The ebay generator restoration thread

Discussion

tamore said:

hi there Blue, i'm in there market for a suitcase genny before mid april. if you get hold of a faulty one and breathe new life into it, i'd be interested.

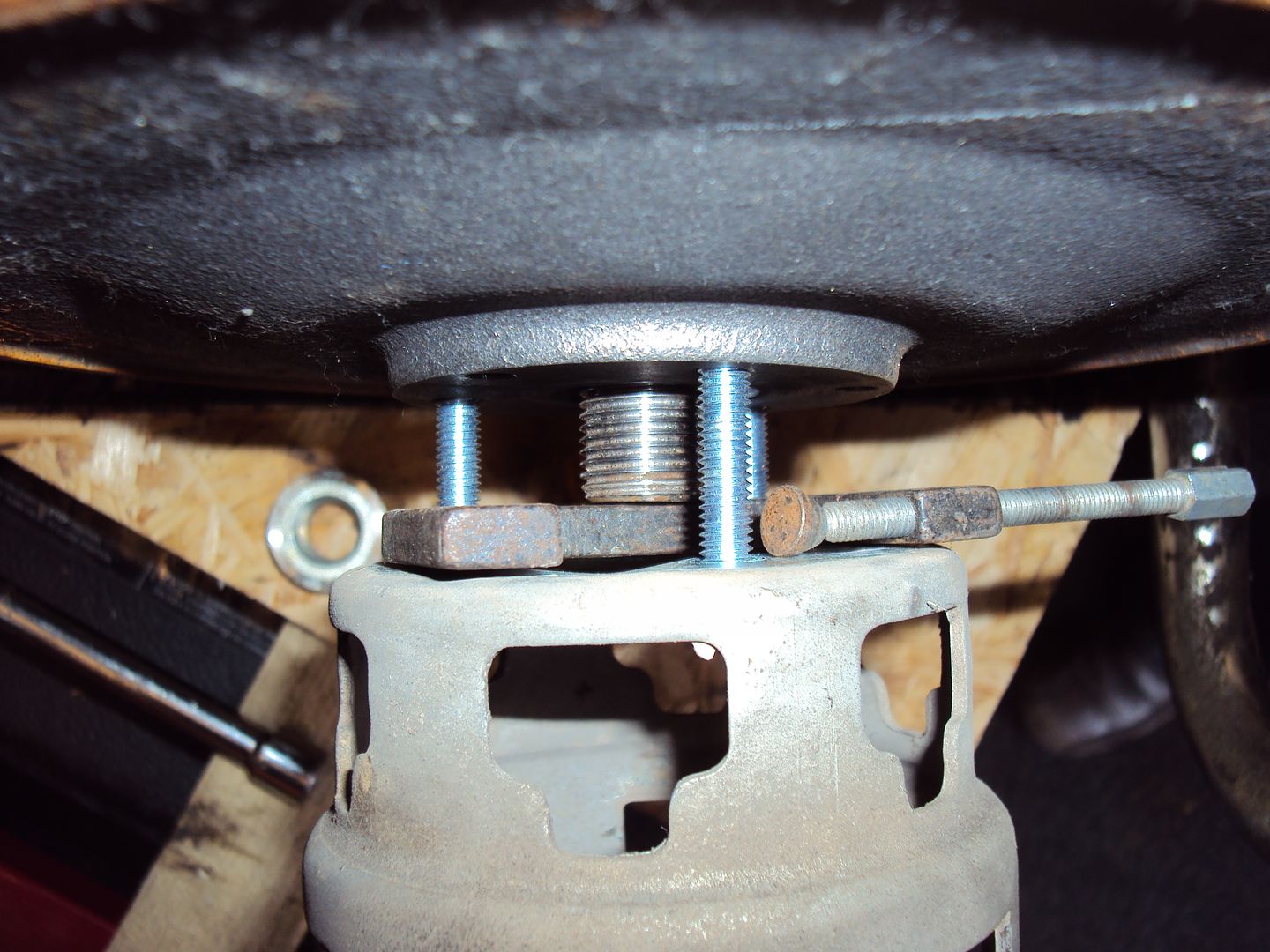

I'll keep an eye out for one.Starter motor fixed today, I had to improvise a hub puller to remove the flywheel to get access to the starter motor bolts.

I just used some longer bolts on the dog cup (pull starts engages into the dog cup) and a small g clamp to apply tension on the shaft.

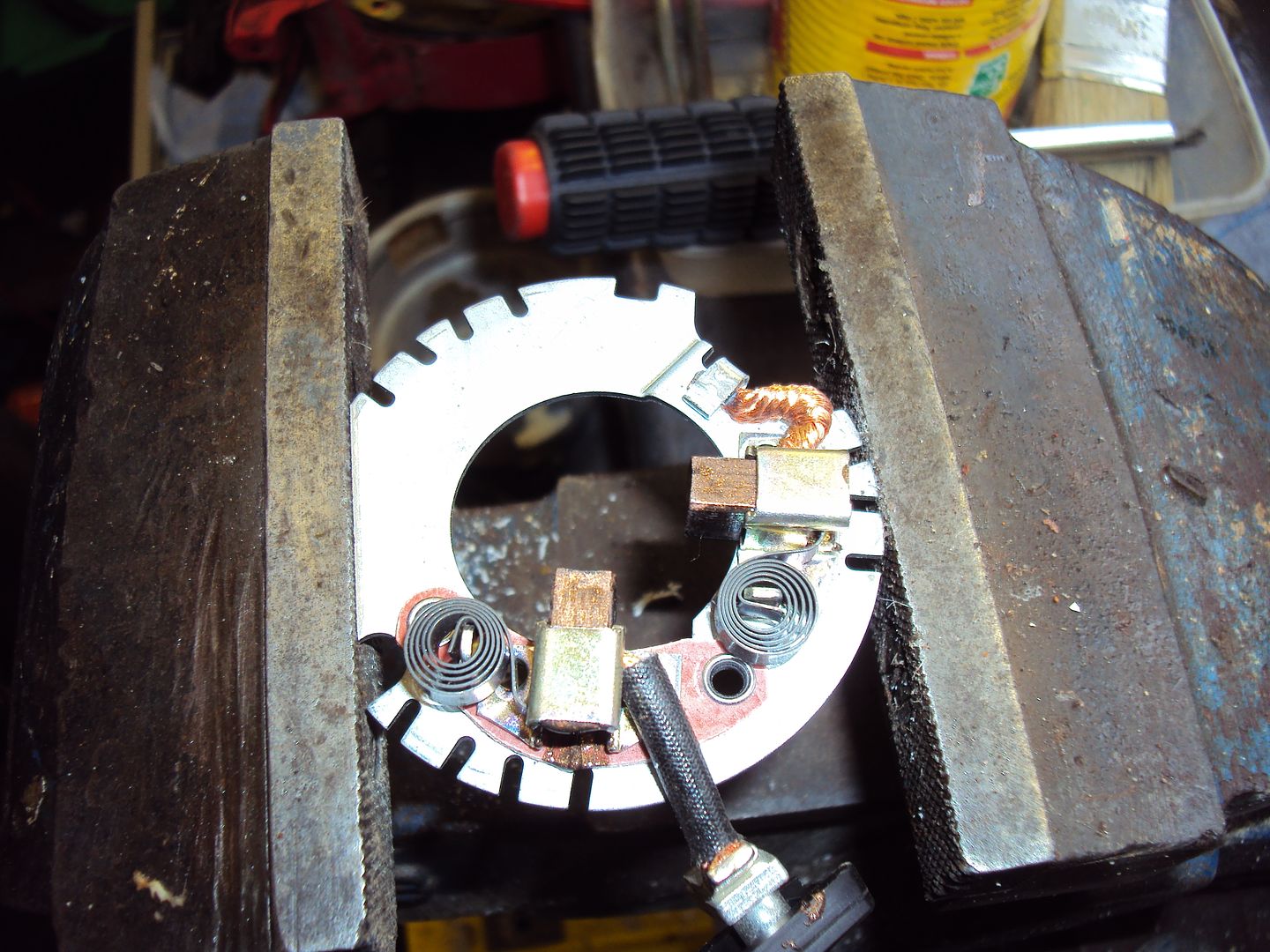

The starter motor had the same problem as before, where the brushes were stuck

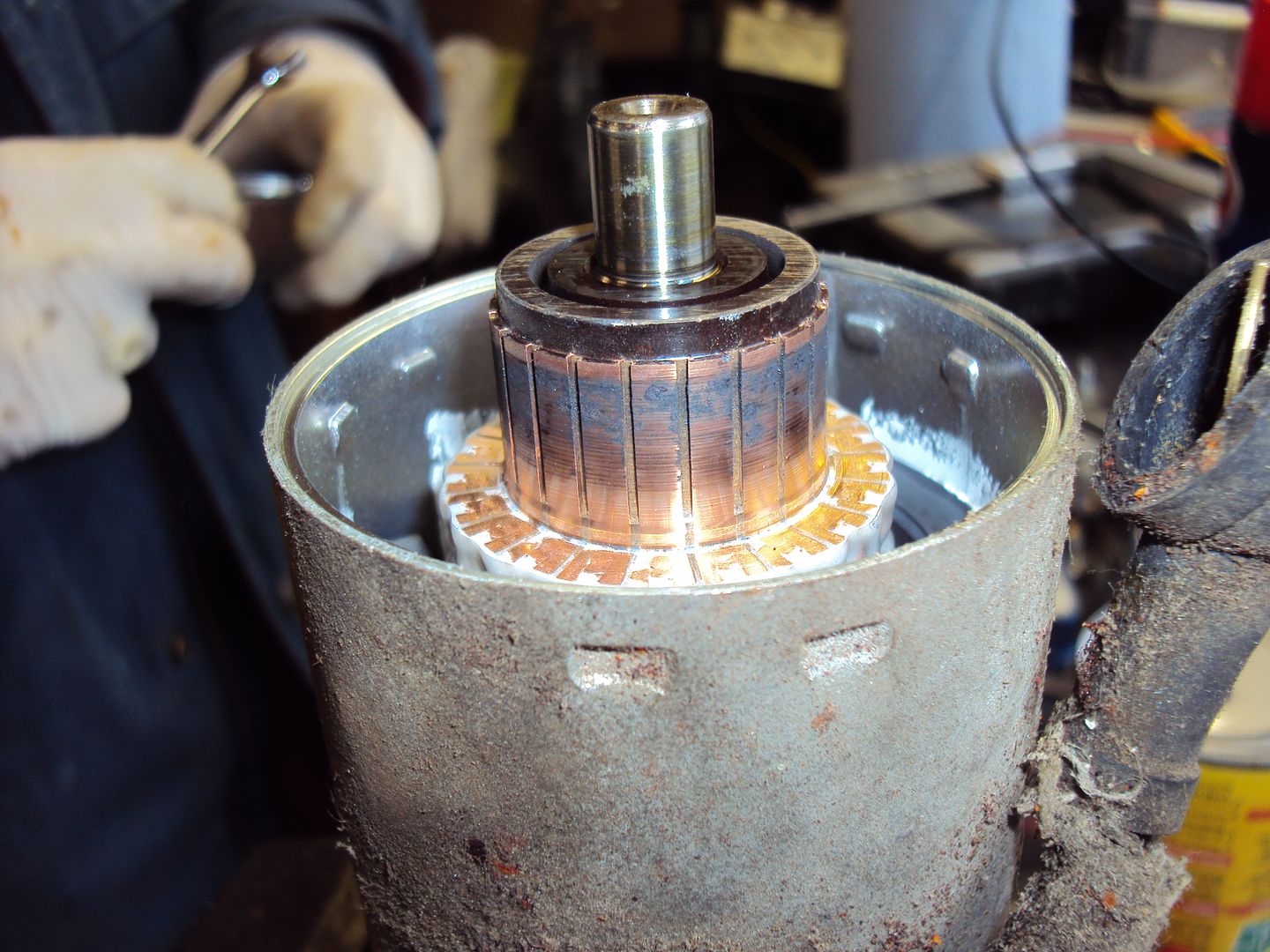

As before the commutator was in good condition.

Brushes freed up with copper grease.

After a near miss involving petrol leaking all over electrical connections I though it would be a good idea to invest in a fire extinguisher. Every workshop/shed should have one.

I also made a start on cleaning the all the covers to make it look a bit more presentable.

Before

After

Happy Jim said:

Smiler. said:

Sorry to appear pedantic, but I think you need to earth those fixing bolts on the sockets.

Great work otherwise though.

Genuine question, Why? They only clamp 2 bits of plastic together?Great work otherwise though.

Jim

hidetheelephants said:

Happy Jim said:

Smiler. said:

Sorry to appear pedantic, but I think you need to earth those fixing bolts on the sockets.

Great work otherwise though.

Genuine question, Why? They only clamp 2 bits of plastic together?Great work otherwise though.

Jim

A manufacturer would have to provide adequate earth connections to comply with the LV Directive.

hidetheelephants said:

TBH it would be easier to put bits of heatshrink on the bolts.

Yep, that's an option but would need to make the set-screws at least 25mm long & use tape over the ends or a cable tie. Heat-shrink has a habit of falling off & with the movement of the unit/vibration.I got so cheesed-off with having to deal with all these little niggles when using insulated enclosures, I designed my own metal ones with detachable gland/accessory plates. Everything is earthed by default.

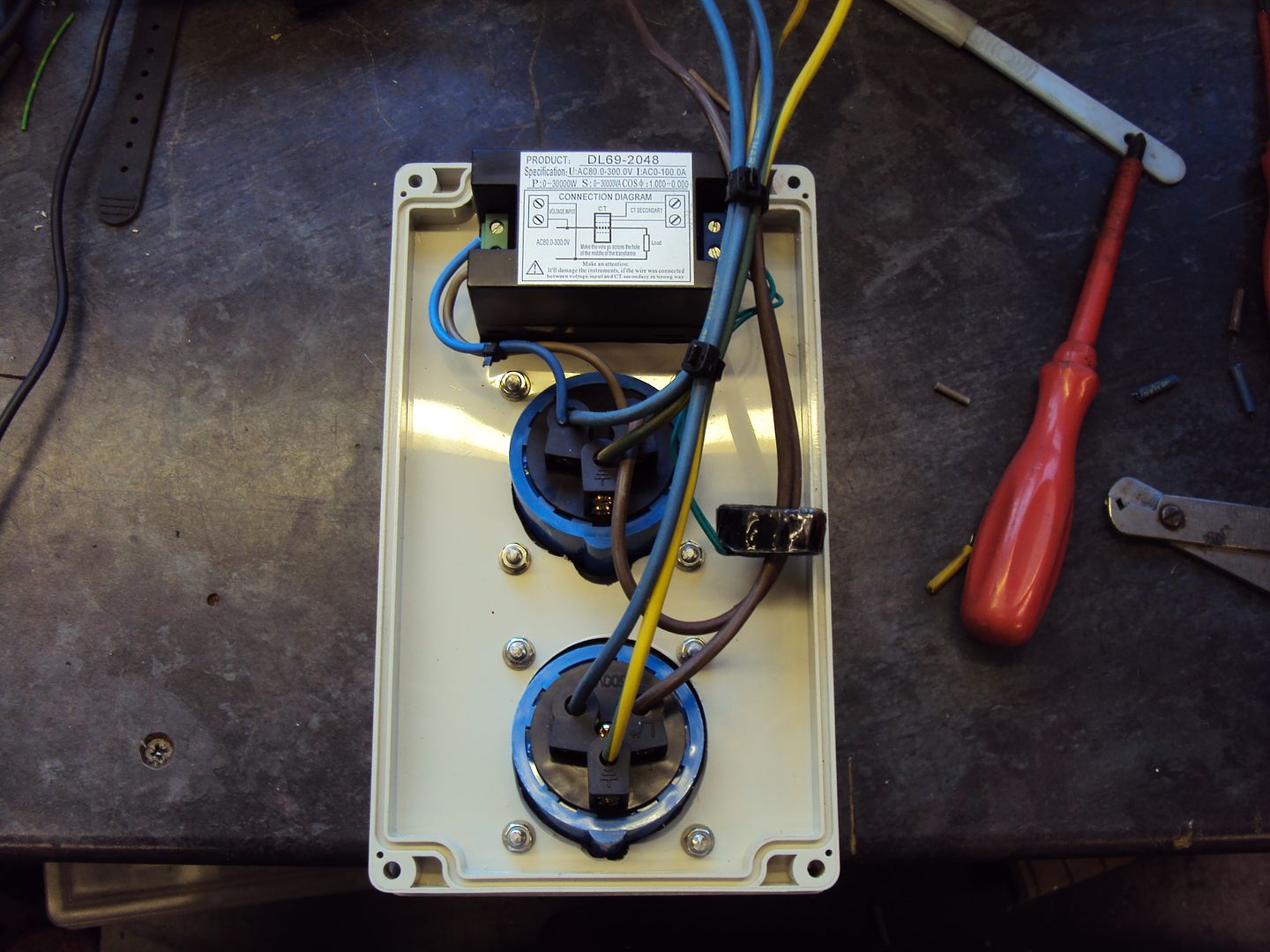

Regarding the earthing of screws, I had considered it when making the box. I’m thinking of adding a aluminium plate to the inside to take care of the earthing of the screws

Picked up another one today, it was from the same person I got the last Honda from. They had sold it, but the buyer never contacted them to pick it up or pay so they offered it to me.

It was quite dusty

This one doesn’t look to have had much use as the oil was still clean.

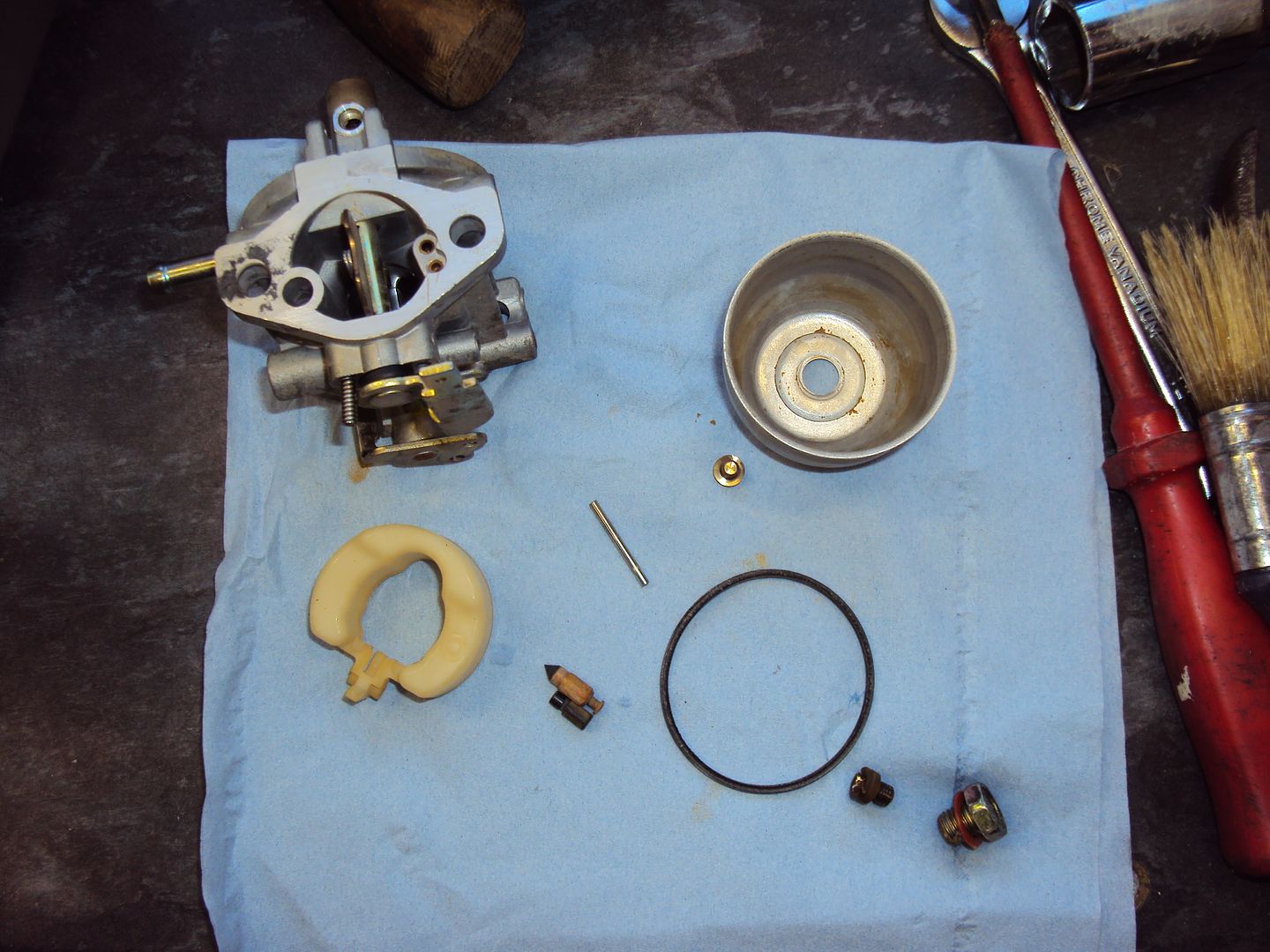

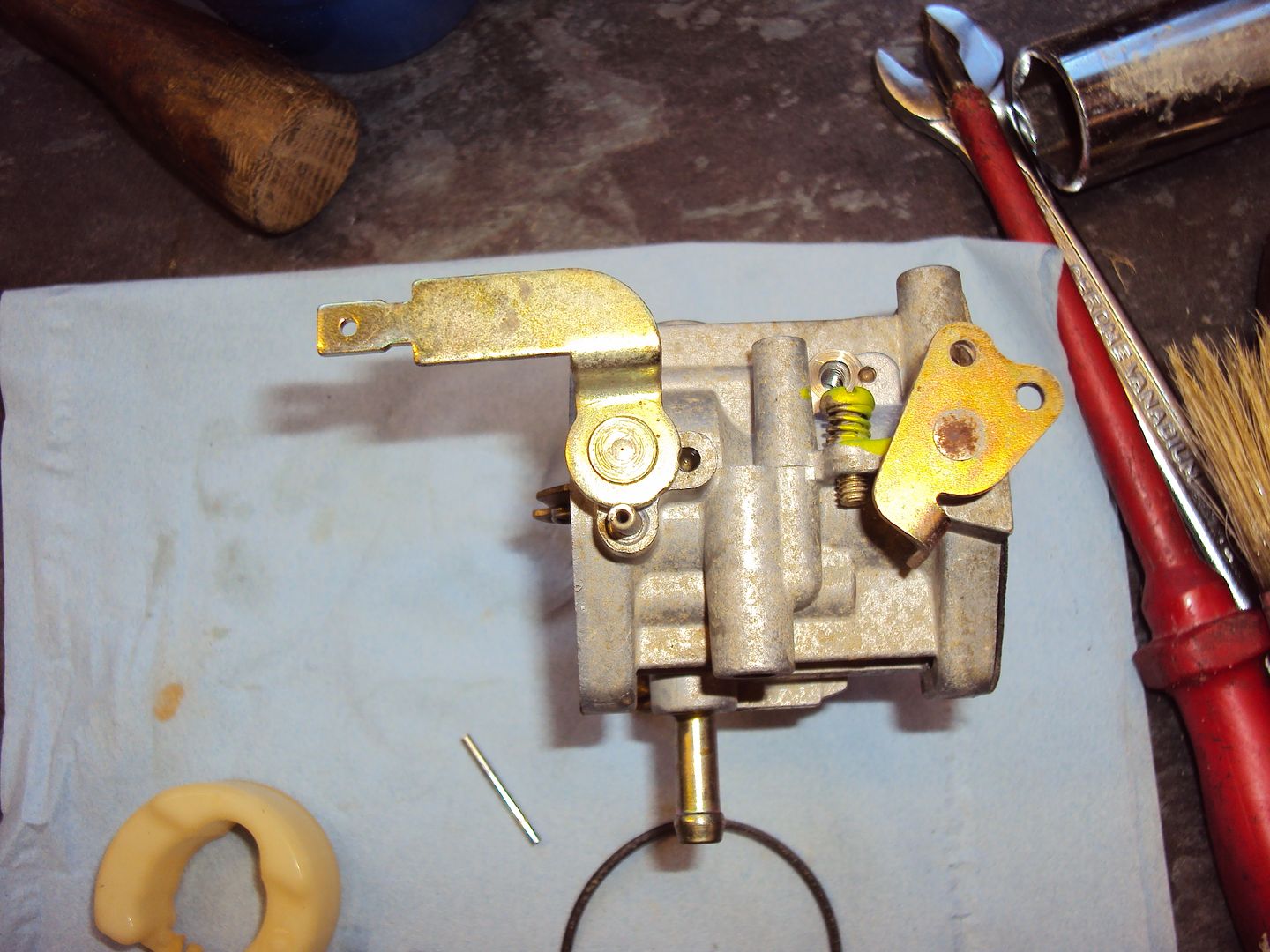

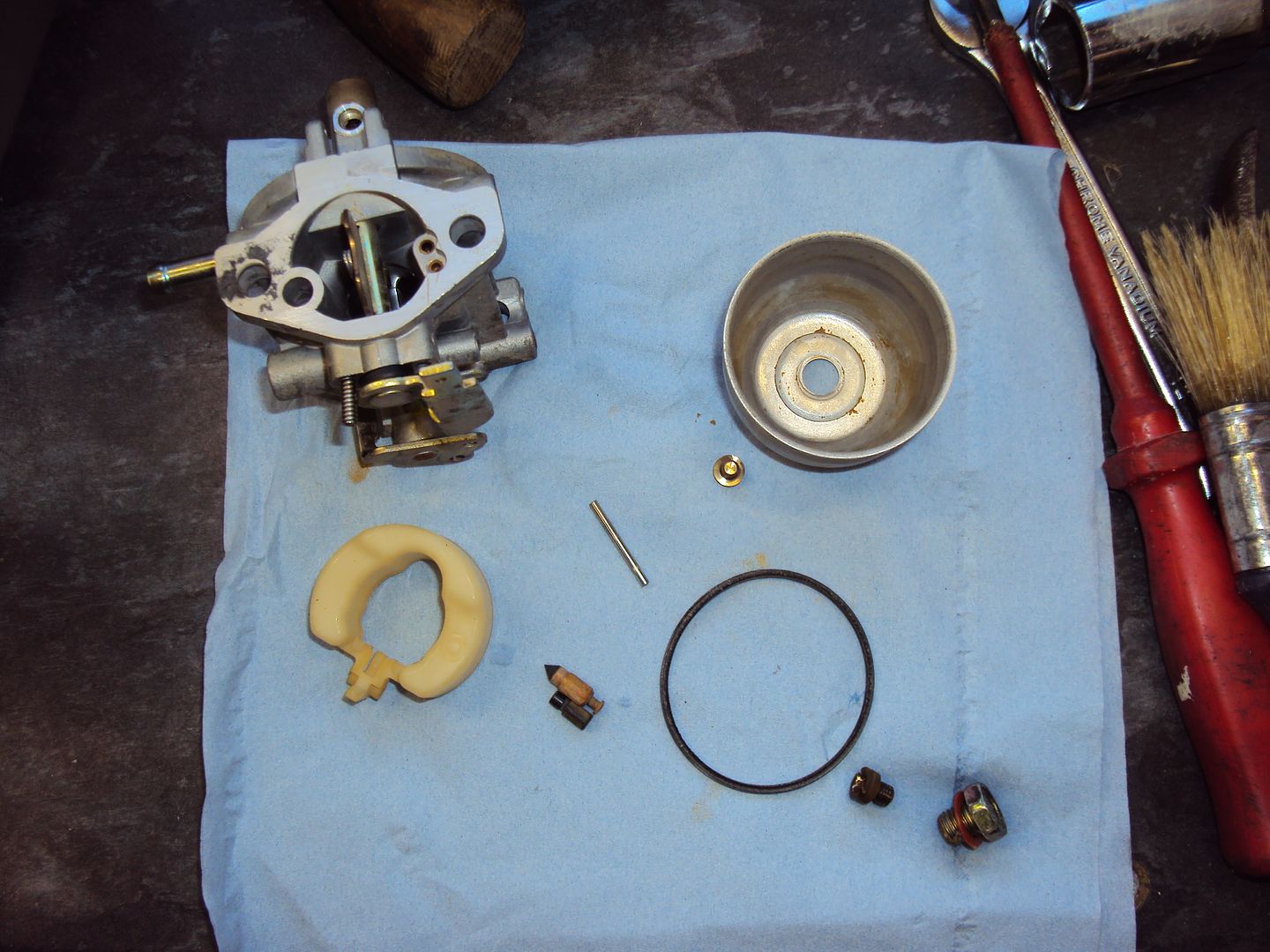

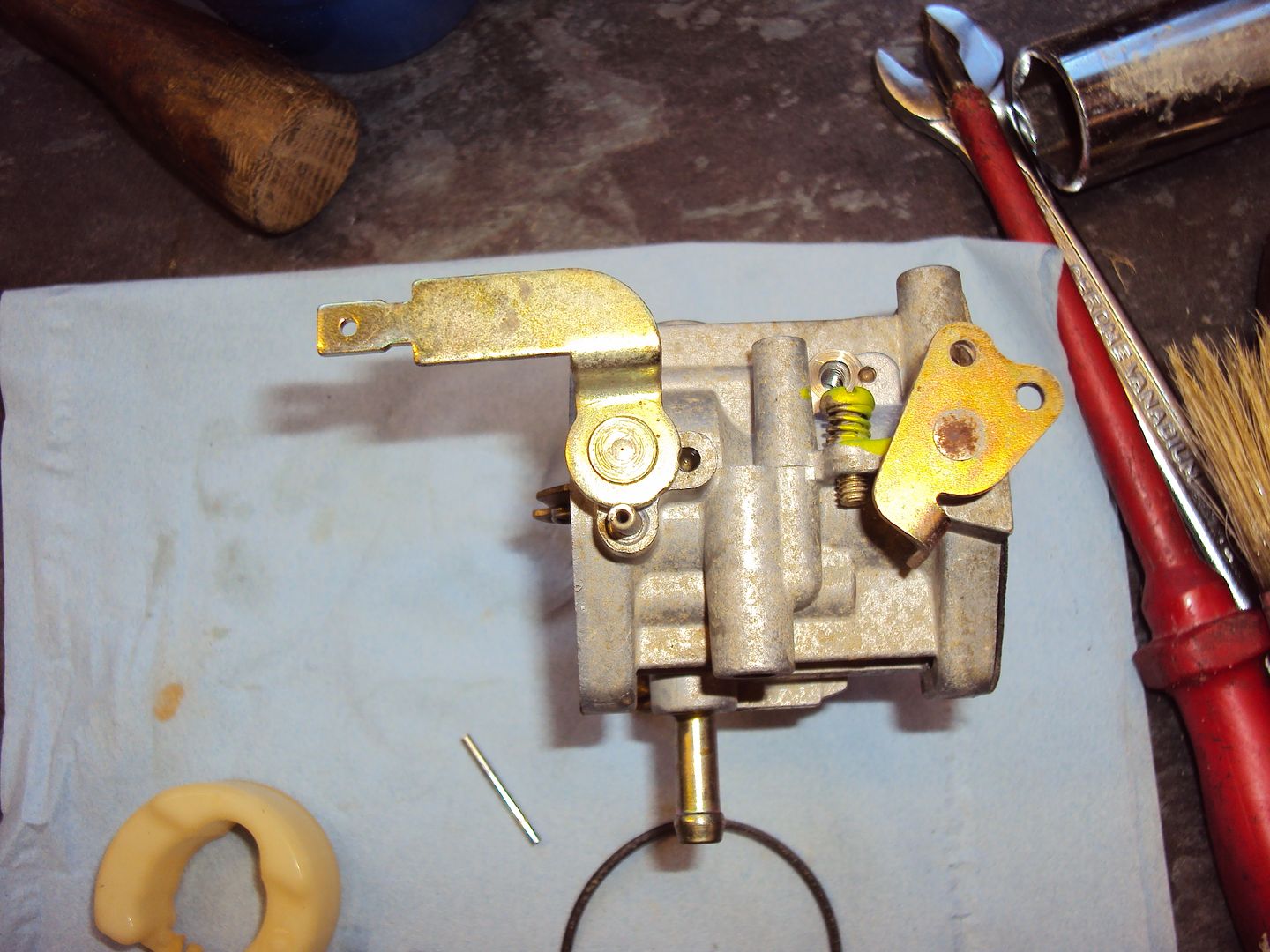

It needed the usual carb clean.

However this time I have new toy to help with the cleaning

Put all the bits in a jar of brake cleaner and ran for 5 min

All cleaned up, had to scrub the bowl with a brush to get the last of the crud out

Carb body looking much better

Crud in bottom of jar

Engine started after a few pulls and settled to a constant speed, power output was fine.

Picked up another one today, it was from the same person I got the last Honda from. They had sold it, but the buyer never contacted them to pick it up or pay so they offered it to me.

It was quite dusty

This one doesn’t look to have had much use as the oil was still clean.

It needed the usual carb clean.

However this time I have new toy to help with the cleaning

Put all the bits in a jar of brake cleaner and ran for 5 min

All cleaned up, had to scrub the bowl with a brush to get the last of the crud out

Carb body looking much better

Crud in bottom of jar

Engine started after a few pulls and settled to a constant speed, power output was fine.

hidetheelephants said:

Condi said:

Looks to be the carb from a Robin/Suberu engine. Costs less than a tenner for a replacement so I just bought a new one as the throttle had seized.

Pah; where's the fun in that?

jet_noise said:

Like shelling peas. Cries of "easy, easy" from the audience

Yeah I know, but the easy fixes give the most profit (no parts to buy), think from start to finish it took me about hour to get it stripped, cleaned and back running.

jet_noise said:

How much time does the ultrasonic cleaner save?

And has Mrs B32 (assuming there is one!) used it on her jewellery yet (akthough possibly not using brake cleaner as the fluid!)

regards,

Jet

It doesn’t save much time, but it does get all the small inaccessible passages inside the carburettor clean. And has Mrs B32 (assuming there is one!) used it on her jewellery yet (akthough possibly not using brake cleaner as the fluid!)

regards,

Jet

No Mrs 32 yet, so no jewellery cleaning. Have done a couple of metal watchstraps though.

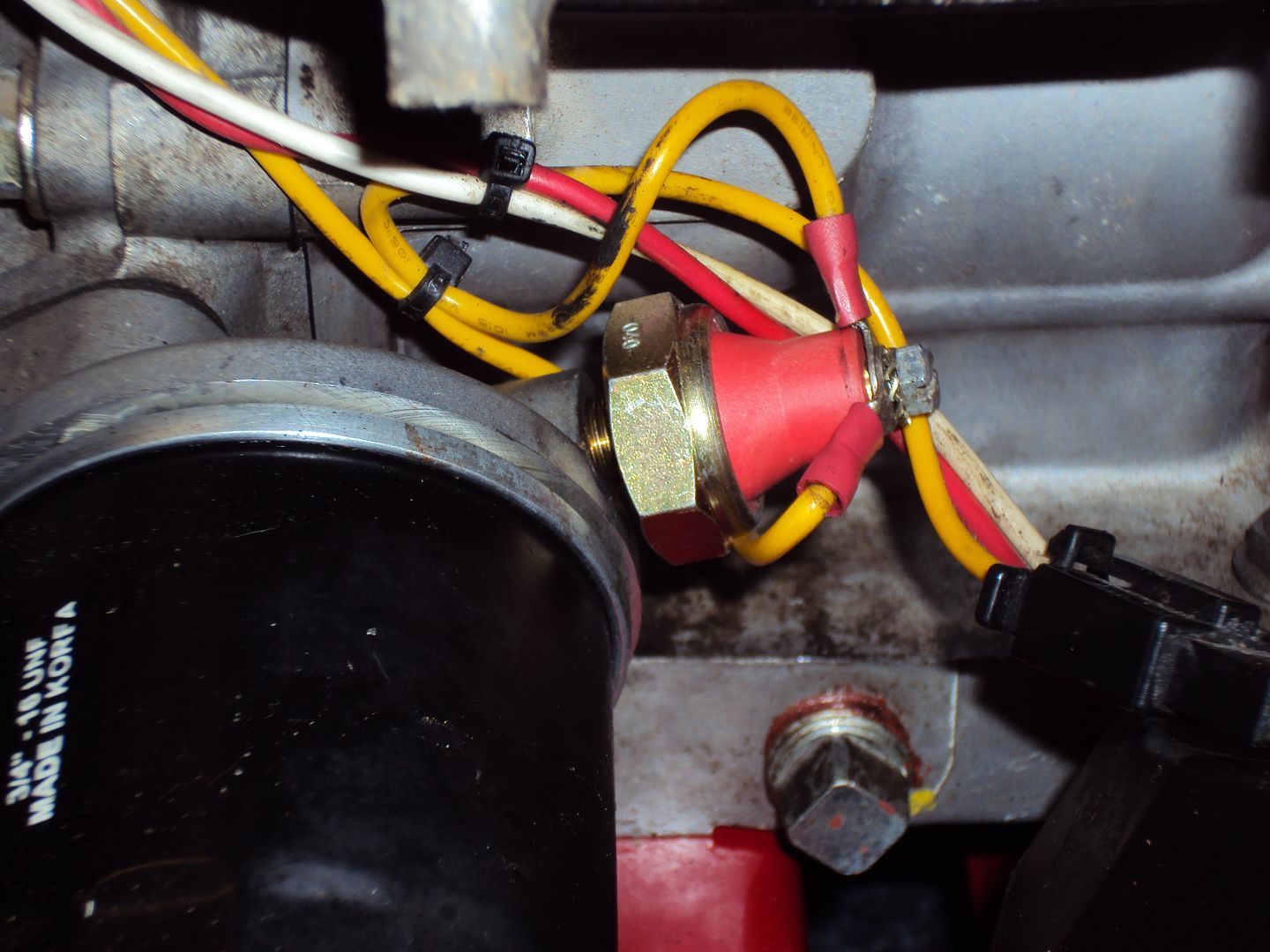

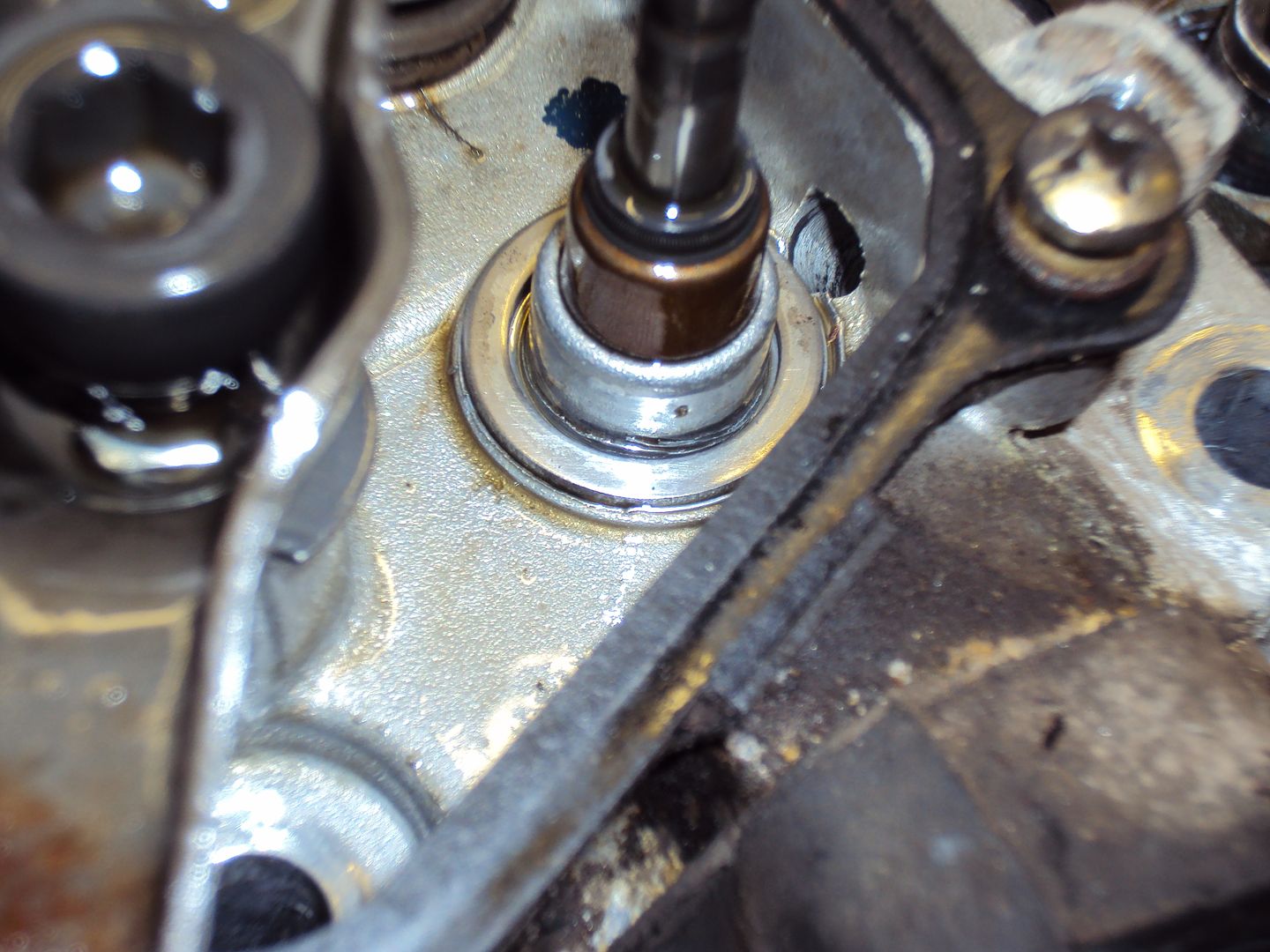

Finished the big Generac today (actually got to use some spanners), started with replacing the oil pressure switch.

The replacement is actually for a Honda, however it was considerably cheaper than the Generac part which was $21 + $39 for international shipping.

Fitted

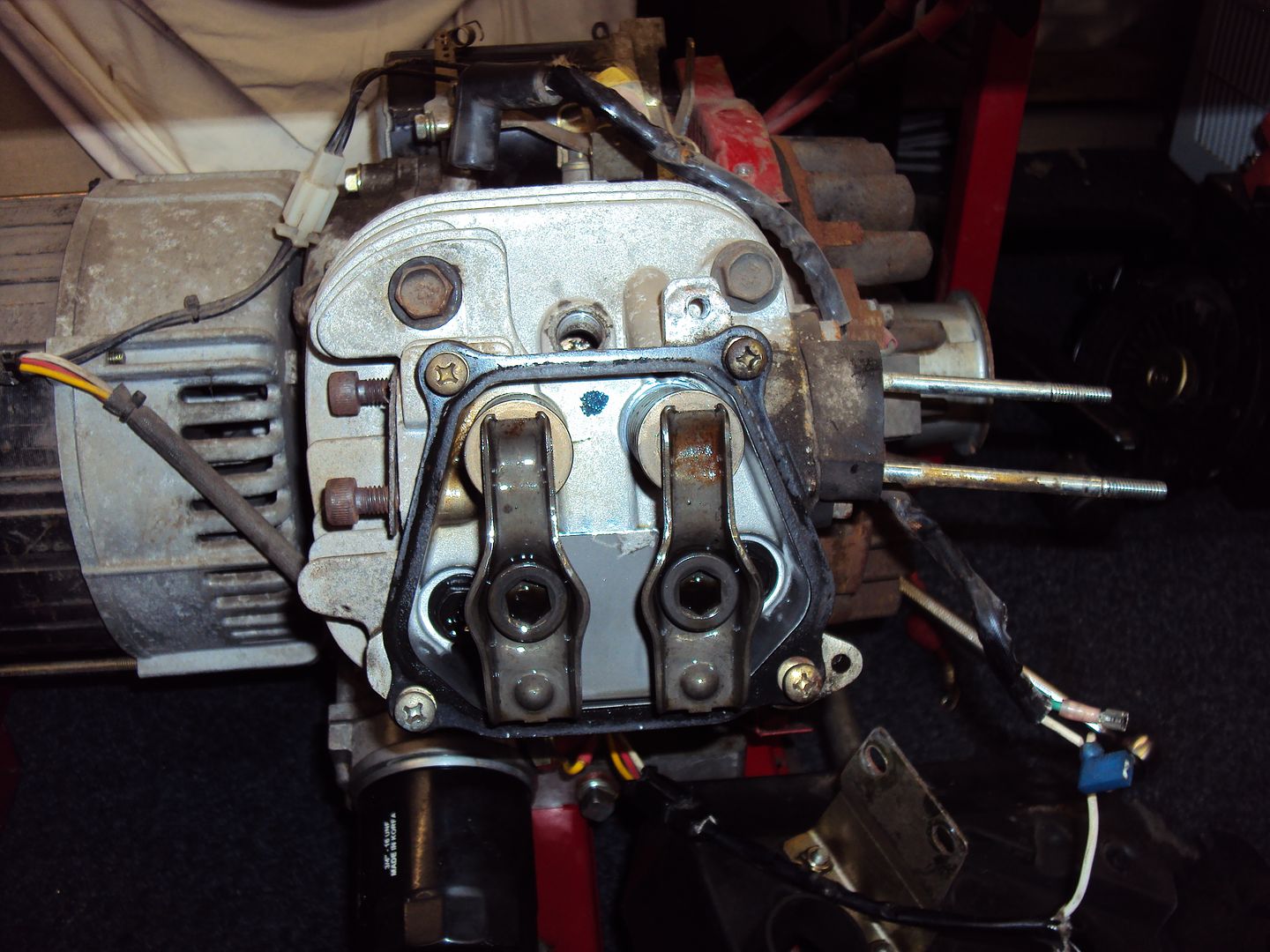

Next I moved on to replacing the washer under the intake valve spring.

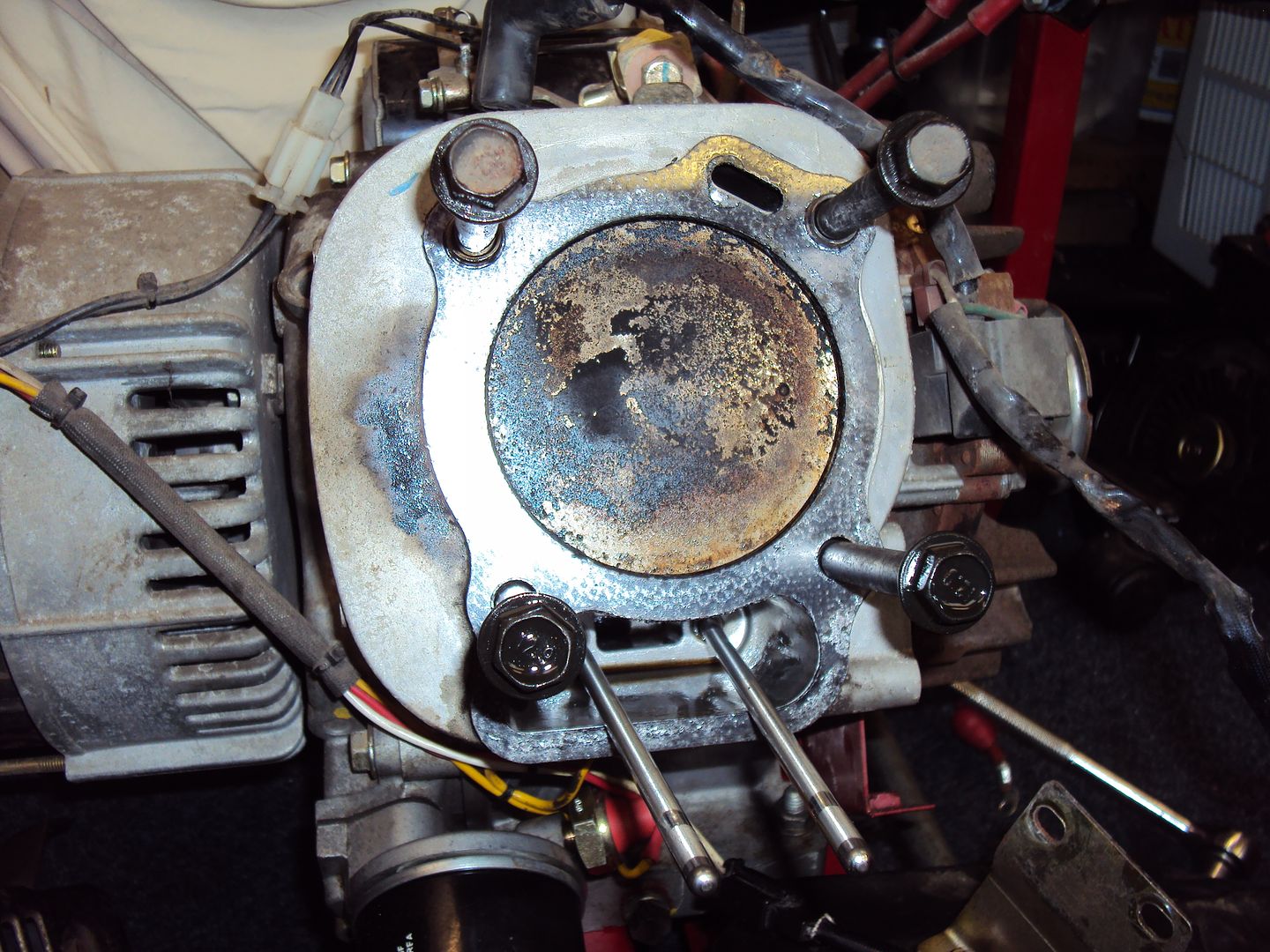

Stripping the head down for removal

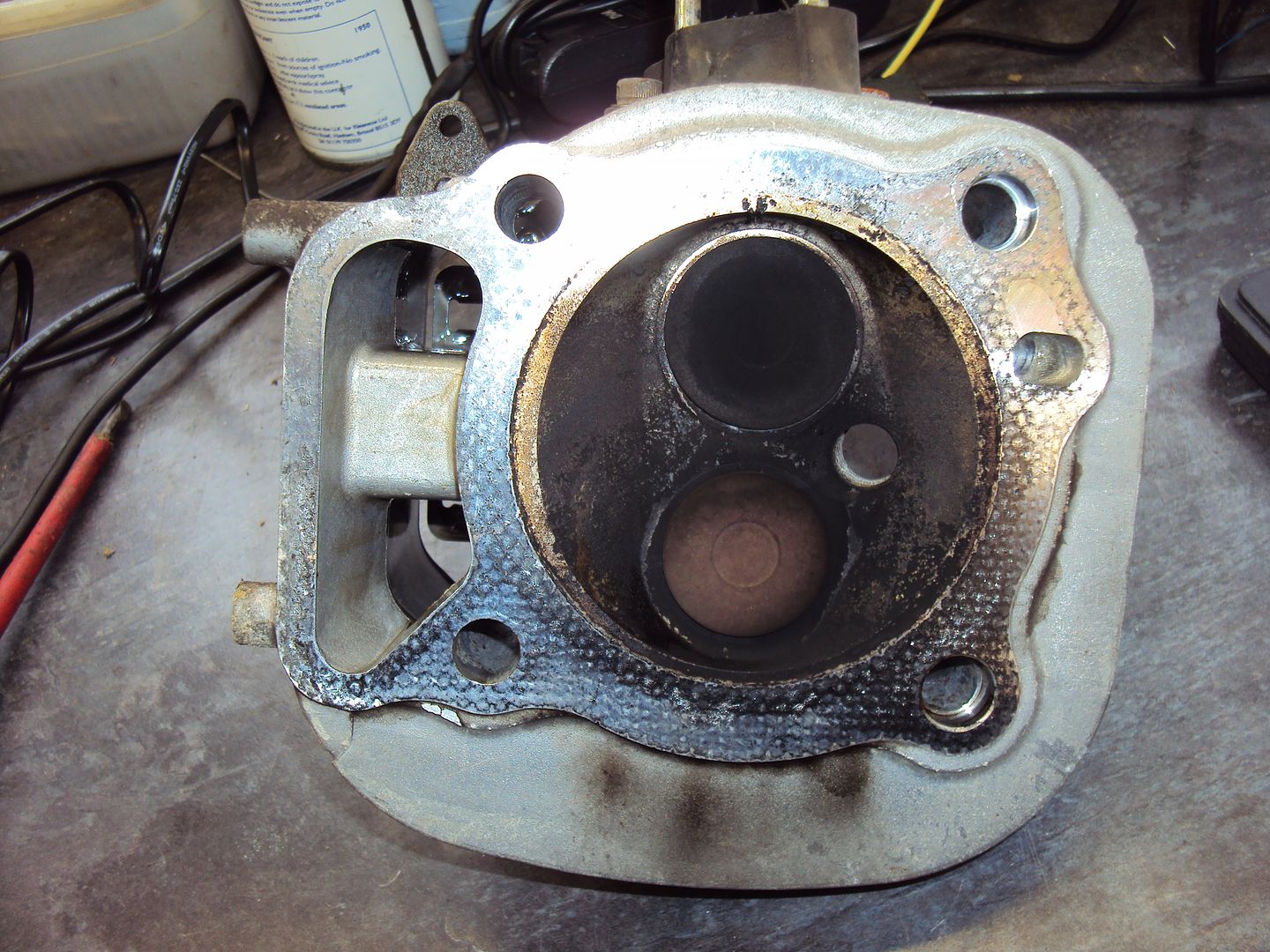

Inside of head, only a small amount of carbon

Piston was reasonably clean

I used a valve spring compressor to compress the spring to release the retainers.

The wear to the head is more obvious with the spring removed

Washer in place.

Didn’t take any pics of the re-assembly, but it all went back together with no issues. Engine started on first pull and sounded a bit smoother.

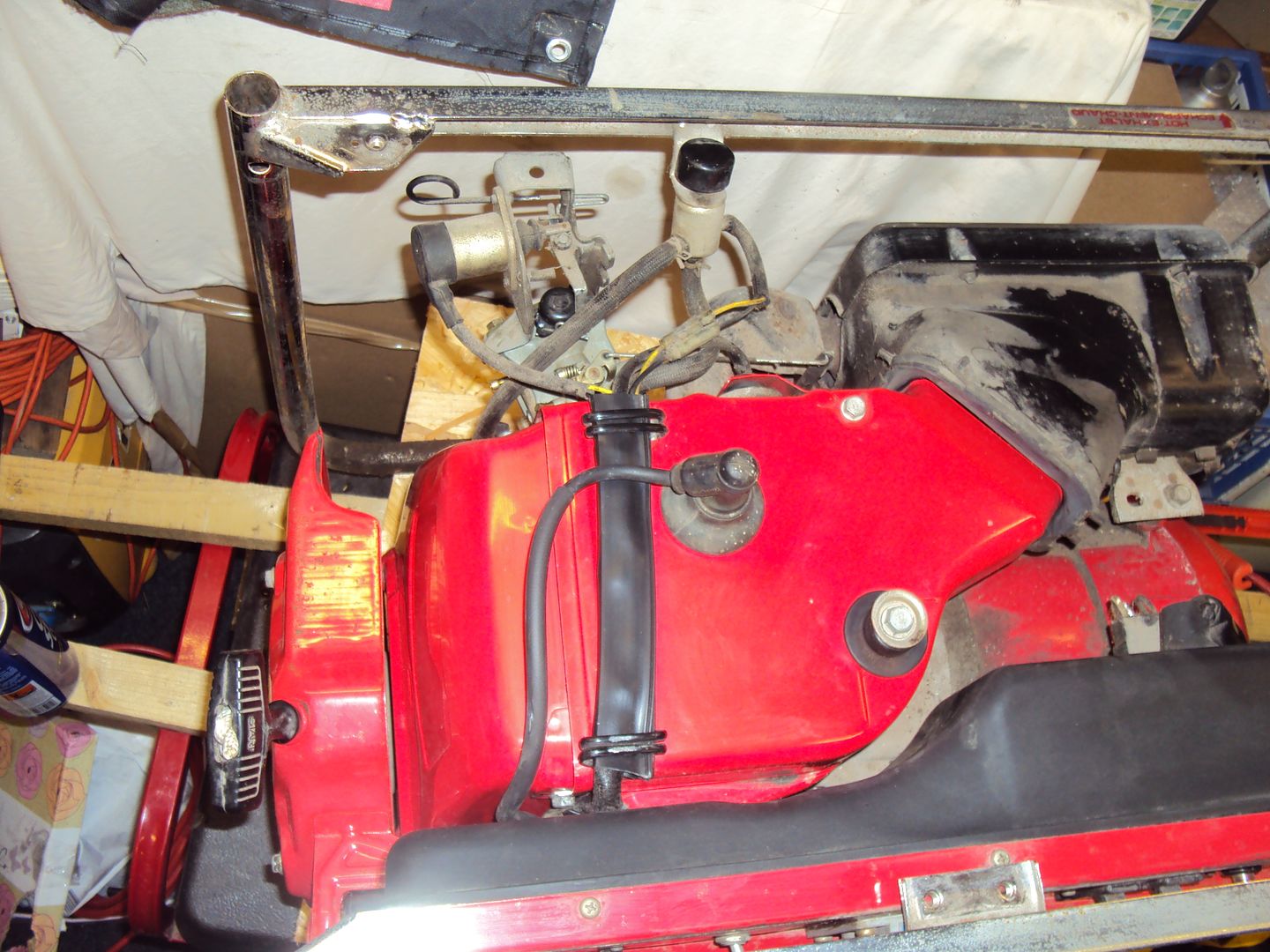

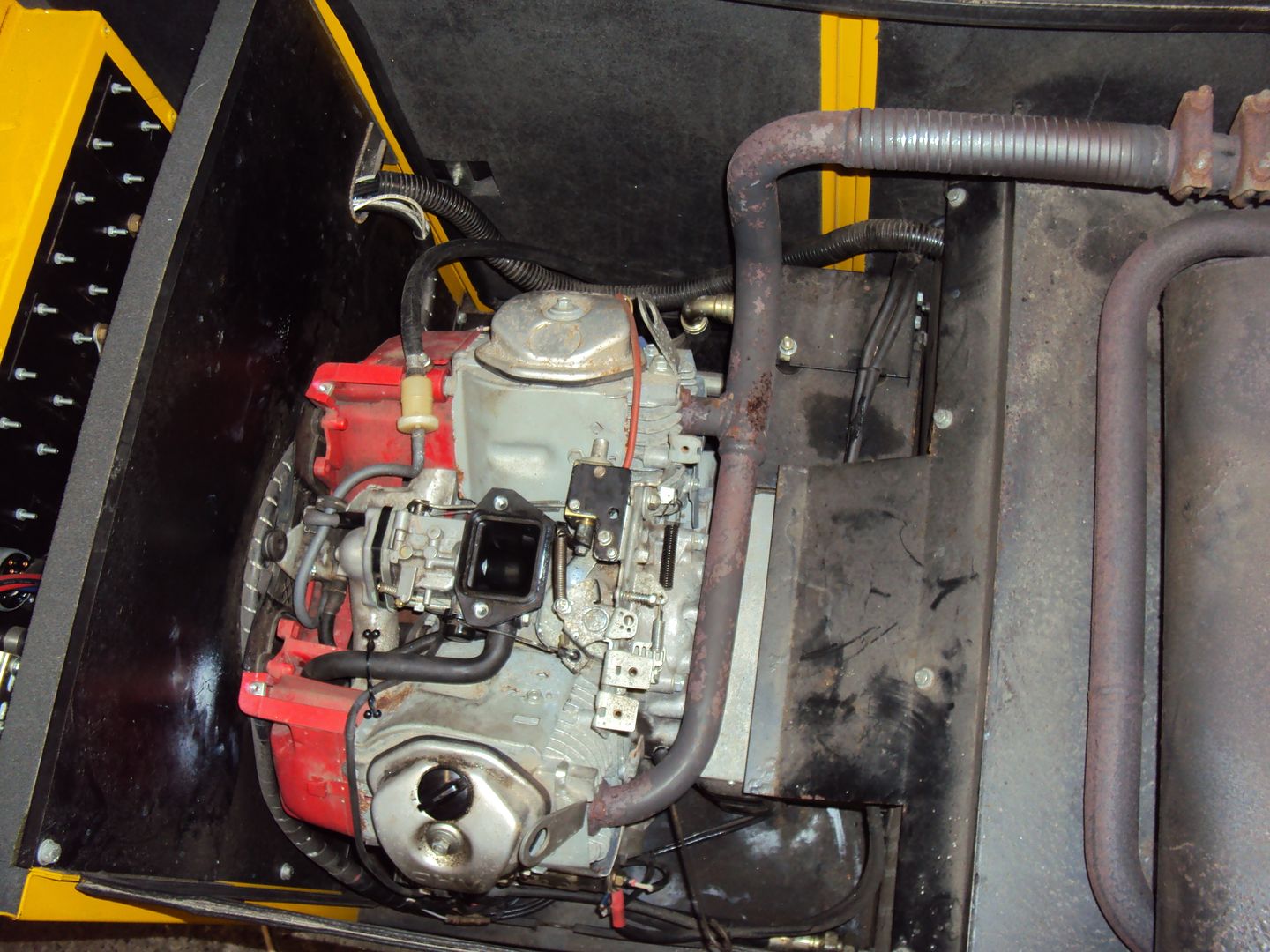

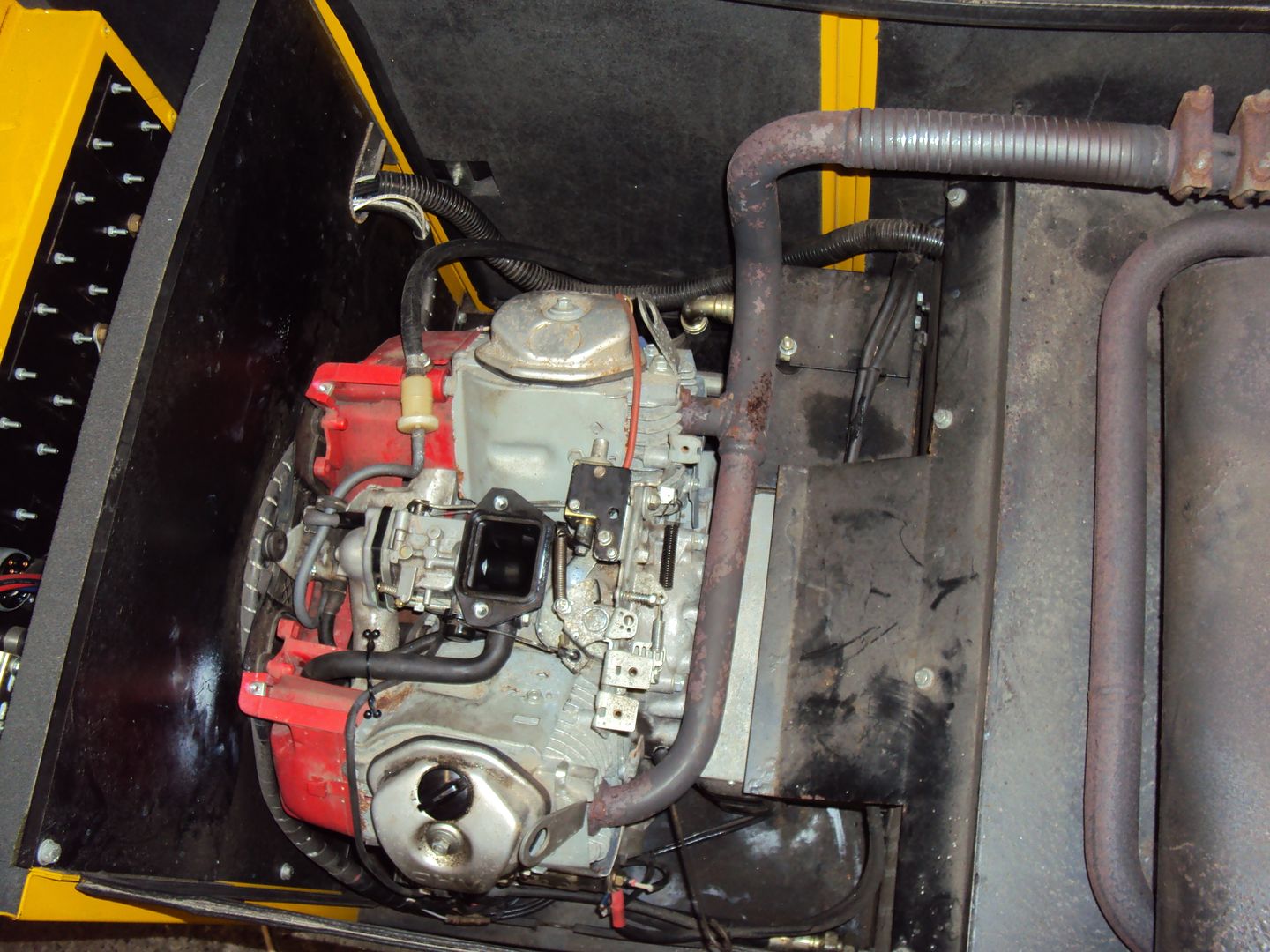

Picked up the latest project, it’s an ex-hire 10kva fitted with a 600cc V-twin. It has problems starting from cold, it would eventually start after a lot of cranking.

The seller had someone look at it but as they were unable to fix it he got fed up with spending money on it.

Due to the size I couldn’t get it up to the usual workshop so had to make do with the garage. Photos show it partially disassembled (was assembled when I got it).

Started with checking the sparkplugs which turned out to be new

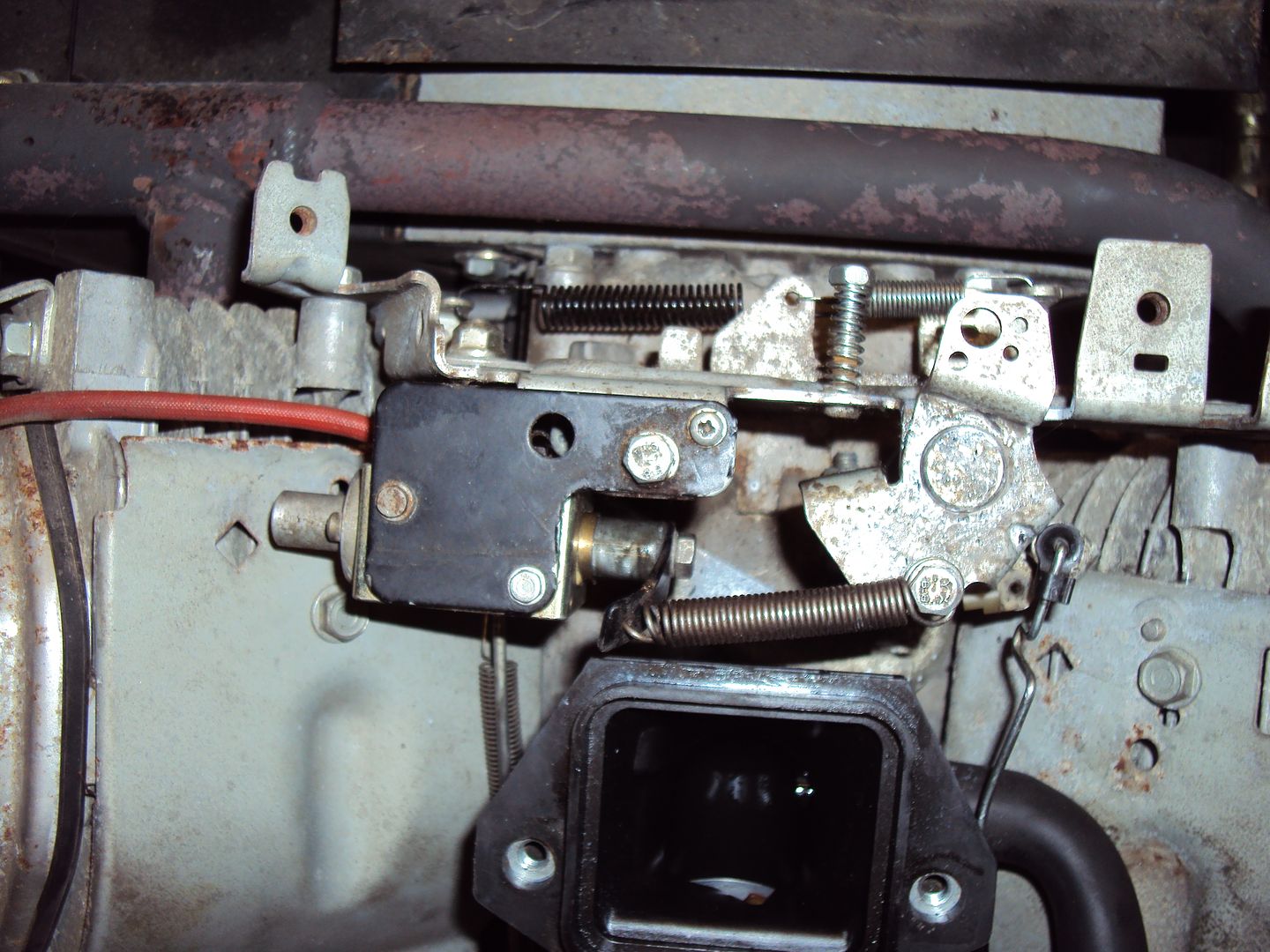

Decided the best place was to start with the choke, which is electrically operated, via button on the front panel that controls a solenoid.

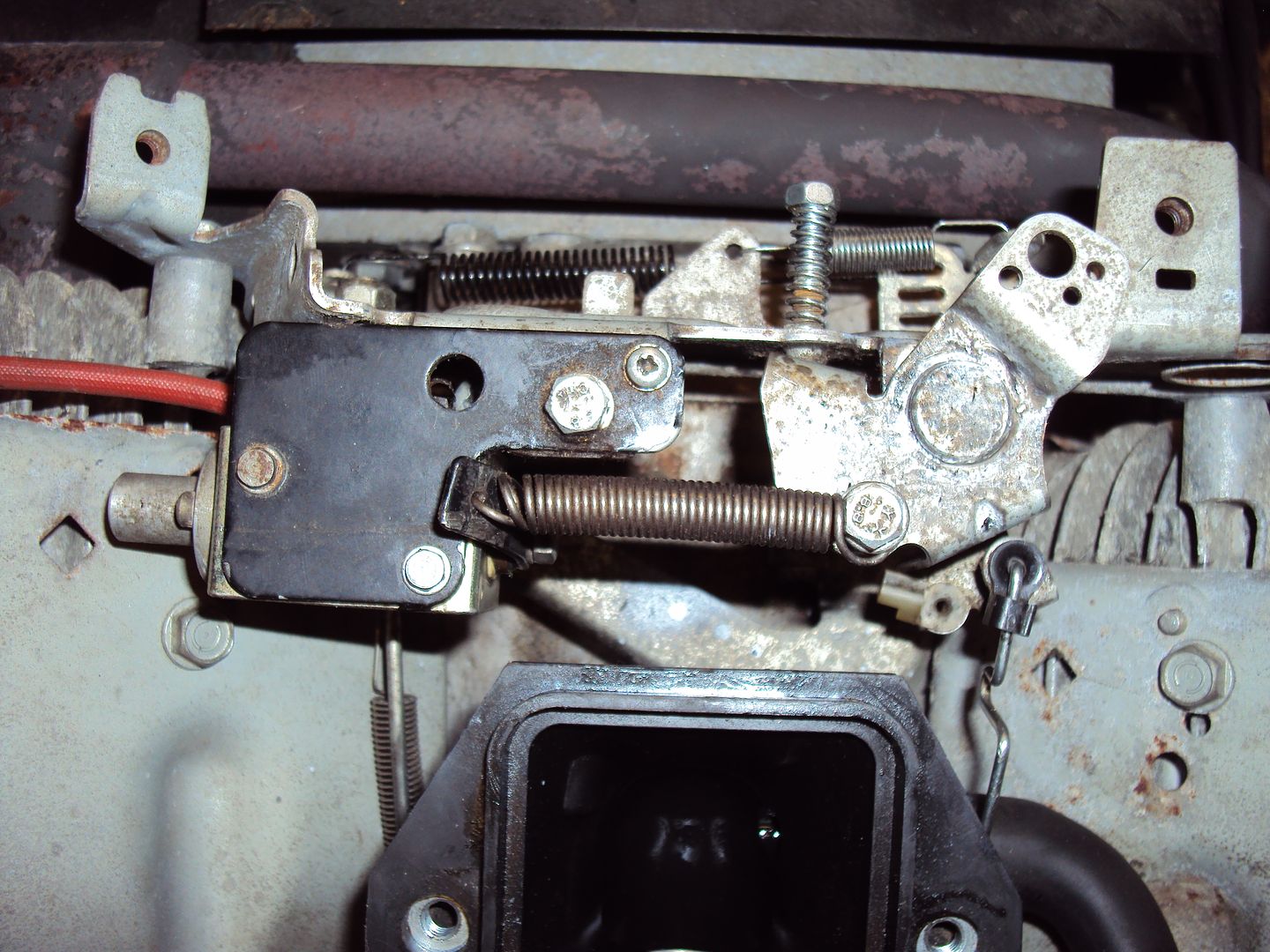

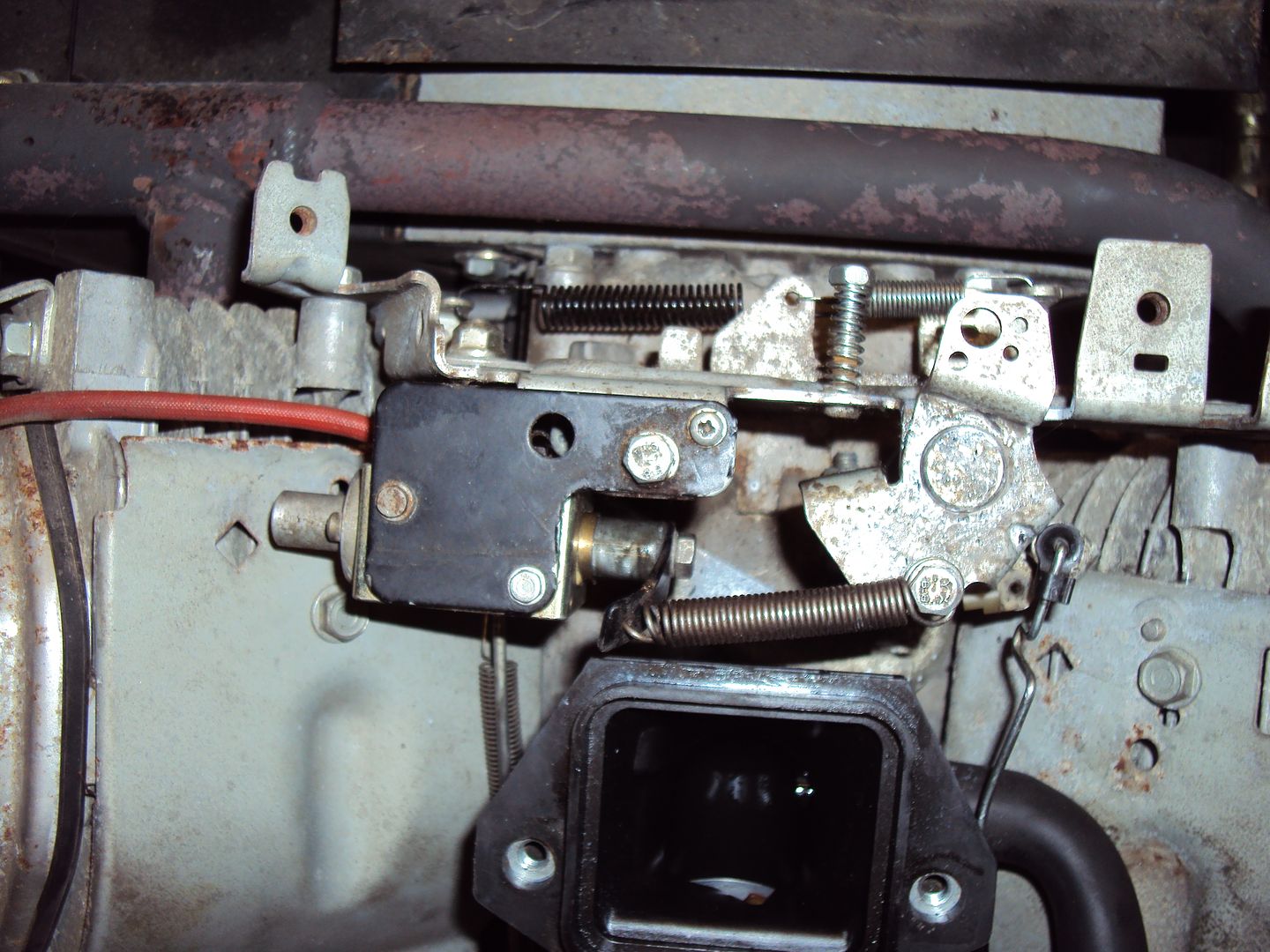

It took a fair bit of disassembly to get to the choke mechanism.

The choke solenoid has the red wire (running parallel with exhaust) going to it.

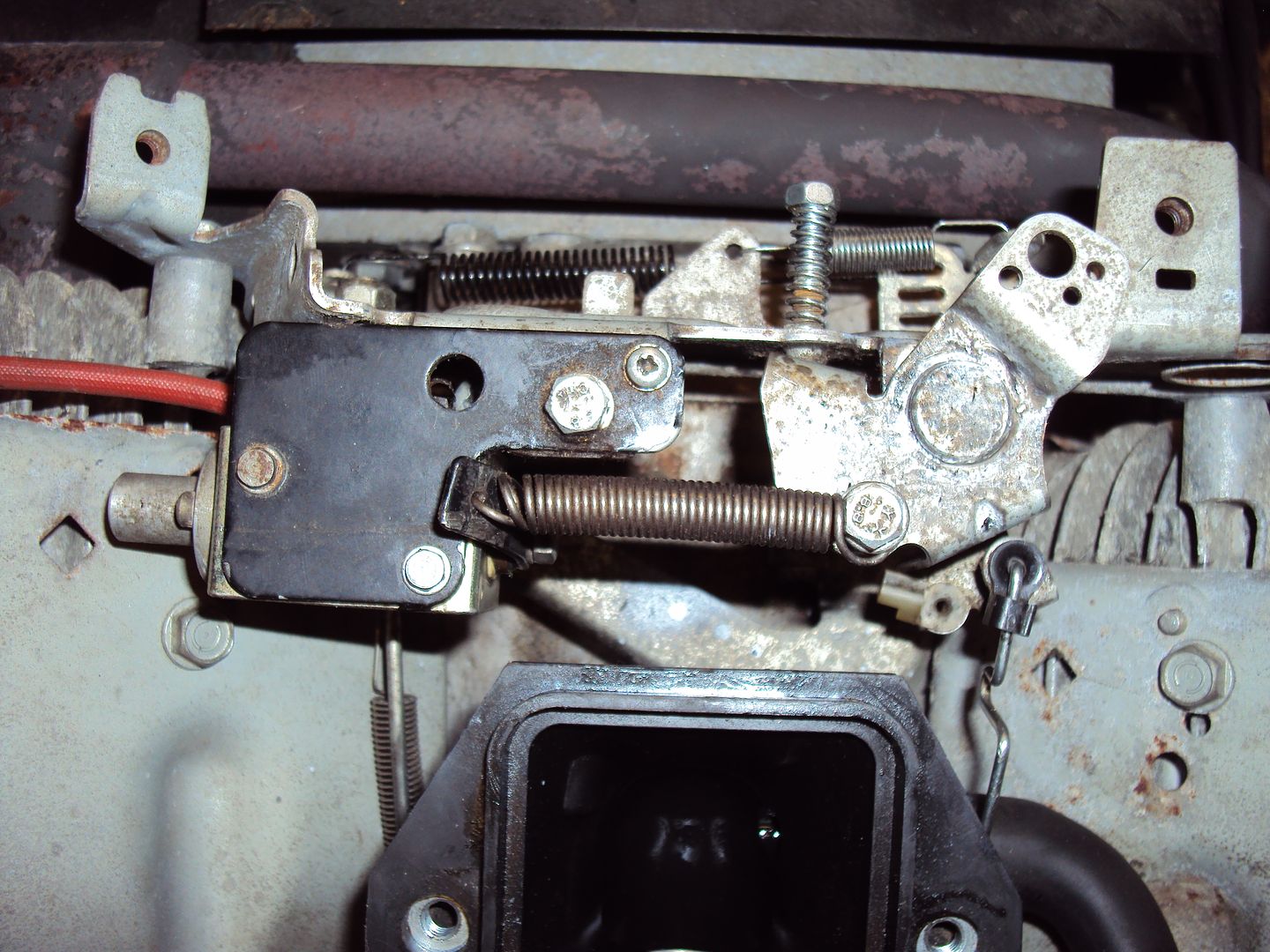

When the choke button is pressed the choke solenoid pulls on a lever via a spring which operates a rod that opens/closes the choke.

Solenoid works fine, with button pressed it pulls in all the way, but the choke valve wasn’t closing enough.

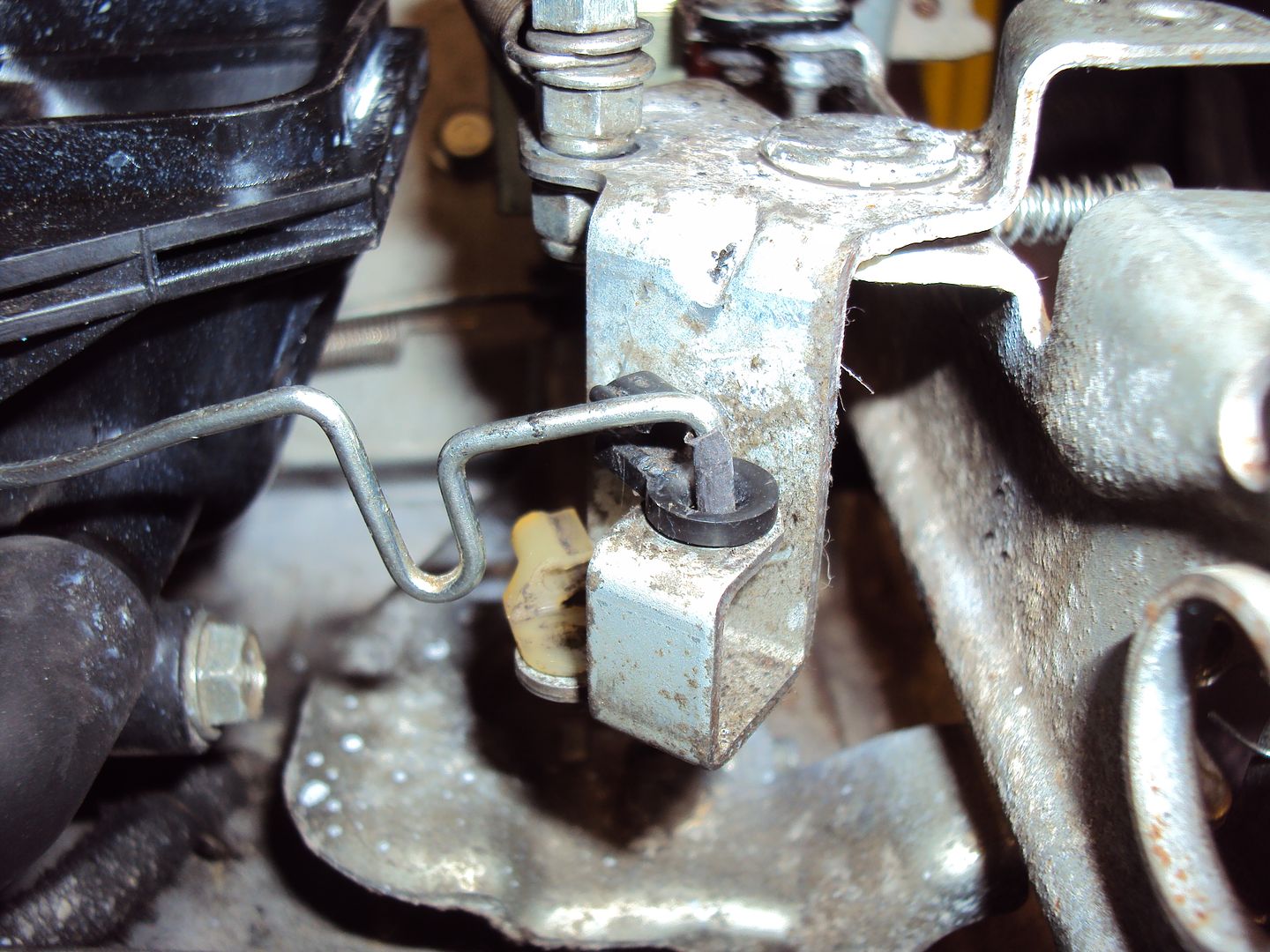

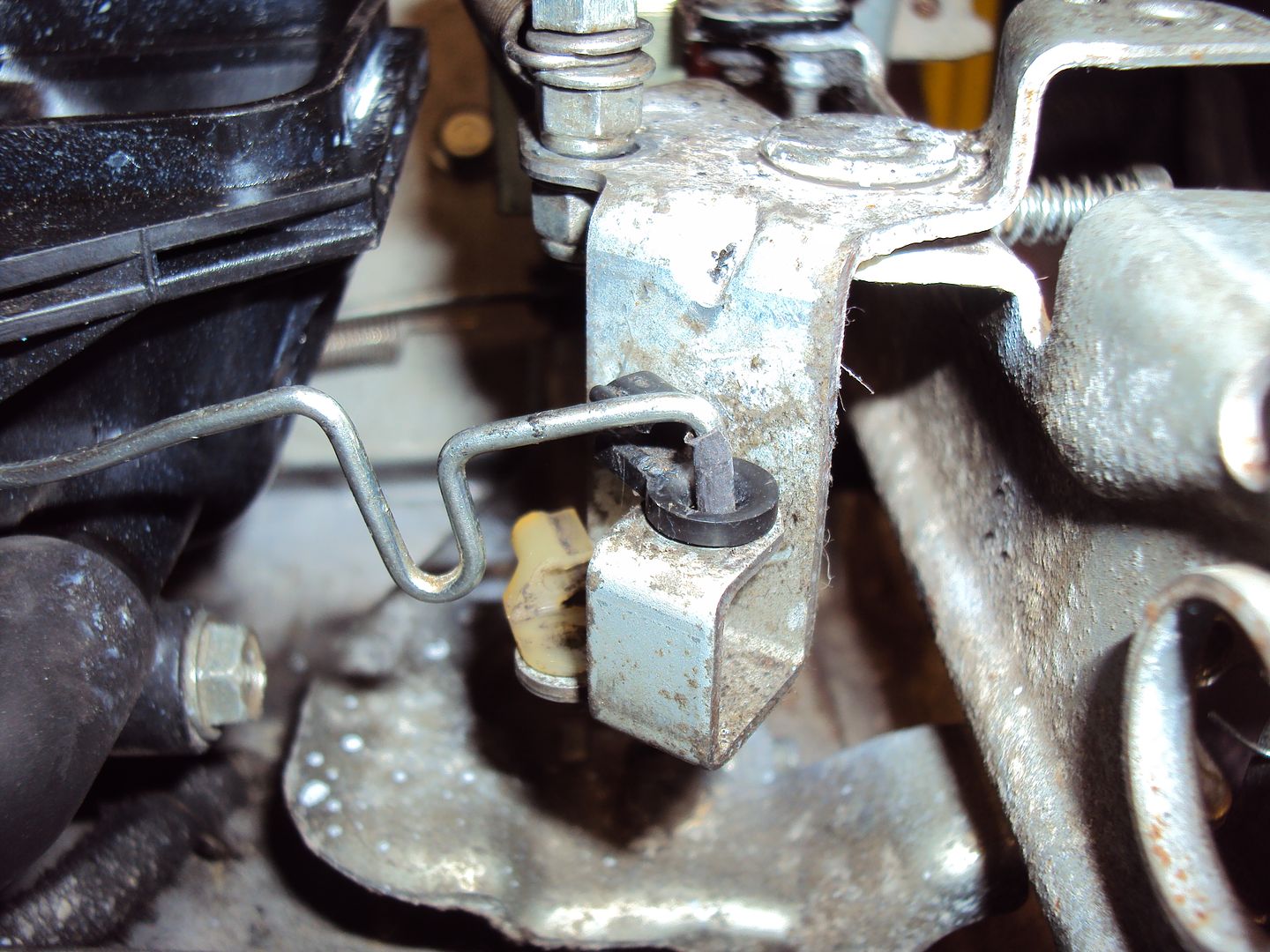

After a lot of poking around we found that a small plastic bush in the lever was worn so the choke rod was loose.

Decided to try a bodge fix by putting some heat shrink on the choke rod.

It worked, with the choke button pressed the engine started straight away.

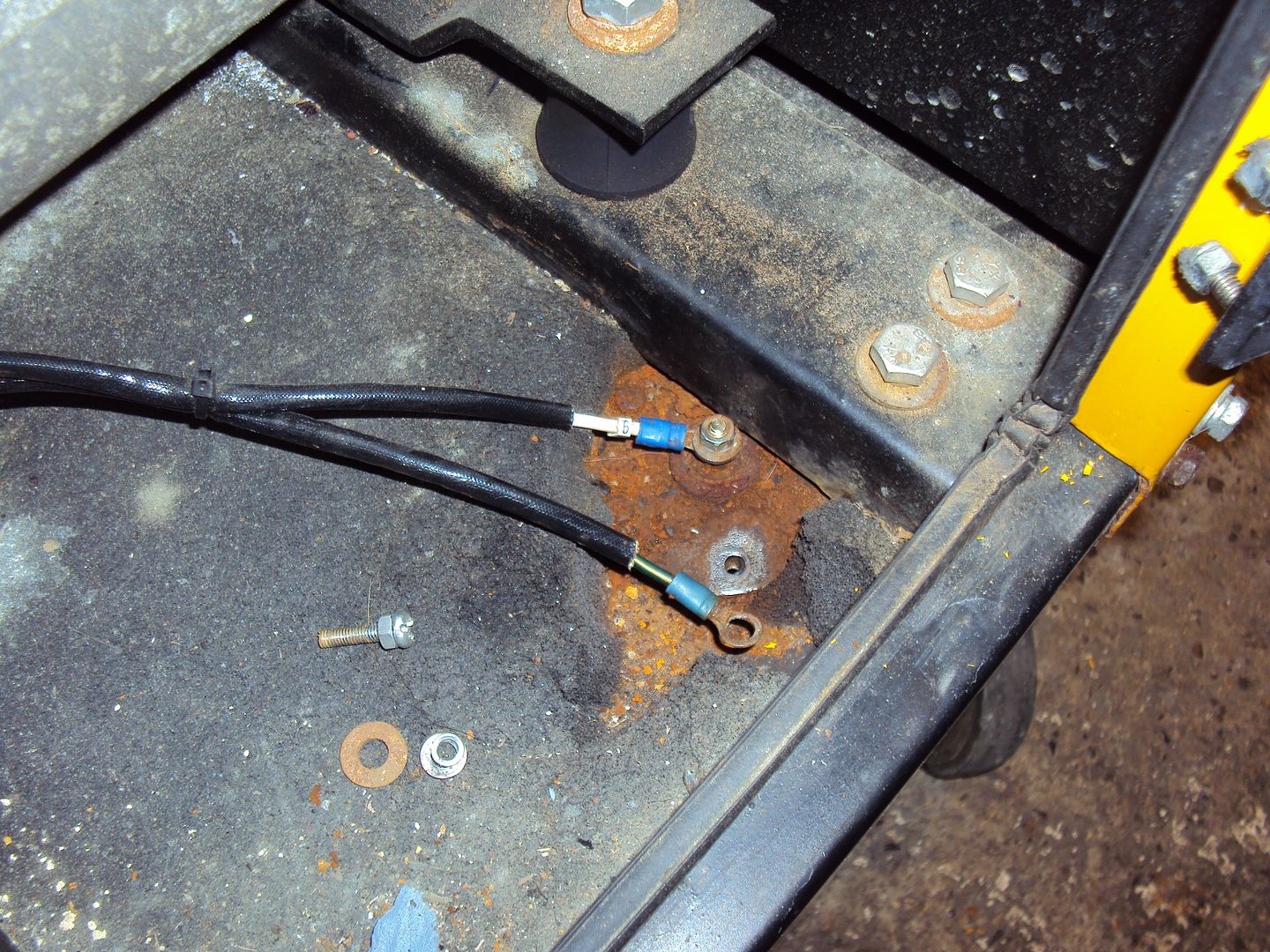

Did all the usual checks, and found the voltage and frequency were a bit high. Also found the fuel gauge wasn’t working.

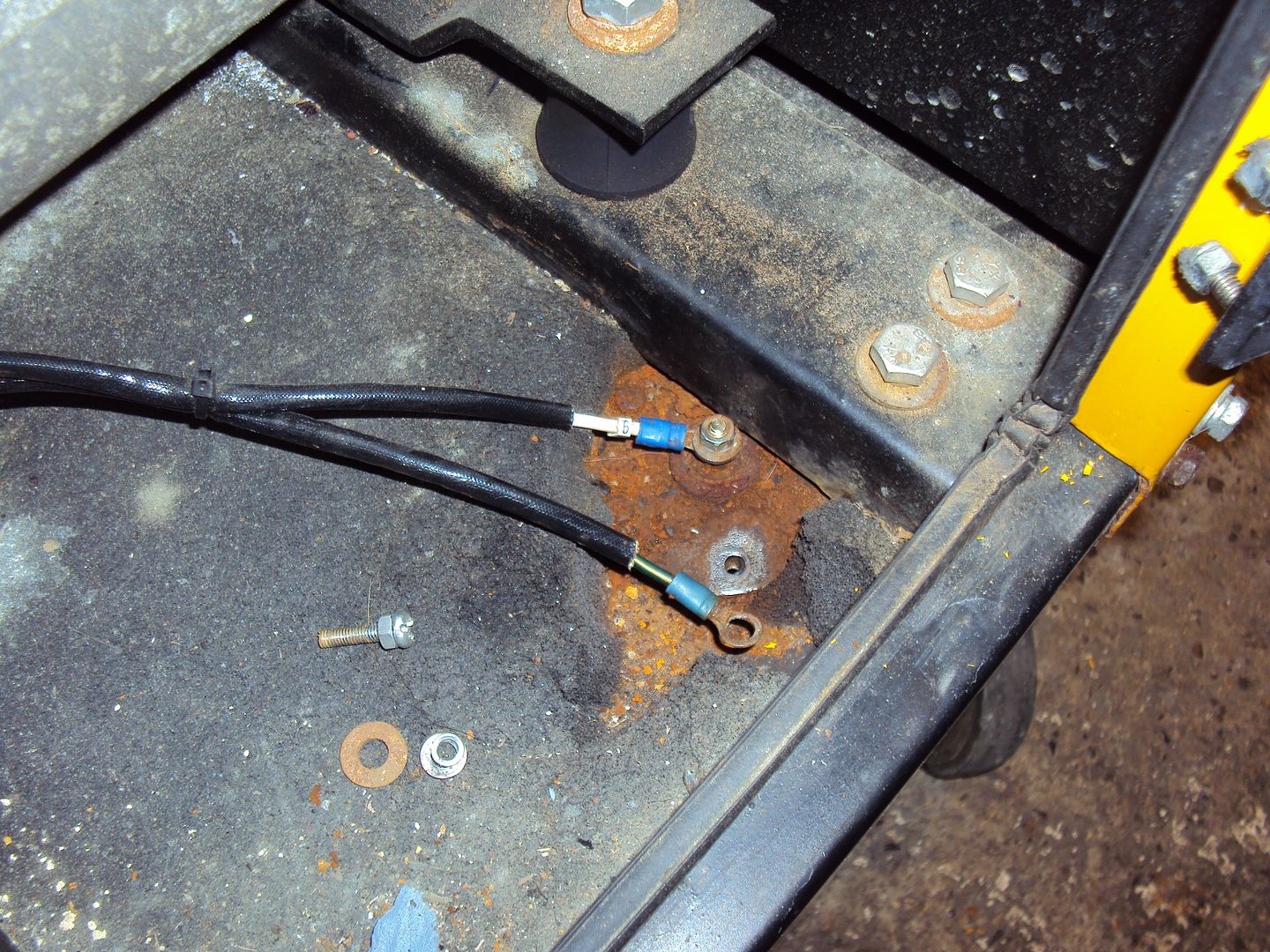

Tested the gauge, which worked so the fault was probably with the sender. The top of the sender unit was covered with rust so I started with cleaning up the earth tag.

Unfortunately it still didn’t work, so I measured the resistance of the sender and found it to be open circuit.

To get the sender out will be a lot of work as is inconveniently located under a cross brace, which supports the alternator.

The plan is to remove the casing and tip the engine & alternator back so the brace can be removed to gain access to the sender. It’s going to be a lot of work!

The seller had someone look at it but as they were unable to fix it he got fed up with spending money on it.

Due to the size I couldn’t get it up to the usual workshop so had to make do with the garage. Photos show it partially disassembled (was assembled when I got it).

Started with checking the sparkplugs which turned out to be new

Decided the best place was to start with the choke, which is electrically operated, via button on the front panel that controls a solenoid.

It took a fair bit of disassembly to get to the choke mechanism.

The choke solenoid has the red wire (running parallel with exhaust) going to it.

When the choke button is pressed the choke solenoid pulls on a lever via a spring which operates a rod that opens/closes the choke.

Solenoid works fine, with button pressed it pulls in all the way, but the choke valve wasn’t closing enough.

After a lot of poking around we found that a small plastic bush in the lever was worn so the choke rod was loose.

Decided to try a bodge fix by putting some heat shrink on the choke rod.

It worked, with the choke button pressed the engine started straight away.

Did all the usual checks, and found the voltage and frequency were a bit high. Also found the fuel gauge wasn’t working.

Tested the gauge, which worked so the fault was probably with the sender. The top of the sender unit was covered with rust so I started with cleaning up the earth tag.

Unfortunately it still didn’t work, so I measured the resistance of the sender and found it to be open circuit.

To get the sender out will be a lot of work as is inconveniently located under a cross brace, which supports the alternator.

The plan is to remove the casing and tip the engine & alternator back so the brace can be removed to gain access to the sender. It’s going to be a lot of work!

I picked up a Kraftech KT6500 genny this weekend for £55 - "no voltage" was the fault. Got it home and had a look inside the alternator - the [aluminium] windings are completely burnt and fused into a large molten blob of ally.

Wife wasn't too happy me wasting £55 of her handbag budget on a POS Chinese genny that is now cluttering up the garage - I blamed you and this thread.

Wife wasn't too happy me wasting £55 of her handbag budget on a POS Chinese genny that is now cluttering up the garage - I blamed you and this thread.

eliot said:

I picked up a Kraftech KT6500 genny this weekend for £55 - "no voltage" was the fault. Got it home and had a look inside the alternator - the [aluminium] windings are completely burnt and fused into a large molten blob of ally.

Wife wasn't too happy me wasting £55 of her handbag budget on a POS Chinese genny that is now cluttering up the garage - I blamed you and this thread.

That often happens when someone plugs the genny in during a power cut, without isolating the house from the mains first. Power comes back on, genny goes bang, normally quite dramatically!Wife wasn't too happy me wasting £55 of her handbag budget on a POS Chinese genny that is now cluttering up the garage - I blamed you and this thread.

eliot said:

I picked up a Kraftech KT6500 genny this weekend for £55 - "no voltage" was the fault. Got it home and had a look inside the alternator - the [aluminium] windings are completely burnt and fused into a large molten blob of ally.

Wife wasn't too happy me wasting £55 of her handbag budget on a POS Chinese genny that is now cluttering up the garage - I blamed you and this thread.

Lol i saw that one on ebay , did a quick google on the make and read the awful reviews , decided to give it a miss .Wife wasn't too happy me wasting £55 of her handbag budget on a POS Chinese genny that is now cluttering up the garage - I blamed you and this thread.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff