posh shed/garage similar to the one you have in mind (although about half the size). like you I have no idea what I am doing, but I am just about finished nonetheless, so I hope that gives you some encouragement.

I ought to come clean about the fact that I am not really into cars (in fact I am blogging about my shed build on a forum about vespas!).

Anyhow, I got off to an easier start than you in that I had a SIP manufacturer cut the panels to my design. I did look briefly into doing what you will need to do, namely to cut them on site, and it is eminently doable, but would be a lot easier with the right tools.

In the US where they do more SIP building they use two things, a beam cutter (to cut the panels) and a hot knife to cut the recess in the insulation. I ended up having to cut a couple of panels in the roof as they were to heavy to lift - lacking the right tools, what I did was definitely not nice, but effective: I used a circular saw to cut through the OSB boards on each side and then pushed the panels onto a raised edge to break the insulation.

Did the panels come with the connecting timbers? This will be your next challenge - the panels fit together with splines - for the walls these are generally mini-sips that fit tightly in a recess between the two abutting panels, and for roofs/floors they are timber. Although a bit OTT in terms of strength, there is nothing to stop you using timber all the way through of course, and it will be easy to source that too.

What is going to take a bit of imagination is cutting the recess in the insulation, and tbh I can’t think of an easy way to do that.

beam cutter

hot knife

I ought to come clean about the fact that I am not really into cars (in fact I am blogging about my shed build on a forum about vespas!).

Anyhow, I got off to an easier start than you in that I had a SIP manufacturer cut the panels to my design. I did look briefly into doing what you will need to do, namely to cut them on site, and it is eminently doable, but would be a lot easier with the right tools.

In the US where they do more SIP building they use two things, a beam cutter (to cut the panels) and a hot knife to cut the recess in the insulation. I ended up having to cut a couple of panels in the roof as they were to heavy to lift - lacking the right tools, what I did was definitely not nice, but effective: I used a circular saw to cut through the OSB boards on each side and then pushed the panels onto a raised edge to break the insulation.

Did the panels come with the connecting timbers? This will be your next challenge - the panels fit together with splines - for the walls these are generally mini-sips that fit tightly in a recess between the two abutting panels, and for roofs/floors they are timber. Although a bit OTT in terms of strength, there is nothing to stop you using timber all the way through of course, and it will be easy to source that too.

What is going to take a bit of imagination is cutting the recess in the insulation, and tbh I can’t think of an easy way to do that.

- Disclaimer * I am not an expert and what I have just told you about cutting would get us both thrown out of the SIP building union in minutes. This is because one of the goals of ‘proper’ SIP building is to create an airtight structure, and to do this you need v accurate cuts. mind you, we are only making expensive sheds, so does it really matter? Good luck!

beam cutter

hot knife

Dog Star said:

I hadn't seen the updates to this - that looks superb!

All build updates are here:http://www.pistonheads.com/gassing/topic.asp?h=0&a...

quite interesting to have a look every month or so as I usually miss the updates unless Im bookmarked.

Du1point8 said:

All build updates are here:

http://www.pistonheads.com/gassing/topic.asp?h=0&a...

quite interesting to have a look every month or so as I usually miss the updates unless Im bookmarked.

Not for this project though http://www.pistonheads.com/gassing/topic.asp?h=0&a...

quite interesting to have a look every month or so as I usually miss the updates unless Im bookmarked.

TA14 said:

Du1point8 said:

All build updates are here:

http://www.pistonheads.com/gassing/topic.asp?h=0&a...

quite interesting to have a look every month or so as I usually miss the updates unless Im bookmarked.

Not for this project though http://www.pistonheads.com/gassing/topic.asp?h=0&a...

quite interesting to have a look every month or so as I usually miss the updates unless Im bookmarked.

Craikeybaby said:

TA14 said:

Du1point8 said:

All build updates are here:

http://www.pistonheads.com/gassing/topic.asp?h=0&a...

quite interesting to have a look every month or so as I usually miss the updates unless Im bookmarked.

Not for this project though http://www.pistonheads.com/gassing/topic.asp?h=0&a...

quite interesting to have a look every month or so as I usually miss the updates unless Im bookmarked.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff

t

t