The ebay generator restoration thread

Discussion

MatrixXXx said:

Just set your multimeter to Hz?

You Normally set the mechanical governour to 2.5 Hz higher than your nominal frequency , then when you load up the generator it will be at 50 Hz at full load (Droop)

My multimeter doesn't do frequency, I might upgrade it to a nice Fluke one day.You Normally set the mechanical governour to 2.5 Hz higher than your nominal frequency , then when you load up the generator it will be at 50 Hz at full load (Droop)

I haven't done a load test since setting the governor, when I do I'll give your suggestion a try if the frequency drops under load

The service manual just says to set the engine speed to 3,200rpm (no load), I don't have a tachometer so just set it up based on the O/P frequency.

If I can build a suitable inductive pickup to work from the spark (magneto fires once for each revolution)I might be able to build a tachometer using a Arduino board to set it up better.

netherfield said:

wish I'd found that, I got one from ebay and it cost more.

wish I'd found that, I got one from ebay and it cost more.Jer_1974 said:

Nice thread. Would be interested in how much profit you made on it.

Thanks  Not sure on profit yet, probably won't sell it until winter.

Not sure on profit yet, probably won't sell it until winter.You must have a 2 pole alternator if is running at 3200 rpm, 4 pole machines run a 1500 rpm = 50Hz, 1800 rpm 60Hz.

you can get a digital multimeter new for under £10.00. all generators will droop under load ( with mechanical governours), as will your AVR , you normally set the voltage higher as well. you would set the voltage droop up at full load. but if you have a compound winding it can be tricky to do.

a multimeter is essential when commissioning a generator, you don't want to put an unknown voltage or frequency into a building, you could end up destroying frequency/voltage sensitive equipment. on some AVR's you can set the voltage higher than the alternator can withstand (Bang)

you can get a digital multimeter new for under £10.00. all generators will droop under load ( with mechanical governours), as will your AVR , you normally set the voltage higher as well. you would set the voltage droop up at full load. but if you have a compound winding it can be tricky to do.

a multimeter is essential when commissioning a generator, you don't want to put an unknown voltage or frequency into a building, you could end up destroying frequency/voltage sensitive equipment. on some AVR's you can set the voltage higher than the alternator can withstand (Bang)

Don't forget the European CE mark of Quality is similar to the "made in China" mark

http://ts1.mm.bing.net/th?&id=HN.6079949650237...

http://ts1.mm.bing.net/th?&id=HN.6079949650237...

woodypup59 said:

Don't forget the European CE mark of Quality is similar to the "made in China" mark

http://ts1.mm.bing.net/th?&id=HN.6079949650237...

CE Marking also covers the machinery directive. it has to be fit for purpose and safe.http://ts1.mm.bing.net/th?&id=HN.6079949650237...

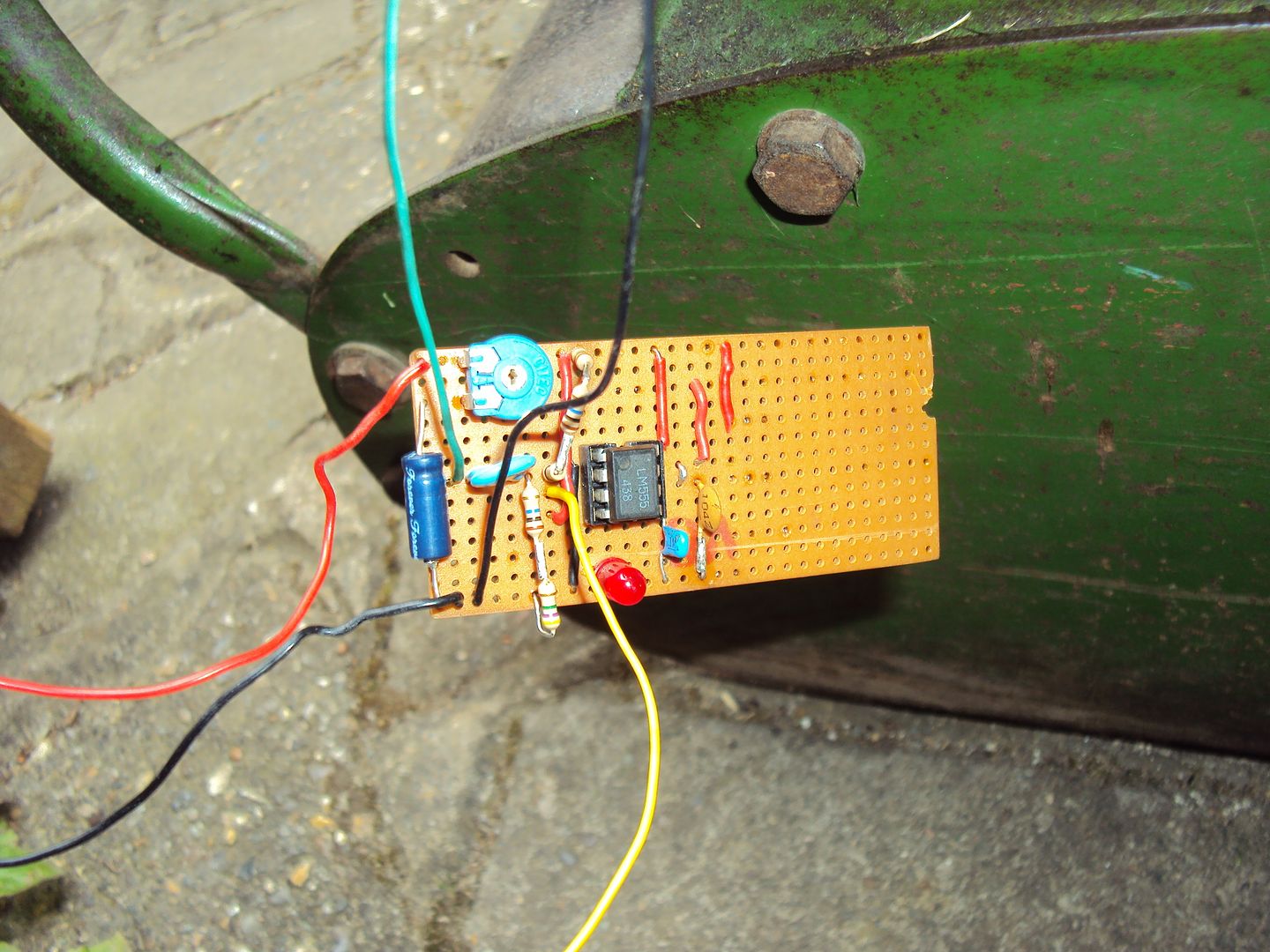

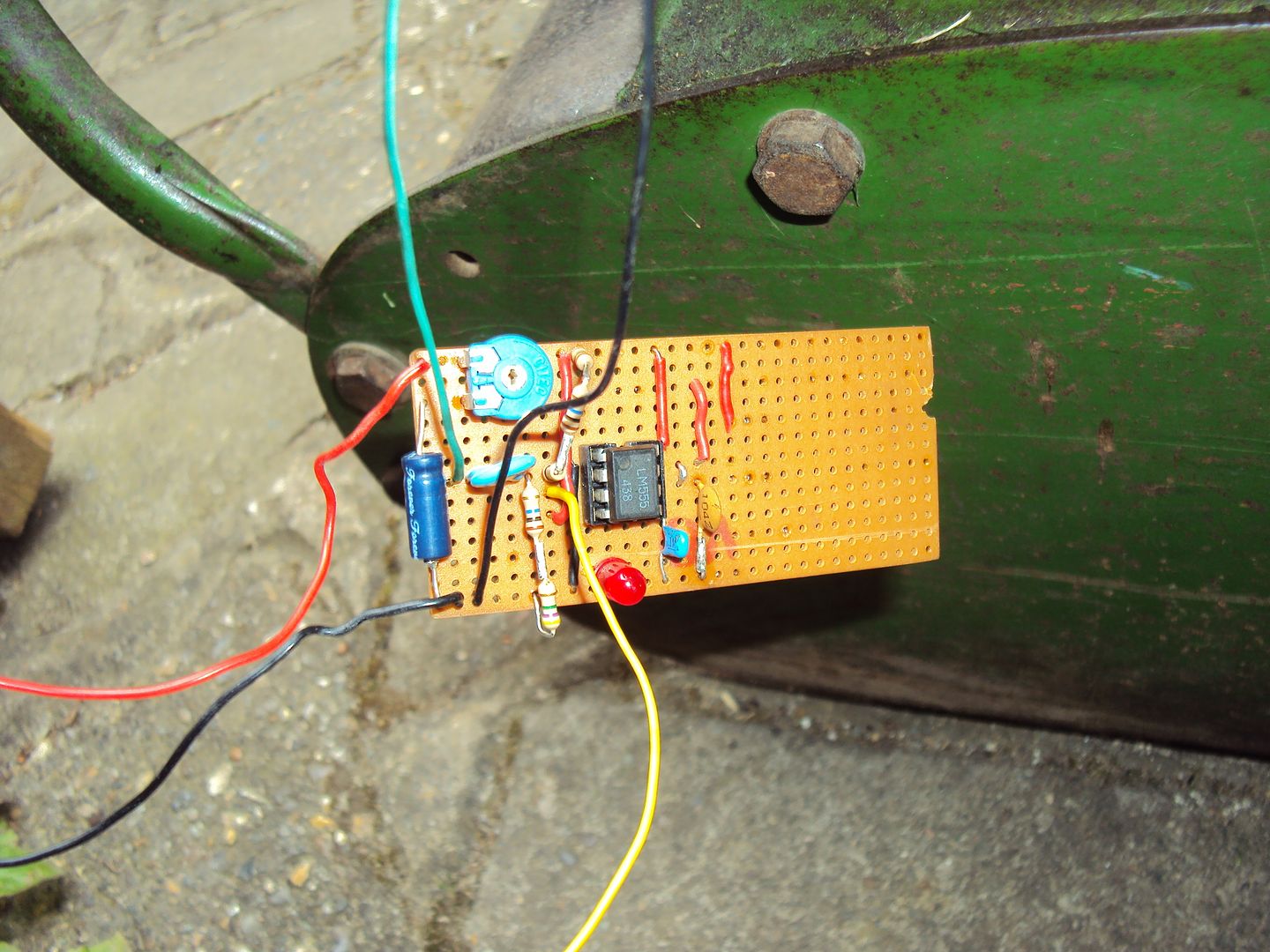

I have started building the tachometer, because the generator doesn’t use points I needed to build something that would pick up the spark and convert it into something I could feed into an Adruino.

After a bit of searching I found this: http://fly.srk.fer.hr/~wgottwe/e98a034.pdf and built the first part which is based around a 555 timer IC. The circuit uses a few turns of wire around the HT lead to pick up the spark pulse.

I constructed the circuit on strip board

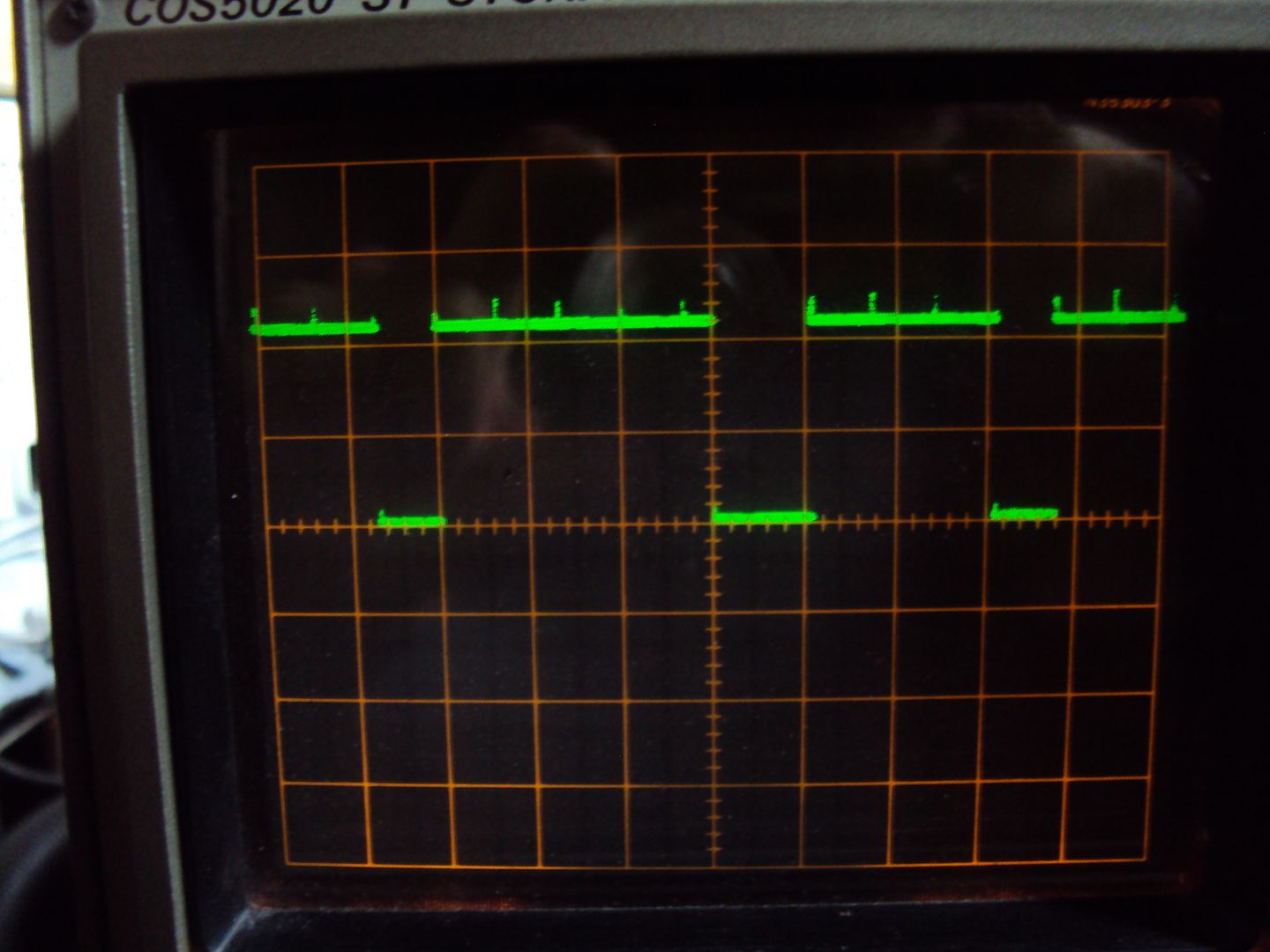

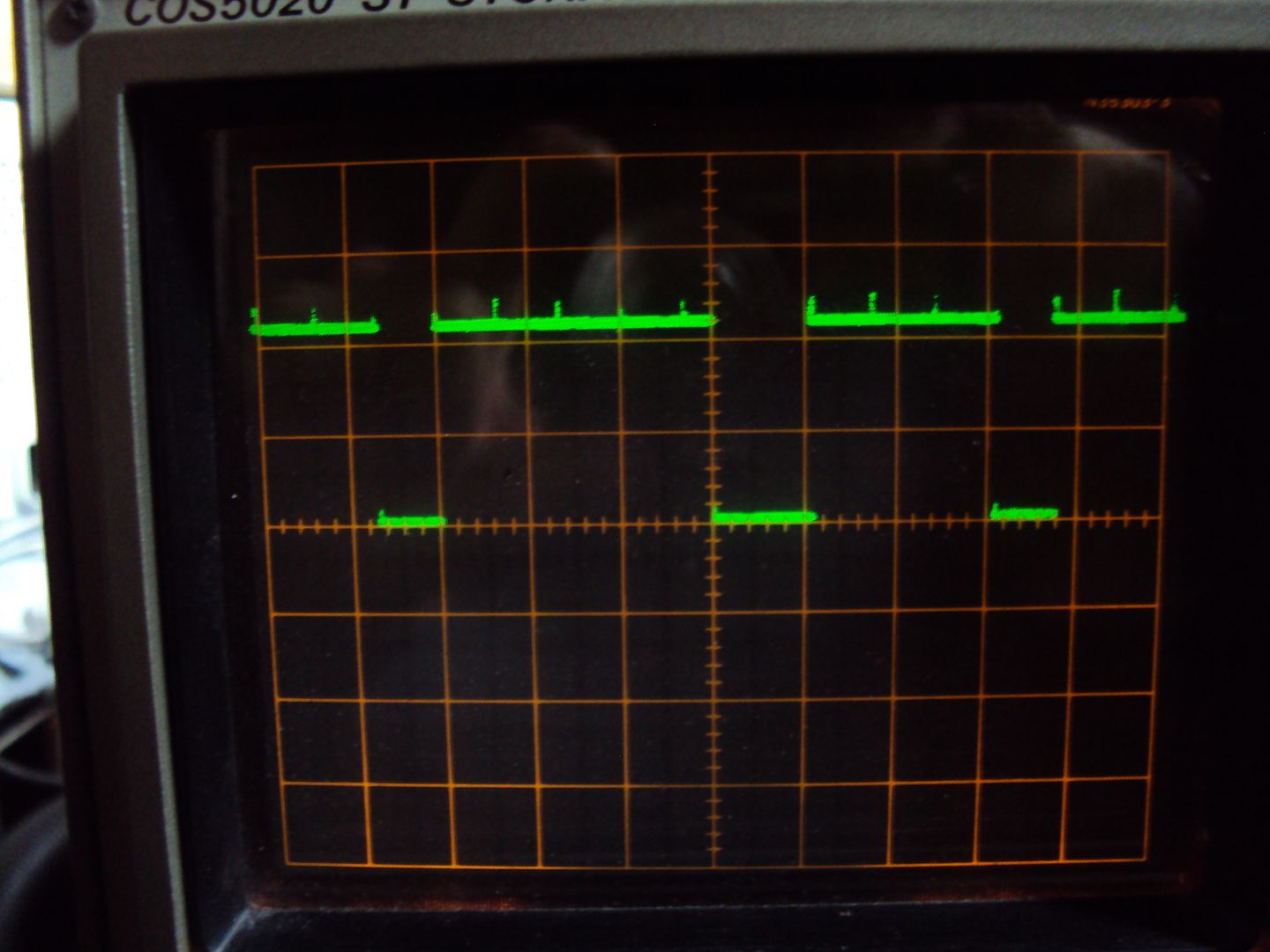

And tested on the lawnmower

Some nice microcontroller compatible pulses

All I need to do now is to write the code on the Adruino to count the pulses and calculate the RPM and display on a screen.

After a bit of searching I found this: http://fly.srk.fer.hr/~wgottwe/e98a034.pdf and built the first part which is based around a 555 timer IC. The circuit uses a few turns of wire around the HT lead to pick up the spark pulse.

I constructed the circuit on strip board

And tested on the lawnmower

Some nice microcontroller compatible pulses

All I need to do now is to write the code on the Adruino to count the pulses and calculate the RPM and display on a screen.

Not having much luck with the DIY tachometer (most likely my rubbish coding ) so decided to tackle the radiator as it has a couple of small cracks which are leaking.

) so decided to tackle the radiator as it has a couple of small cracks which are leaking.

When I removed the radiator I noticed there were bits of scale in the water (had flushed it through during the original strip down) so I broke out a birthday present from last year,

http://www.maplin.co.uk/p/handheld-video-optic-ins...

And had a look inside

Not looking too good so I decided to try some kettle de-scalier, after a couple of treatments it looked a lot better.

To repair the cracks I borrowed a 200w soldering ion from work (normal soldering ion on left)

Soldered up the cracks with plumbing solder.

I re-assembled everything and ran it up, and there were no leaks. Have since put some Holts speedflush in the cooling system to clean it up before re-filling with a 50/50 mix of anti freeze.

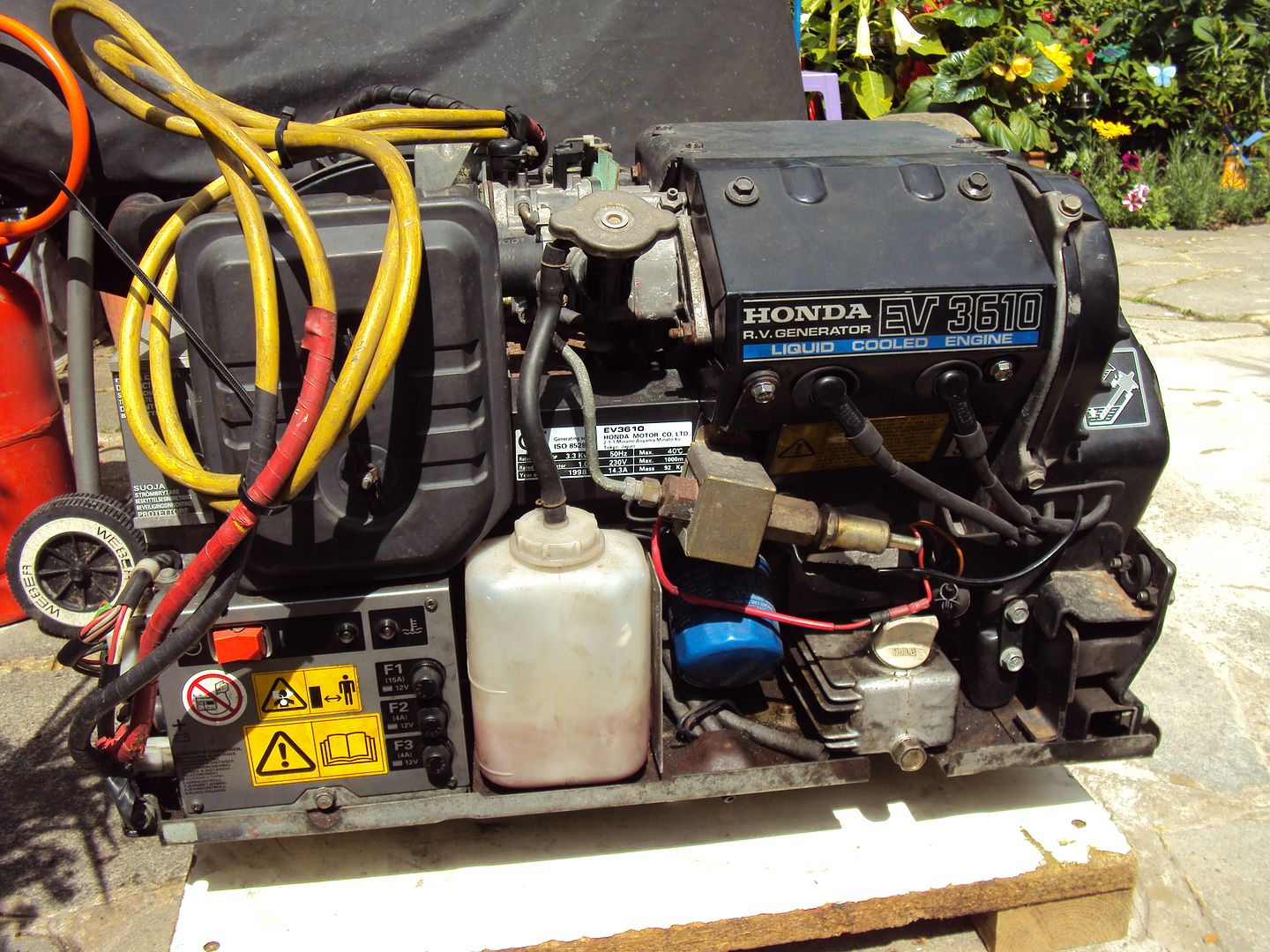

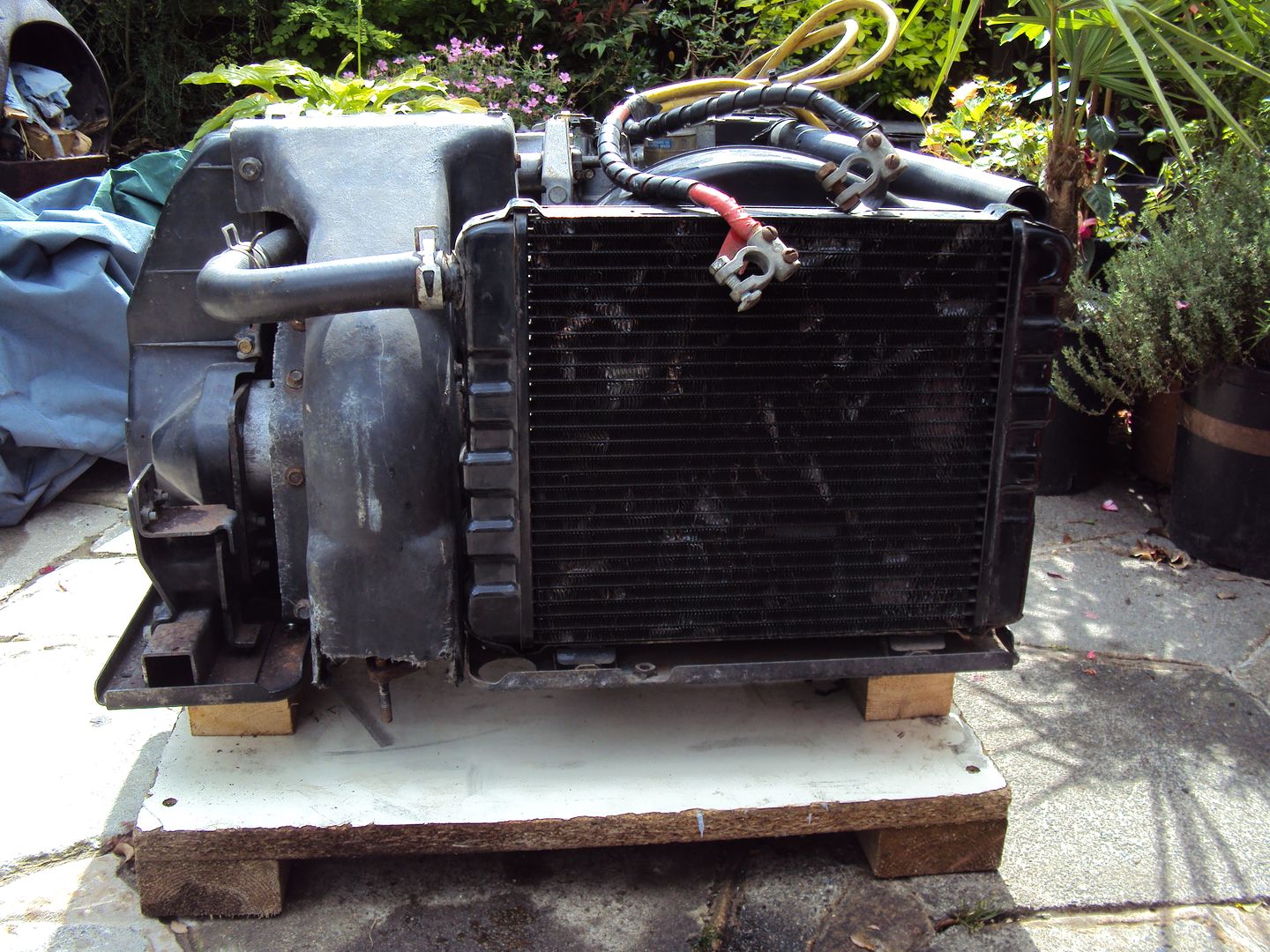

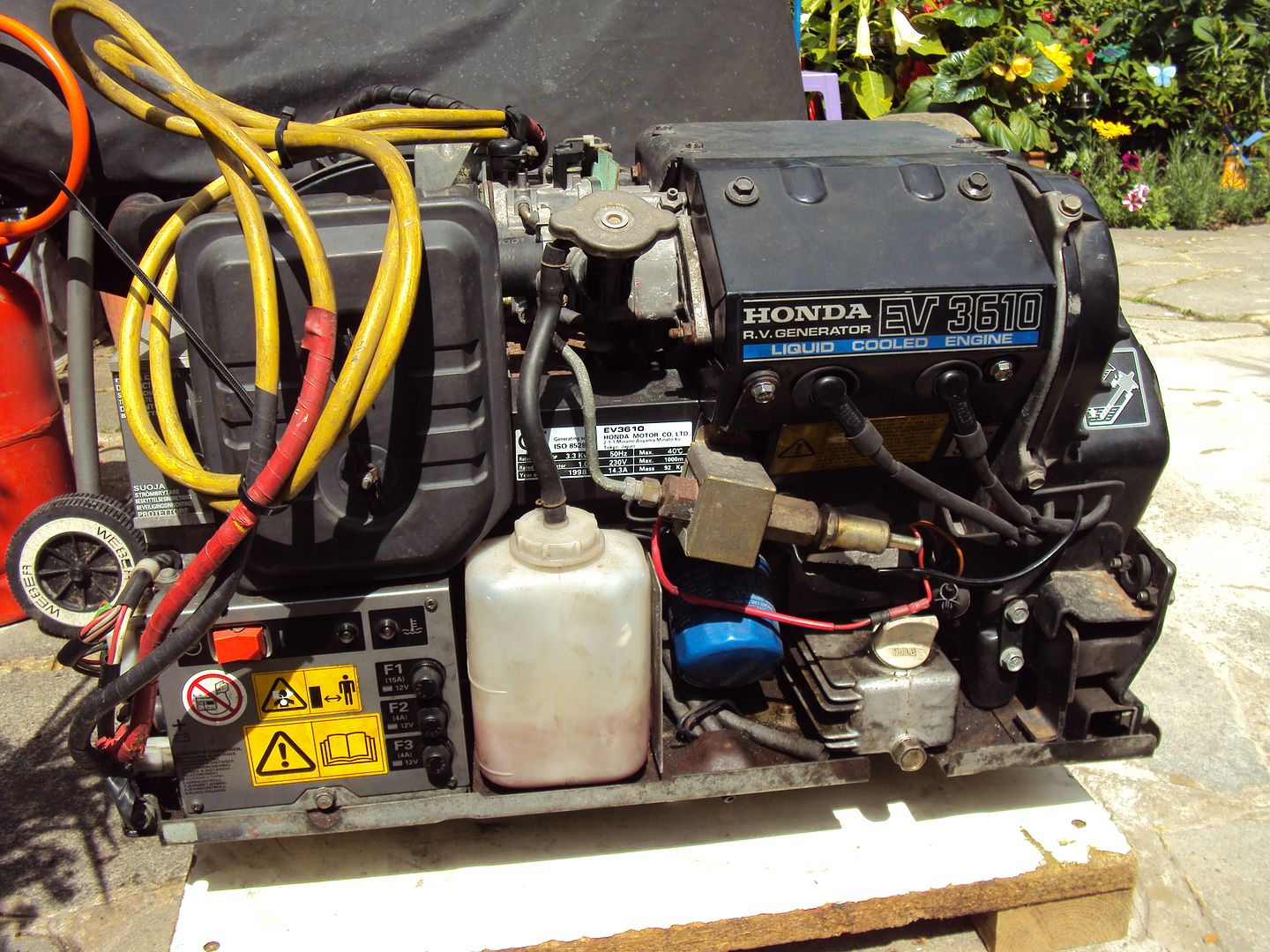

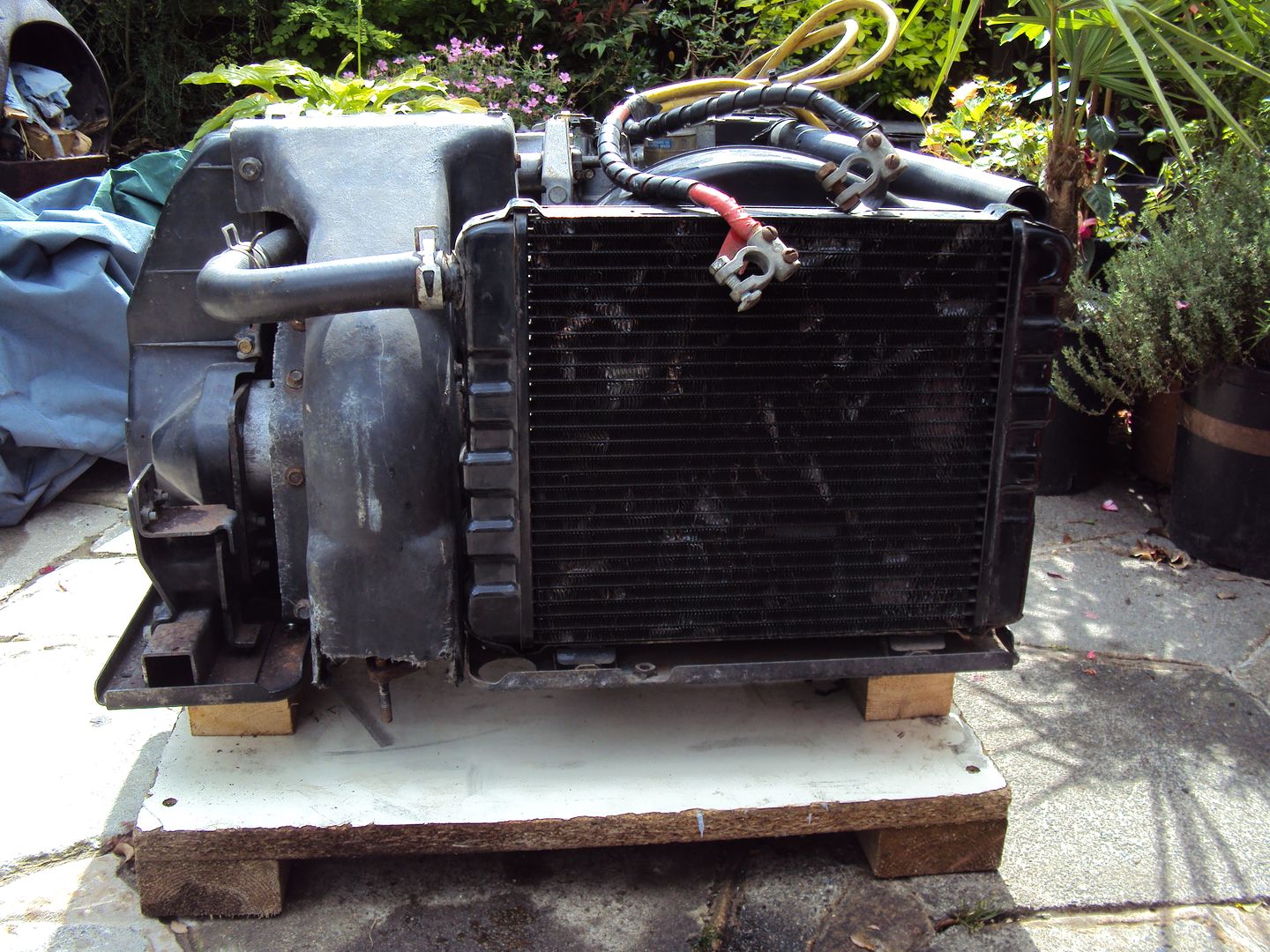

Whilst trawling ebay I found the next project which I picked up yesterday,

It is essentially the same, as ex5500 except it is for mounting in a motor home so doesn’t have the big case and fuel tank.

The fault with this one is that it will run for a while before cutting out. The seller told me that it has had a new cam belt and head gasket, after a quick inspection I could see new gaskets everywhere, so that’s good.

Hopefully it should be an easy fix, the plan is to check the obvious stuff first like the fuel pump and carburettor, if it’s not these it might be the oil pump again.

) so decided to tackle the radiator as it has a couple of small cracks which are leaking.

) so decided to tackle the radiator as it has a couple of small cracks which are leaking.

When I removed the radiator I noticed there were bits of scale in the water (had flushed it through during the original strip down) so I broke out a birthday present from last year,

http://www.maplin.co.uk/p/handheld-video-optic-ins...

And had a look inside

Not looking too good so I decided to try some kettle de-scalier, after a couple of treatments it looked a lot better.

To repair the cracks I borrowed a 200w soldering ion from work (normal soldering ion on left)

Soldered up the cracks with plumbing solder.

I re-assembled everything and ran it up, and there were no leaks. Have since put some Holts speedflush in the cooling system to clean it up before re-filling with a 50/50 mix of anti freeze.

Whilst trawling ebay I found the next project which I picked up yesterday,

It is essentially the same, as ex5500 except it is for mounting in a motor home so doesn’t have the big case and fuel tank.

The fault with this one is that it will run for a while before cutting out. The seller told me that it has had a new cam belt and head gasket, after a quick inspection I could see new gaskets everywhere, so that’s good.

Hopefully it should be an easy fix, the plan is to check the obvious stuff first like the fuel pump and carburettor, if it’s not these it might be the oil pump again.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff

The reading waggles around like a Mini speedometer.

The reading waggles around like a Mini speedometer.