The ebay generator restoration thread

Discussion

Latest progress update

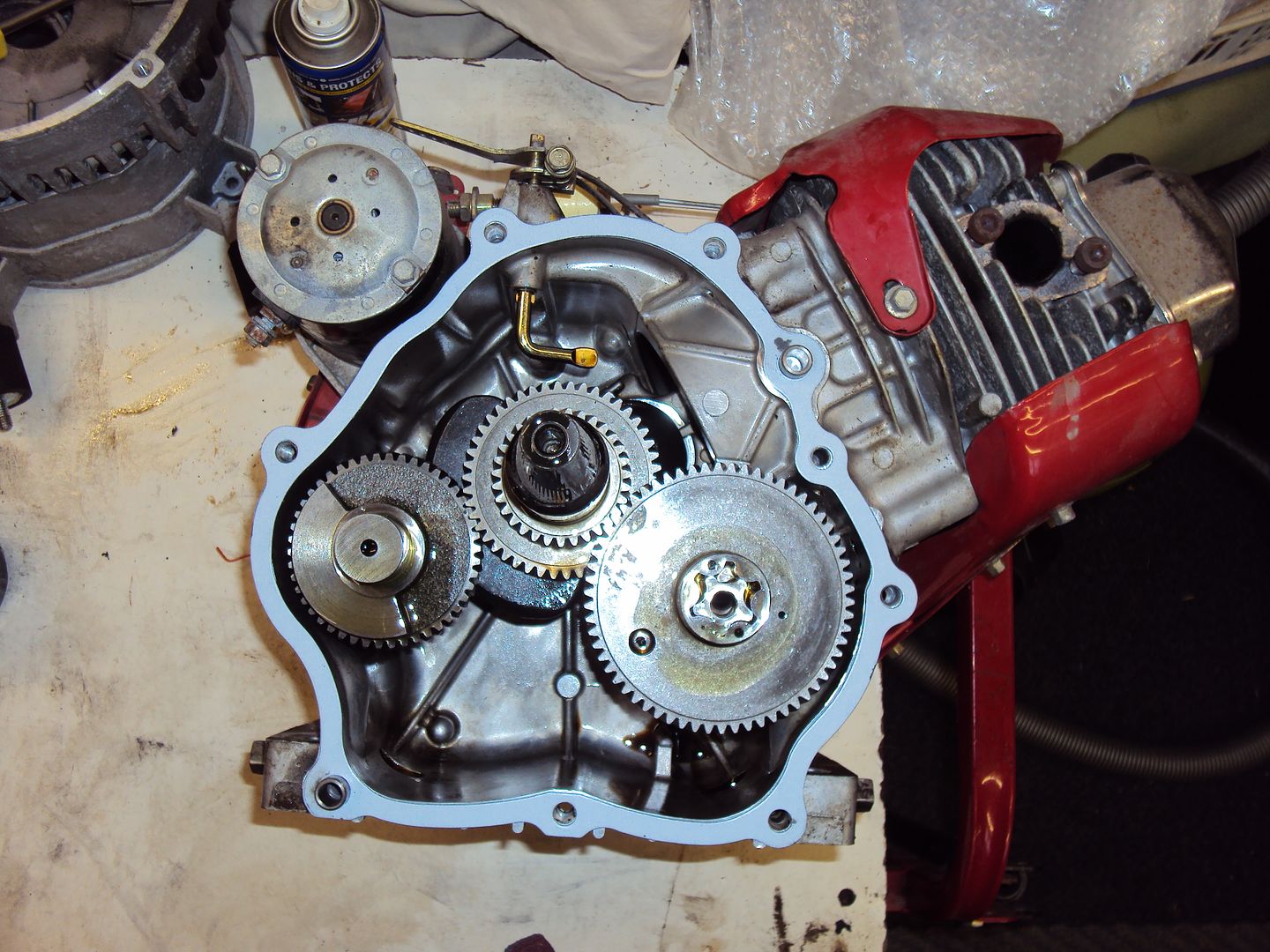

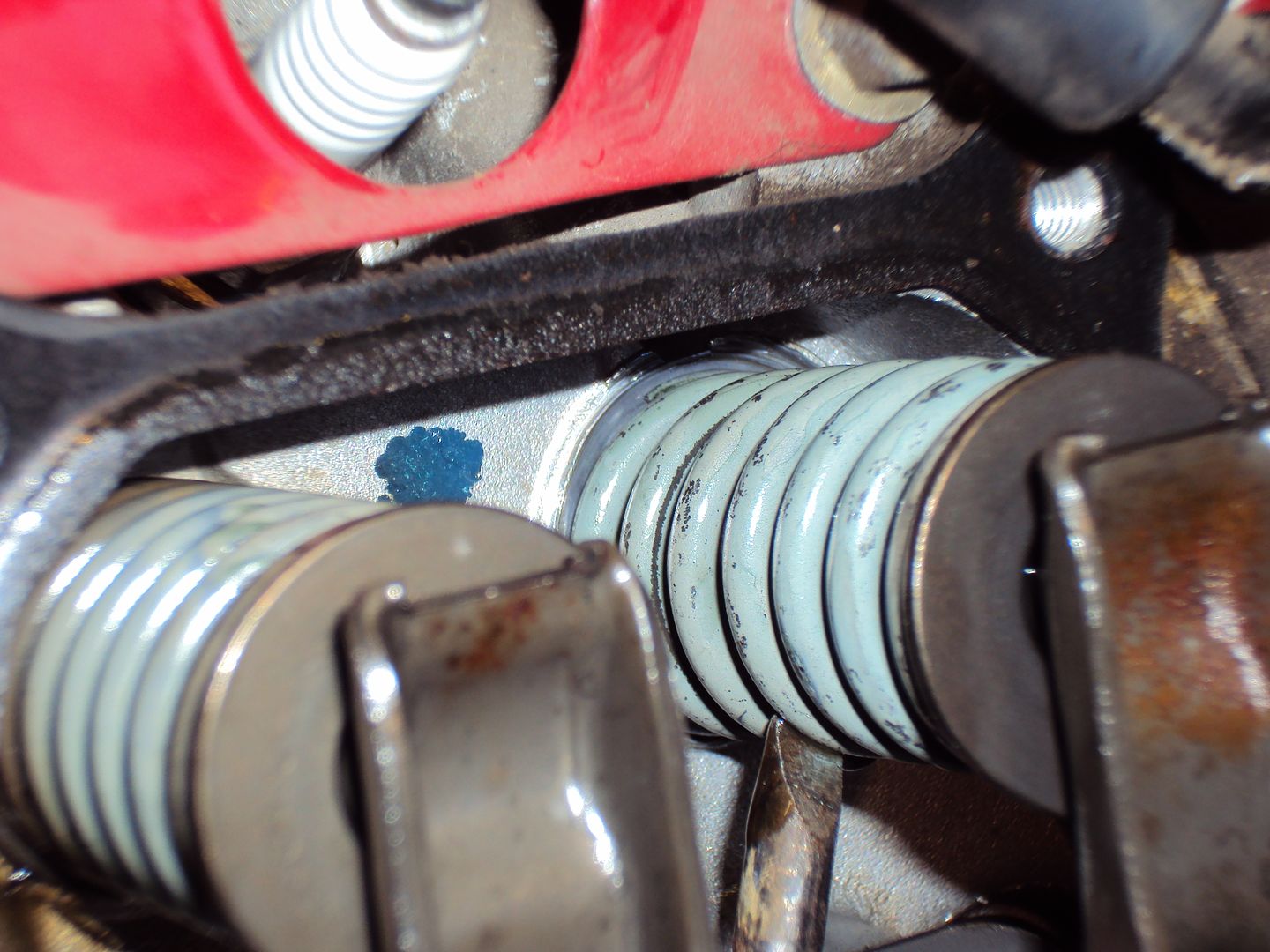

The crankcase gasket and crankshaft seal arrived from the USA

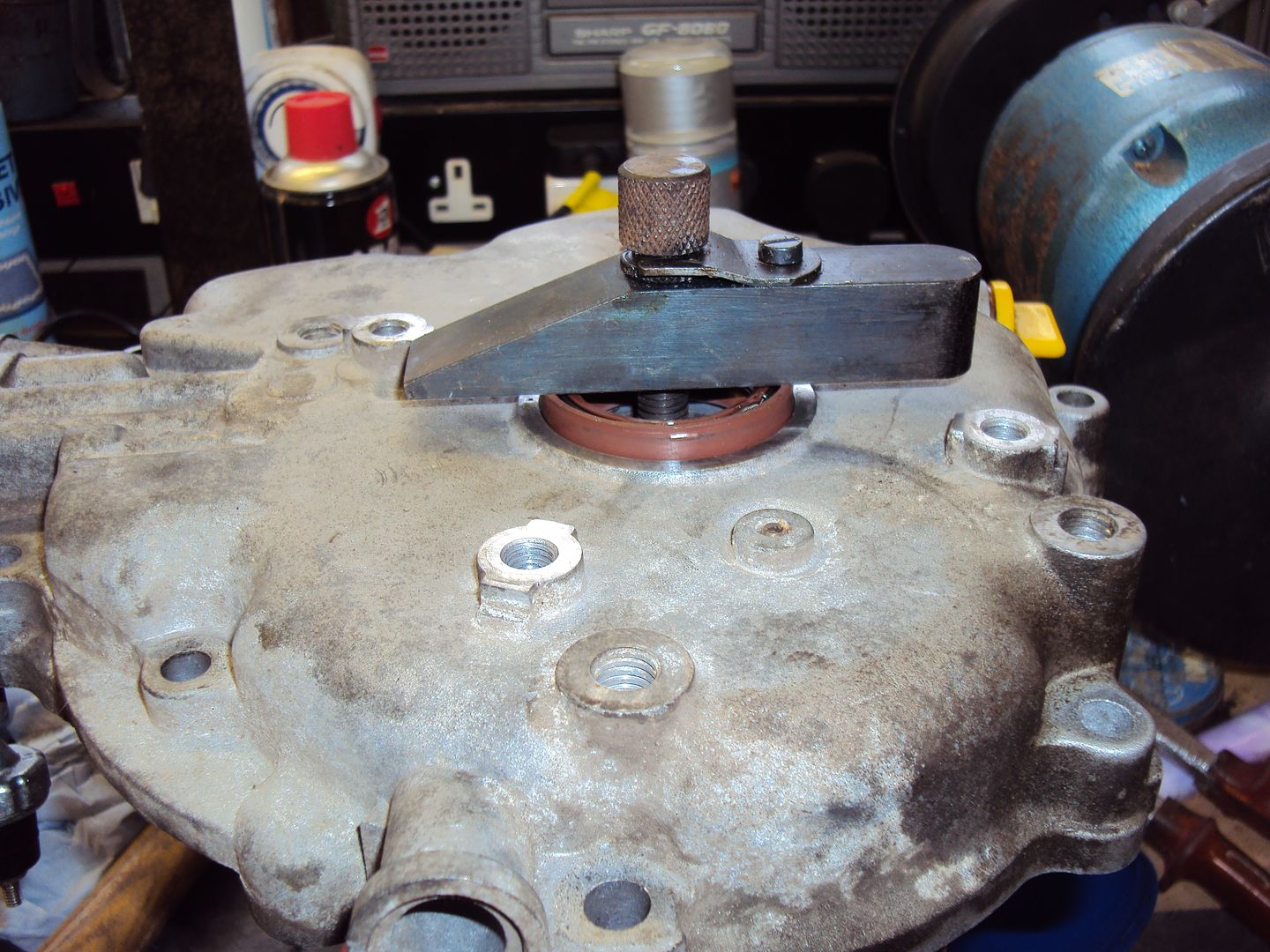

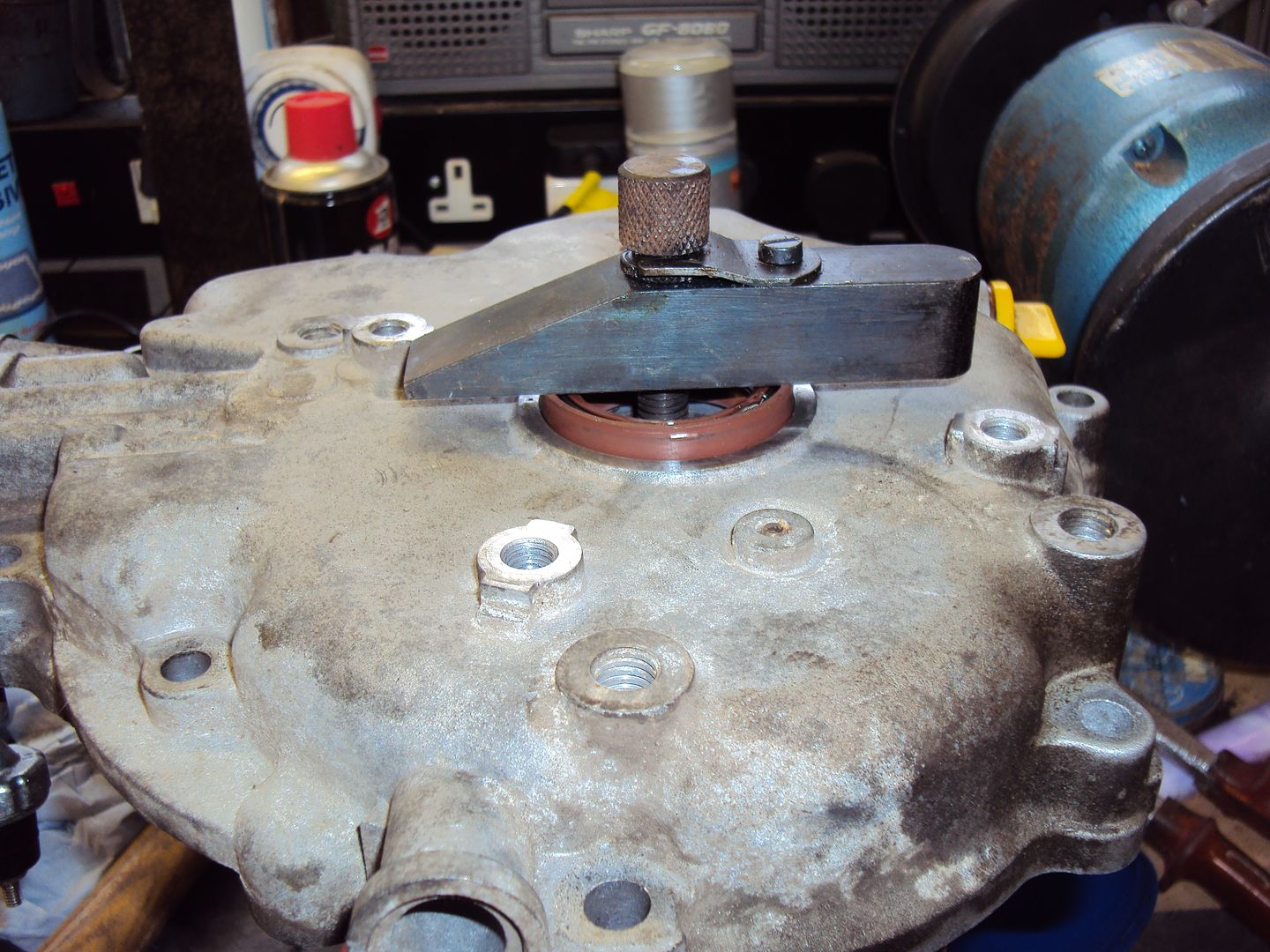

Sorry I didn’t take photos of the whole process (got carried away with the rebuild). I pressed the new crankshaft oil seal into the end casing using a toolmakers clamp. The old seal was placed on top of the new seal to protect it.

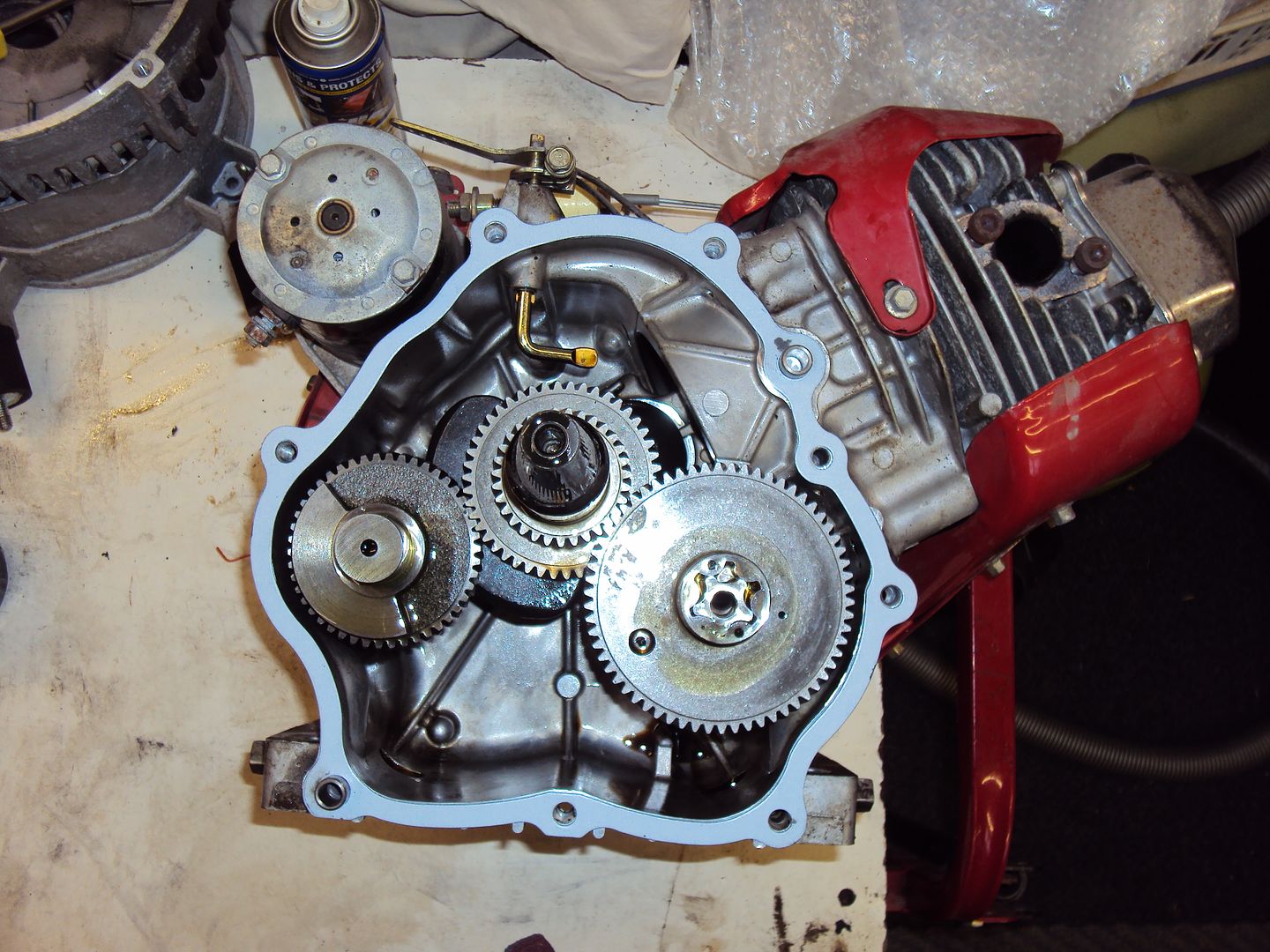

Cleaned up the engine casing and fitted the new gasket and oiled all the shafts so they would slide back into the end casing.

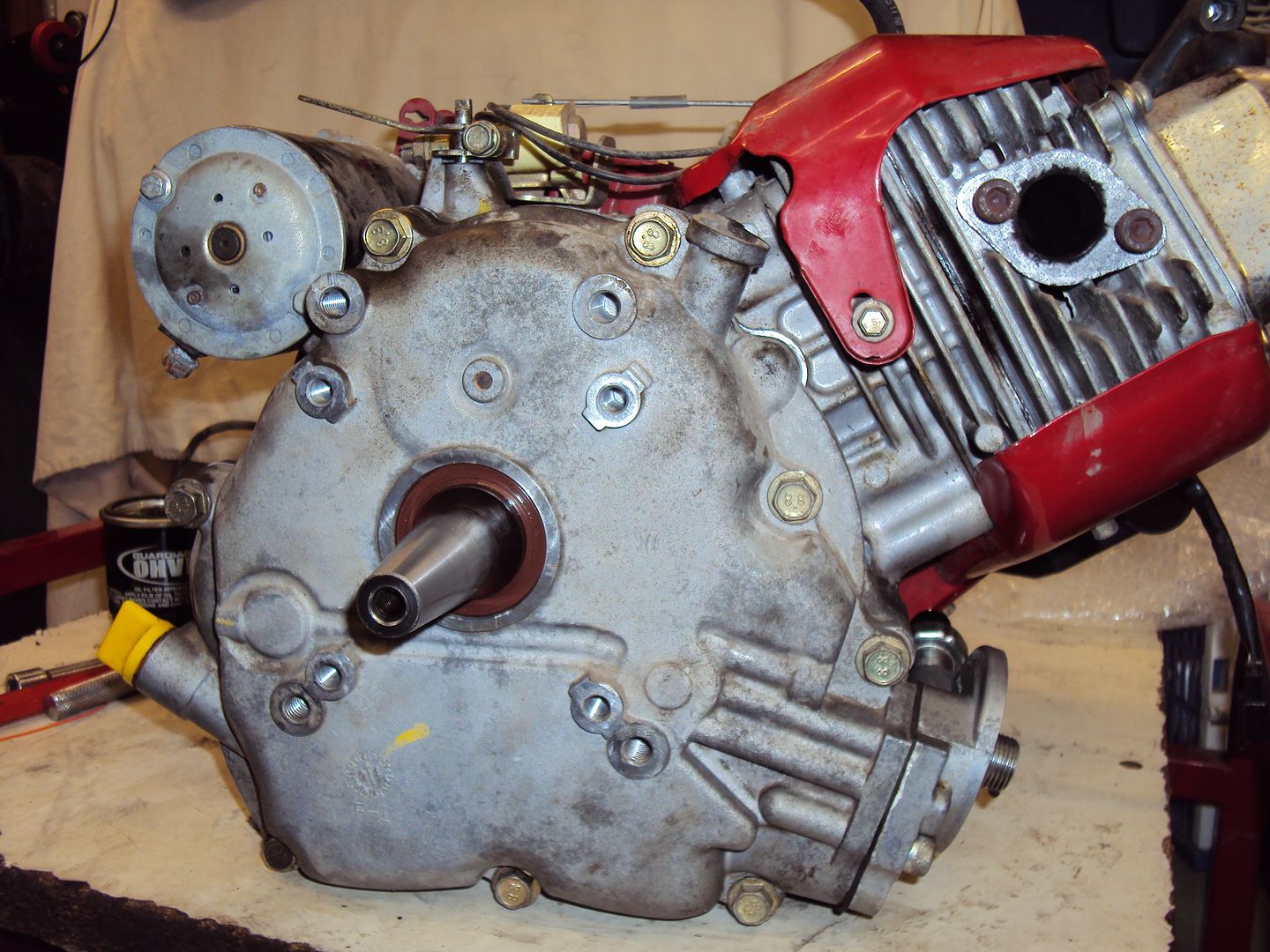

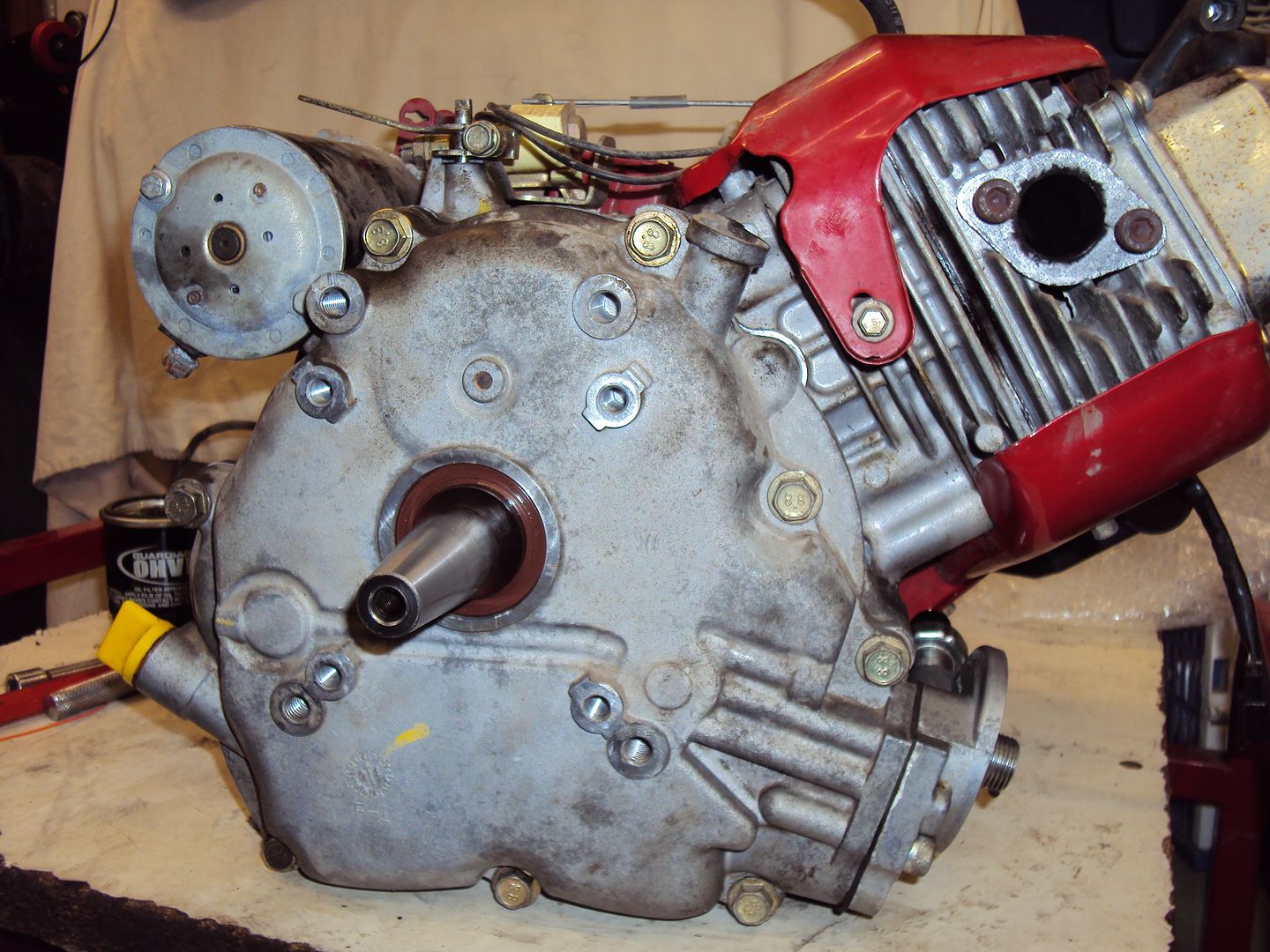

End casing back on and engine assembled

The engine is now back in the frame the alternator and ancillaries have been reassembled and attached to the engine. I was a bit nervous when it came to starting it, but it all went fine. The engine started on the second pull and settled down to a nice idle.

I never found where the broken up washer fitted, its size didn’t match any of the shafts inside the engine. The engine seems to be running fine without it.

Just need to set the running speed to get the correct frequency and build an additional panel so I can fit some 16A sockets.

The crankcase gasket and crankshaft seal arrived from the USA

Sorry I didn’t take photos of the whole process (got carried away with the rebuild). I pressed the new crankshaft oil seal into the end casing using a toolmakers clamp. The old seal was placed on top of the new seal to protect it.

Cleaned up the engine casing and fitted the new gasket and oiled all the shafts so they would slide back into the end casing.

End casing back on and engine assembled

The engine is now back in the frame the alternator and ancillaries have been reassembled and attached to the engine. I was a bit nervous when it came to starting it, but it all went fine. The engine started on the second pull and settled down to a nice idle.

I never found where the broken up washer fitted, its size didn’t match any of the shafts inside the engine. The engine seems to be running fine without it.

Just need to set the running speed to get the correct frequency and build an additional panel so I can fit some 16A sockets.

creationracing said:

Just got back a few days ago - only got to work on the 1000kw set but didn't get to the point where we could start it. Lots of instrument / PLC issues to resolve. Anyway, t'was an MTU 12V 4000 P63 engine with a Leroy Somer alternator attached.

Similar to this but with a remote radiator:

Mmmmm V12, I bet that will sound nice when runningSimilar to this but with a remote radiator:

As I have some spare time over the xmas break I thought I should try and finish the outstanding generator projects.

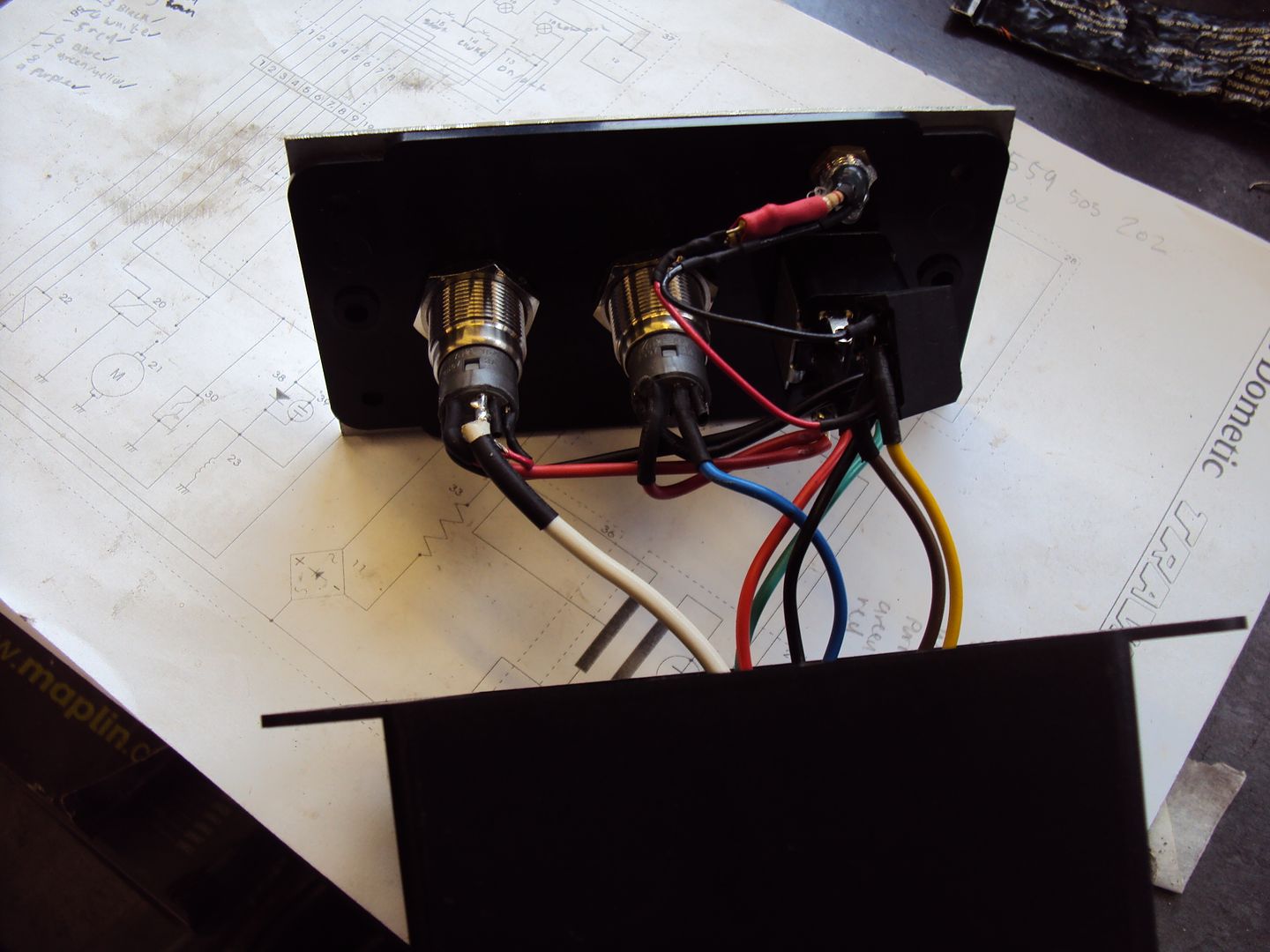

The Dometic generator needed a control panel so the electric start could be used, so I ordered a couple of switches, some multi core cable (trailer lighting cable) and a connector. I polished some aluminium to make the front panel and used metal stamps to label the switch functions.

Wiring behind the switches, the run LED needed some additional resistors adding (inside red heat shrink tube), as the supply was 50V which I only discovered after burning a LED and resistor out (I assumed it was 12V).

So that finishes the Dometic generator off, just need to clean it up and find it a new home.

On to the Generac.

As I’m thinking of hanging on to this one I wanted to add some 16A sockets as the Generac only has the American style 3 pin (120V) and 4 pin (120V & 240V) sockets which isn’t much use in the UK.

First thought was to make a replacement front panel with 16A sockets, but that meant I would have had to get new circuit breakers and rewire the whole thing.

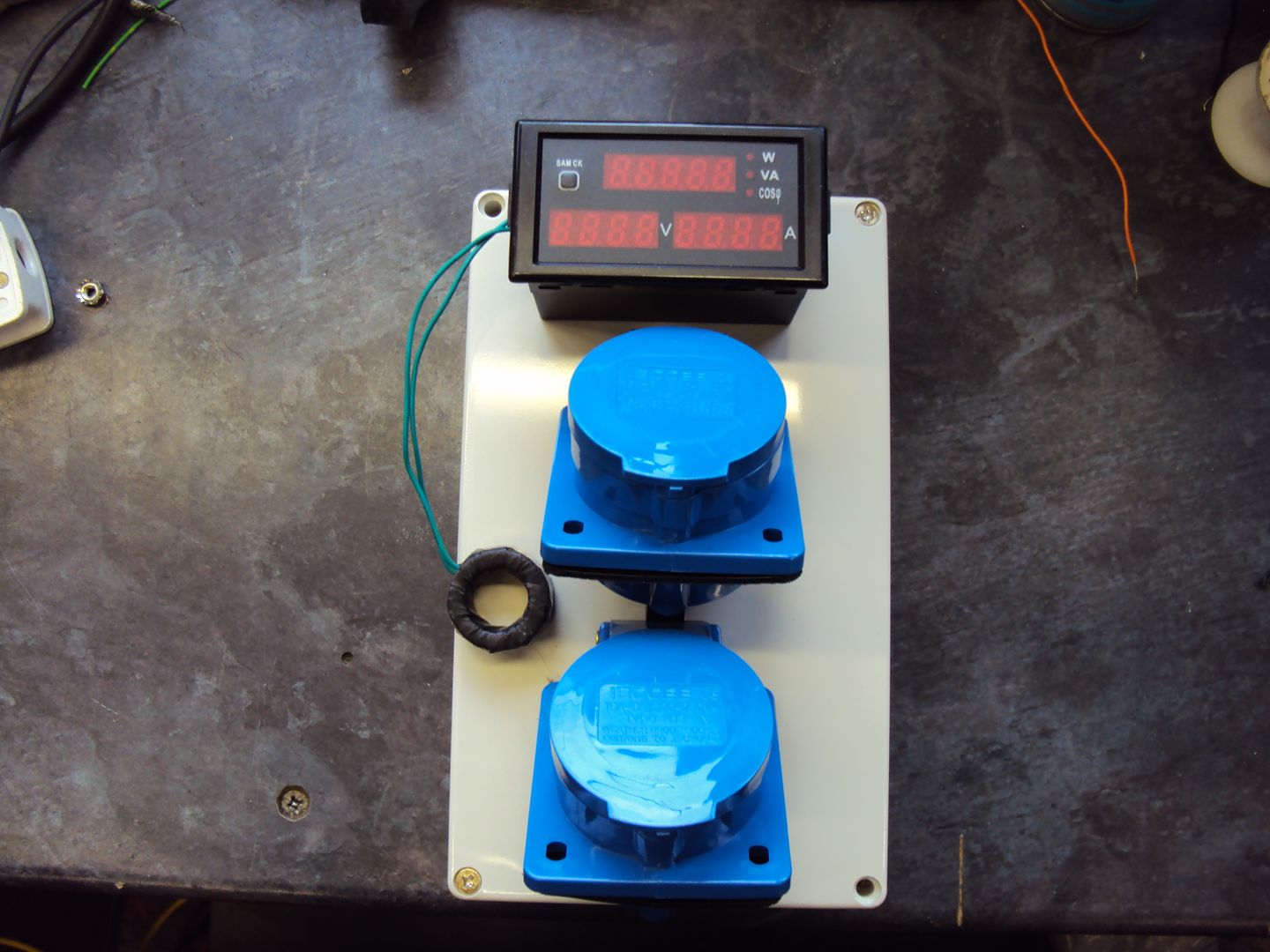

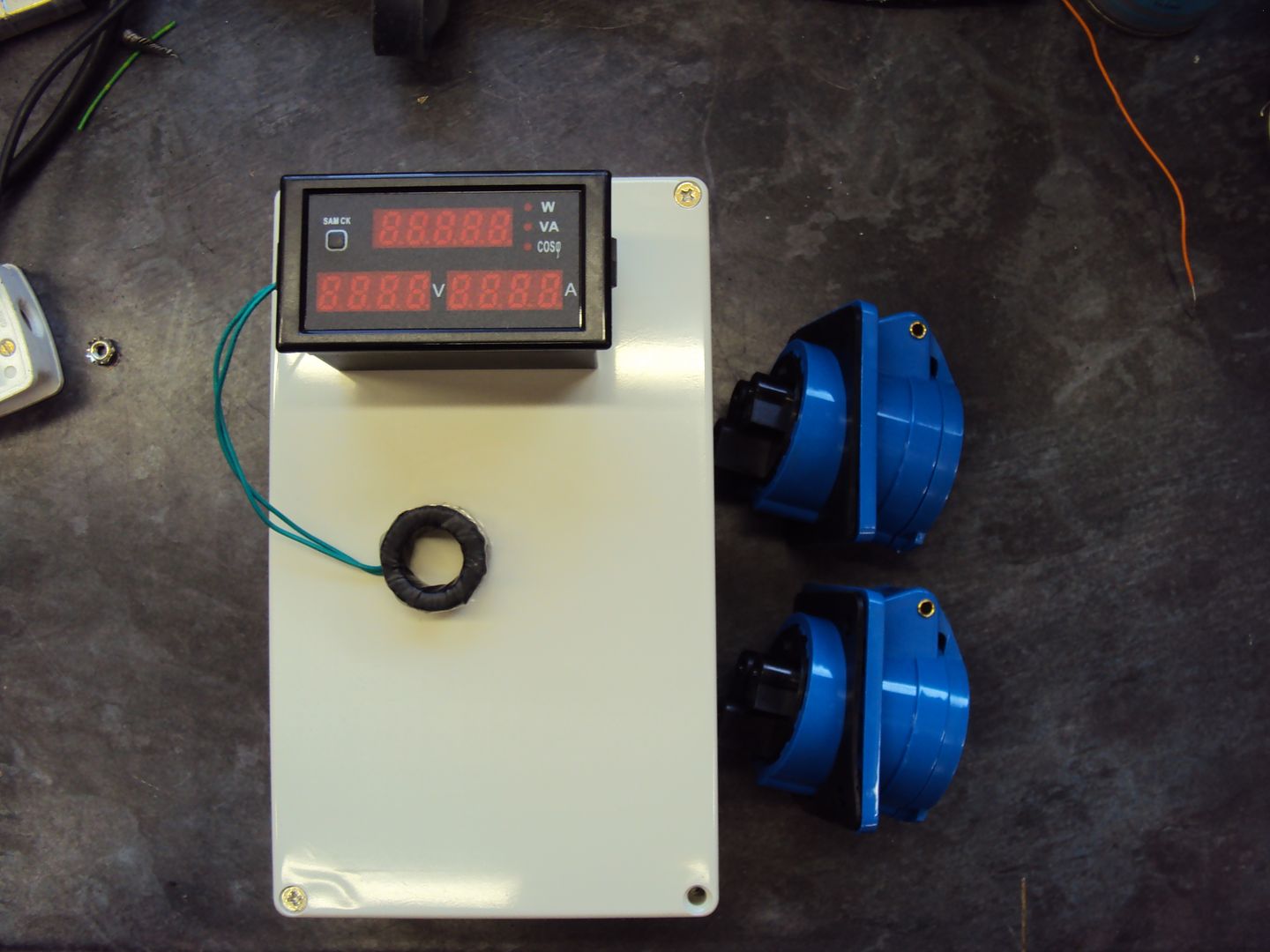

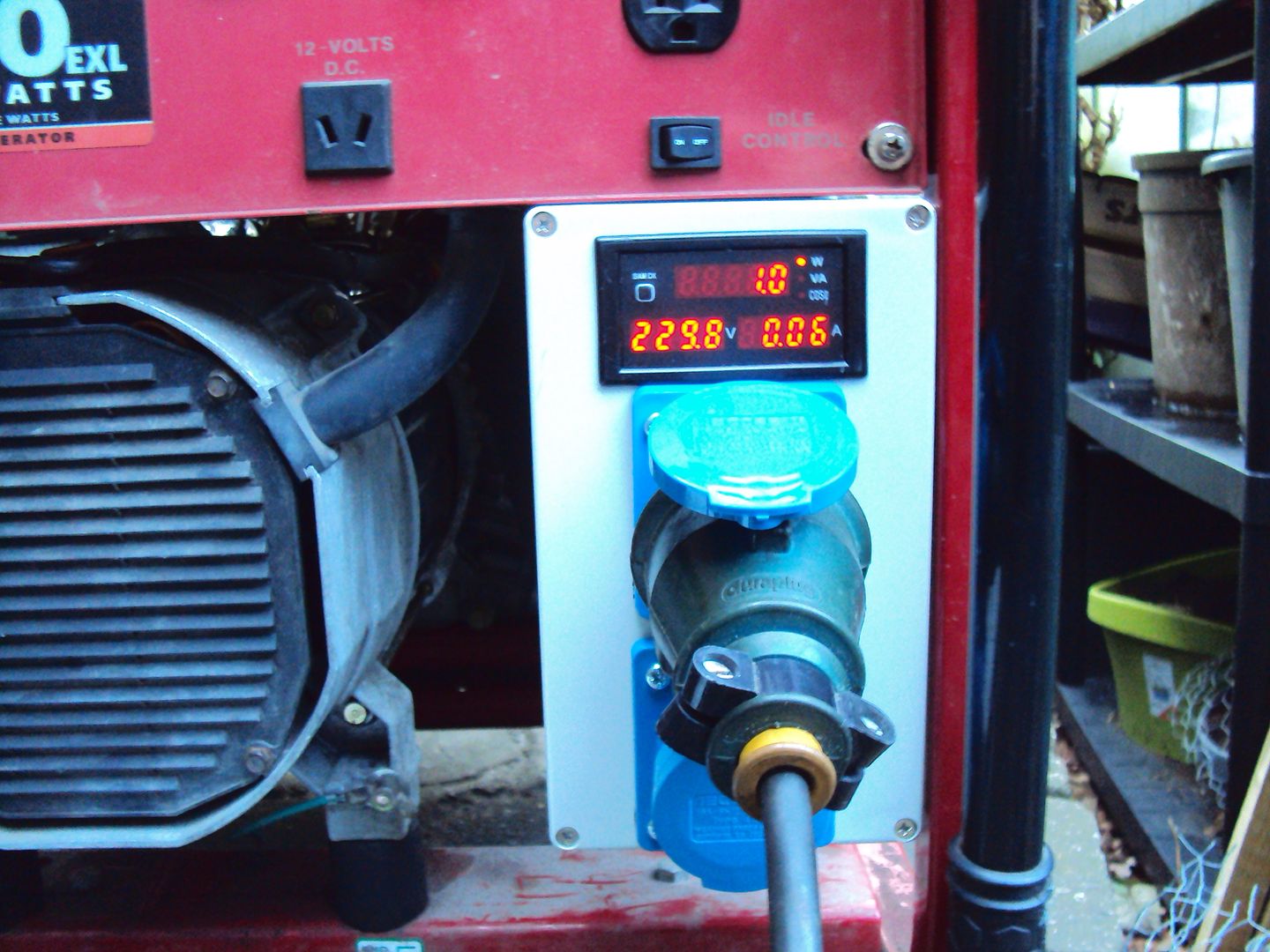

The second option which I went for was to add an additional panel with the sockets so I purchased a plastic box, 2x 16A sockets and a power meter which shows the voltage, current and load in watts (not bad for £12!)

I plan on mounting the box below the existing panel

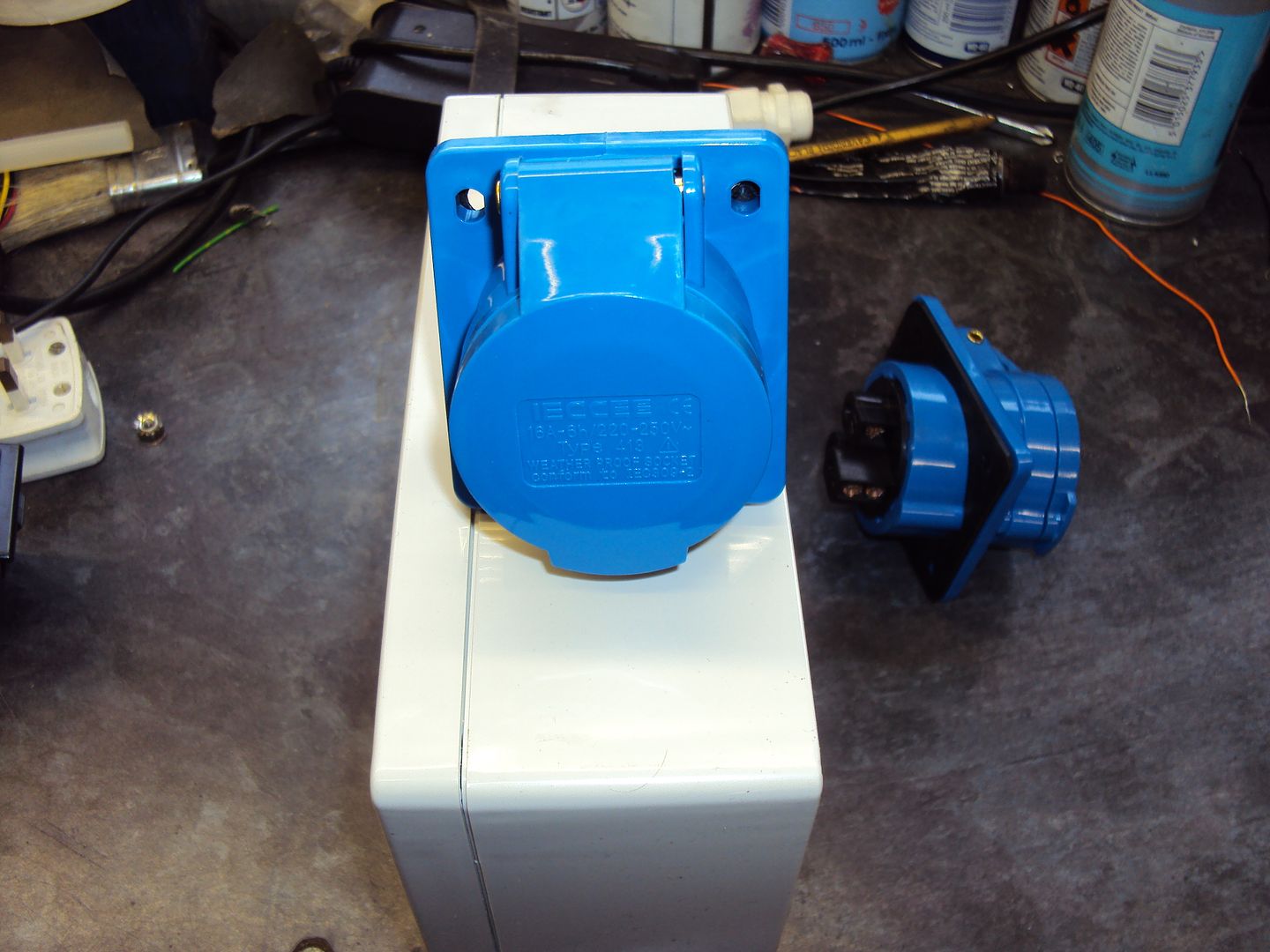

However with the sockets and power meter it was going to be a tight fit. The next size up box would be too big to fit in the gap so another option was to leave the power meter in the front of the box and mount the plugs on the side.

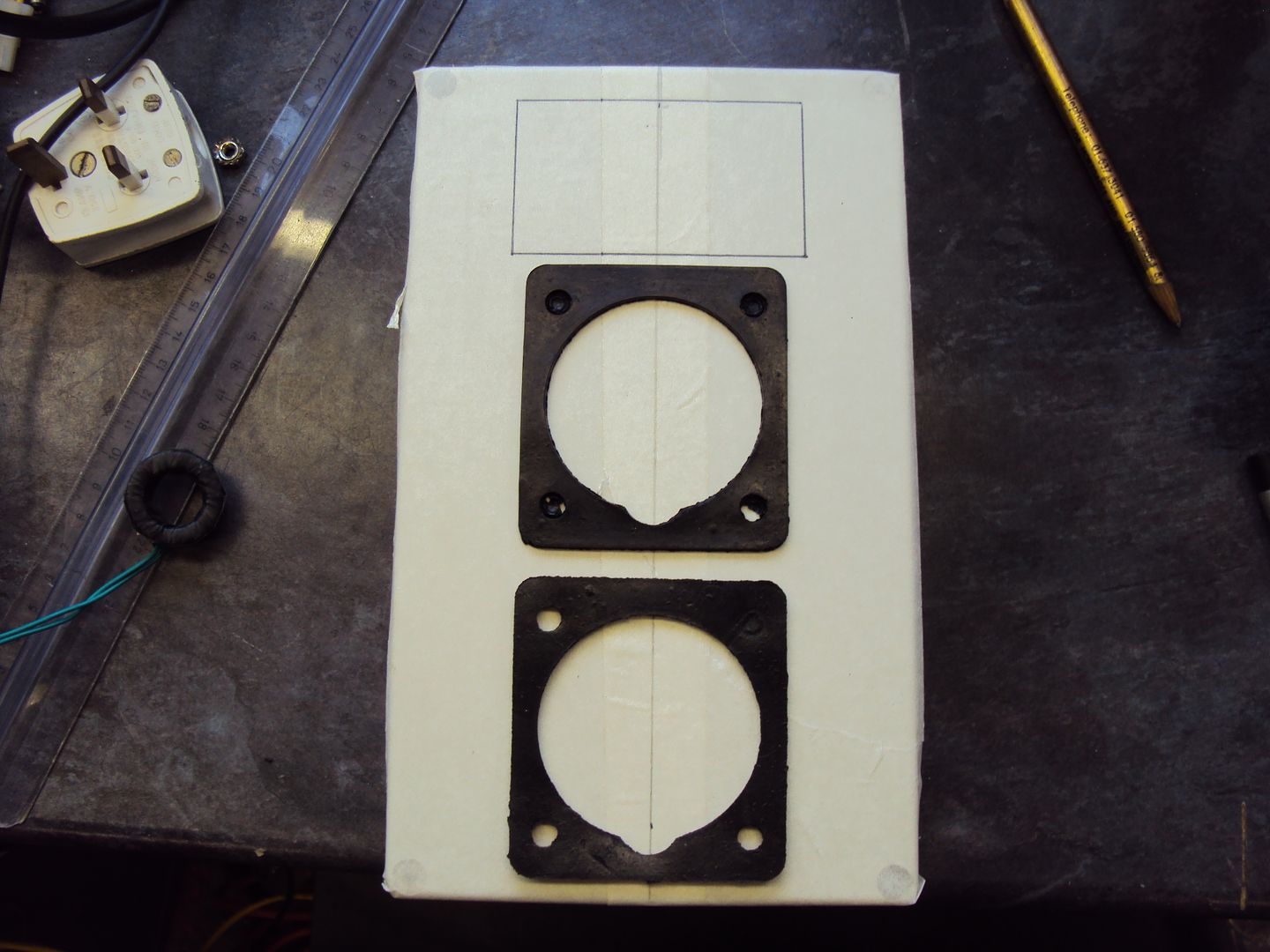

I would prefer to mount the sockets on the front of the box so I marked it out to see if it would fit

Just to make sure I mounted the plugs on a scrap piece of wood the same distance apart as they would be on the plastic box.

Check spacing with plugs in sockets

It’s tight but ok , more to follow….

always a pleasure Blue32.

I can't help feeling, however, you've let practicality get in the way of more creative switch button names.

Can you find room for a "turbo" or a "punch it Chewie" even if they don't actually do anything

ETA and how could I forget the "do not press this" button

regards,

Jet

I can't help feeling, however, you've let practicality get in the way of more creative switch button names.

Can you find room for a "turbo" or a "punch it Chewie" even if they don't actually do anything

ETA and how could I forget the "do not press this" button

regards,

Jet

S6PNJ said:

Hi Blue32 - any chance you can let me know where you got the little meter from please? It would be good to add something like that to my little generator.

Cheapnese power meterS6PNJ said:

Hi Blue32 - any chance you can let me know where you got the little meter from please? It would be good to add something like that to my little generator.

Here you go  http://www.ebay.co.uk/itm/AC80-300V-100A-Mini-LED-...

http://www.ebay.co.uk/itm/AC80-300V-100A-Mini-LED-...Last update for the year

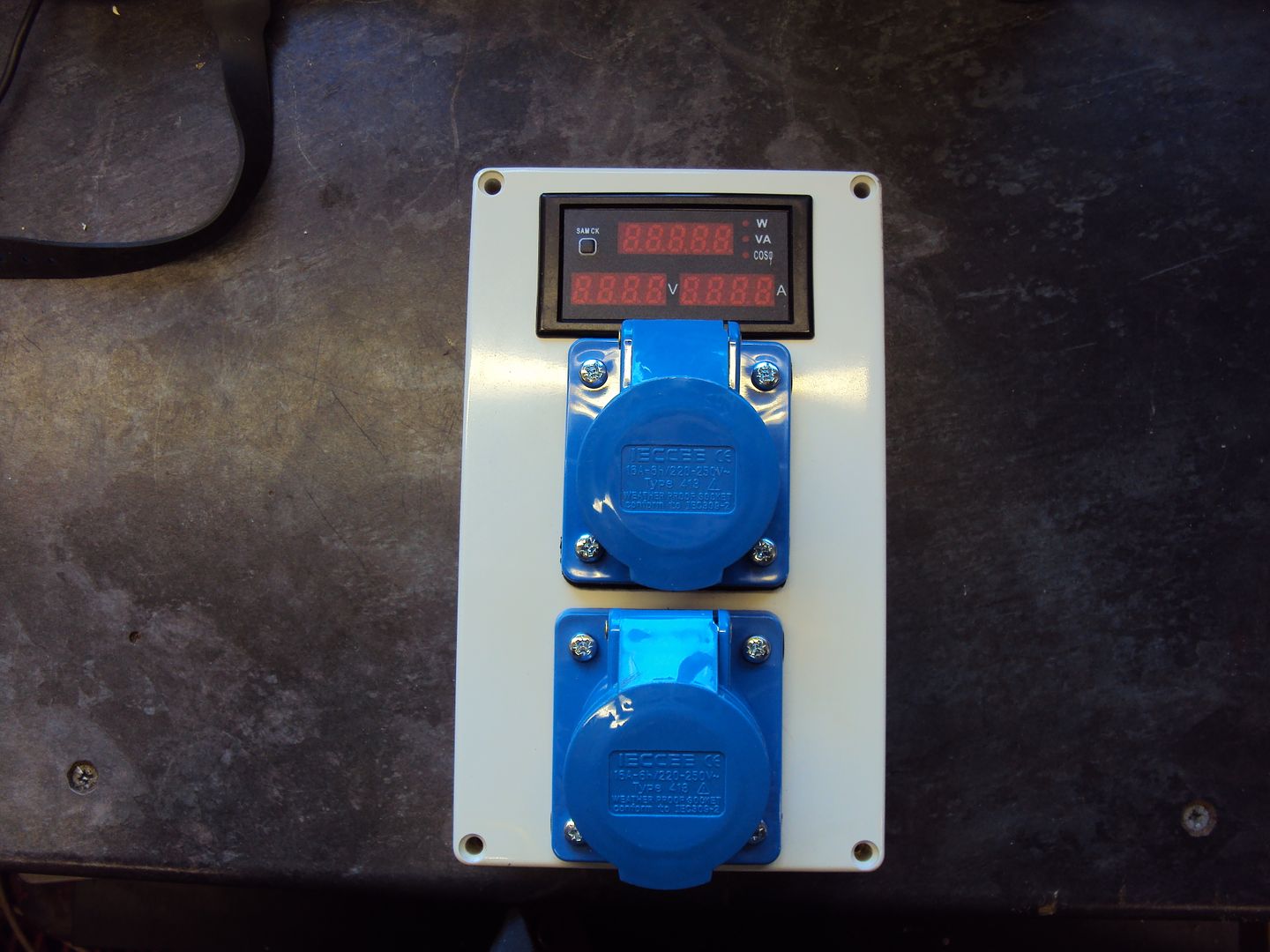

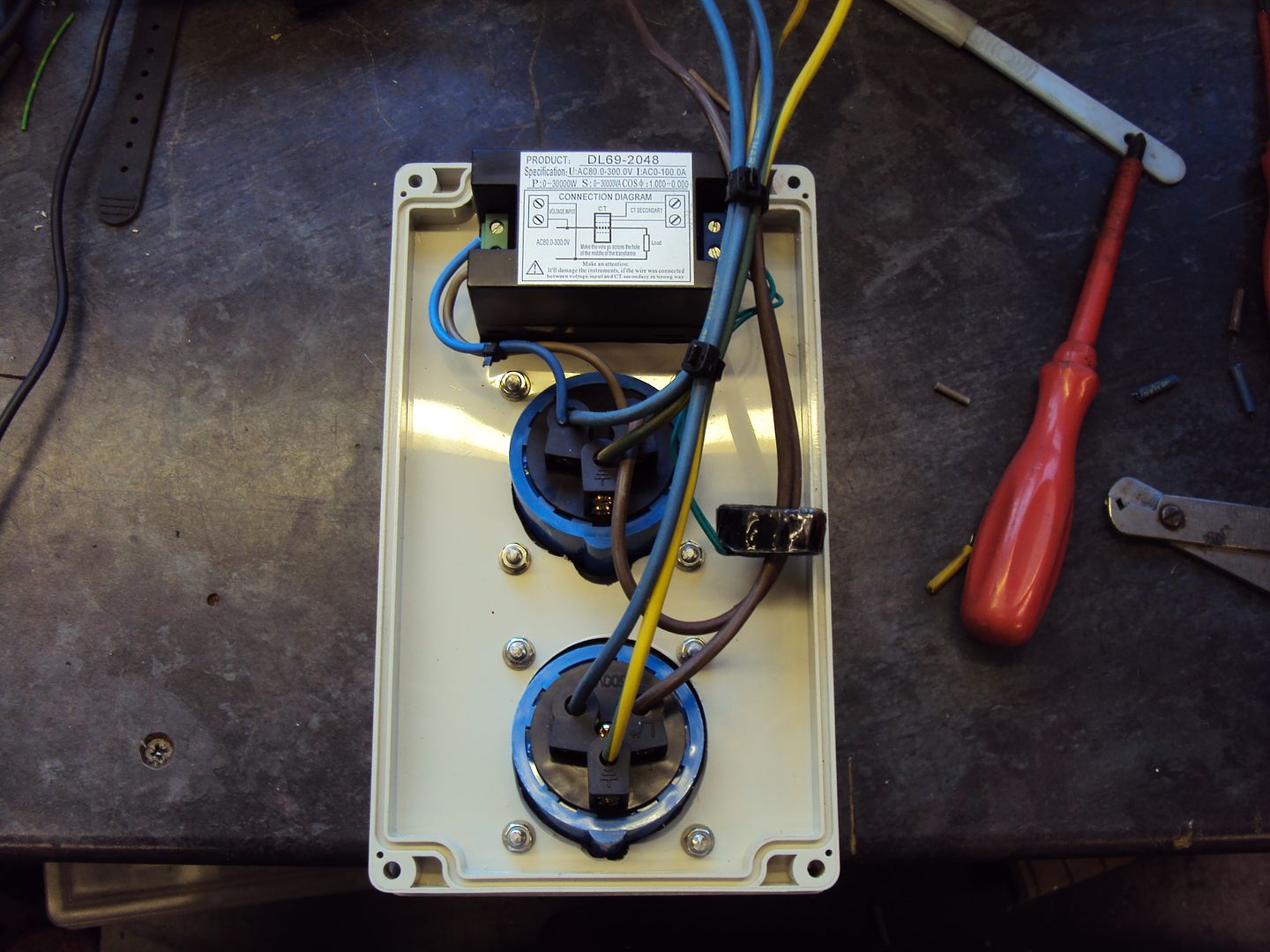

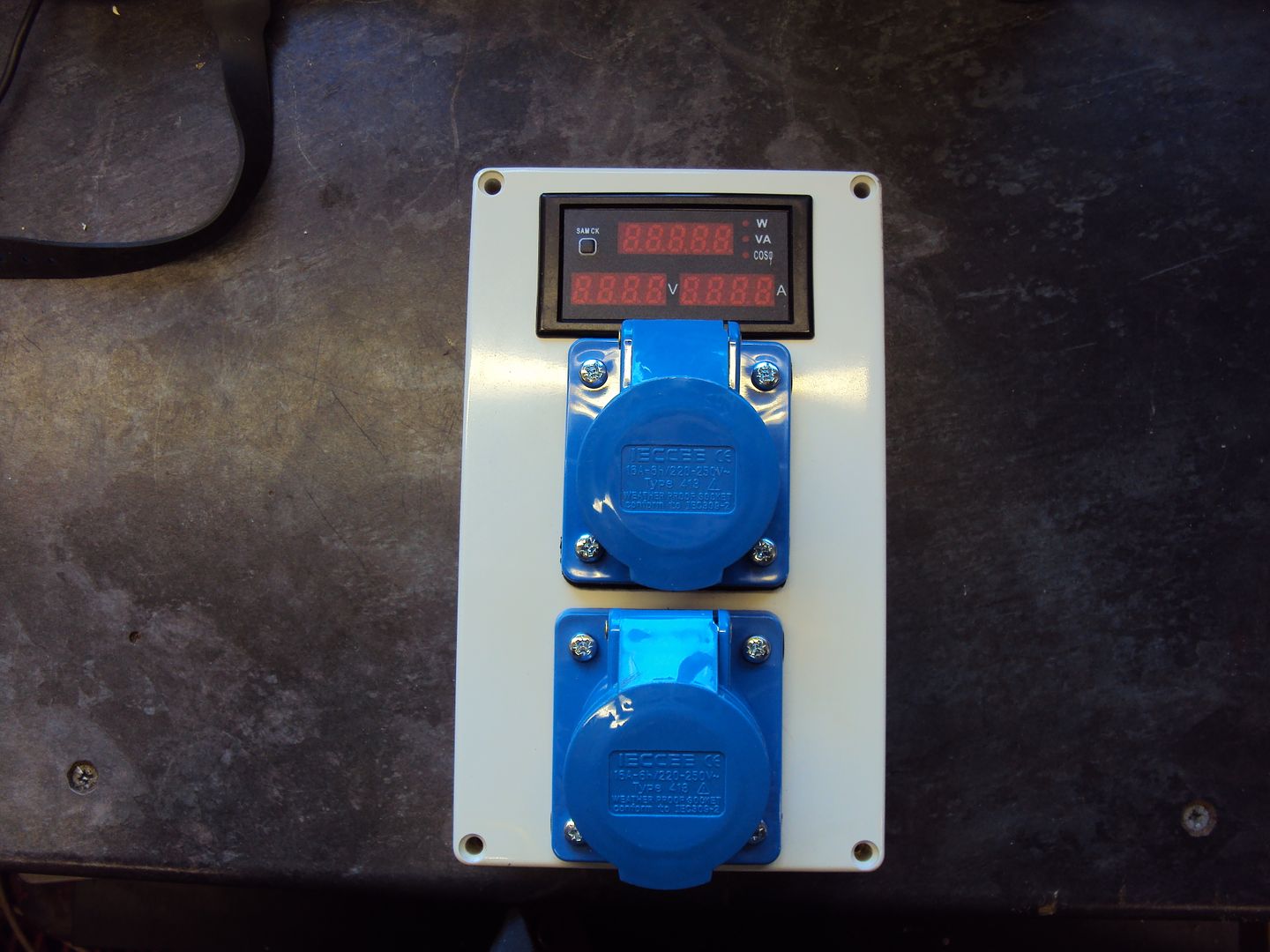

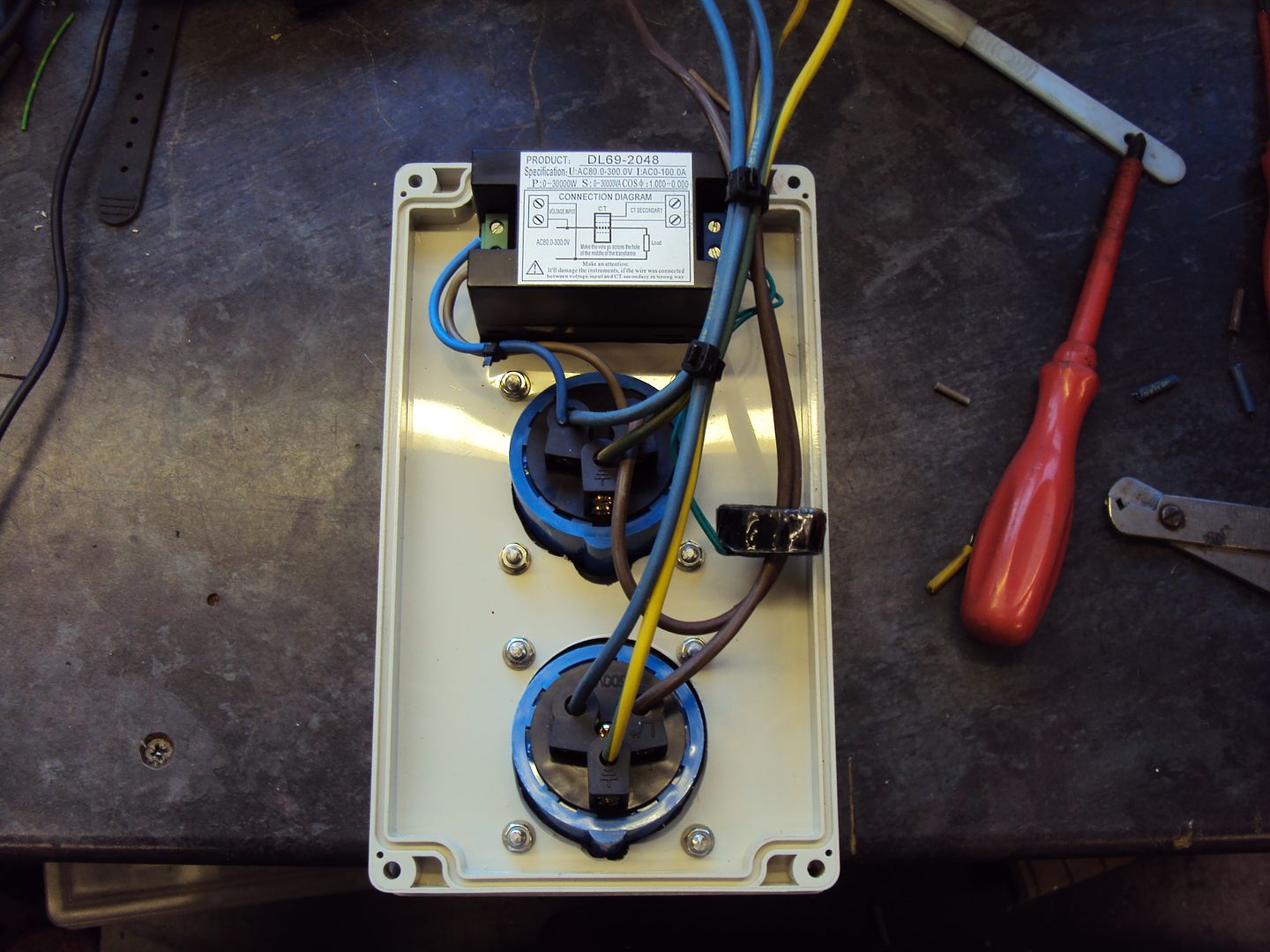

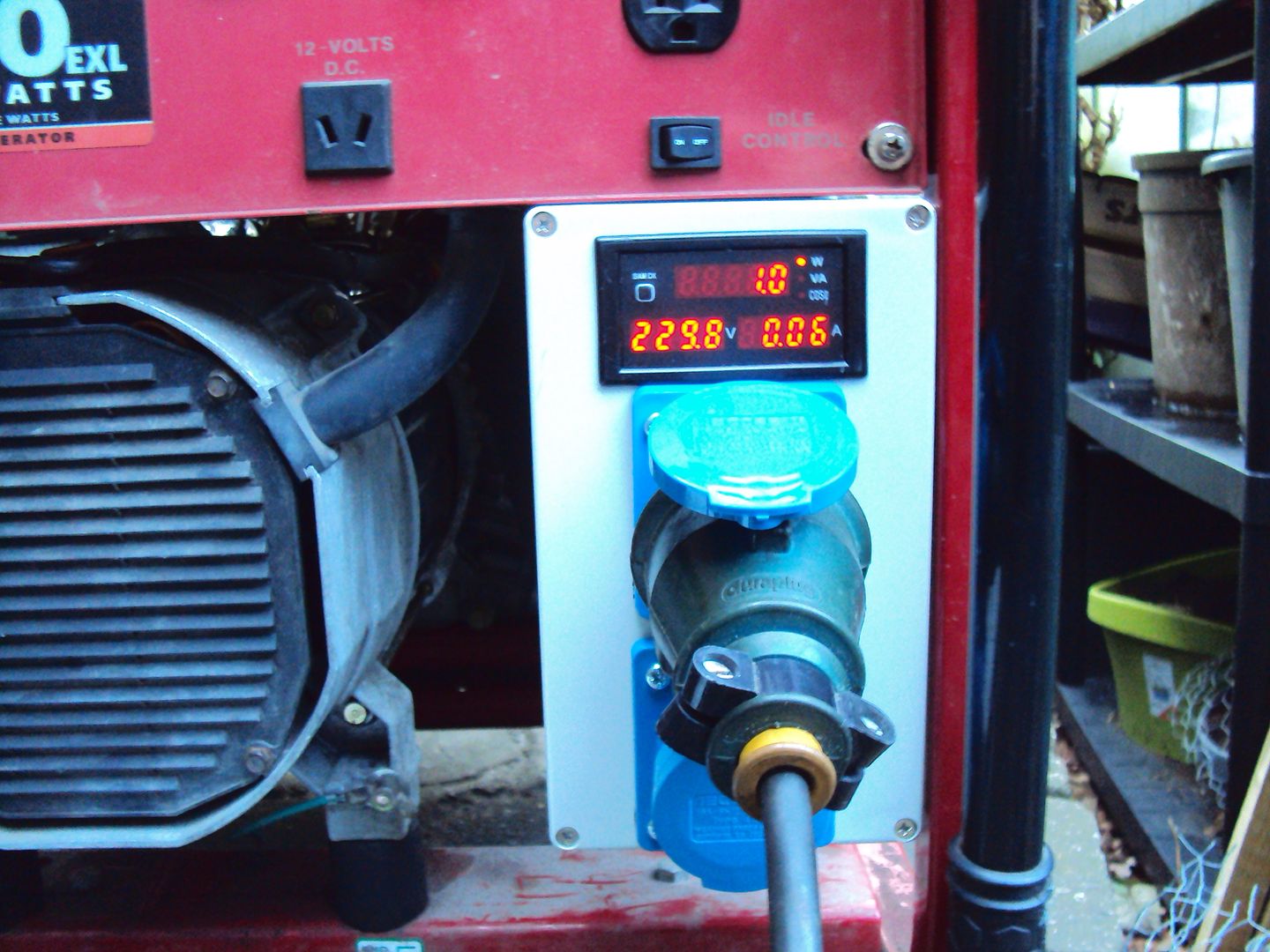

I have finished building the box, sockets and meter mounted

Wiring, just need to connect it to the existing wiring in the generator panel

How it should look when completed

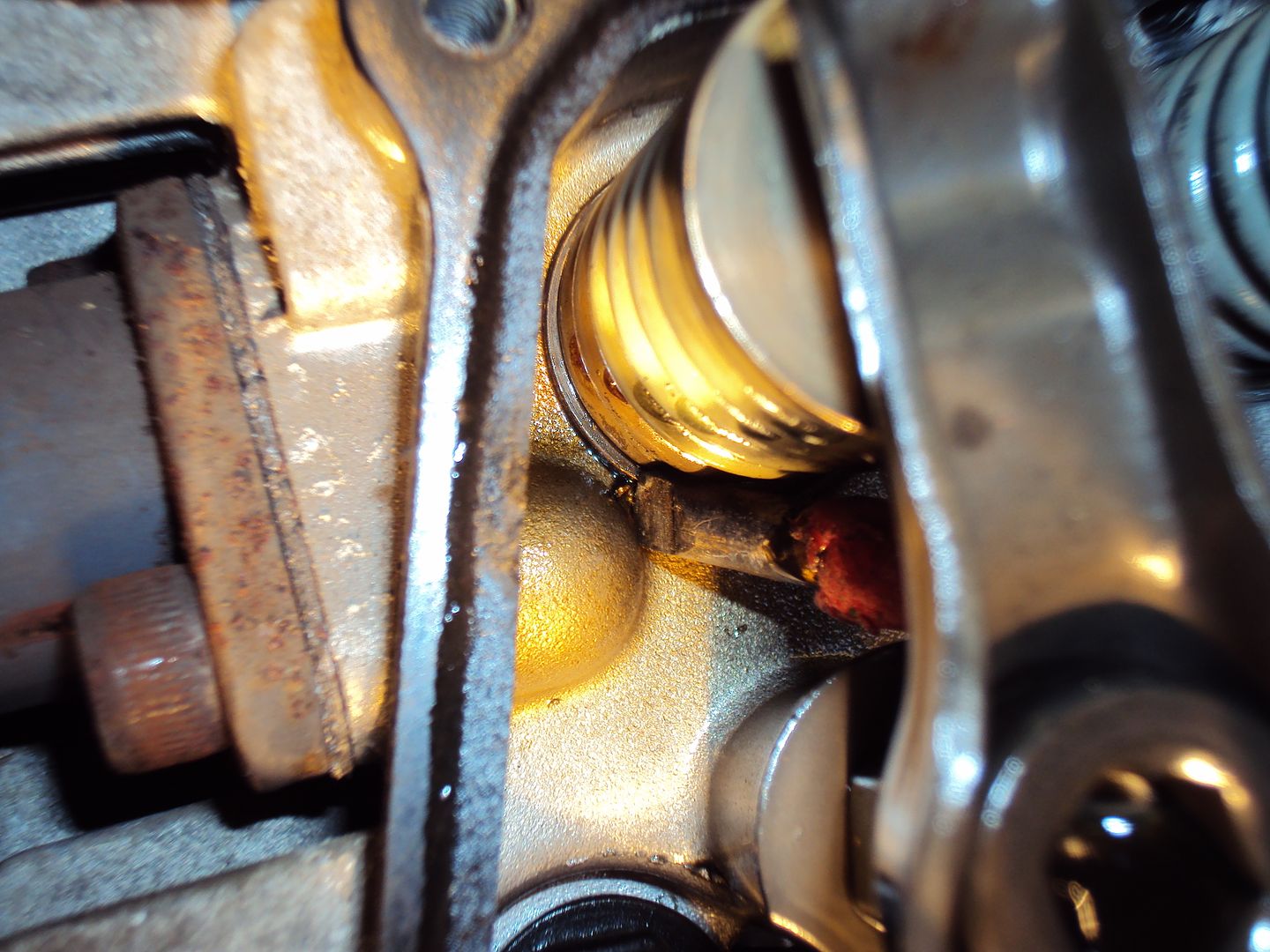

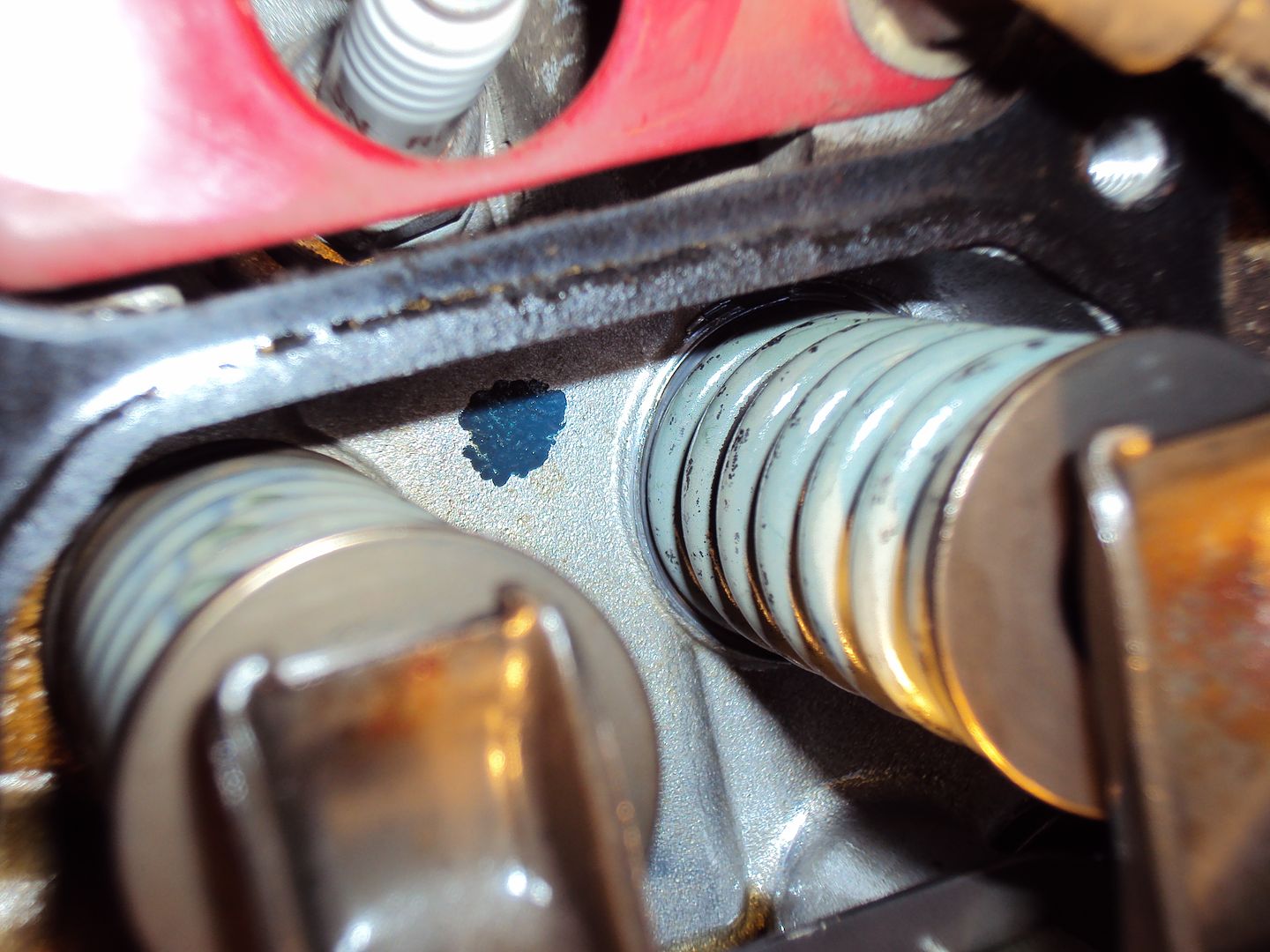

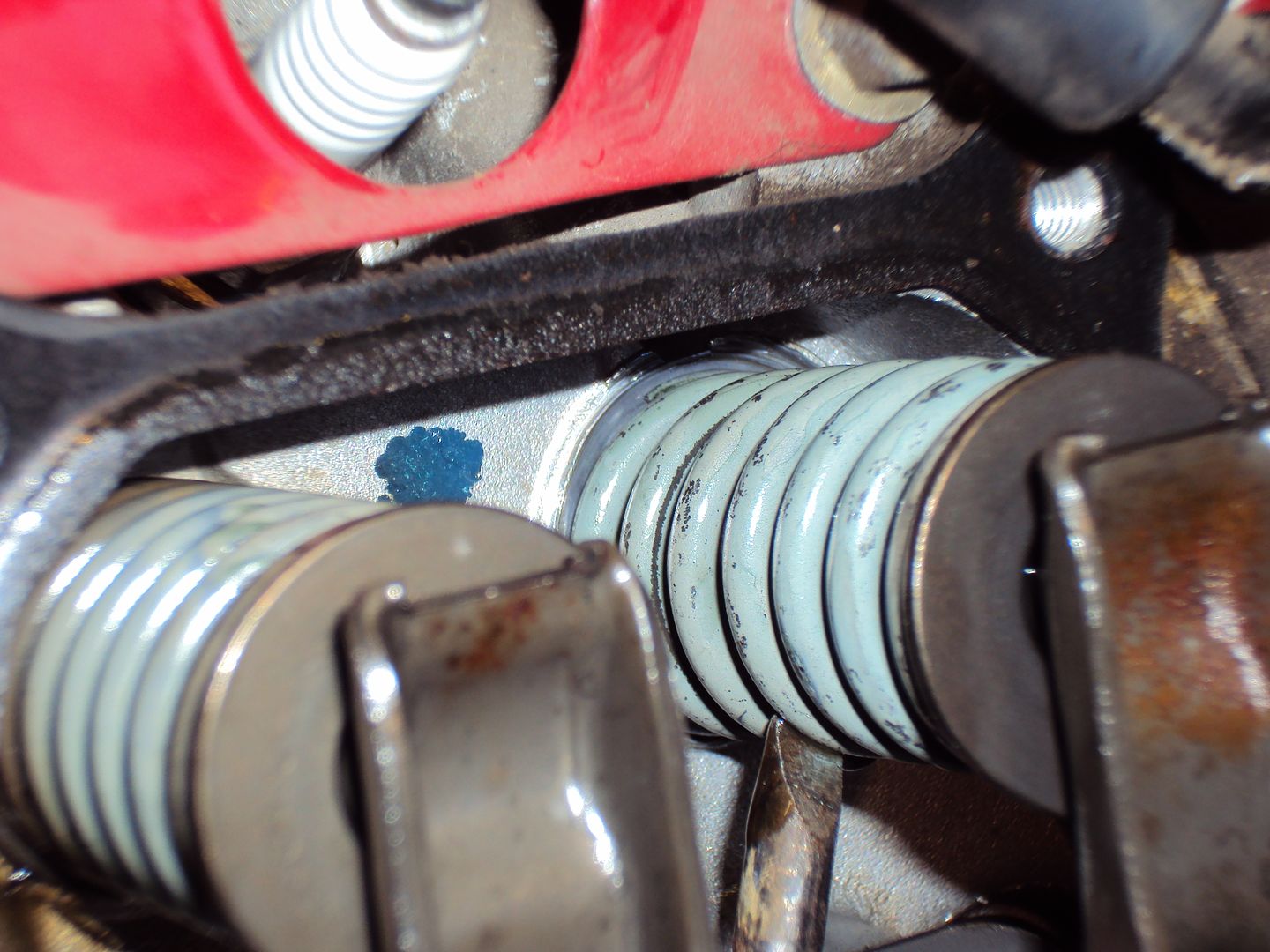

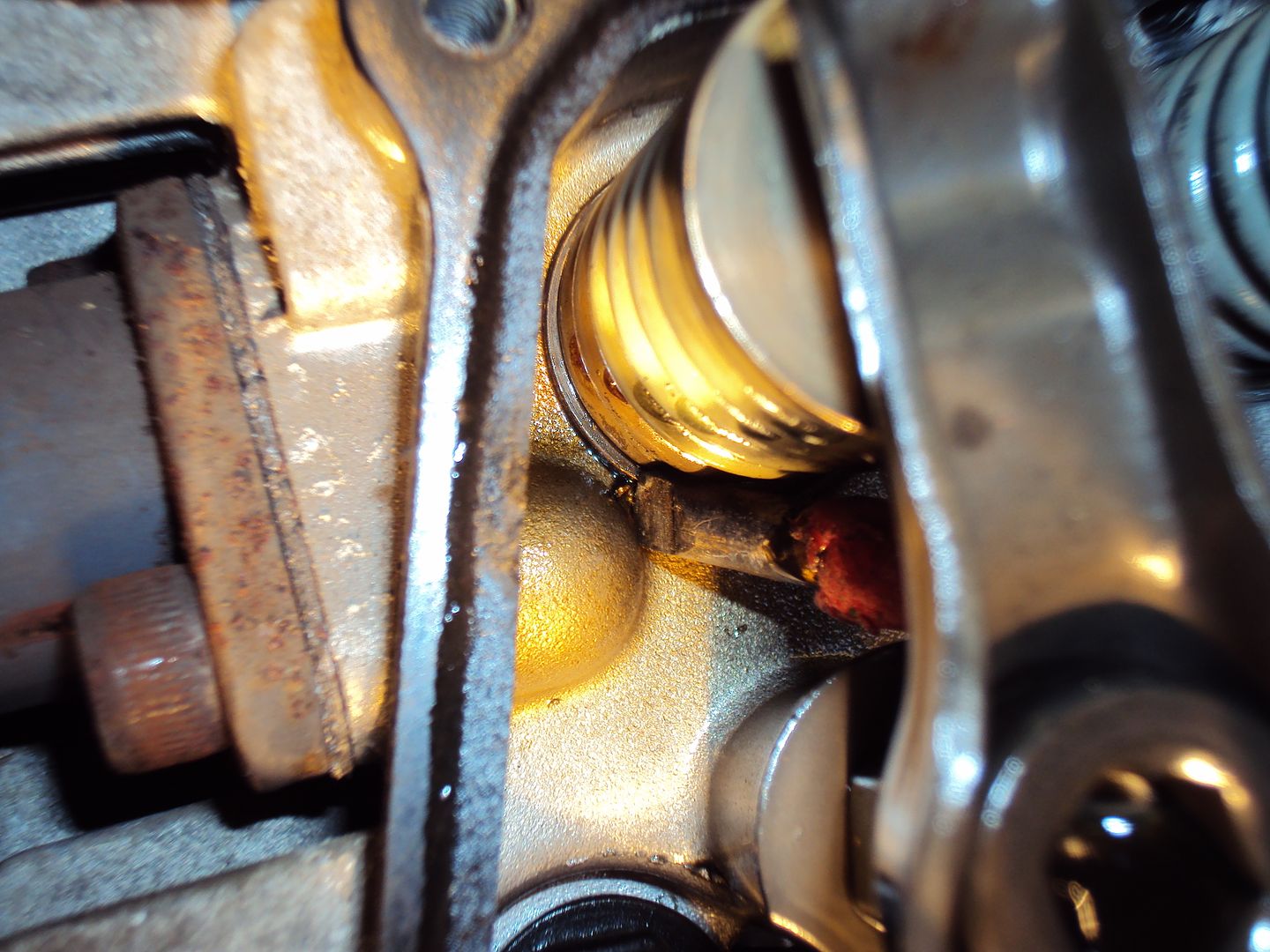

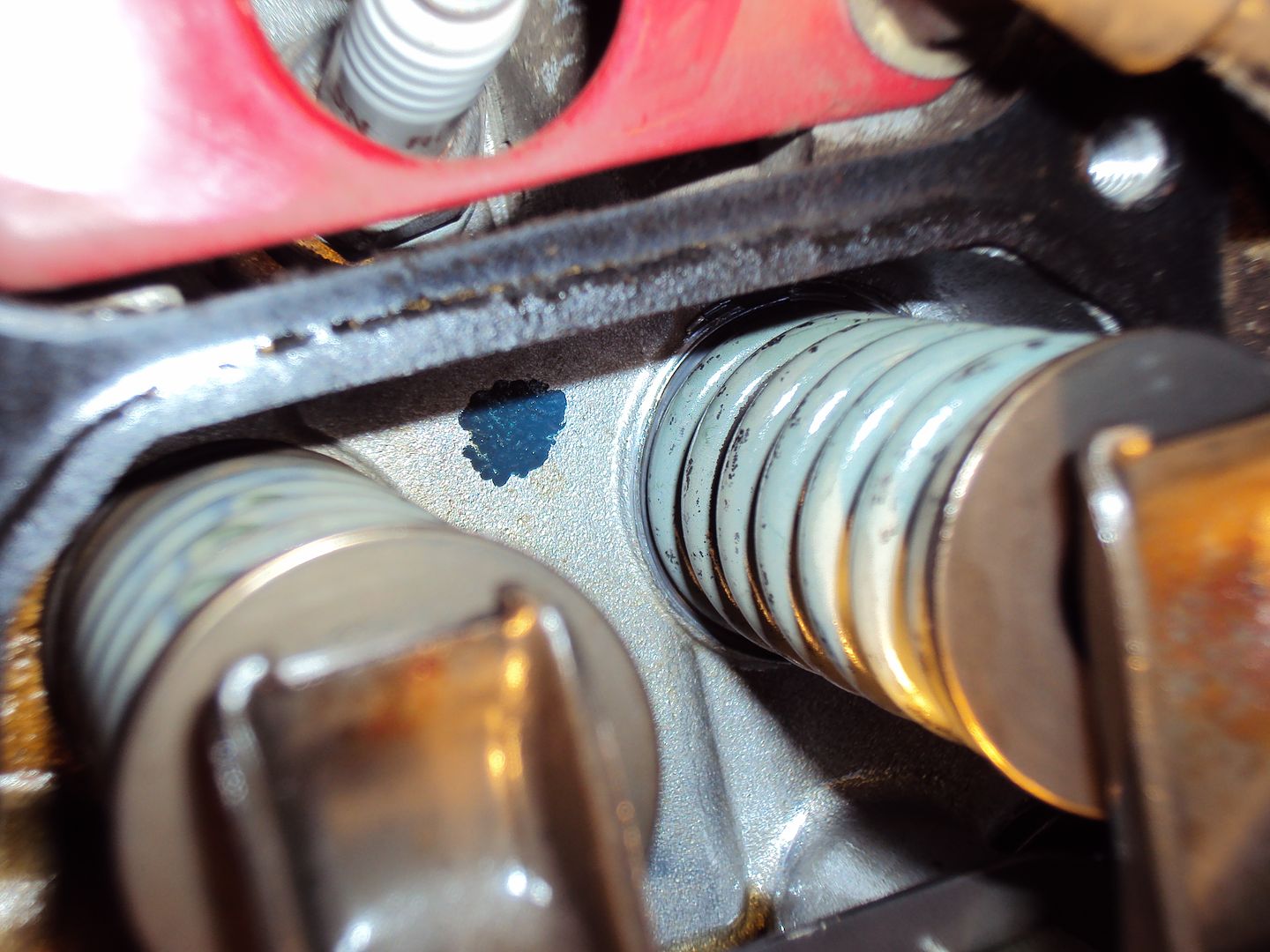

Oh and I have worked out where the mystery washer that I found in the sump came from. After looking at the engine diagram I noticed there are washers shown under the valve springs, the washers are there to stop the steel spring wearing into the aluminium head. I took the valve cover off to check

Exhaust valve, washer present under spring

Intake valve, no washer

I levered the spring to one side, there is a visible groove worn into the head

Just to confirm I compared the bit of broken washer against the valve spring

To replace the washer the cylinder head will need to be removed so the valve spring can be released. Something to look forward to next year….

I have finished building the box, sockets and meter mounted

Wiring, just need to connect it to the existing wiring in the generator panel

How it should look when completed

Oh and I have worked out where the mystery washer that I found in the sump came from. After looking at the engine diagram I noticed there are washers shown under the valve springs, the washers are there to stop the steel spring wearing into the aluminium head. I took the valve cover off to check

Exhaust valve, washer present under spring

Intake valve, no washer

I levered the spring to one side, there is a visible groove worn into the head

Just to confirm I compared the bit of broken washer against the valve spring

To replace the washer the cylinder head will need to be removed so the valve spring can be released. Something to look forward to next year….

Blue32 said:

Last update for the year

To replace the washer the cylinder head will need to be removed so the valve spring can be released. Something to look forward to next year….

Don't need to go that far. Take spark plug out, turn to BDC, find rope slightly thinner than plughole. Insert end of rope in hole until you can't get any more in, rotate to compress rope inside and up against cylinder head,. This will stop the valve from dropping when you then compress spring, remove collets, remove spring, insert washer and reassemble. To replace the washer the cylinder head will need to be removed so the valve spring can be released. Something to look forward to next year….

It worked for me on a SAAB 99 many years ago.

Amused2death said:

Blue32 said:

Last update for the year

To replace the washer the cylinder head will need to be removed so the valve spring can be released. Something to look forward to next year….

Don't need to go that far. Take spark plug out, turn to BDC, find rope slightly thinner than plughole. Insert end of rope in hole until you can't get any more in, rotate to compress rope inside and up against cylinder head,. This will stop the valve from dropping when you then compress spring, remove collets, remove spring, insert washer and reassemble. To replace the washer the cylinder head will need to be removed so the valve spring can be released. Something to look forward to next year….

It worked for me on a SAAB 99 many years ago.

Just another variation on the theme.

Amused2death said:

Don't need to go that far. Take spark plug out, turn to BDC, find rope slightly thinner than plughole. Insert end of rope in hole until you can't get any more in, rotate to compress rope inside and up against cylinder head,. This will stop the valve from dropping when you then compress spring, remove collets, remove spring, insert washer and reassemble.

It worked for me on a SAAB 99 many years ago.

Neat!

It worked for me on a SAAB 99 many years ago.

Amused2death said:

Don't need to go that far. Take spark plug out, turn to BDC, find rope slightly thinner than plughole. Insert end of rope in hole until you can't get any more in, rotate to compress rope inside and up against cylinder head,. This will stop the valve from dropping when you then compress spring, remove collets, remove spring, insert washer and reassemble.

It worked for me on a SAAB 99 many years ago.

Thanks, will give that a try. I don’t really want to strip it down if I don’t have to.

It worked for me on a SAAB 99 many years ago.

Managed to put one of my fixed generators to good use yesterday. At about 4pm the mains cable out in the street blew up. It lifted paving slabs and the fire brigade were in attendance until a repair crew turned up. The damaged cable took out the supply to 24 properties.

As the Generac is in need of a repair we used the Kippor seen on page 4 to power the house. It was running continuously from 4:30 until 10:00pm keeping the heating, fridge’s and more importantly TV & internet running.

Power was finally restored at 02:15 this morning.

I had a bit of free time today, so finished off the 16A socket modification (just had to do a final sanity check on the wiring).

Started the generator, and it worked (no load)

With 2kW heater

Just need to adjust the voltage so it’s closer to 240V

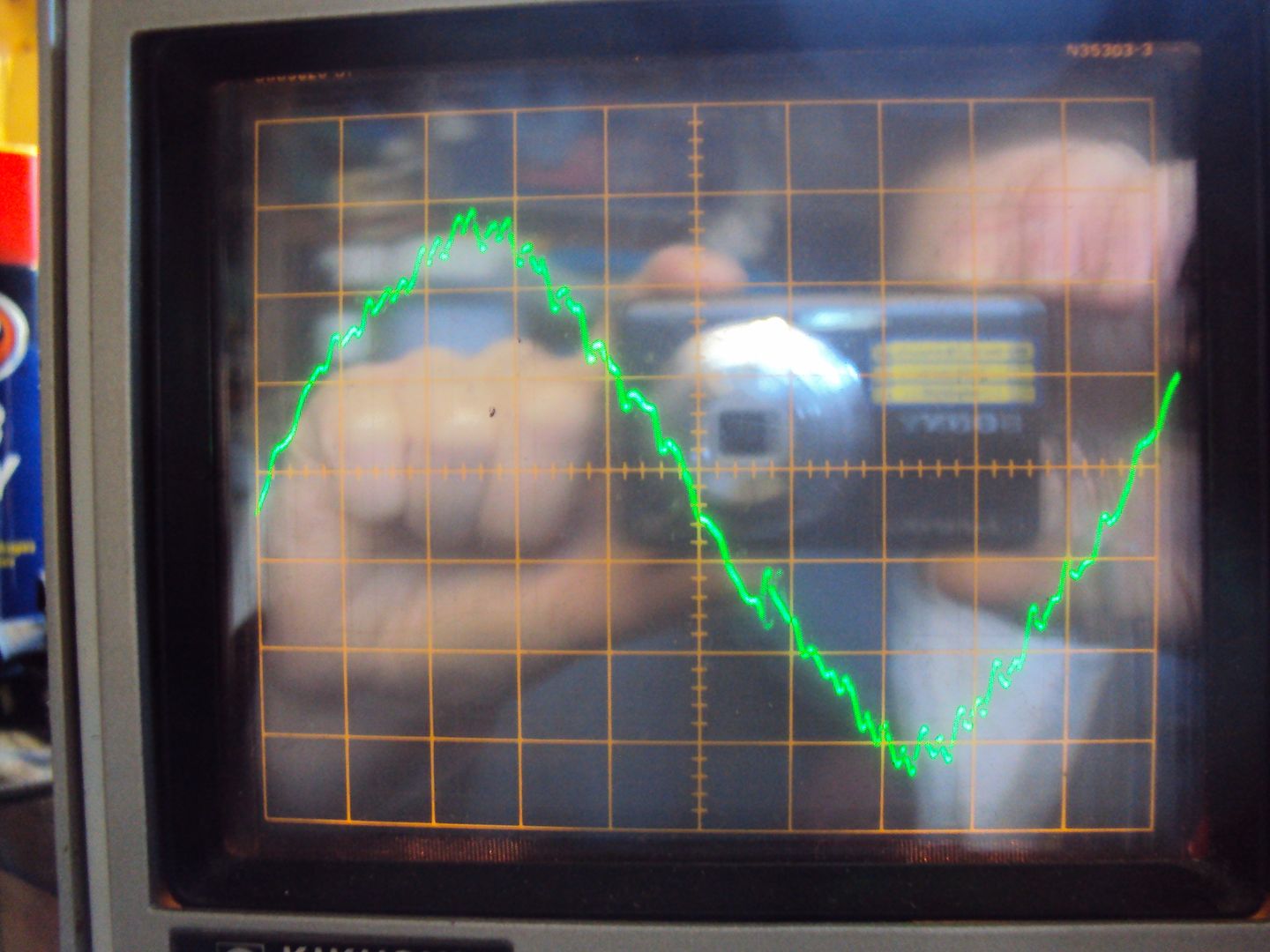

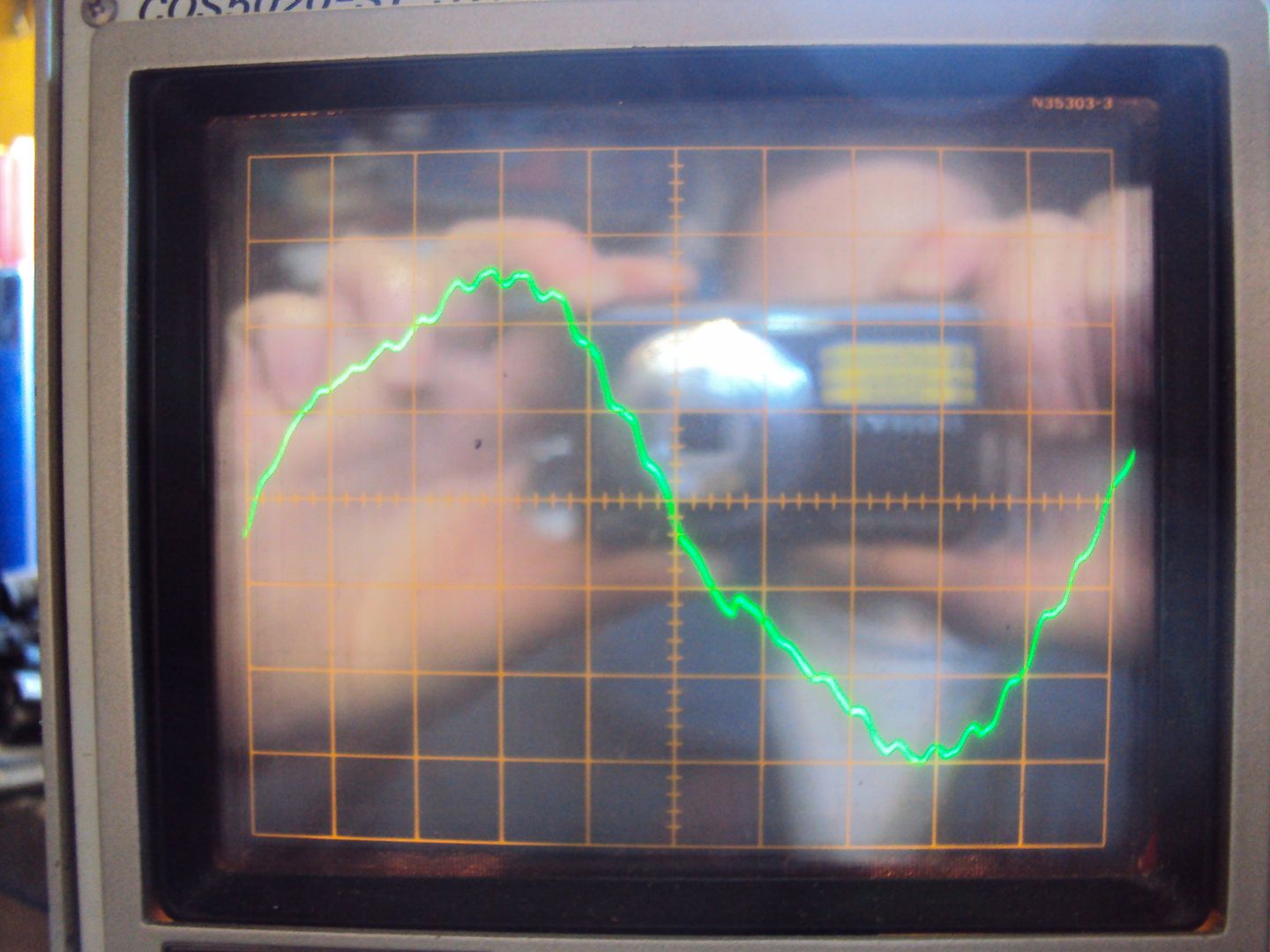

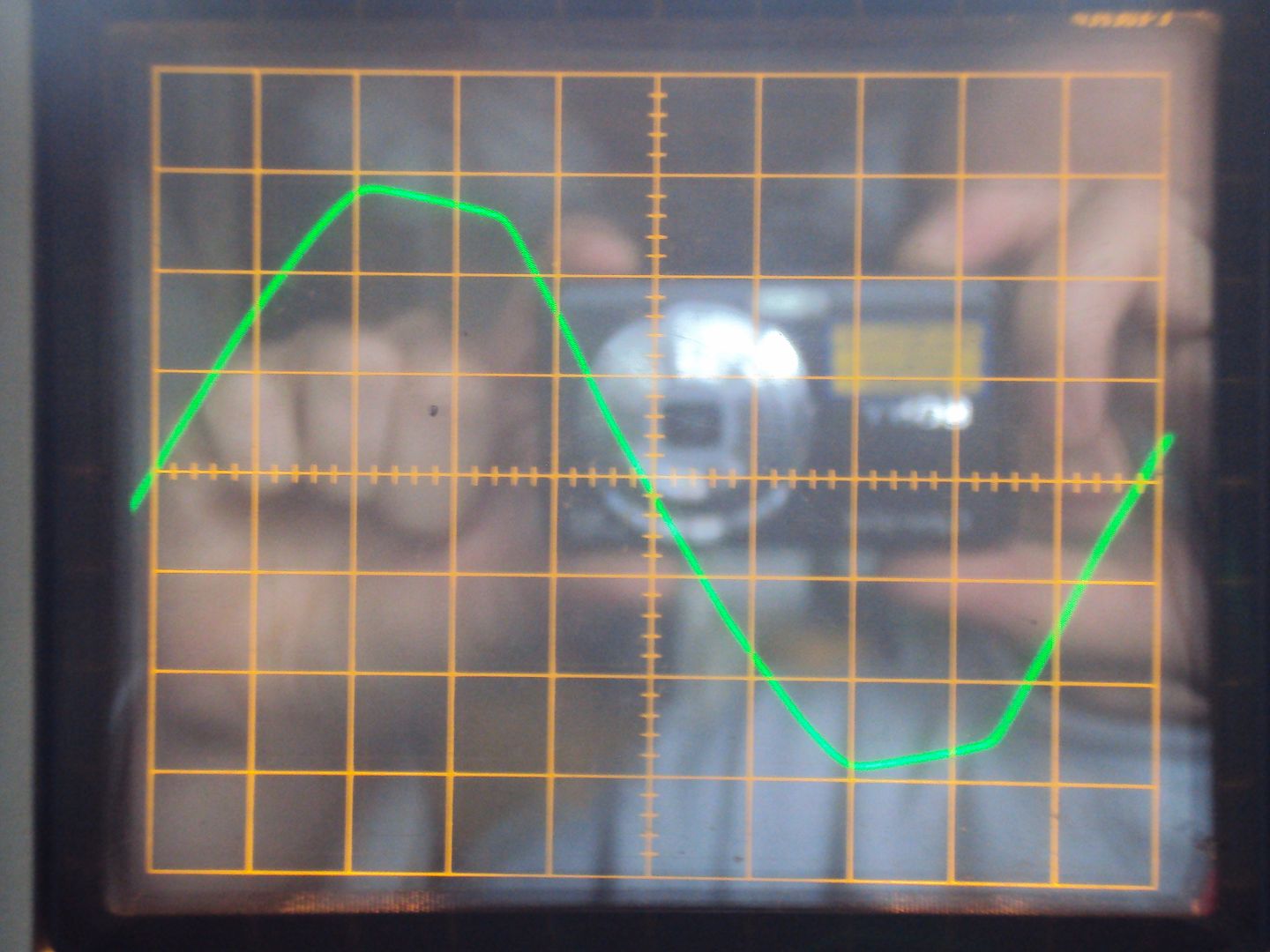

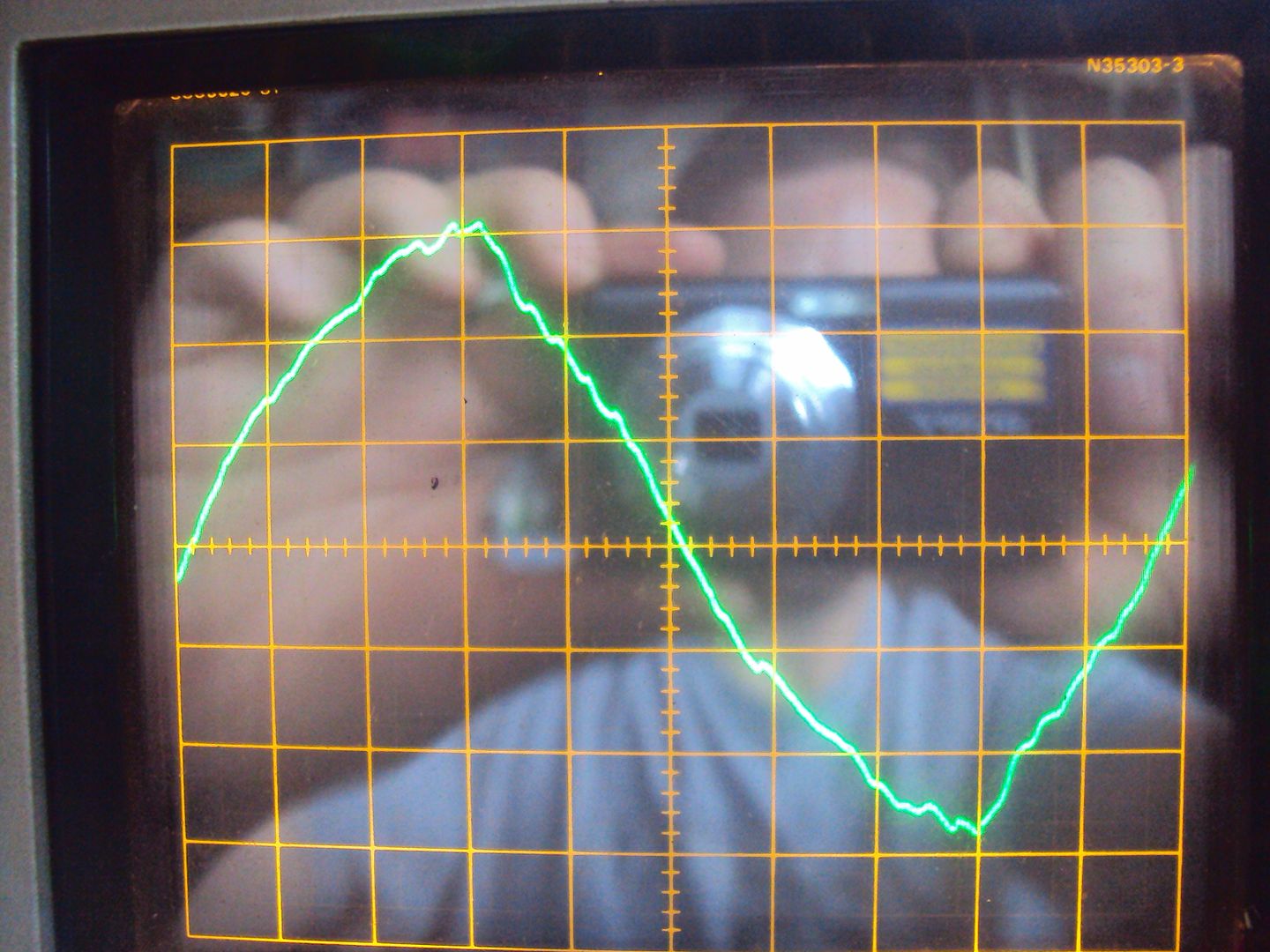

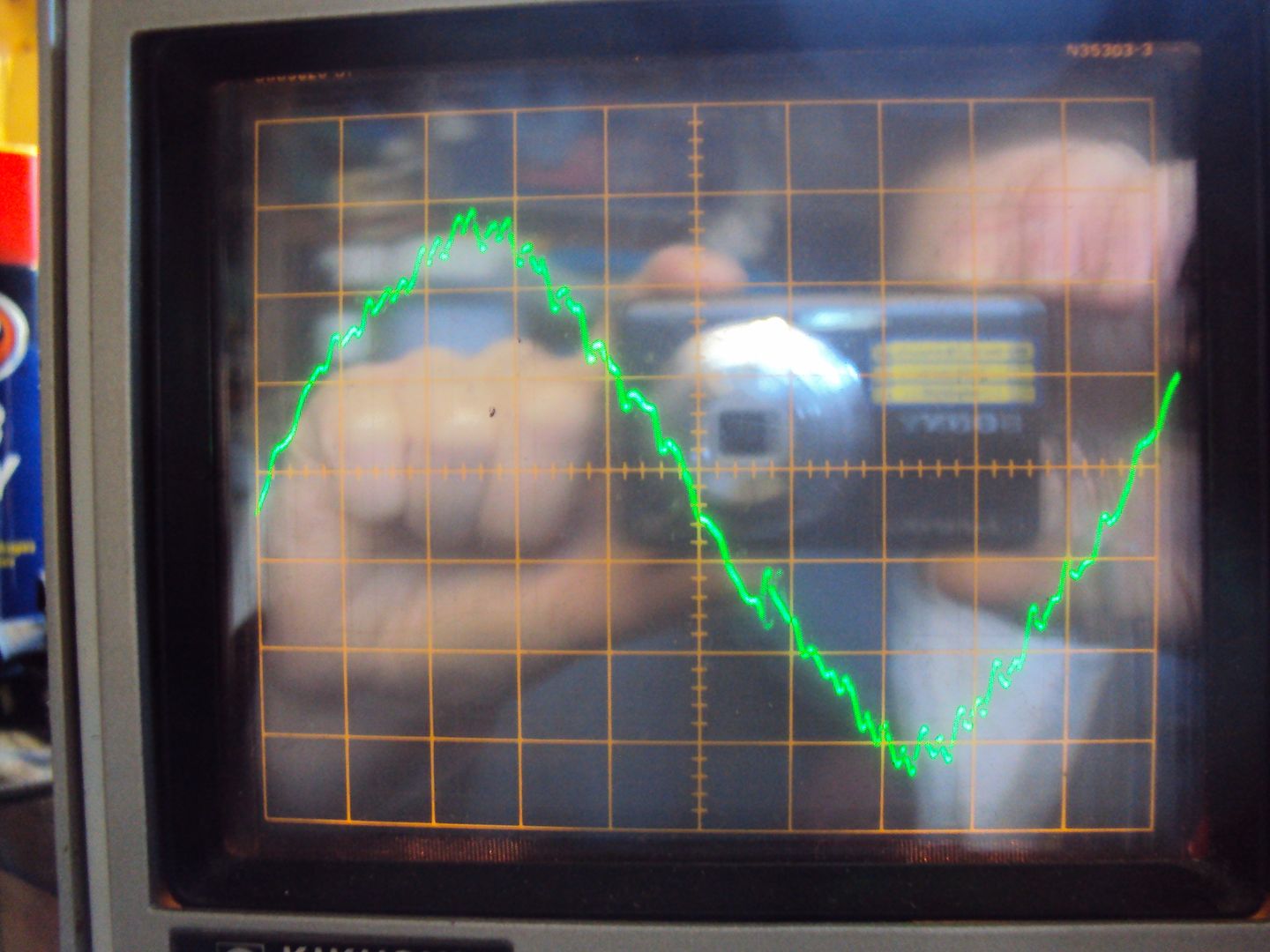

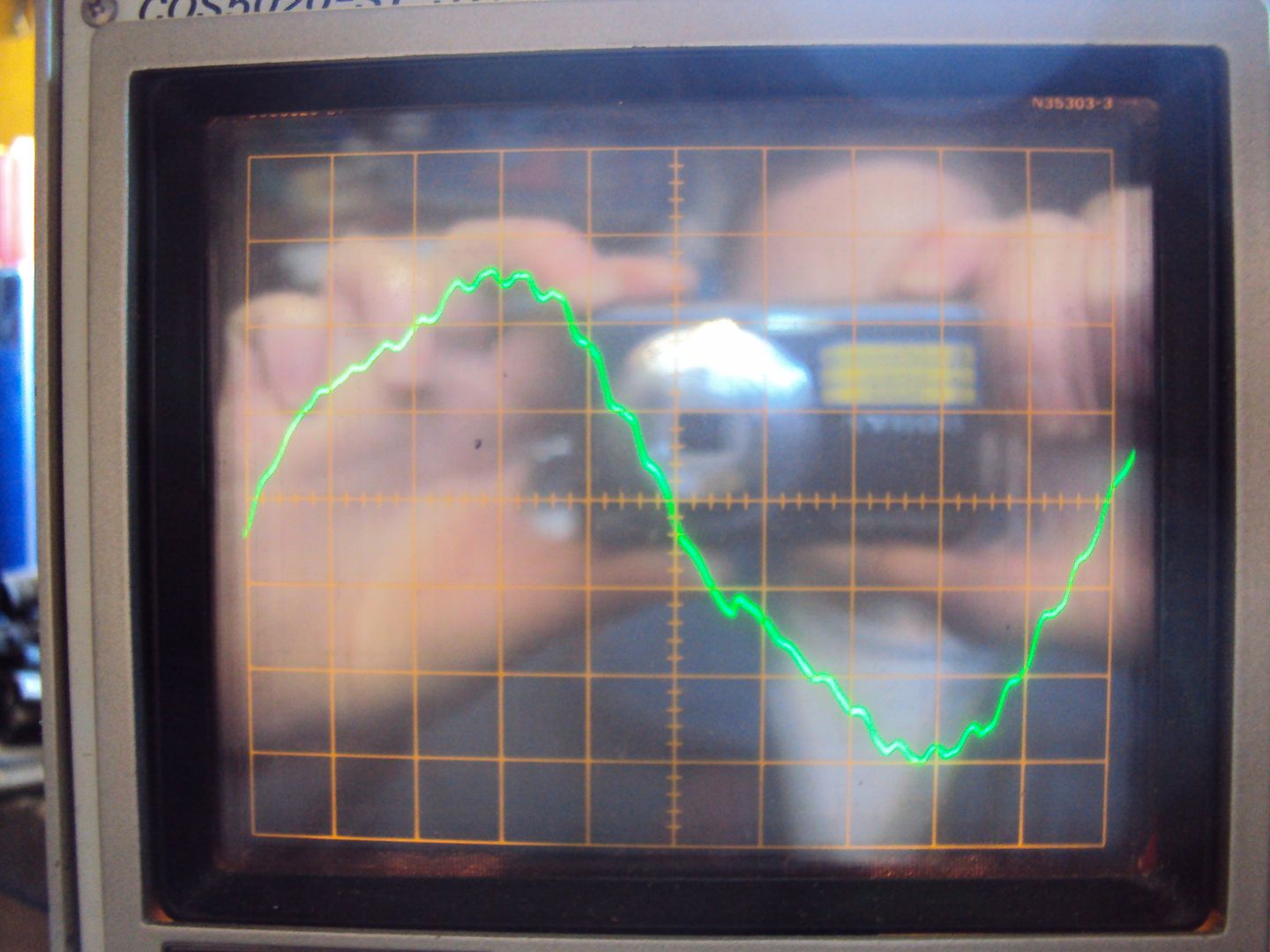

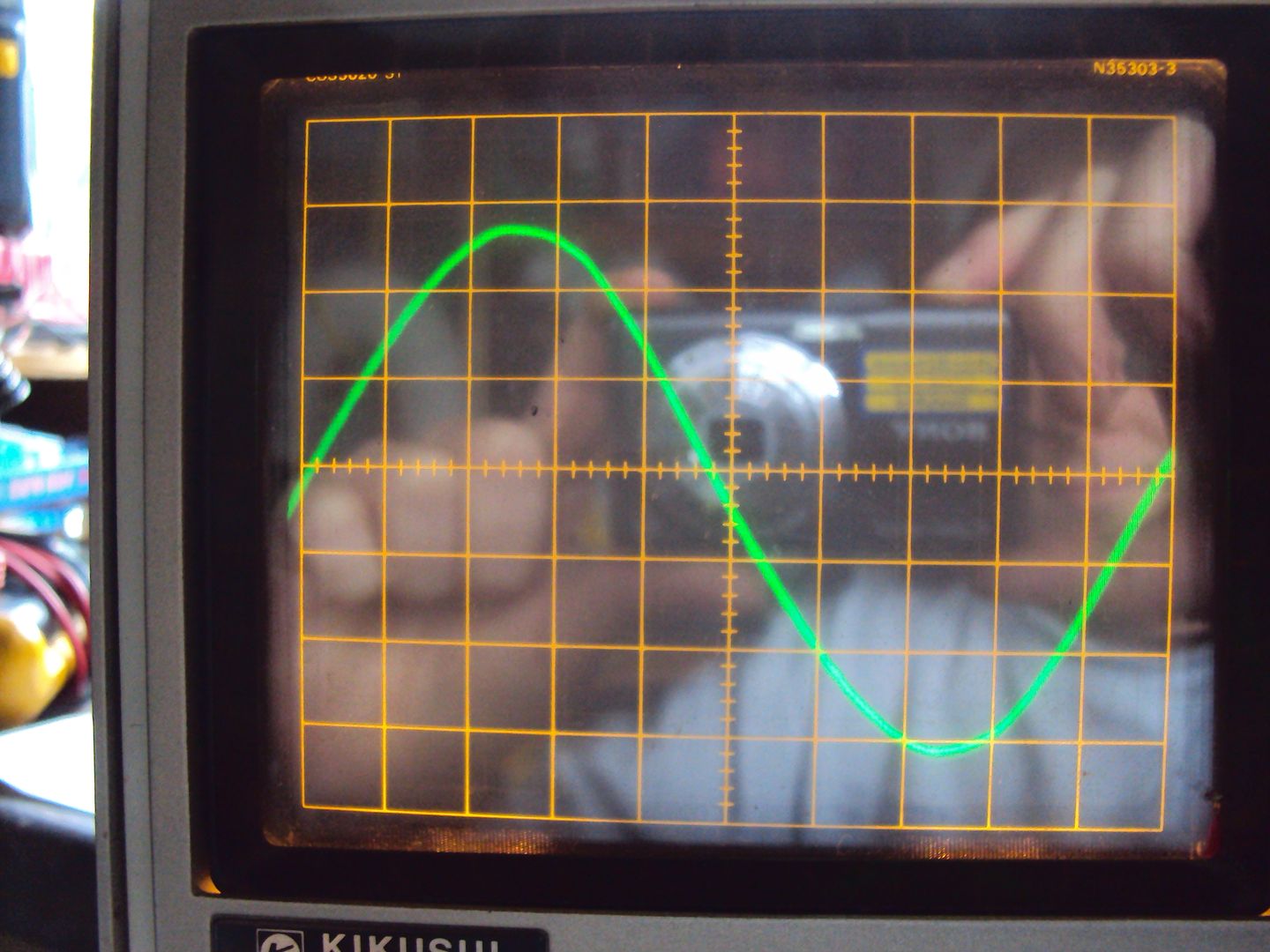

Out of curiosity I dug out the oscilloscope and hooked it up to the output via a transformer (for safety) to have a look at how clean the AC signal was.

AC signal with no load applied

With 2kW load

I was hoping it would be a bit cleaner than that. I guess the AVR/regulator is quite basic as that’s probably the worst output I have seen from a generator. Unless that is sign of another impending component failure?

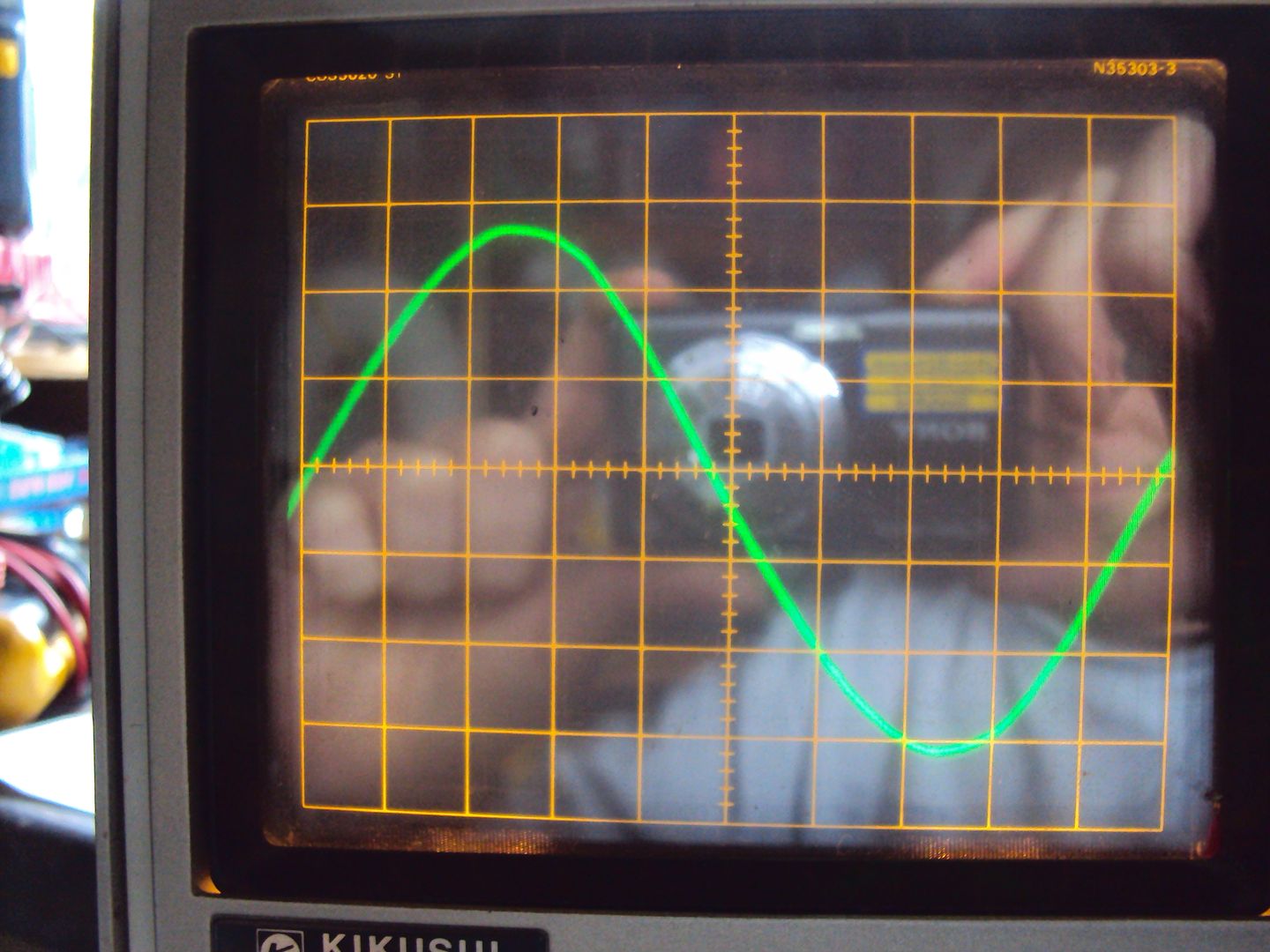

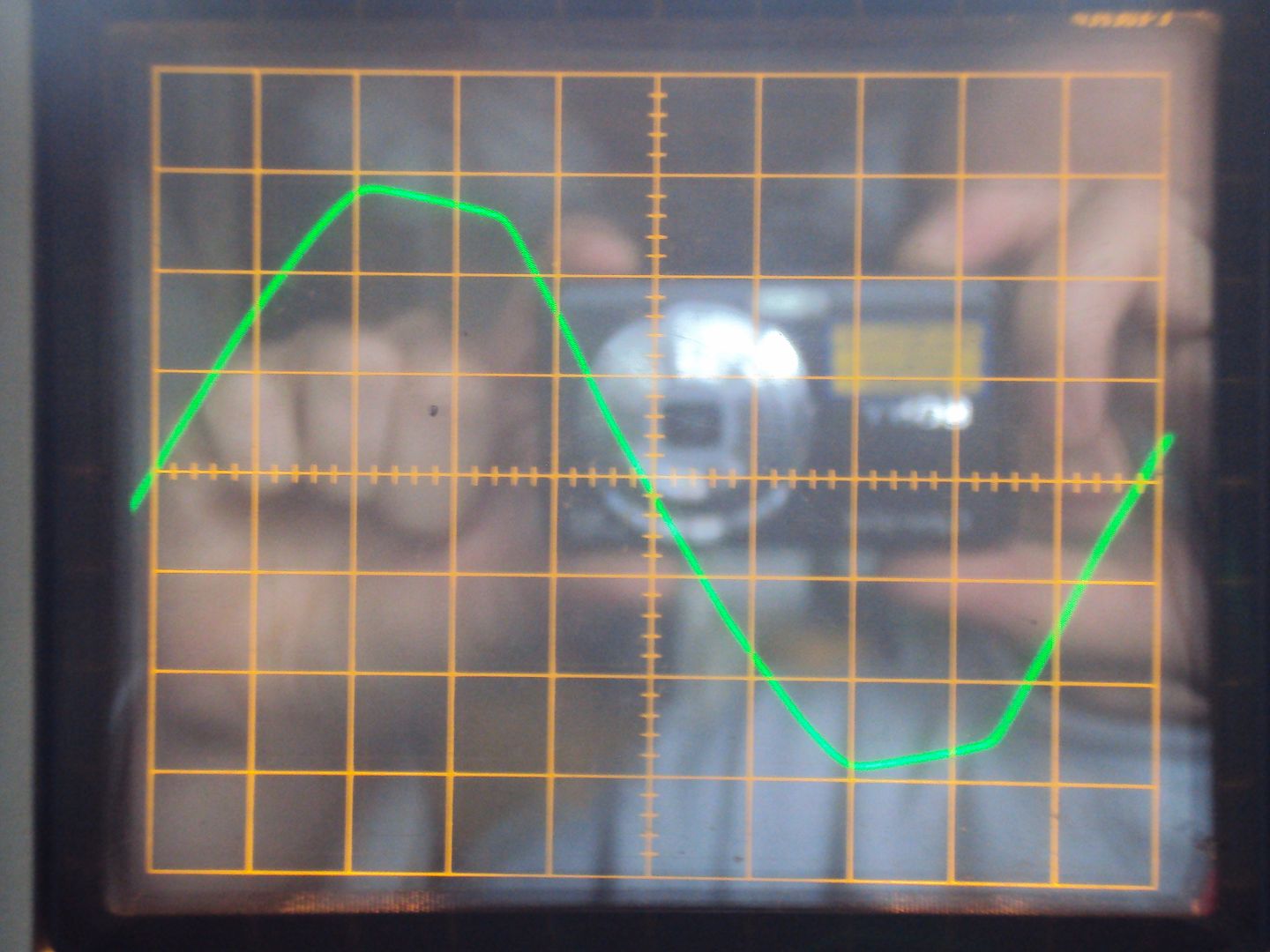

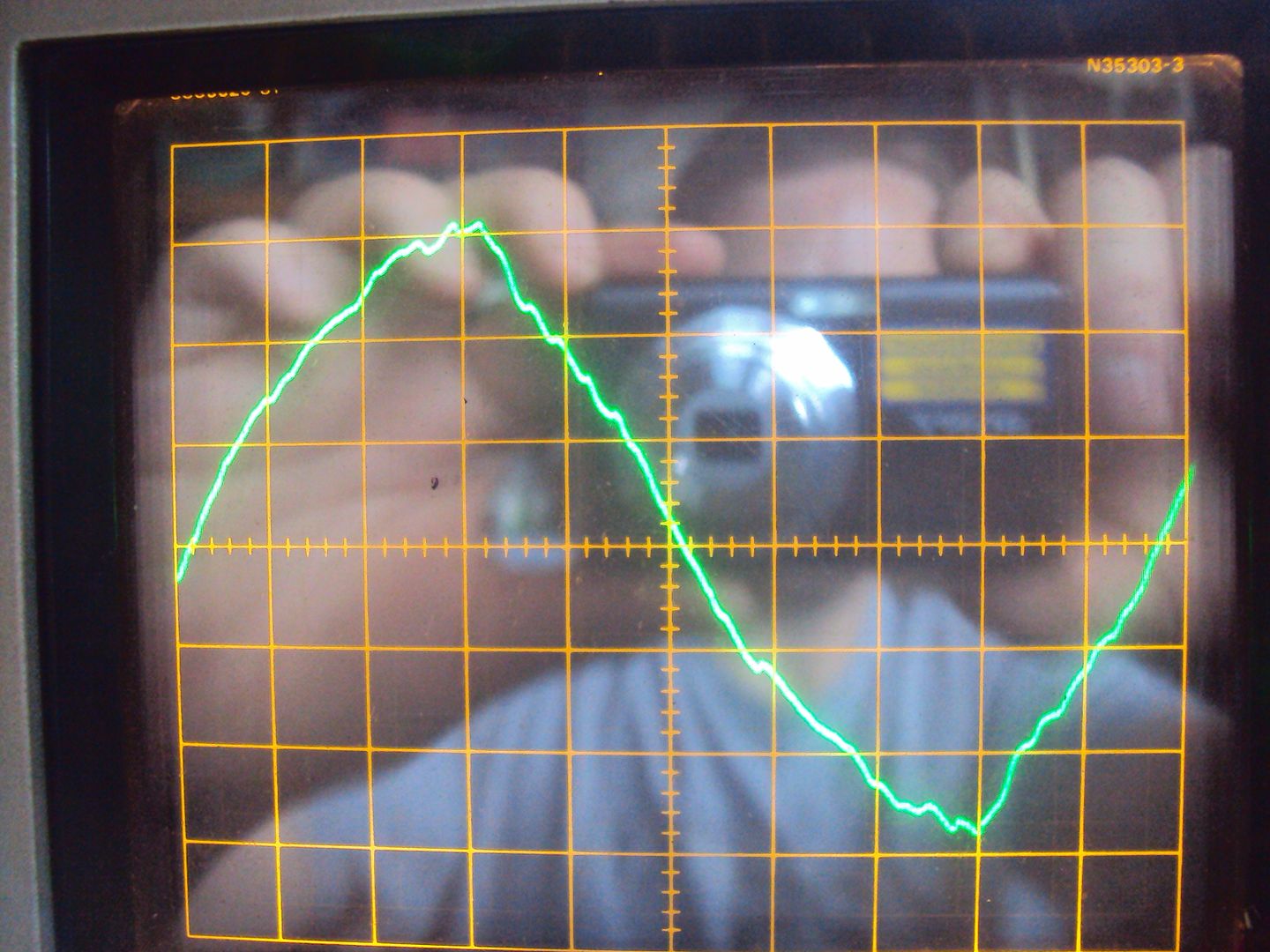

For reference this is the mains into the shed

Honda EX5500 (no load)

Kippor KGE3000Ti pure sine wave digital inverter (no load)

Still need to sort out the washer under the valve spring.

Oh, and tomorrow I’m off to pick up the next project so stay tuned

Started the generator, and it worked (no load)

With 2kW heater

Just need to adjust the voltage so it’s closer to 240V

Out of curiosity I dug out the oscilloscope and hooked it up to the output via a transformer (for safety) to have a look at how clean the AC signal was.

AC signal with no load applied

With 2kW load

I was hoping it would be a bit cleaner than that. I guess the AVR/regulator is quite basic as that’s probably the worst output I have seen from a generator. Unless that is sign of another impending component failure?

For reference this is the mains into the shed

Honda EX5500 (no load)

Kippor KGE3000Ti pure sine wave digital inverter (no load)

Still need to sort out the washer under the valve spring.

Oh, and tomorrow I’m off to pick up the next project so stay tuned

I picked up the latest project earlier, which was a Honda EMS3800, bigger brother to the EMS2800 seen previously on page 5.

It had the usual problem where it won’t start.

Started with the usual steps, checking for spark & fuel. Initially there was no spark, which was traced to low oil. Once we topped the oil up we had spark.

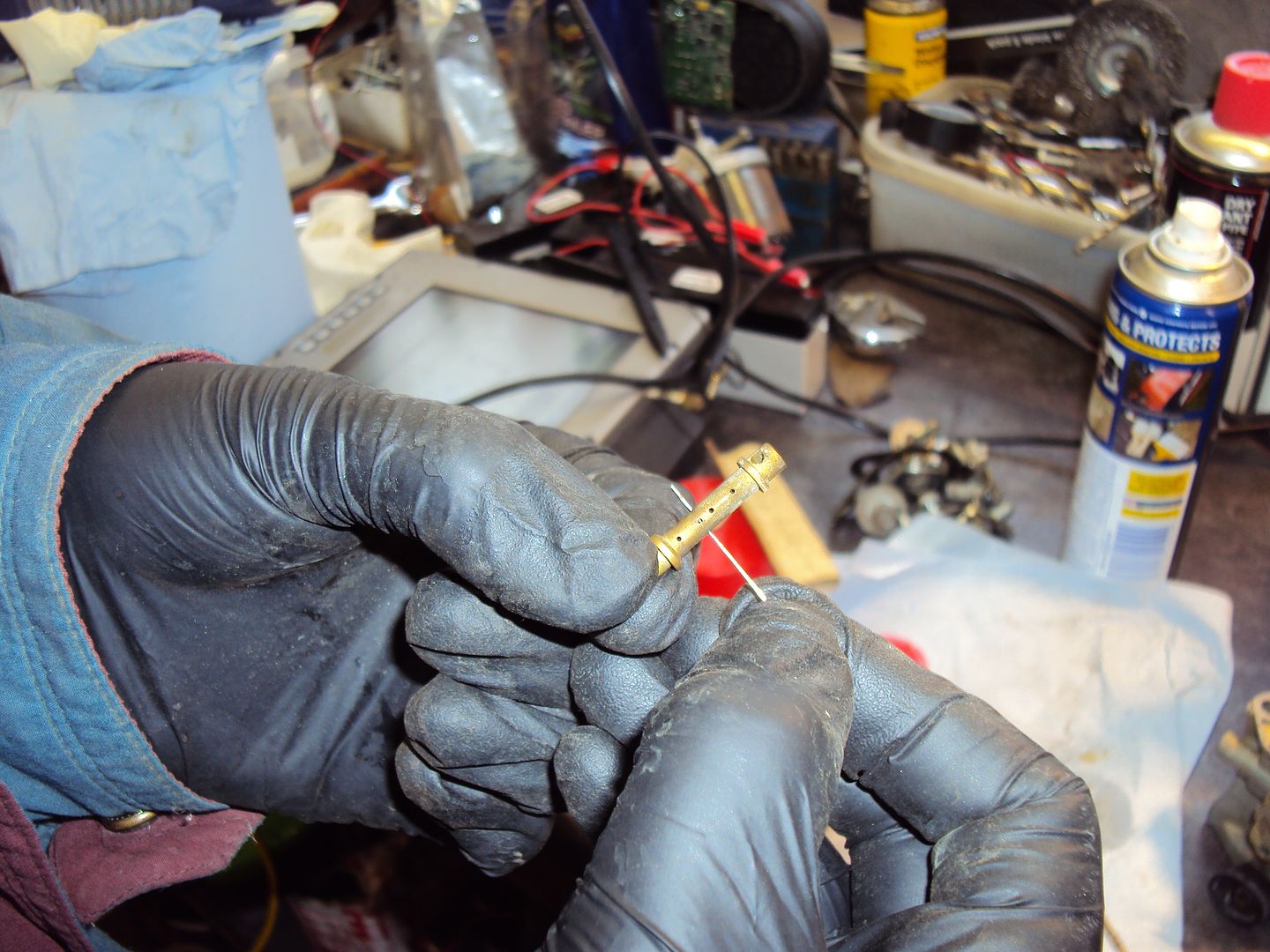

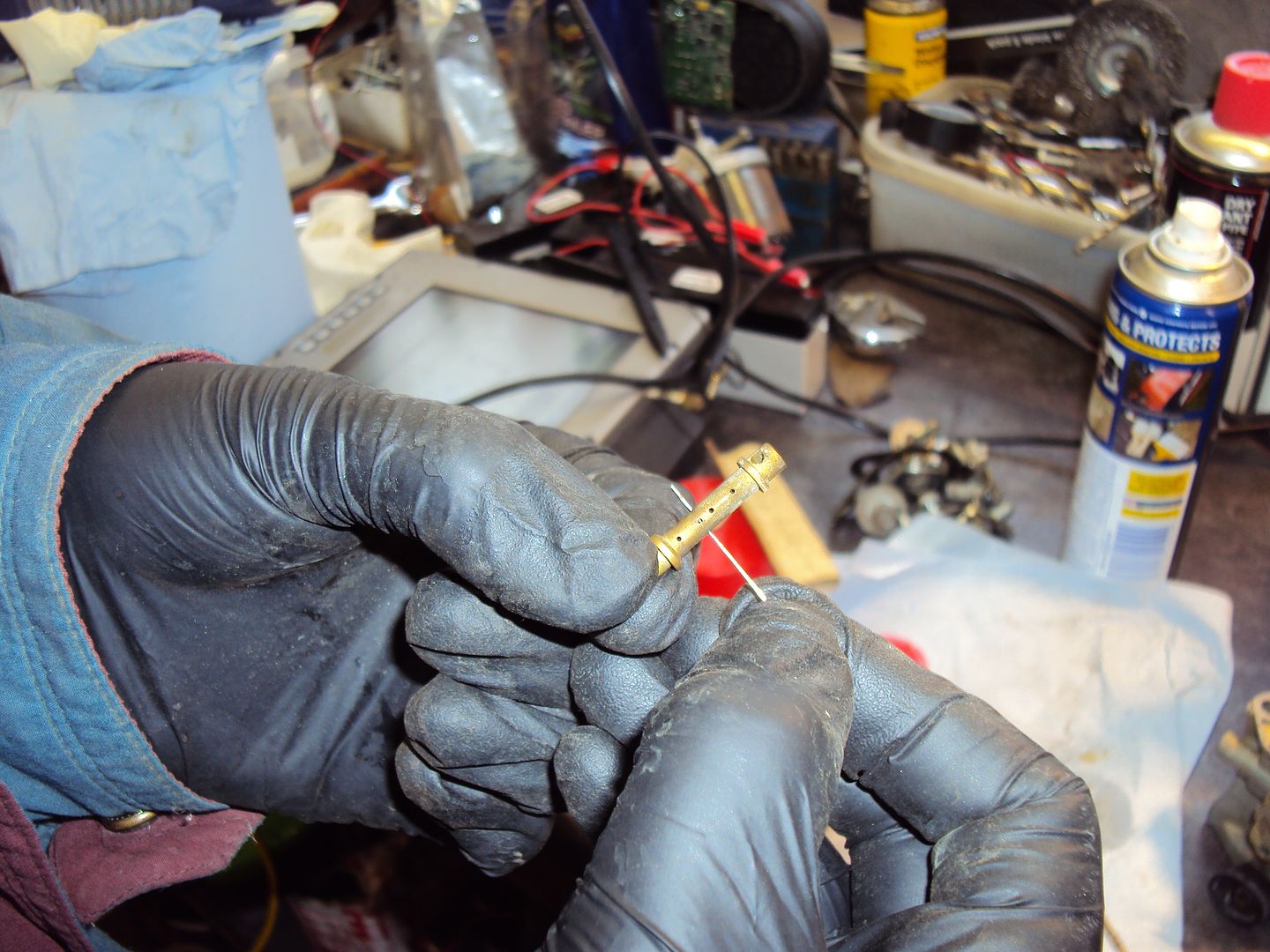

Next was fuel, we stripped the carburettor down and again found the usual problem where it was full of stale fuel and crud.

Float bowl

Main jet tube

Removing main jet

Cleaning the main jet with a pin

Once the carburettor was cleaned up and back together the engine spluttered and almost fired on the first pull, on the second pull it fired into life and settled down to a nice constant speed. It even generated power , I like Honda’s as never had a bad one yet

, I like Honda’s as never had a bad one yet

The 406cc side valve engine in this sounds a lot sweeter and smoother than the 410cc engine in the Generac.

It all starts getting a bit dae ja vue at this point, as this generator also has the electric start which like the 2800 on page 5 wasn’t connected.

I tried hooking up the starter to a battery, but it didn’t work, the motor ran for about a second and gave up. It couldn’t be the same thing again could it?

More to follow (it was too cold In the shed to do any more today)

It had the usual problem where it won’t start.

Started with the usual steps, checking for spark & fuel. Initially there was no spark, which was traced to low oil. Once we topped the oil up we had spark.

Next was fuel, we stripped the carburettor down and again found the usual problem where it was full of stale fuel and crud.

Float bowl

Main jet tube

Removing main jet

Cleaning the main jet with a pin

Once the carburettor was cleaned up and back together the engine spluttered and almost fired on the first pull, on the second pull it fired into life and settled down to a nice constant speed. It even generated power

, I like Honda’s as never had a bad one yet

, I like Honda’s as never had a bad one yet

The 406cc side valve engine in this sounds a lot sweeter and smoother than the 410cc engine in the Generac.

It all starts getting a bit dae ja vue at this point, as this generator also has the electric start which like the 2800 on page 5 wasn’t connected.

I tried hooking up the starter to a battery, but it didn’t work, the motor ran for about a second and gave up. It couldn’t be the same thing again could it?

More to follow (it was too cold In the shed to do any more today)

netherfield said:

Do you ever get rid of any, or have you just got a shed full off generators

The shed is getting a bit full, current stock:

Kippor IG3000, keeping this one as it cost me more to fix than it would sell for.

Dometic/Honda 2.5kvA, this will be on ebay in the spring as it’s for motor homes/horse boxes so might be more popular.

Generac 7500, undecided was thinking of keeping but might still re-sell.

Honda 3800, fix, clean up and sell.

Just waiting for the DailyWail to print another story about running out of electricity and wait for the panic buying of generators to begin

Brother D said:

Loving this thread!

(Small question... How's does low oil prevent spark)?

There is a float switch in the sump which kills the ignition if the oil is too low to prevent engine damage. (Small question... How's does low oil prevent spark)?

These small engines rely on “splash” lubrication where the action of the crank hitting the oil splashes the oil over the inside of the engine. If the level is too low the oil doesn’t get splashed so things start to get damaged.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff