The ebay generator restoration thread

Discussion

catfood12 said:

Good work OP, great thread too. I wish I had as much spare time as you.....

Do we have to buy them from ebay to qualify, and do they have to be broken ?

Thanks, I have only spent an hour or two in the evenings/weekends on these, it's just something to tinker with instead of watching rubbish TV.

Do we have to buy them from ebay to qualify, and do they have to be broken ?

They don't have to be broken, but working ones are not much of a challenge

Thought I should update progress,

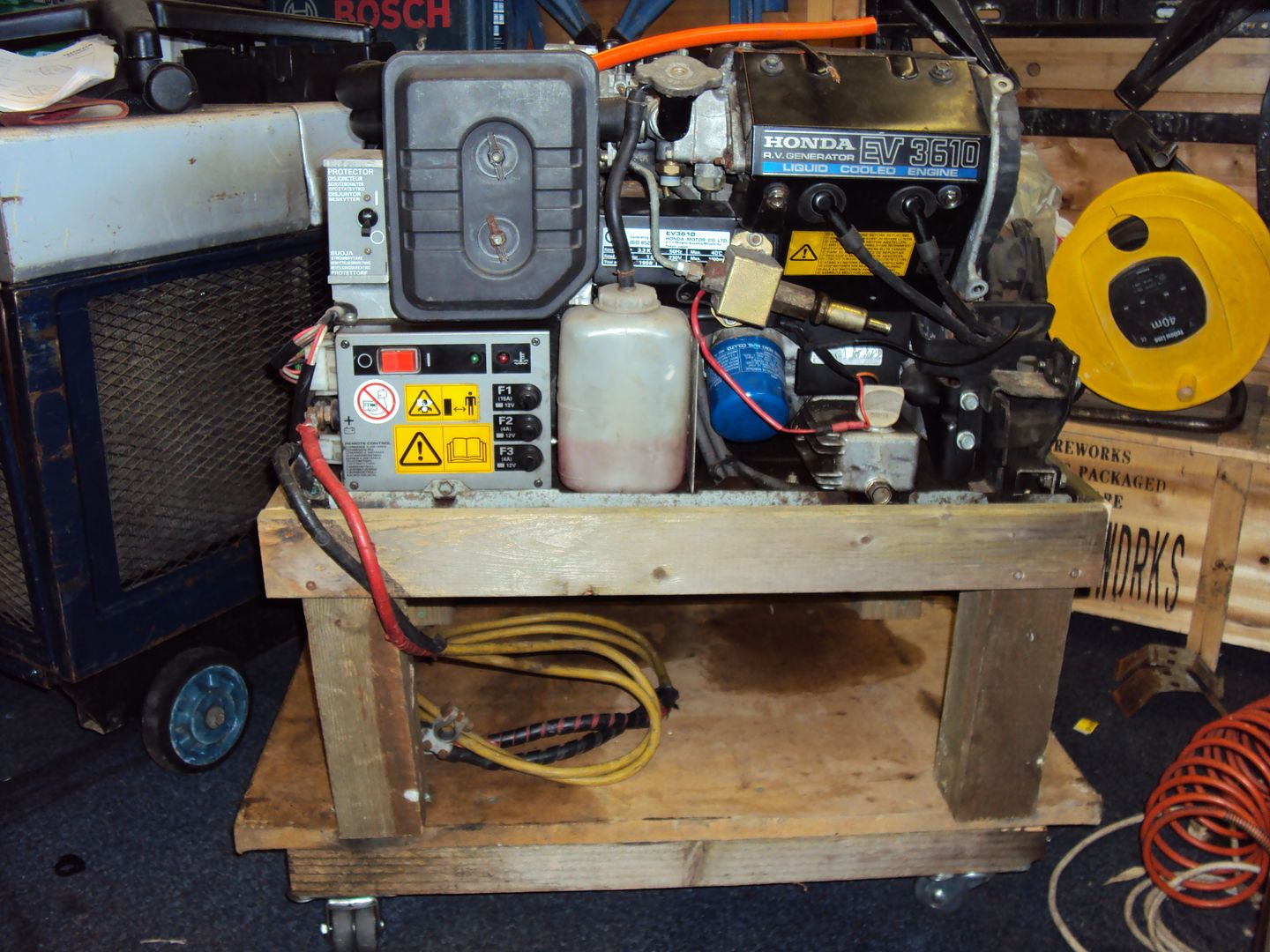

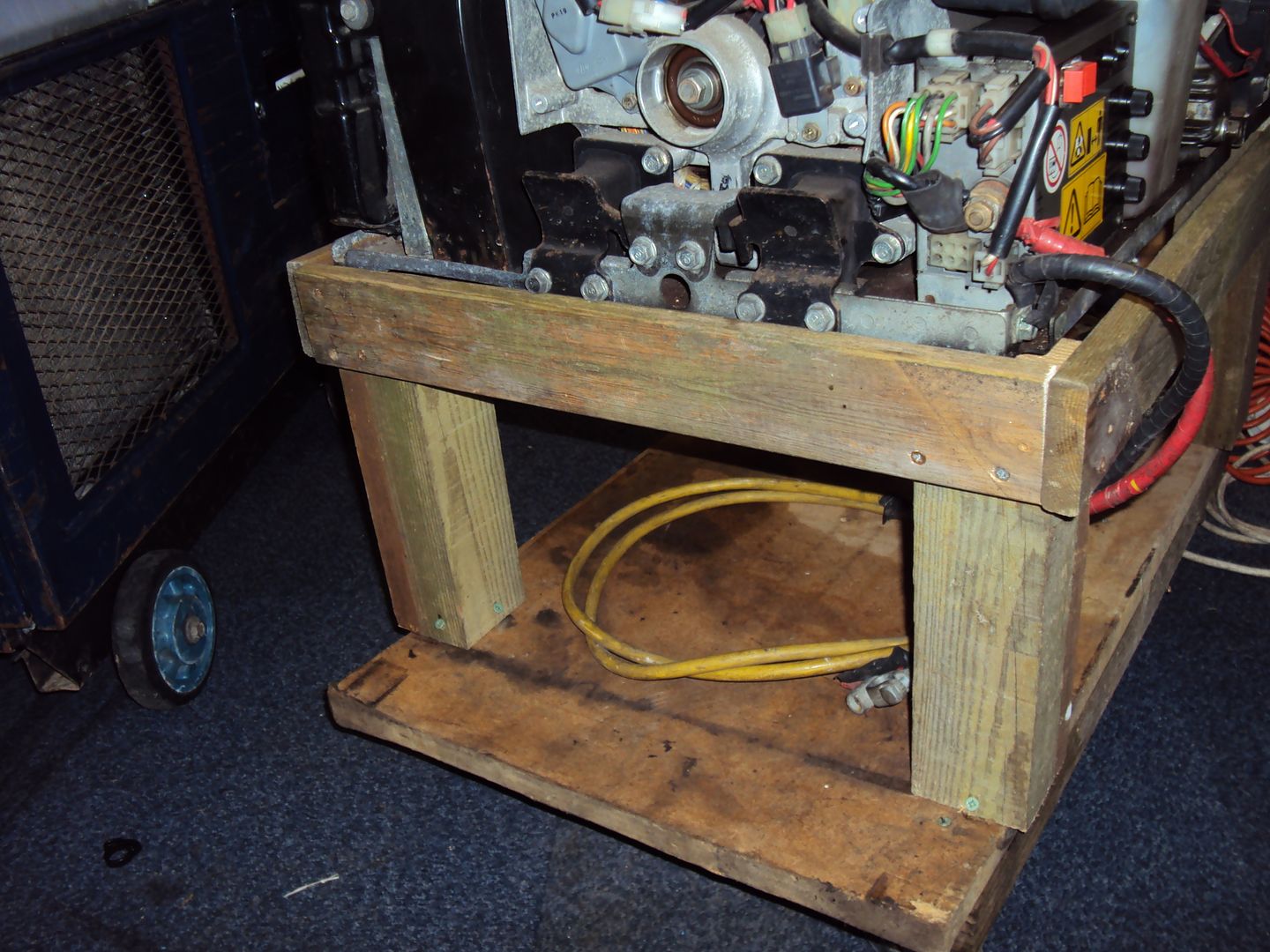

I started by building a stand for the generator as it needed to be raised up as the exhaust goes through the base and out the bottom.

Norm Abram would be proud

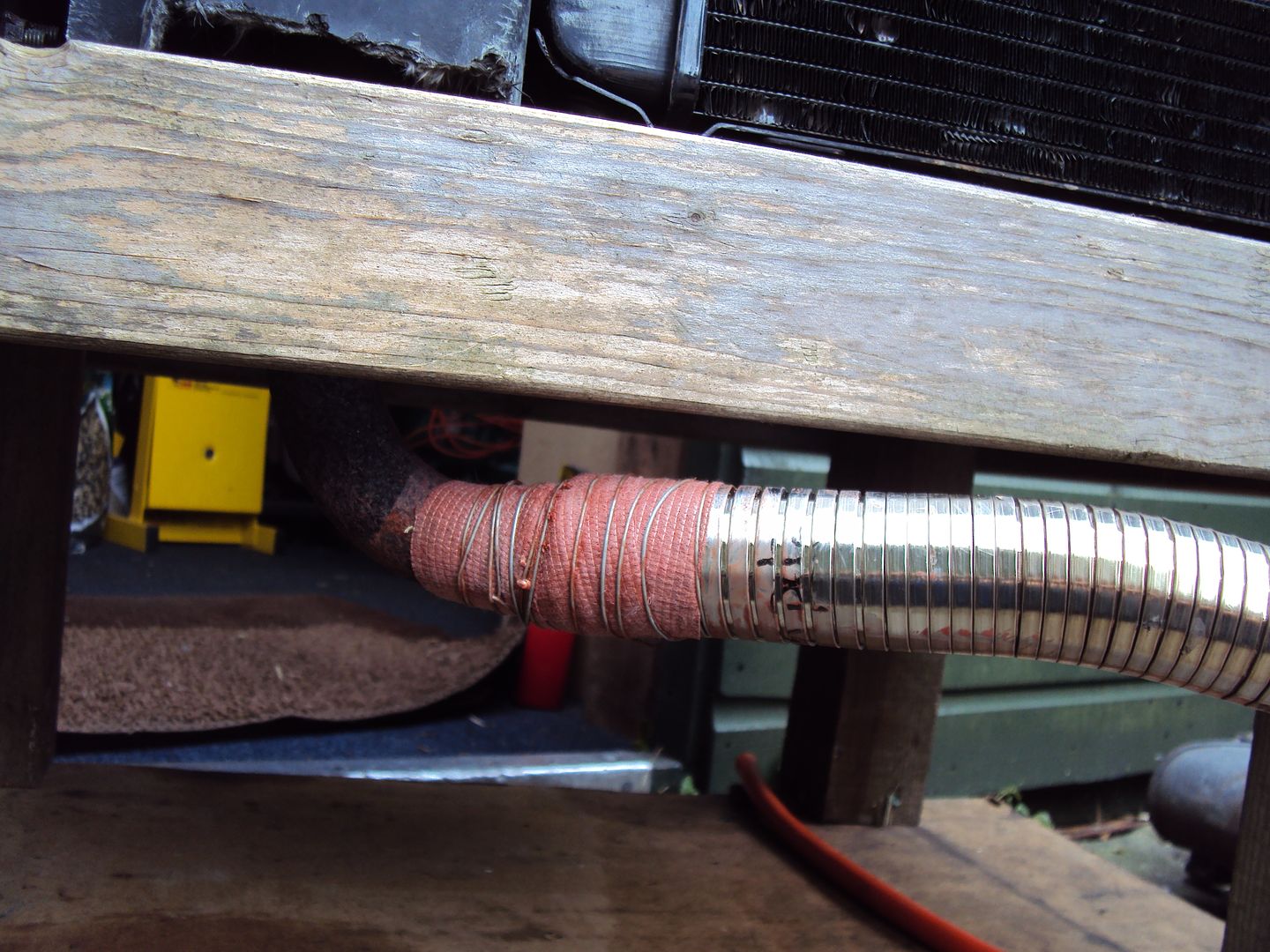

Next I hooked up the exhaust, had to buy some stainless steel flexi tube to connect the silencer to the engine

As I don’t have a welder I used some Gun Gum tape to seal the joints.

When I tried starting the engine it would run for a second or two with misfiring before cutting out. I took the spark plugs out and cleaned them, which cured the misfire.

After a quick clean with a wire brush

After some further testing I was able to get the engine to run by hotwiring the fuel pump and disconnection the kill line to the magneto.

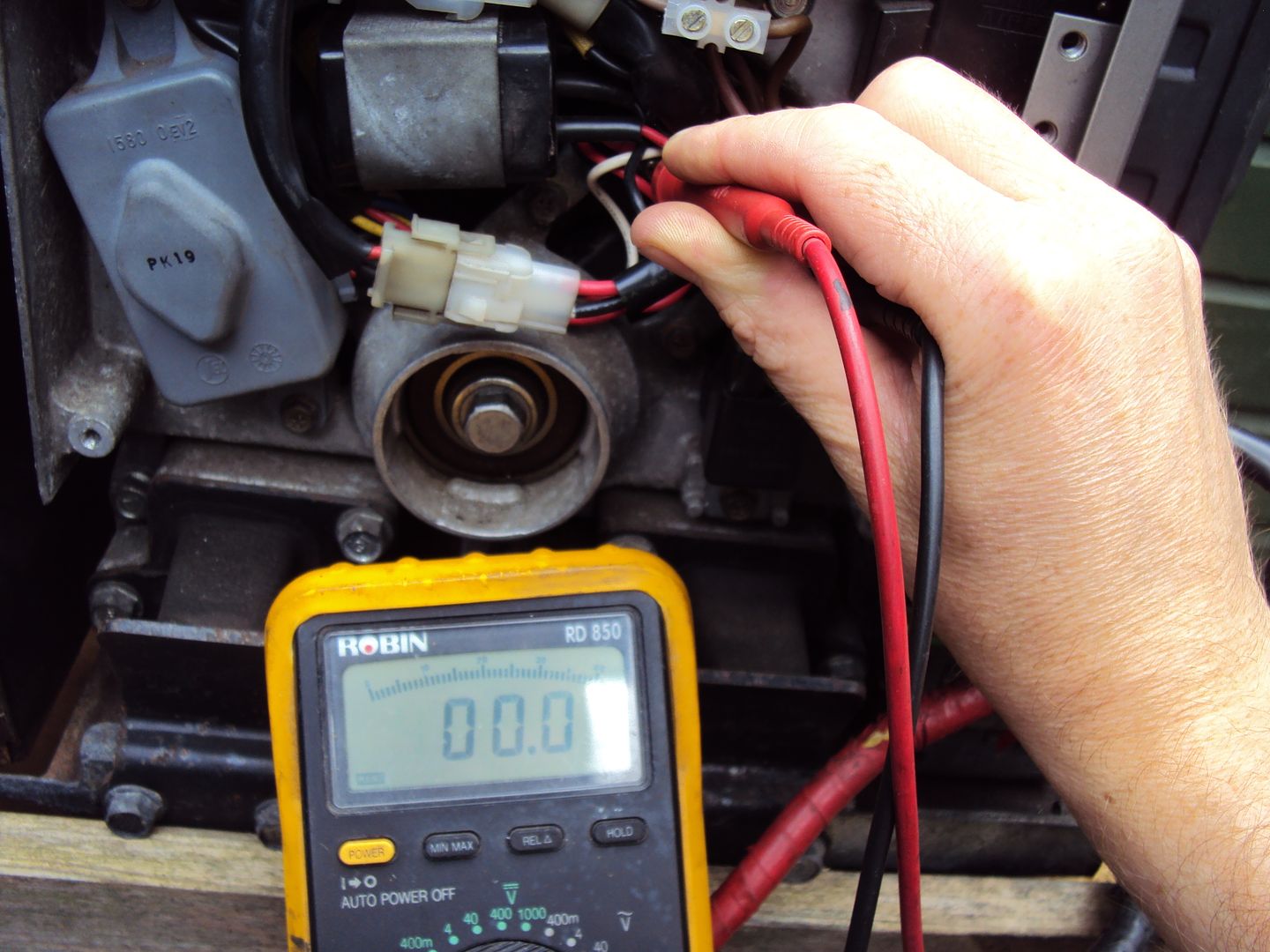

With the engine running I could test the alternator, which initially had no output. The next step was to check all the connections and the resistance of the windings.

The alternator has 3 sets of windings, the main windings that make the 240V and 2 sets of sub windings.

The main winding resistance appeared to be ok, was about the same as the EX5500

Main winding resistance

The sub windings had a similar value, not sure if this was right or not but at least they weren’t shot/open circuit.

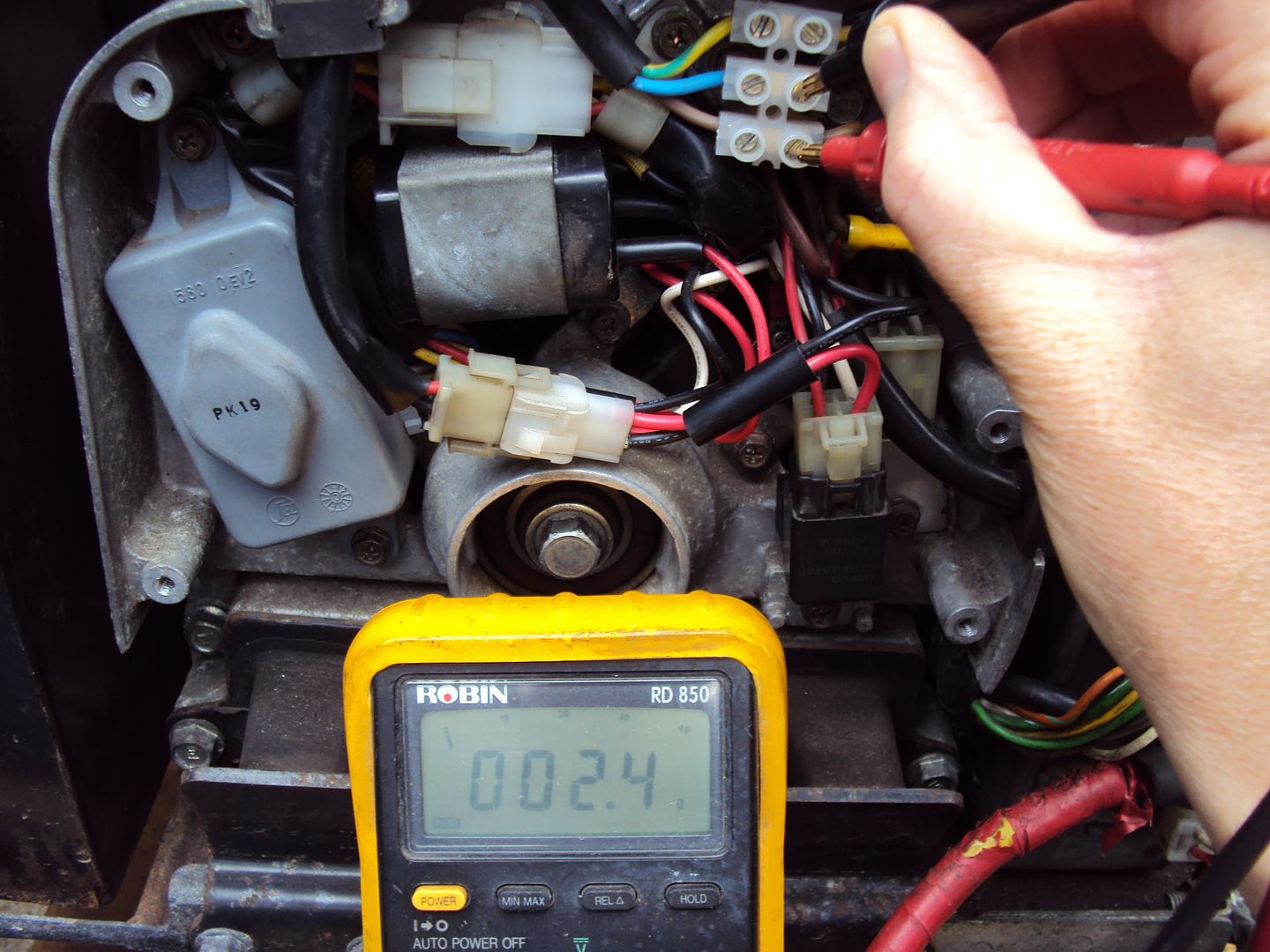

The next thing to check was the “rotor” (bit that spins inside the alternator), during starting a voltage is applied to the rotor to “excite” the main windings.

Once running the AVR (Automatic Voltage Regulator) which is the grey rectangular box with the diamond shaped bit applies a voltage to the rotor to maintain the output voltage. The AVR varies the voltage based on the load.

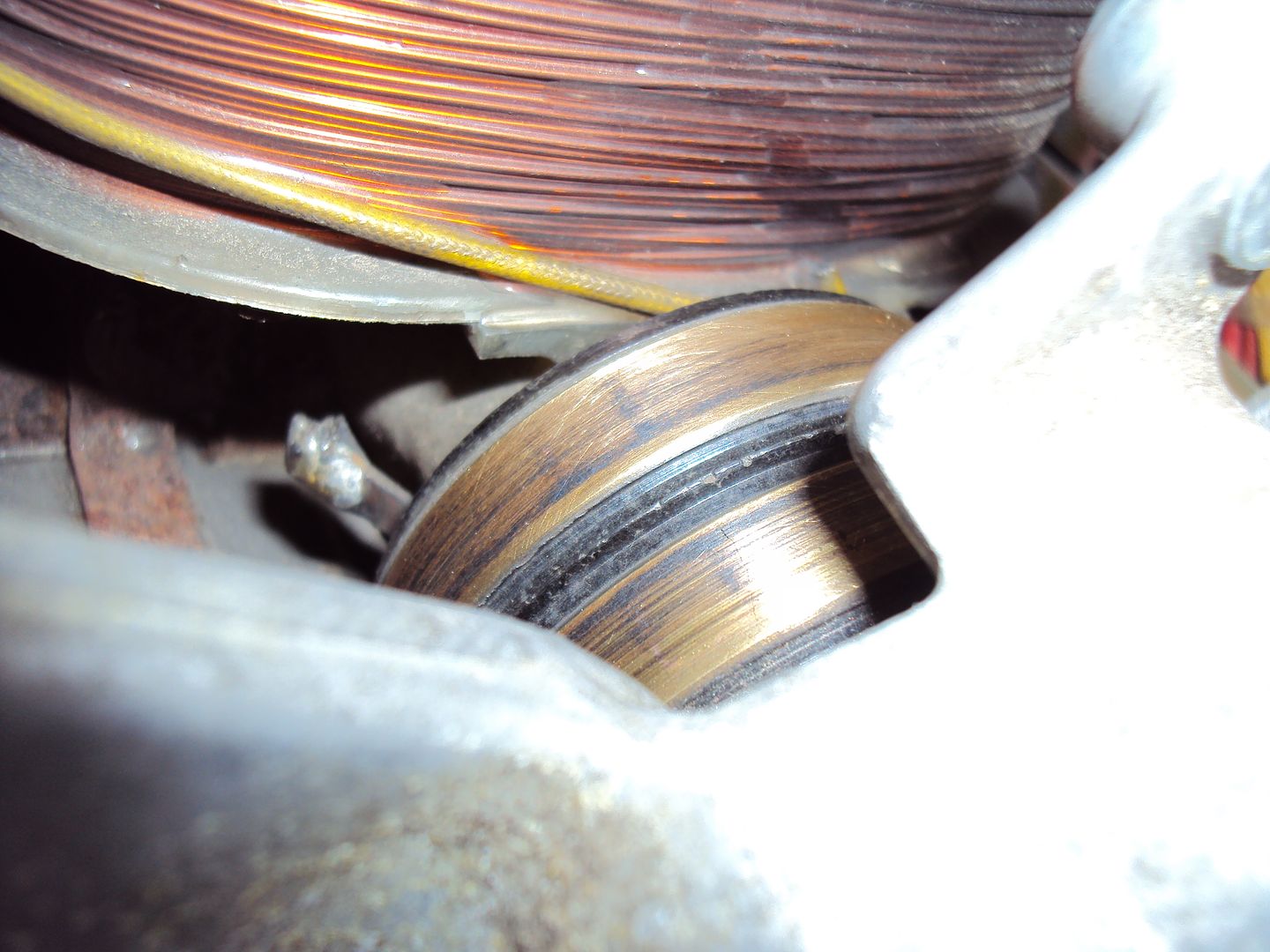

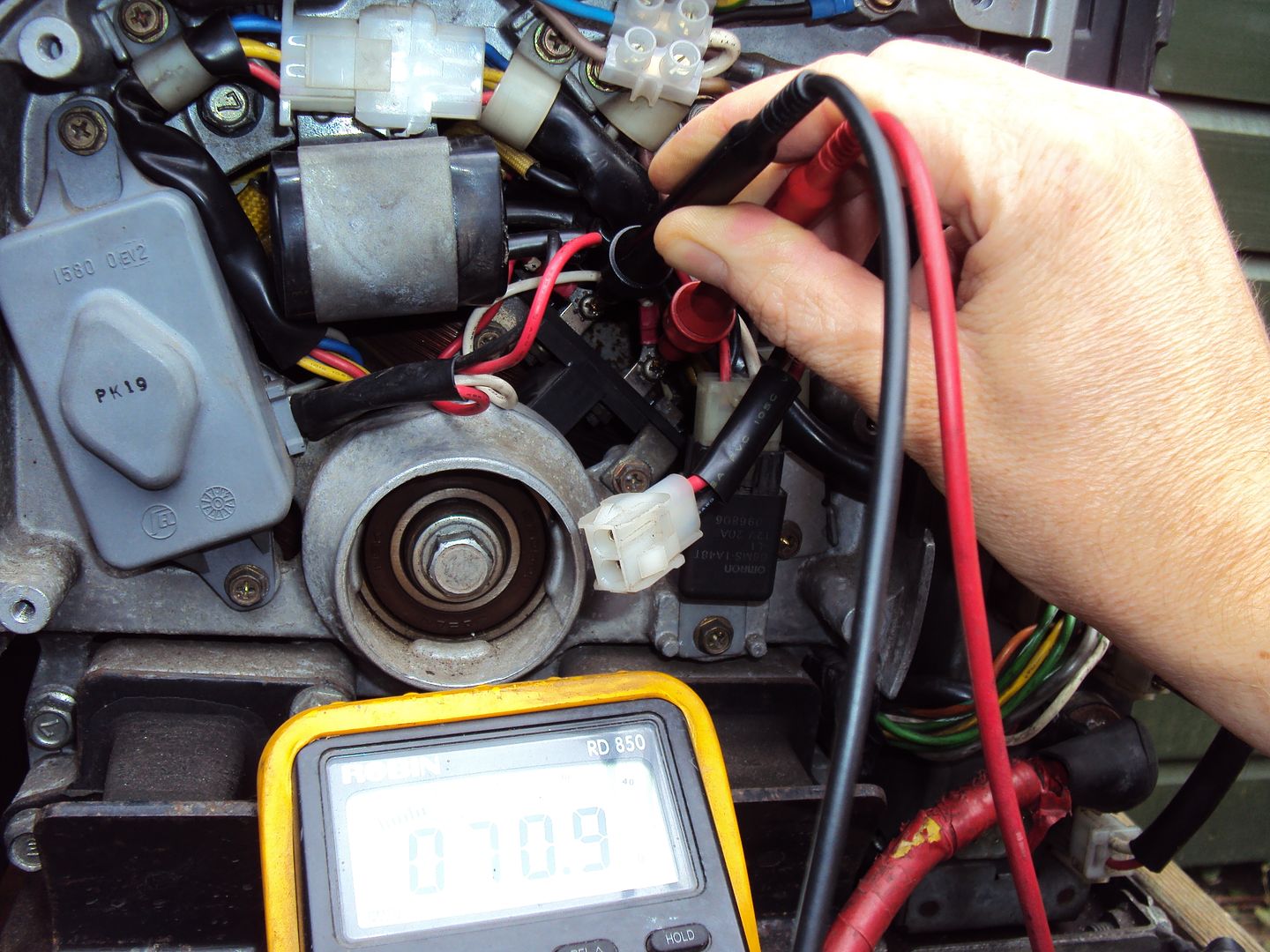

The rotor is connected via carbon brushes which run on brass slip rings, on testing the resistance was very high in the 100’s of ohms when it should be around 60 ohm.

The reading is not 0 ohm, there is a 4 flashing to show it is exceeding the range, couldn’t get the camera to pick it up.

I removed the brushes and inspected the slip rings, which were completely black with dirt (didn’t get a picture). The slip rings were cleaned with a scotch bright cloth.

During

After

Resistance after cleaning

After putting everything back together, I started the engine and it worked

. It turns out that the control unit was detecting the alternator wasn’t working properly so was shutting the engine down.

. It turns out that the control unit was detecting the alternator wasn’t working properly so was shutting the engine down. Have now had it running for over an hour powering various things with no problems at all.

If I hadn’t needed to buy the bits for the exhaust, the repair cost would have been £0.00

Next step is to give it a clean as the chassis is a bit oily, once that’s done it will be sold (for a profit hopefully) and keep an eye out foe the next project.

Edited by Blue32 on Tuesday 5th August 17:58

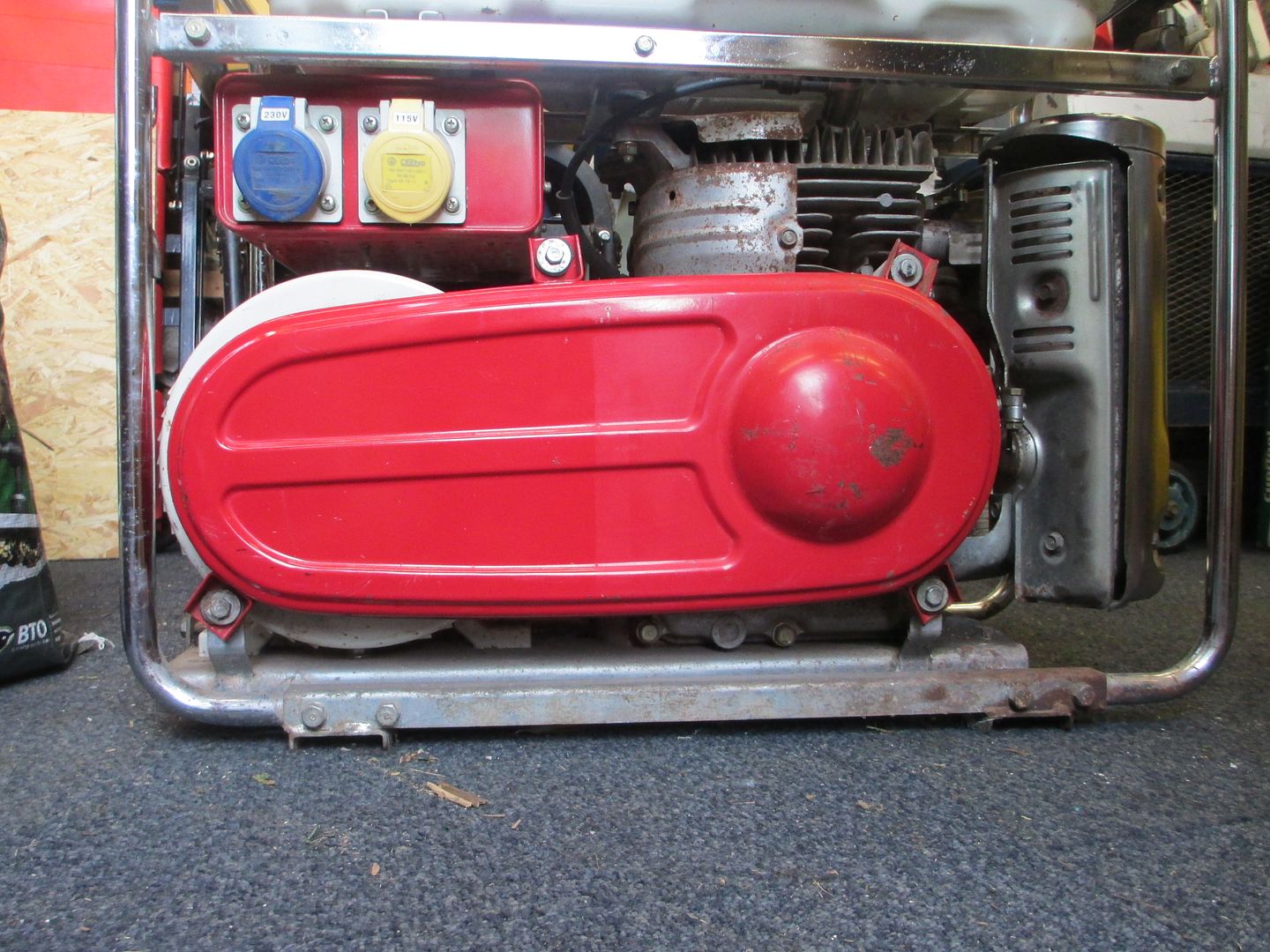

I sold the Honda motorhome generator last week, and used some of the profits to purchase the next project. This time I went for a suitcase type generator (wanted something which doesn’t need 2 people to move)

The fault with this one was that it wouldn’t start, so I started with the obvious things like checking for spark and there is fuel in it as there isn’t much else that can go wrong. The spark was good, however there wasn’t any fuel getting to the carburettor.

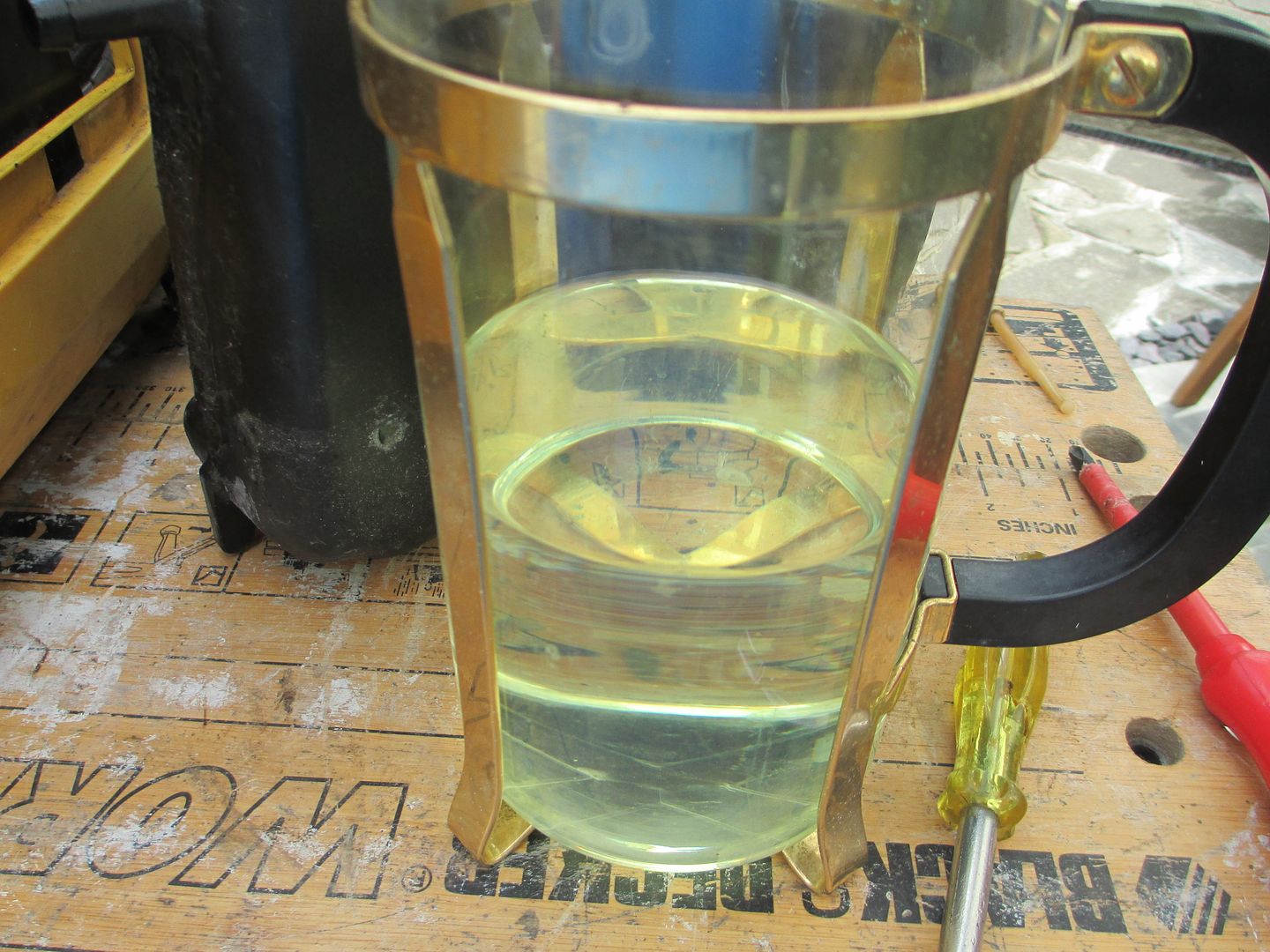

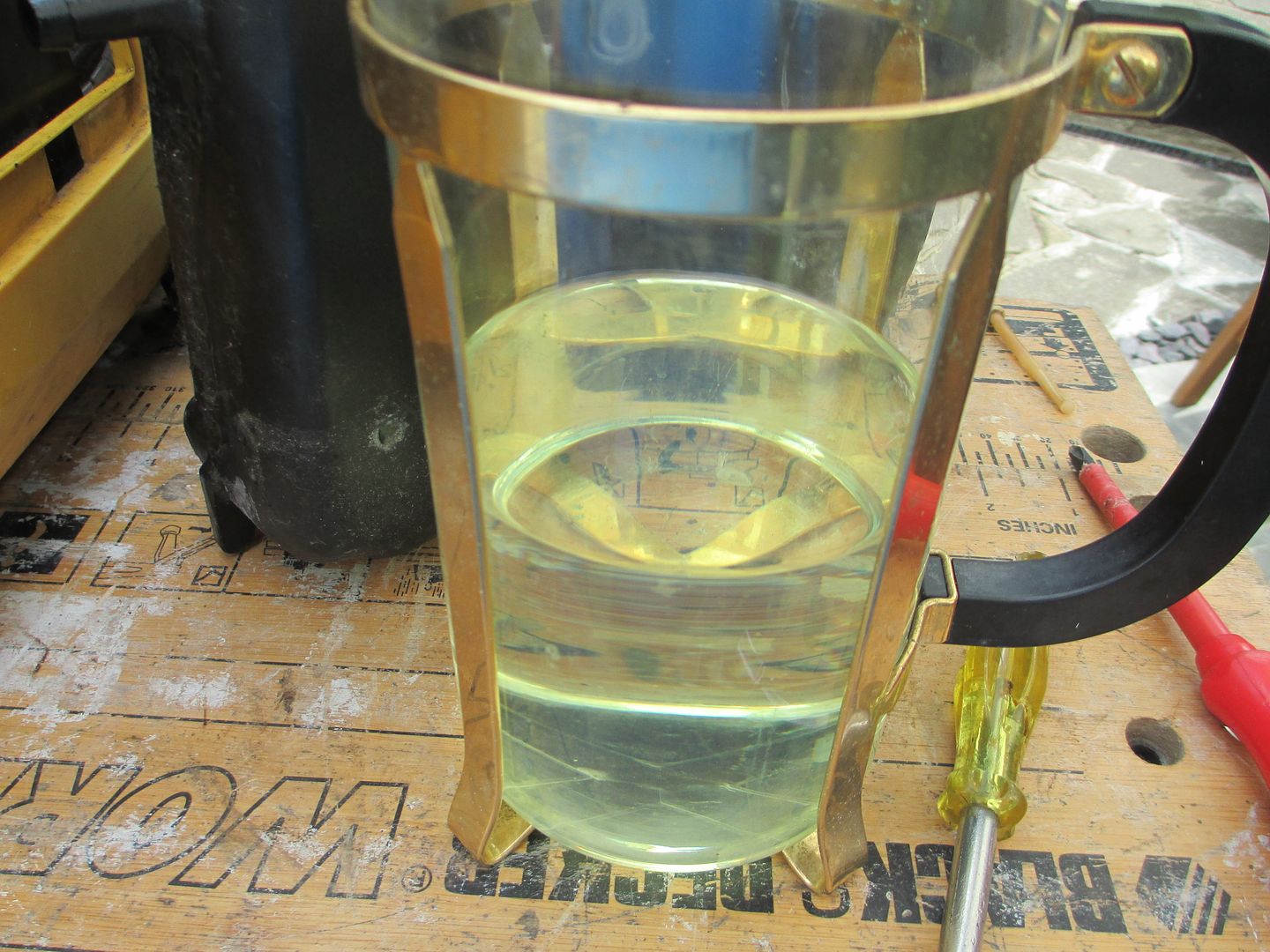

I removed the fuel tank and drained it into a jug, as I thought the in-line fuel filter might be blocked

I’m sure petrol shouldn’t be that colour!

The fuel filter is held in the fuel pipe, the filter didn’t look too bad.

I cleaned the filter and put some fresh petrol in the tank

And after a fuel pulls it spluttered in to life , so all it needed was fresh fuel. I like these zero cost fixes

, so all it needed was fresh fuel. I like these zero cost fixes .

.

Once it had been running for a while I thought it would be good to change the oil as I don’t know how old it is.

Top Tip (ala Edd China) use a bit of card to direct the oil out of the case. (sorry for the out of focus photo)

If you don’t the oil will spill inside and run down the front of the case and all over the bench. (I found out the hard way, hot engine oil moves very quickly)

The oil was quite black, (not brown like the photo)

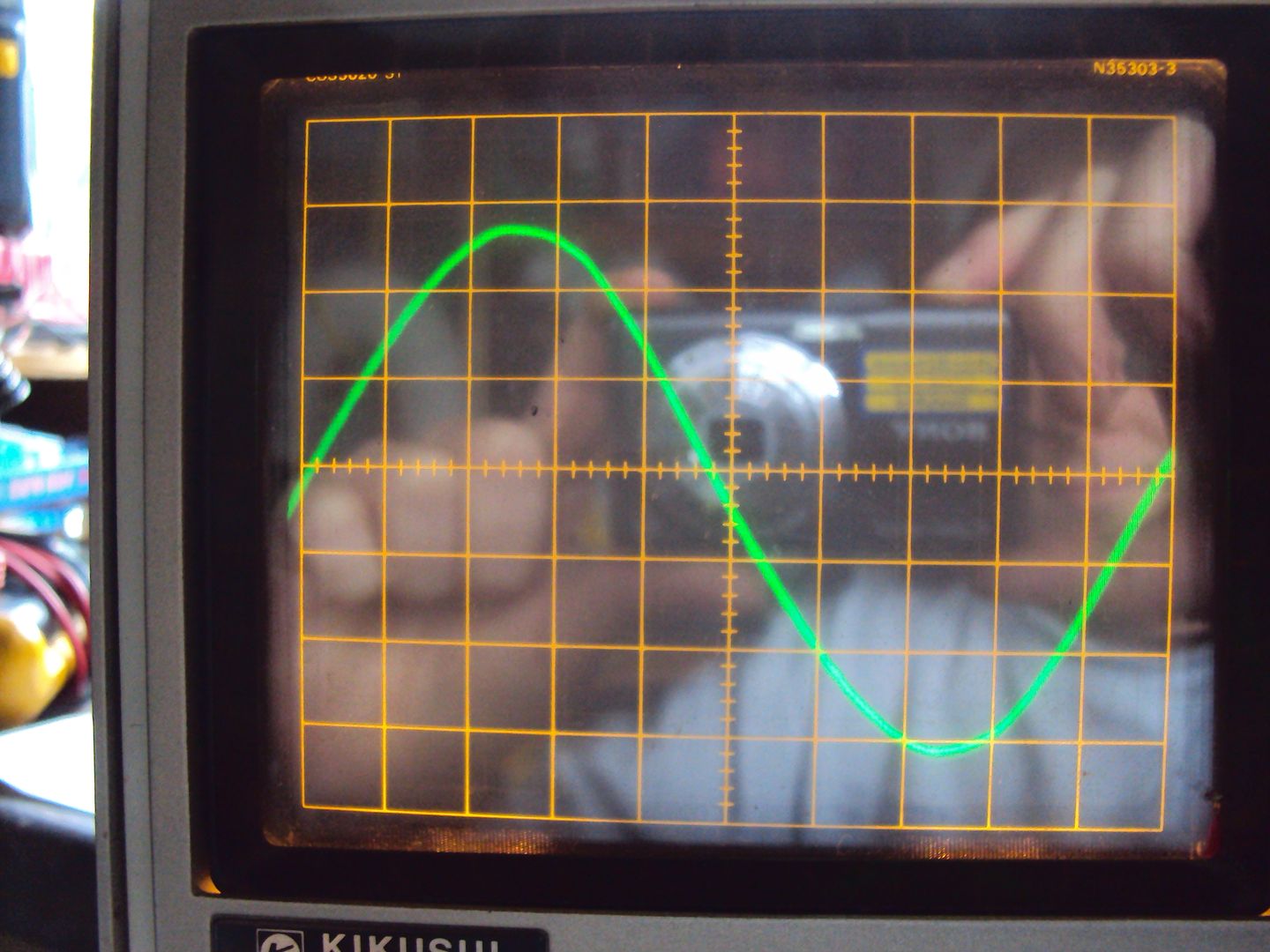

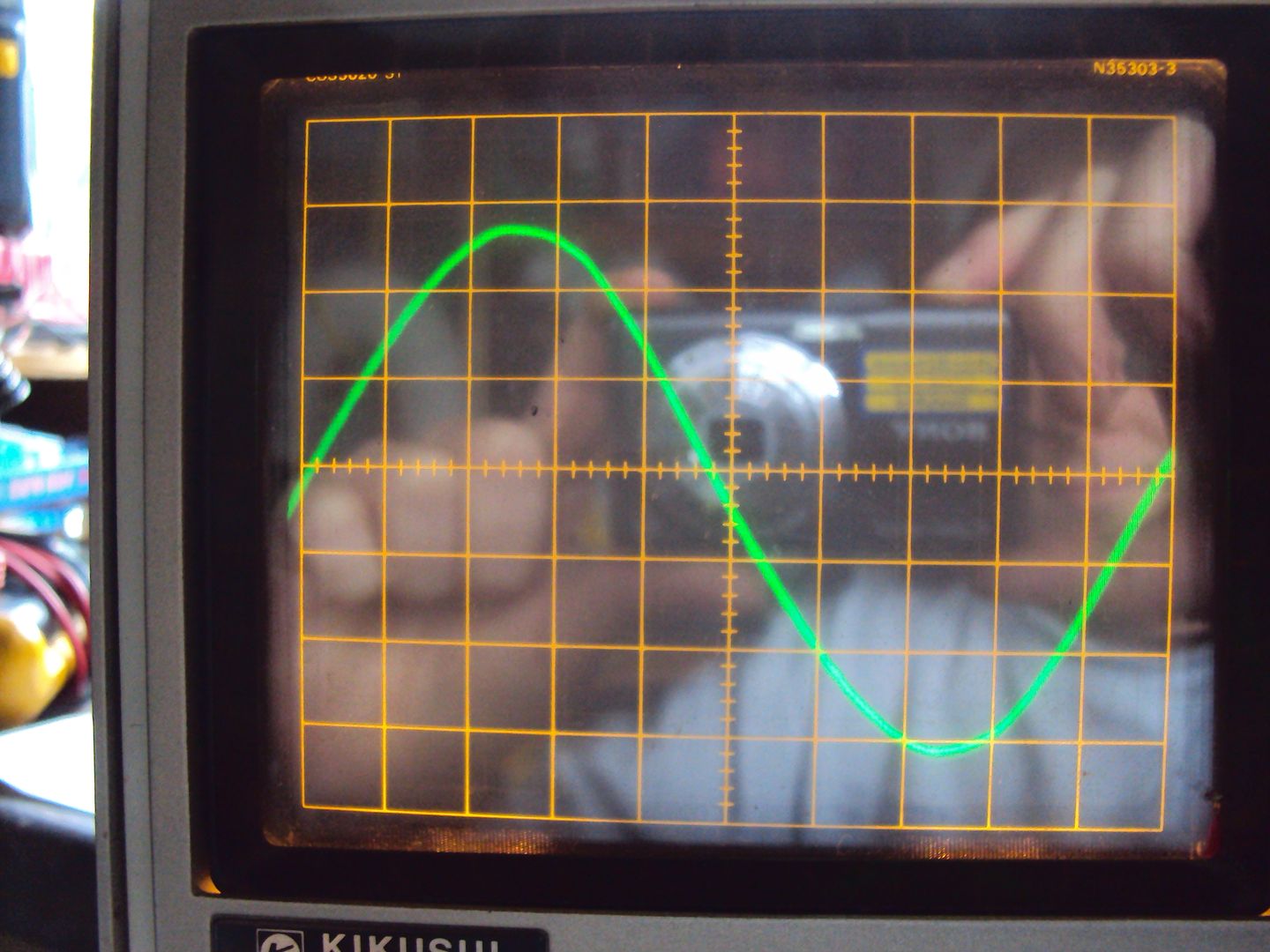

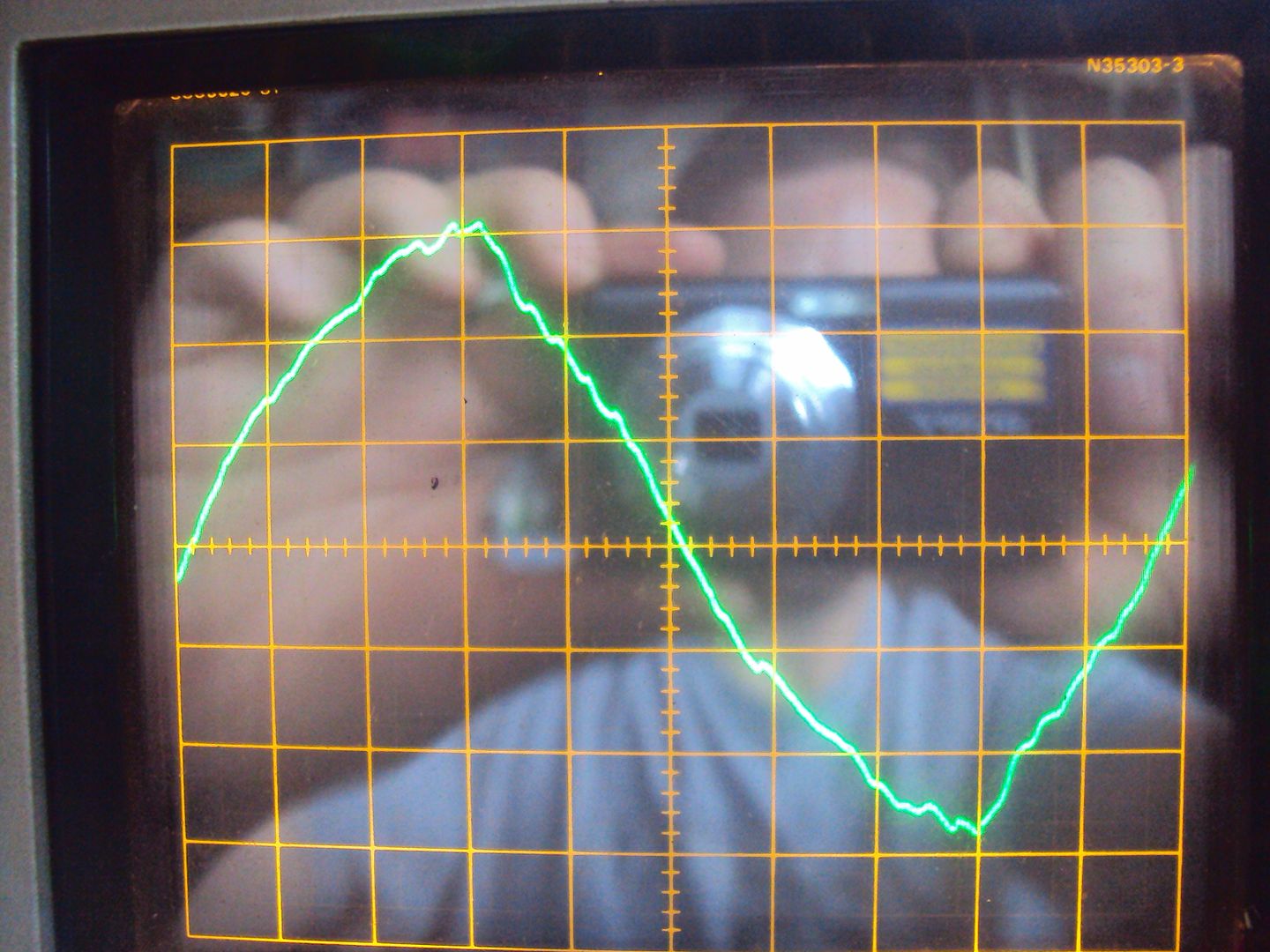

Once fresh oil was added I started it up and hooked it up to the oscilloscope just to see what the output was like.

spot on 50HZ

This generator is an inverter type, the alternator puts out 3 phase (I think) which is converted to DC, then back to AC using electronics. This gives a nice clean AC signal which is why this type of generator is good for use with sensitive electronics.

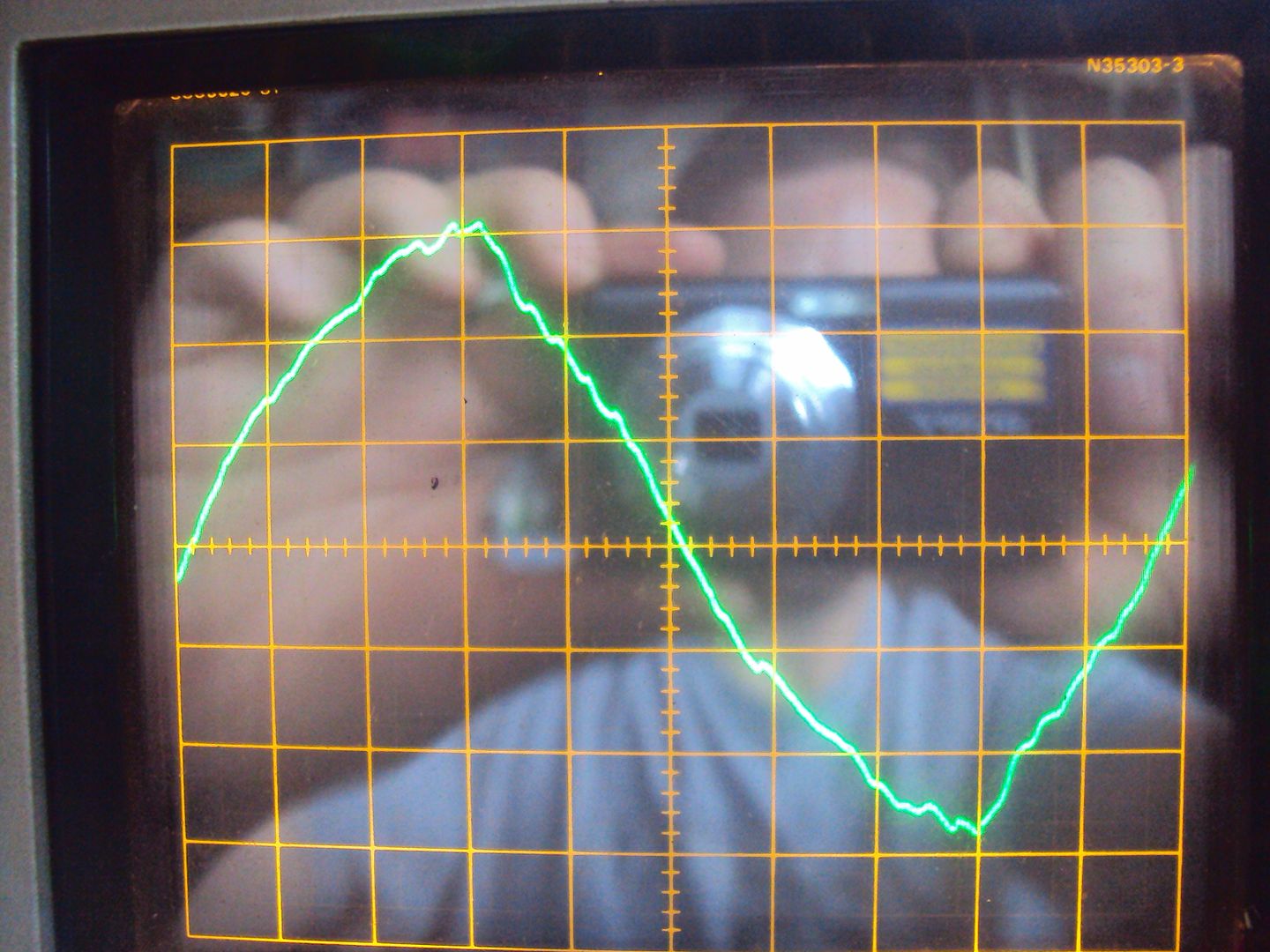

For reference this it the output of the Big Honda I started this thread with.

The fault with this one was that it wouldn’t start, so I started with the obvious things like checking for spark and there is fuel in it as there isn’t much else that can go wrong. The spark was good, however there wasn’t any fuel getting to the carburettor.

I removed the fuel tank and drained it into a jug, as I thought the in-line fuel filter might be blocked

I’m sure petrol shouldn’t be that colour!

The fuel filter is held in the fuel pipe, the filter didn’t look too bad.

I cleaned the filter and put some fresh petrol in the tank

And after a fuel pulls it spluttered in to life

, so all it needed was fresh fuel. I like these zero cost fixes

, so all it needed was fresh fuel. I like these zero cost fixes .

.Once it had been running for a while I thought it would be good to change the oil as I don’t know how old it is.

Top Tip (ala Edd China) use a bit of card to direct the oil out of the case. (sorry for the out of focus photo)

If you don’t the oil will spill inside and run down the front of the case and all over the bench. (I found out the hard way, hot engine oil moves very quickly)

The oil was quite black, (not brown like the photo)

Once fresh oil was added I started it up and hooked it up to the oscilloscope just to see what the output was like.

spot on 50HZ

This generator is an inverter type, the alternator puts out 3 phase (I think) which is converted to DC, then back to AC using electronics. This gives a nice clean AC signal which is why this type of generator is good for use with sensitive electronics.

For reference this it the output of the Big Honda I started this thread with.

[quote=Blue32]I have started building the tachometer, because the generator doesn’t use points I needed to build something that would pick up the spark and convert it into something I could feed into an Adruino.

you can buy a frequency meter for a few quid (240VAC), speed is directly related to Hz. they are normally dual scaled speed and frequency.

you can also get tachos that run off the charge alt (d connection).

you can buy a frequency meter for a few quid (240VAC), speed is directly related to Hz. they are normally dual scaled speed and frequency.

you can also get tachos that run off the charge alt (d connection).

We went a bit mad over the bank holiday weekend and bought 2 more generators. The first was another Kipor suitcase identical to the last one. The description of the fault was:

“Engine will not run. It starts, splutters and stops - and very often will not start at all. I have no idea what is wrong, nor if it will generate once the engine is running.”

I took a chance thinking it was the stepper motor which operates the throttle as this is the most likely cause.

On disassembly we found the fuel pipe from the tank had a kink preventing the fuel from flowing

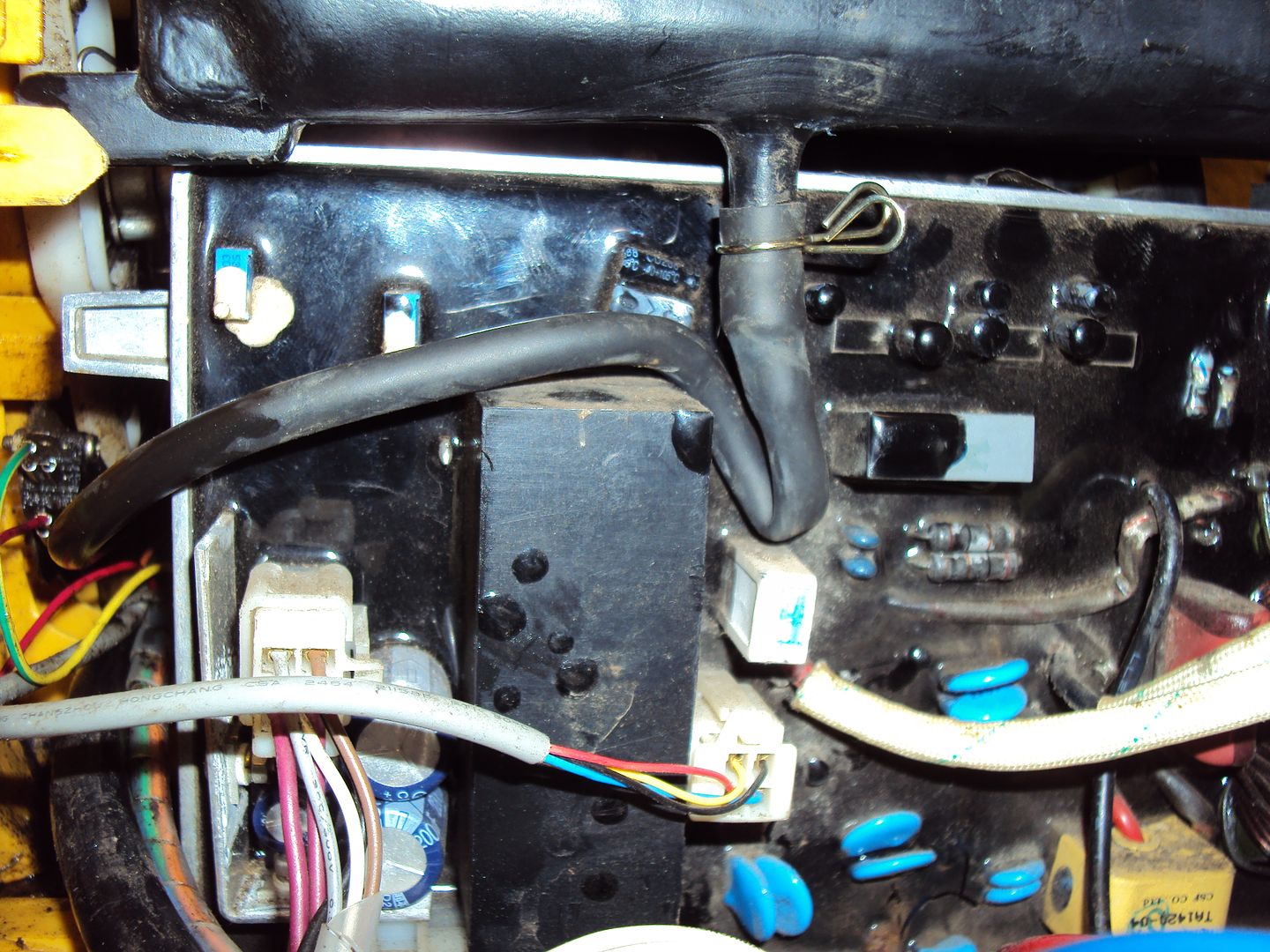

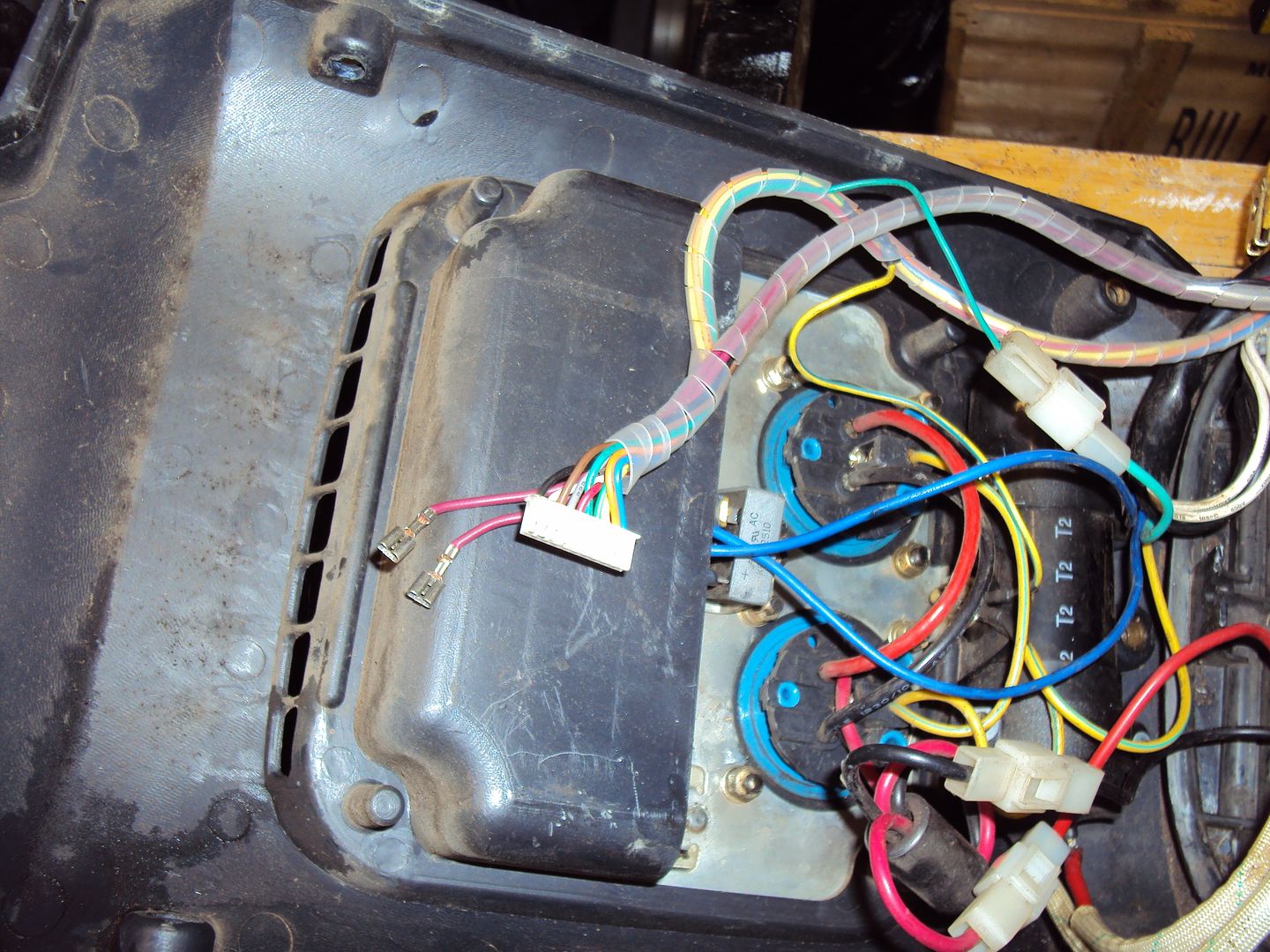

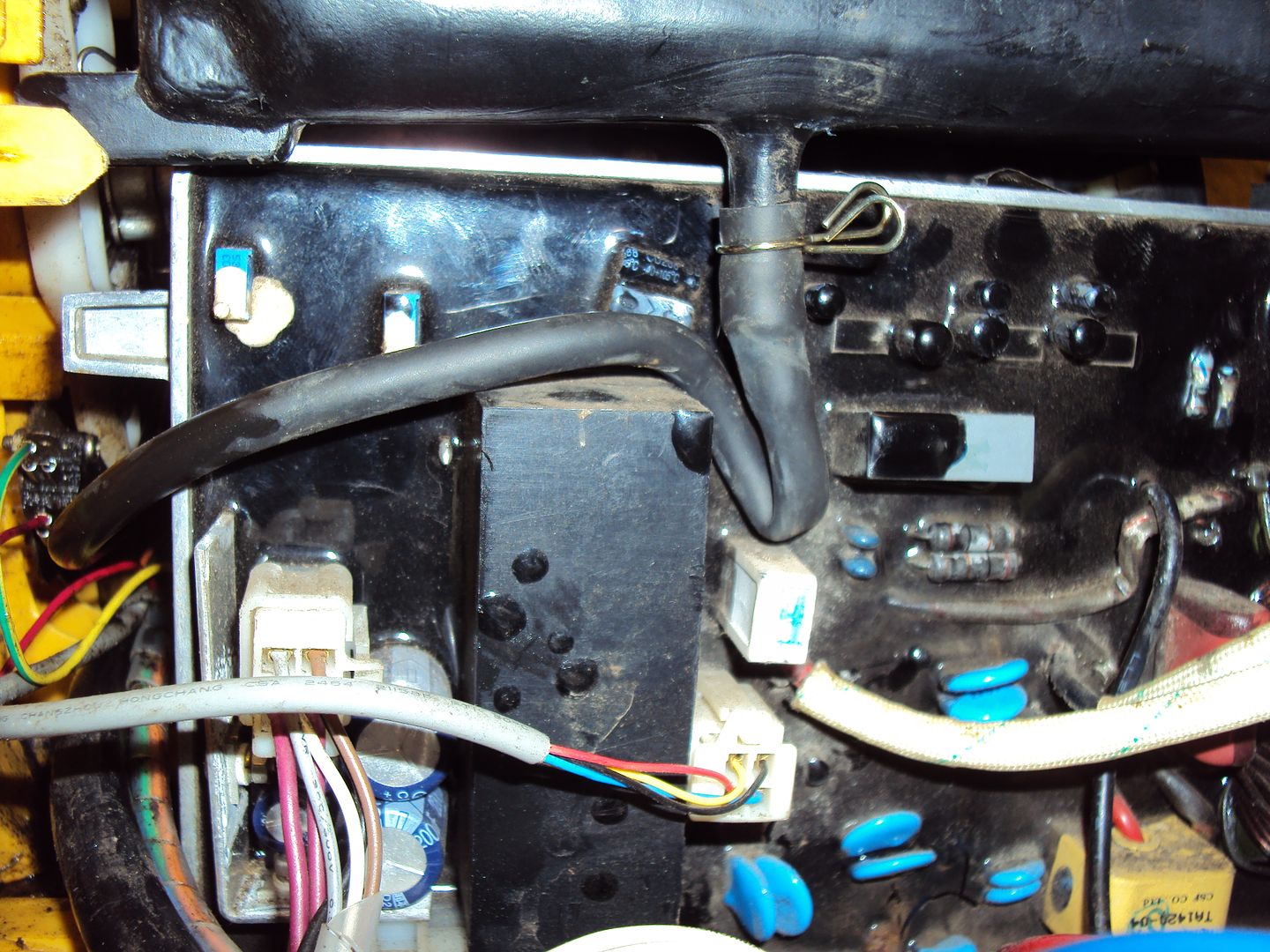

And that the ignition control unit was unplugged.

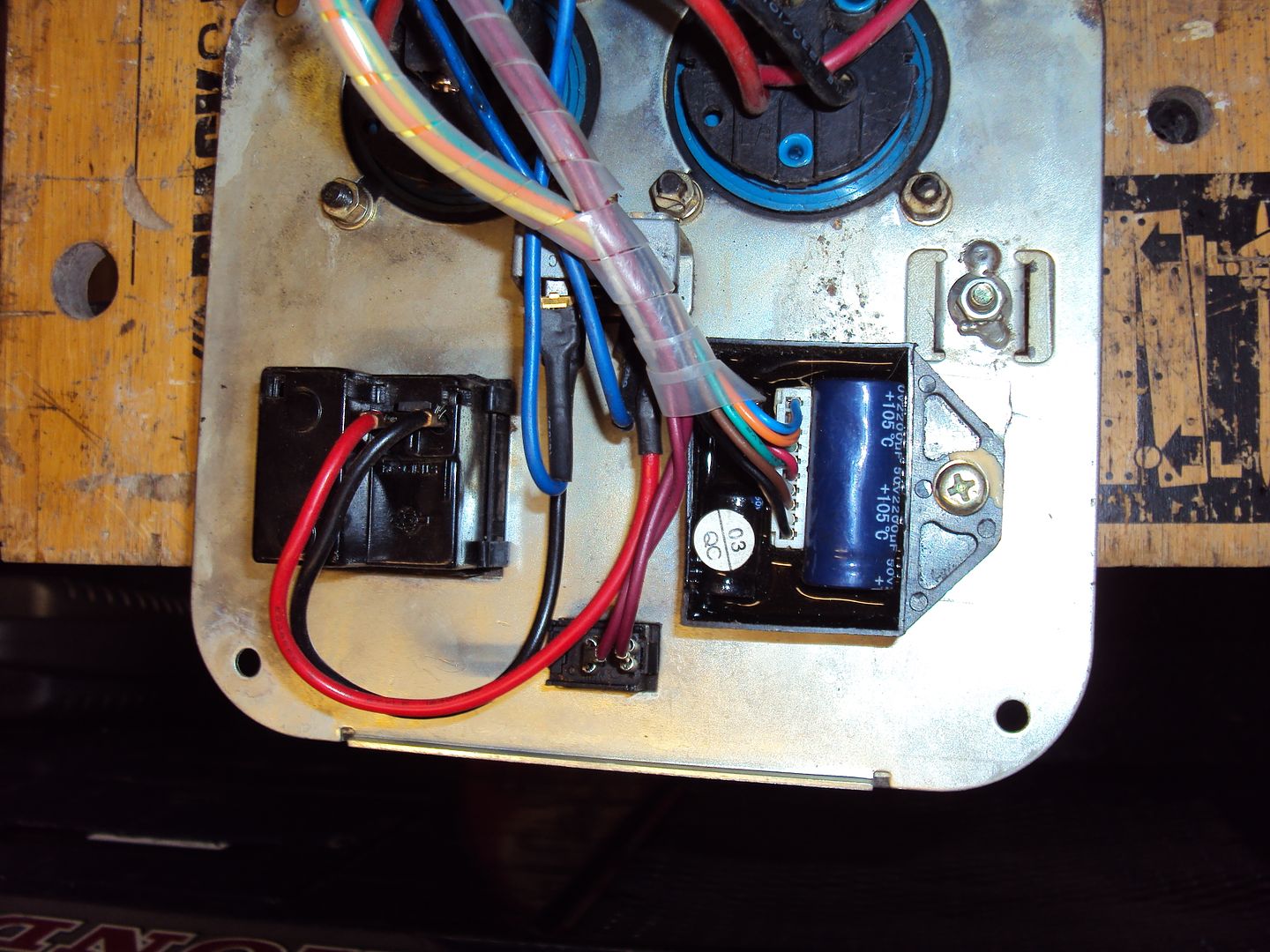

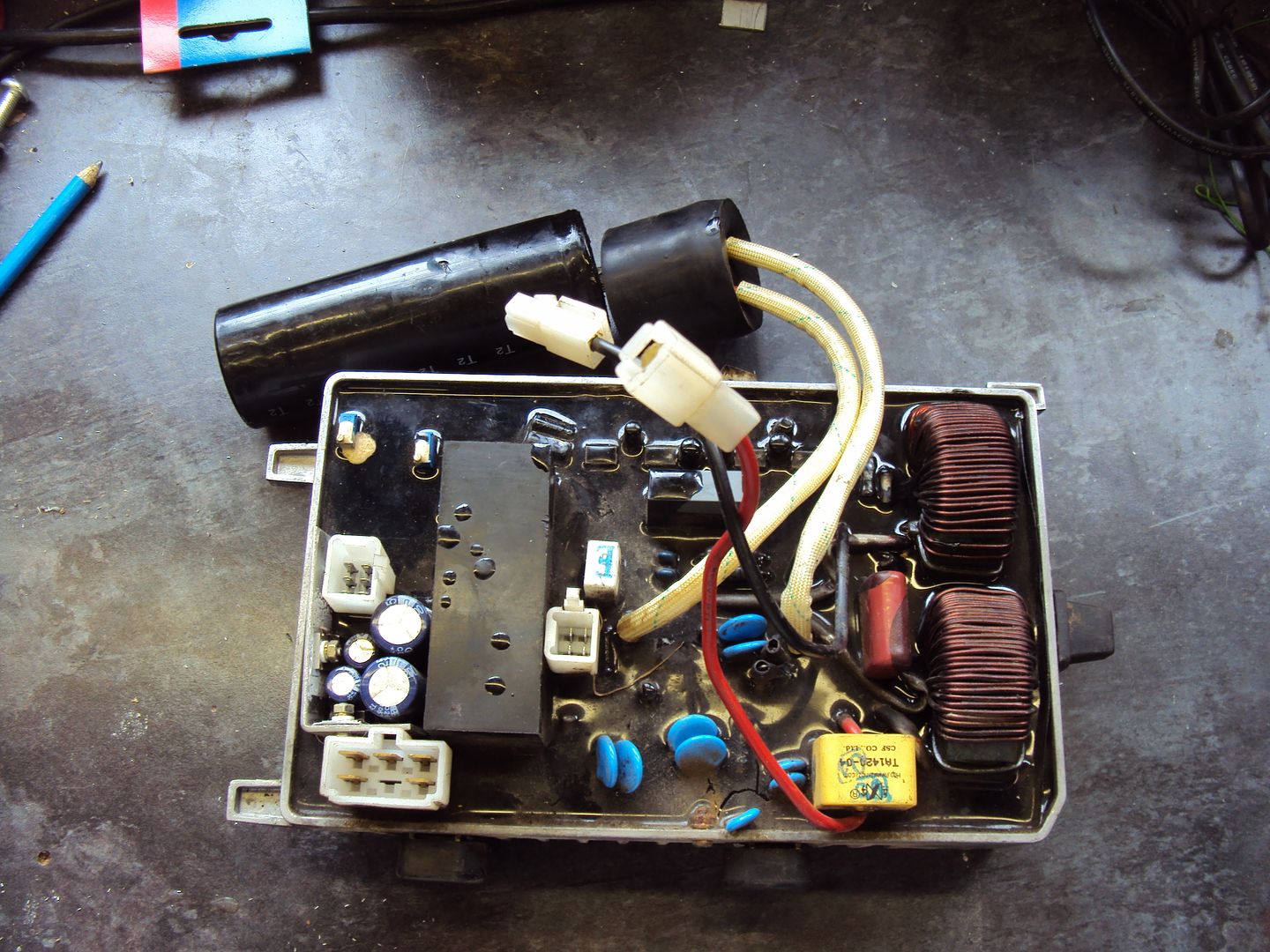

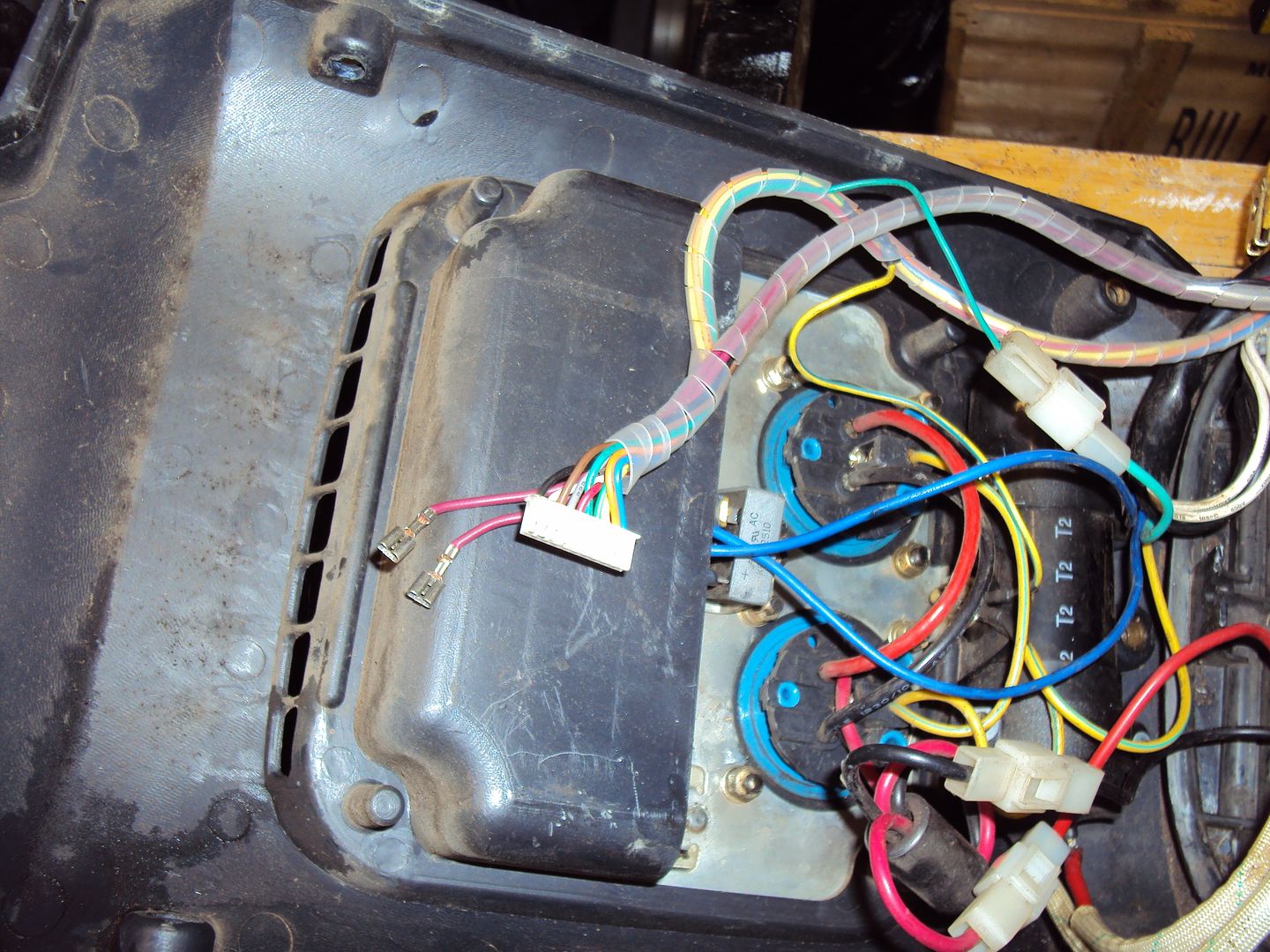

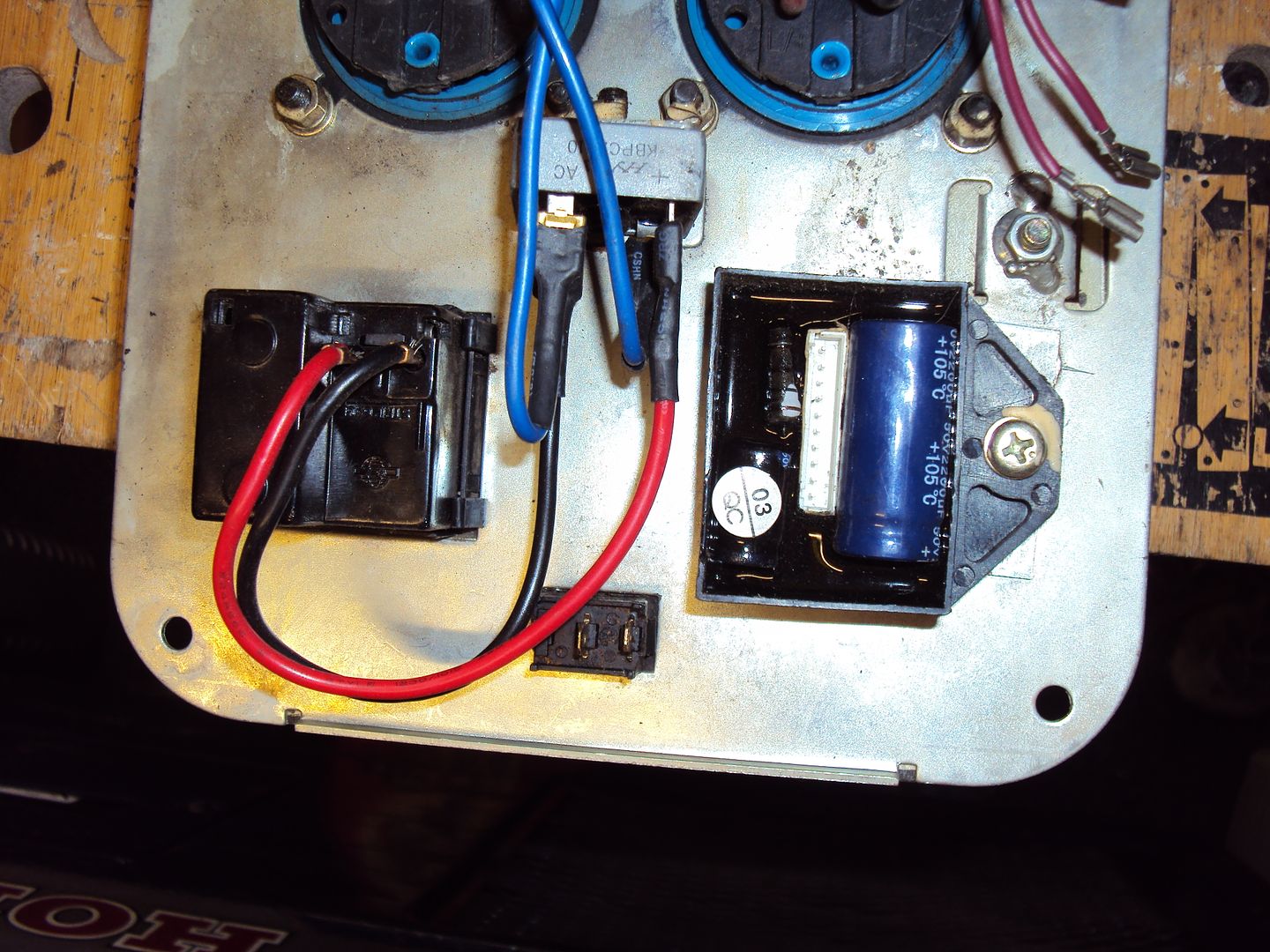

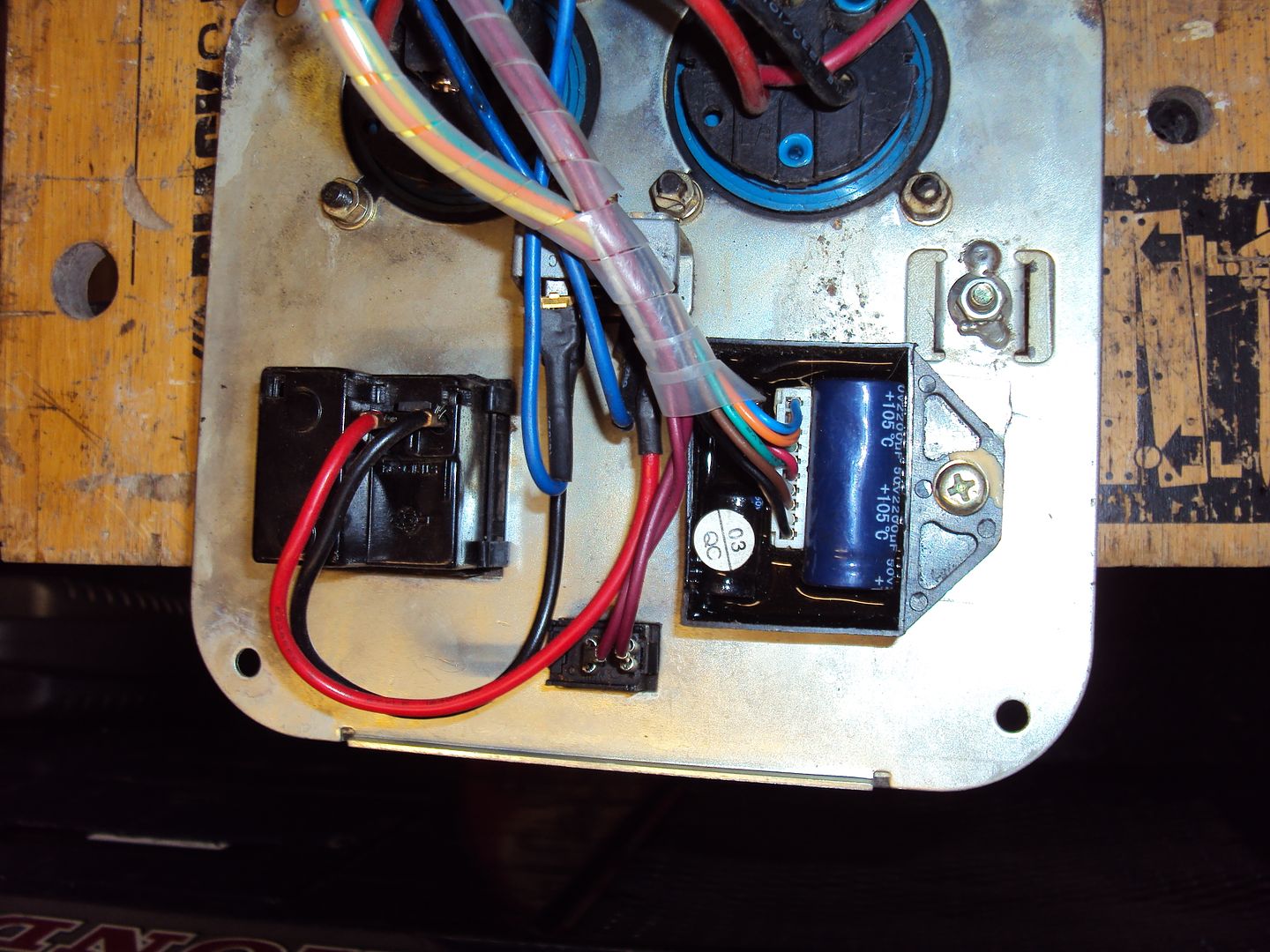

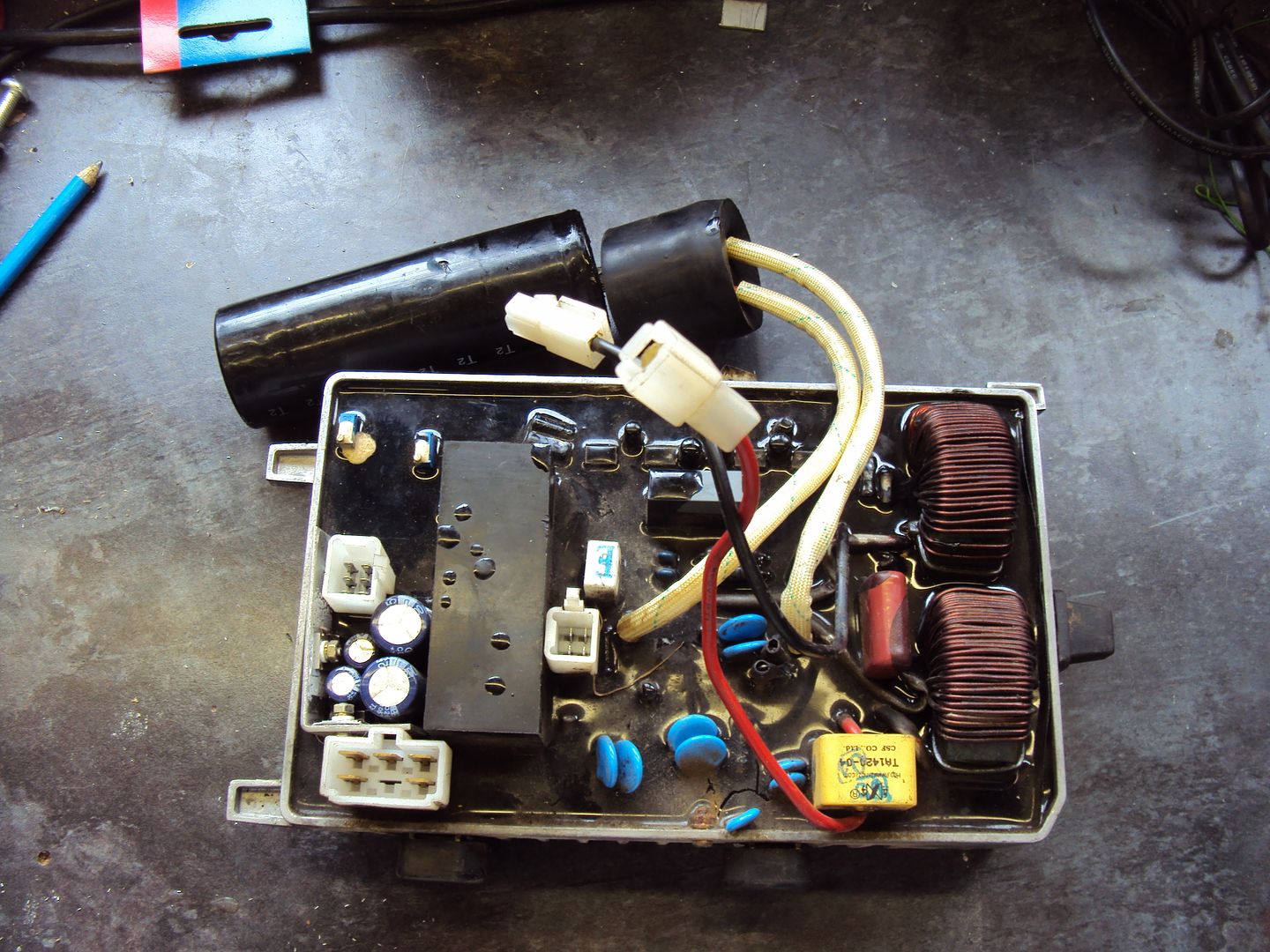

As soon as these were rectified, it started straight away, however it wasn’t outputting any power. After some further testing we determined the inverter unit was at fault.

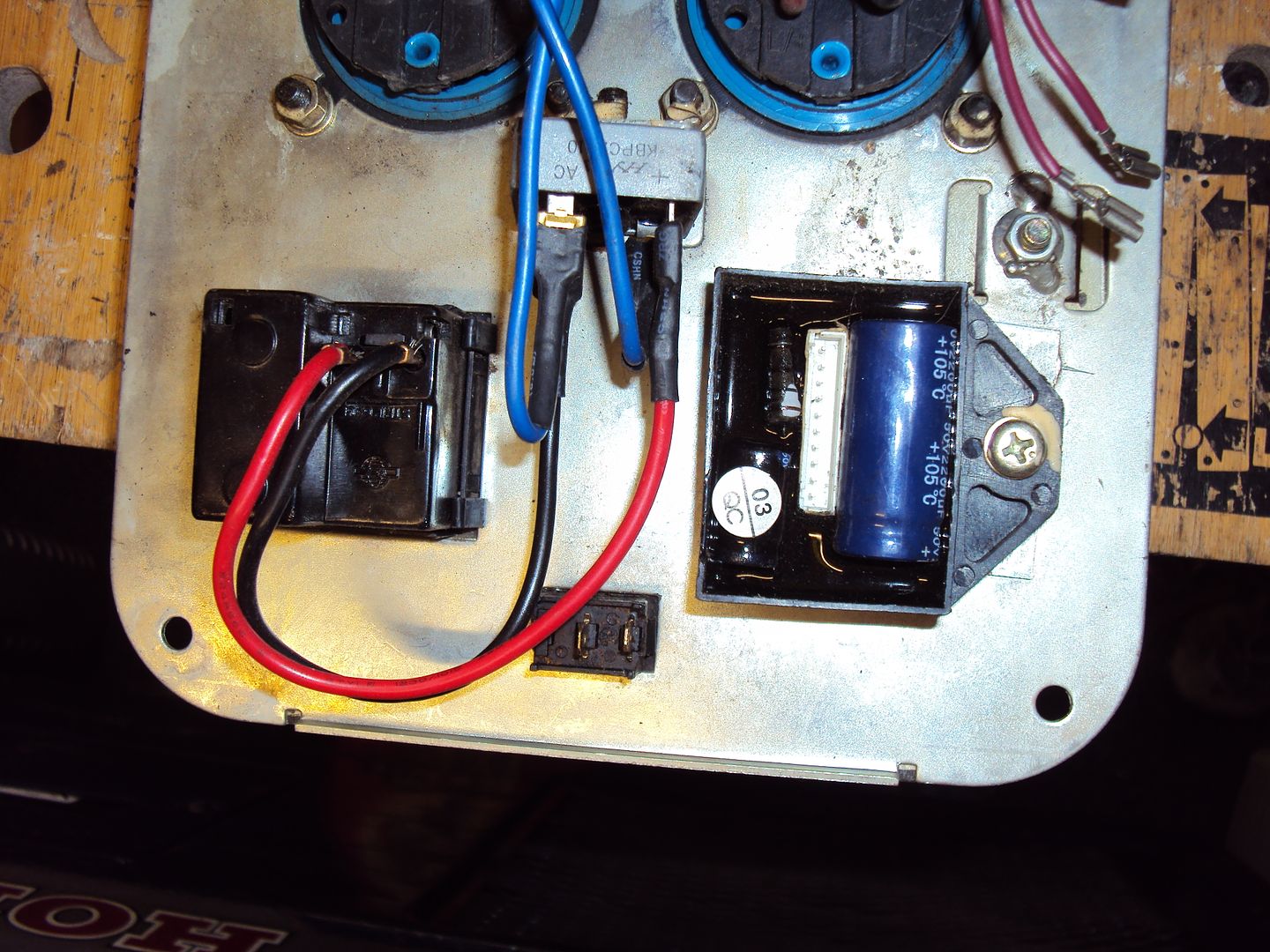

I thought there might be an easy fix as the capacitor wasn’t looking too healthy as it was bulging

After a quick test the capacitor was found to be ok, so it looks like the fault is inside the inverter unit with no chance if repair as it is all potted.

I’m currently deciding how to proceed with this one as the replacement inverter costs nearly as much as a working unit sells for.

On to the second one we bought.

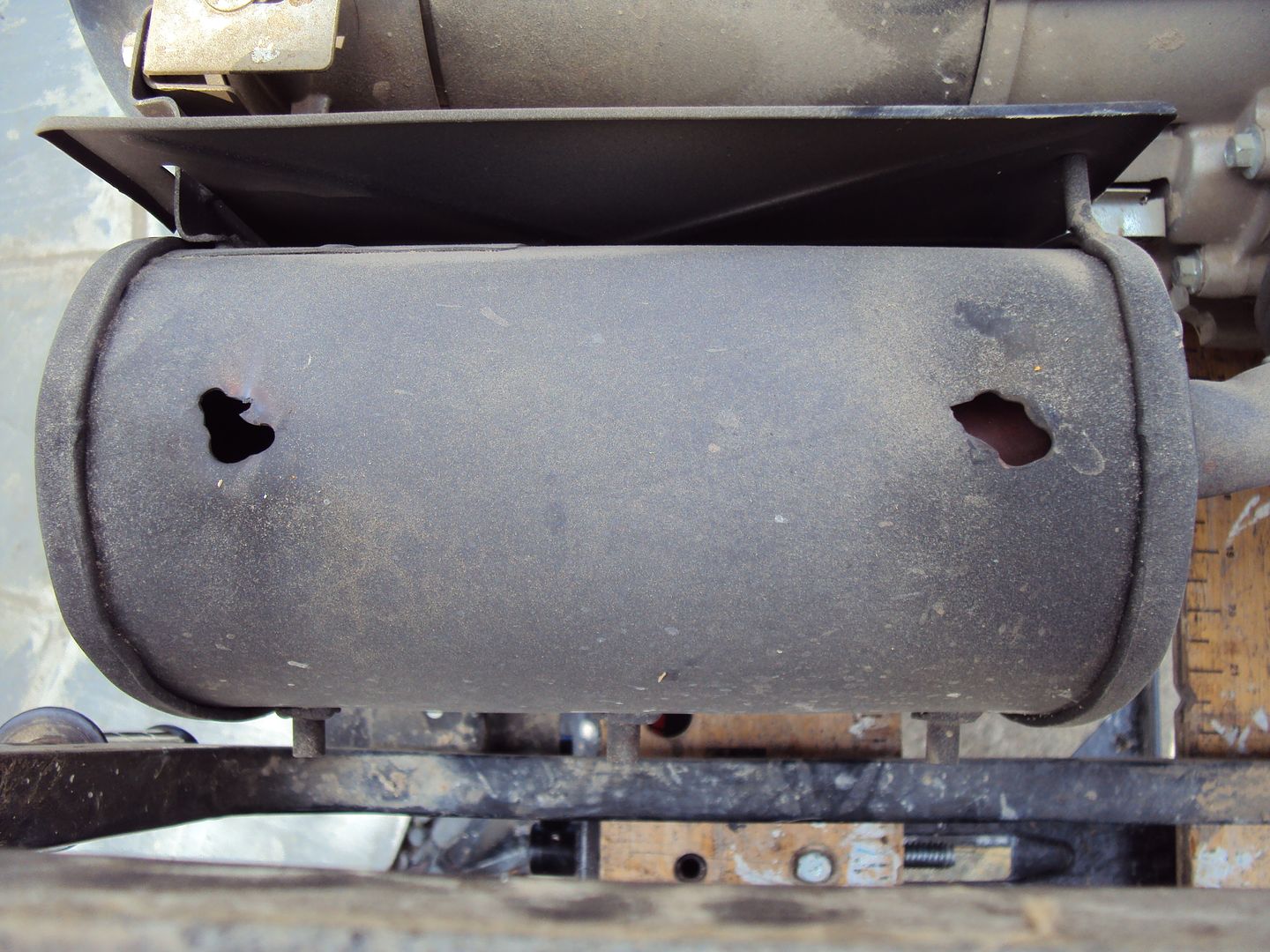

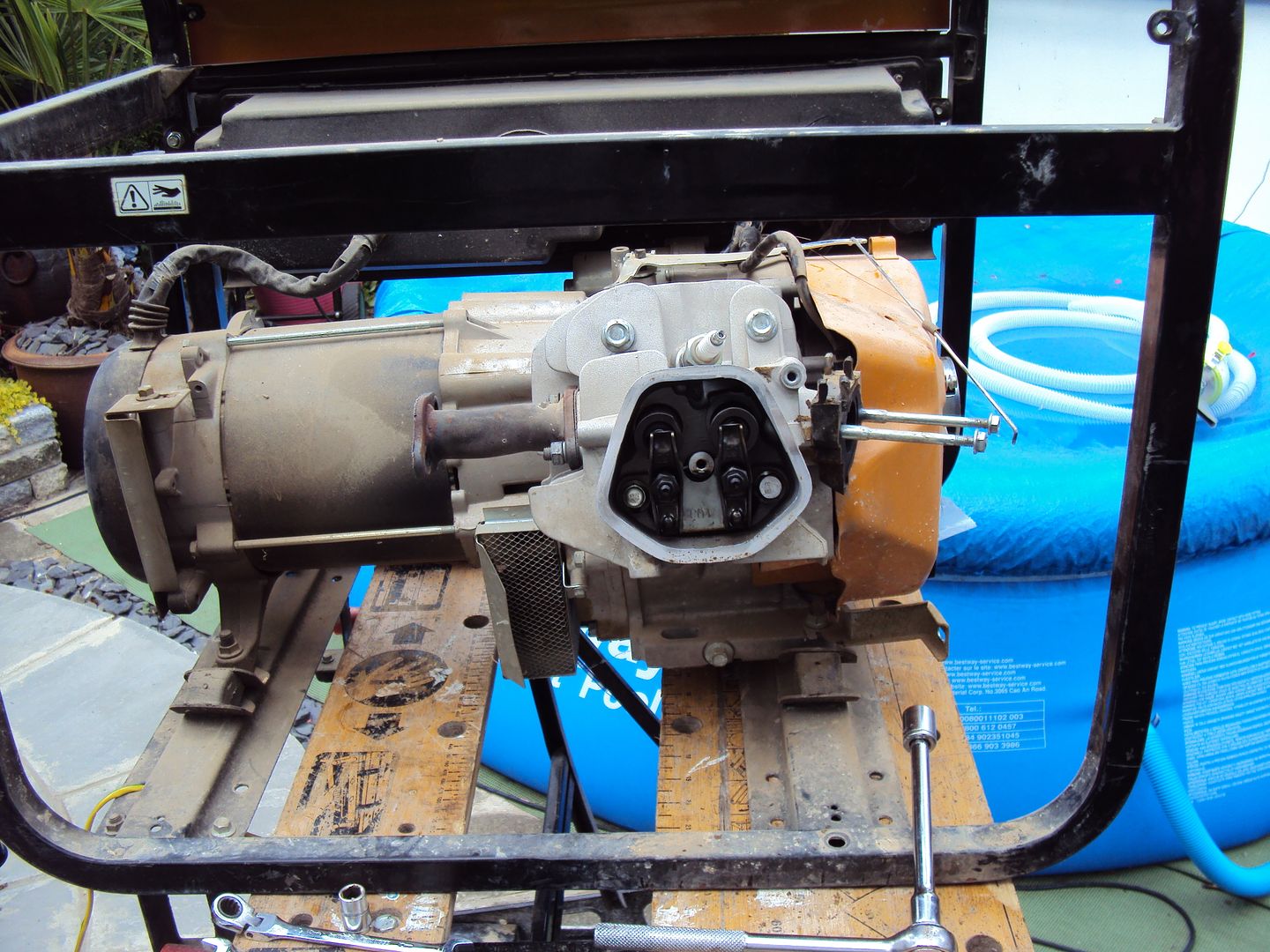

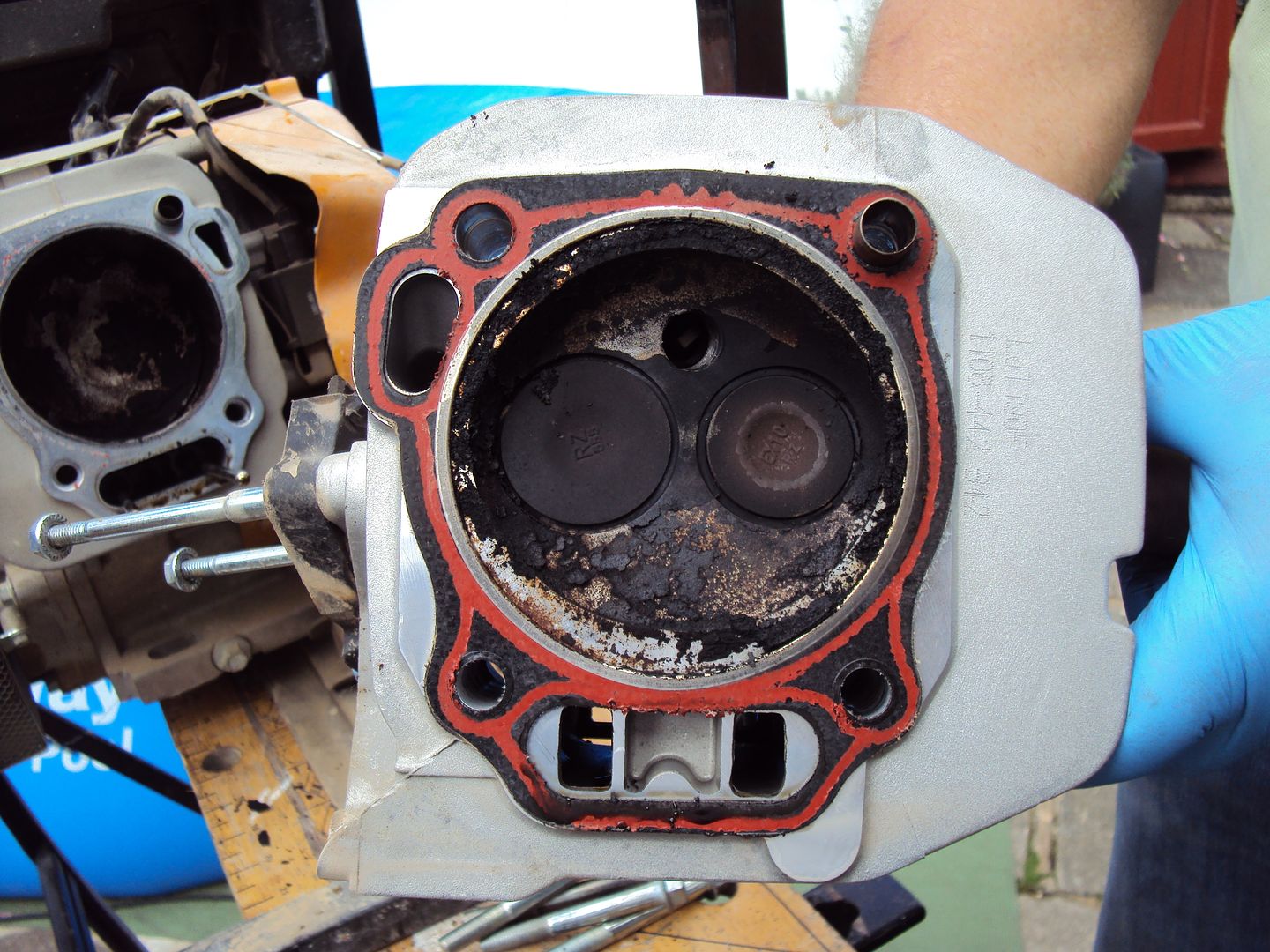

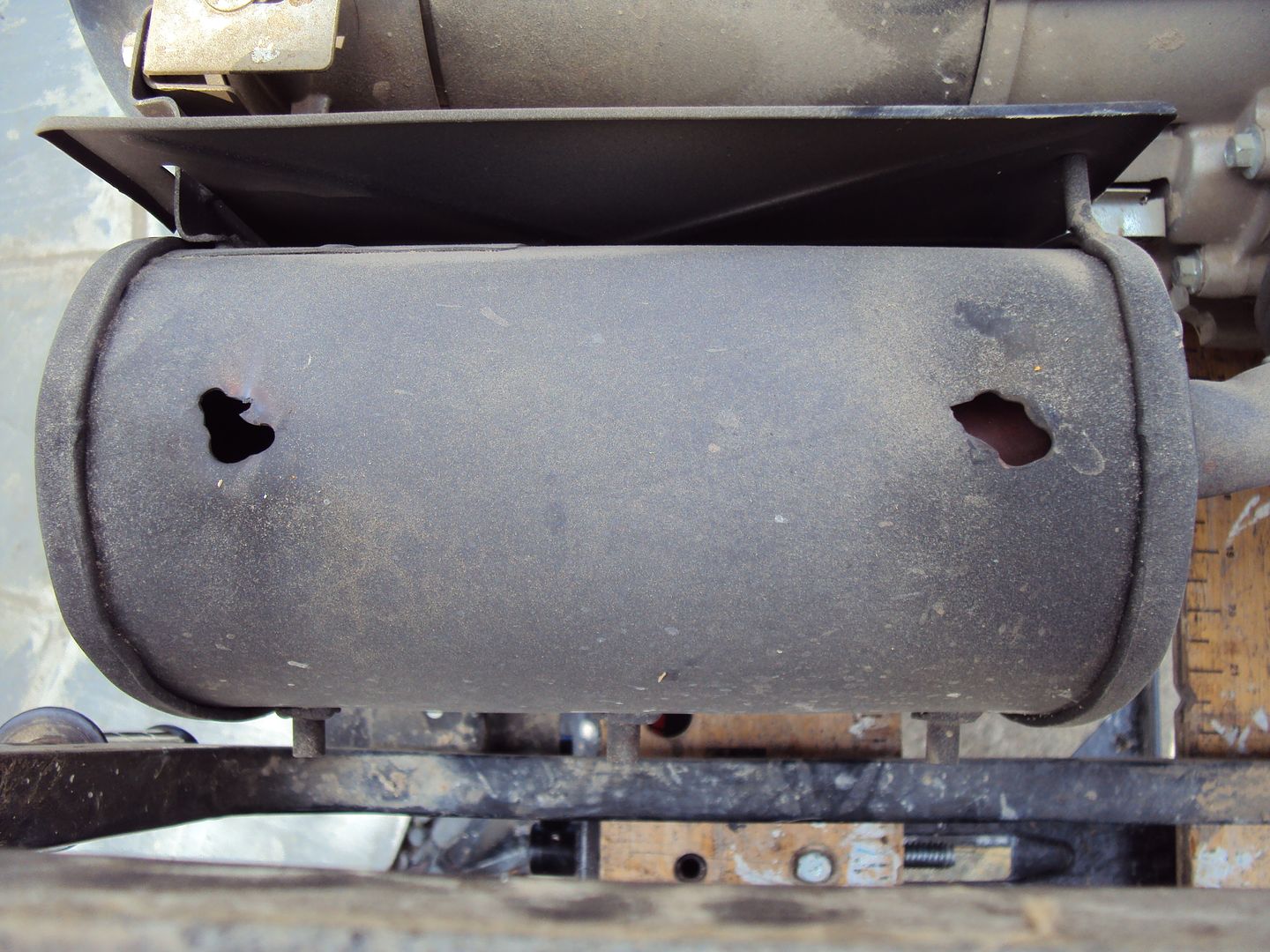

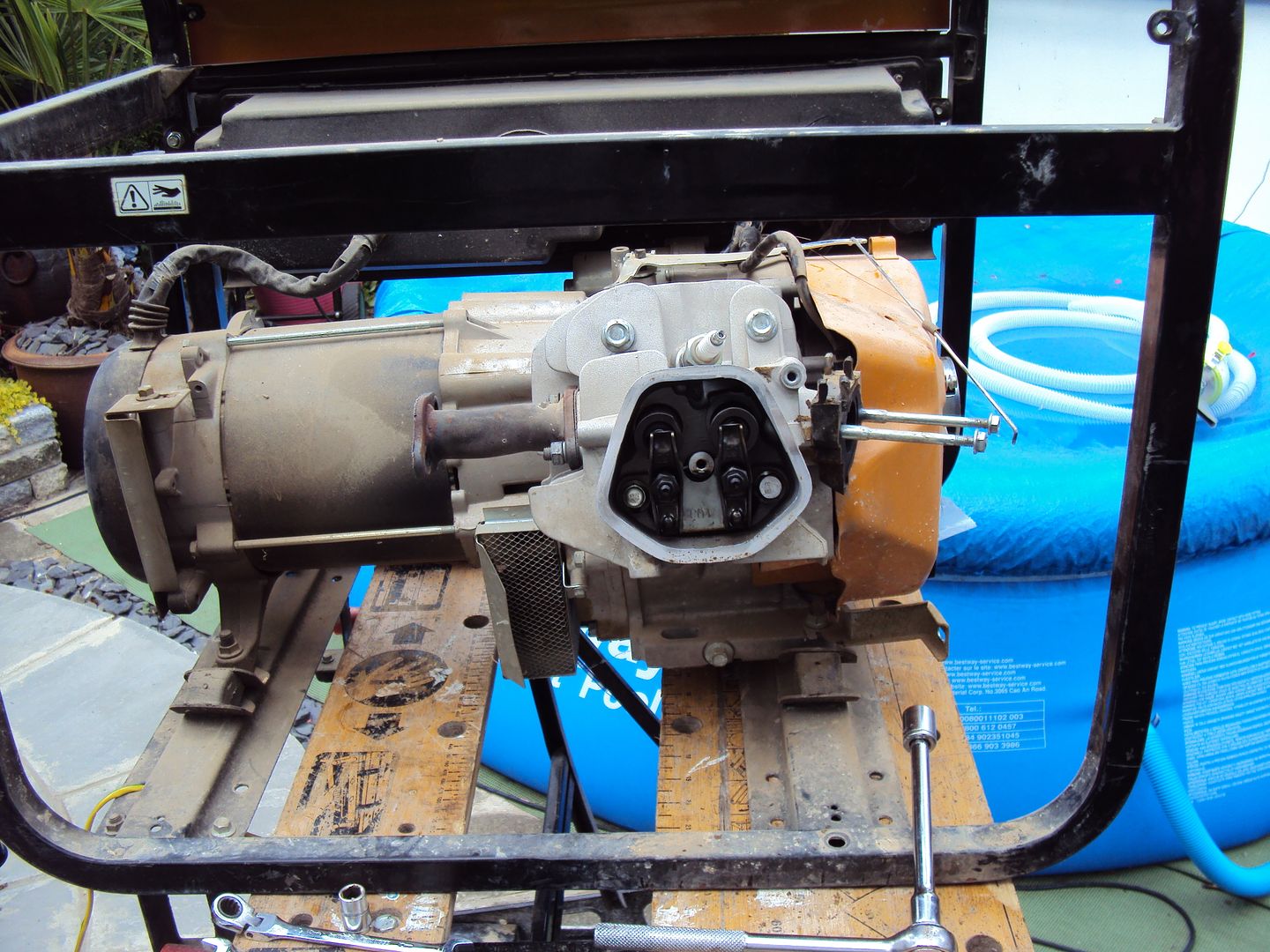

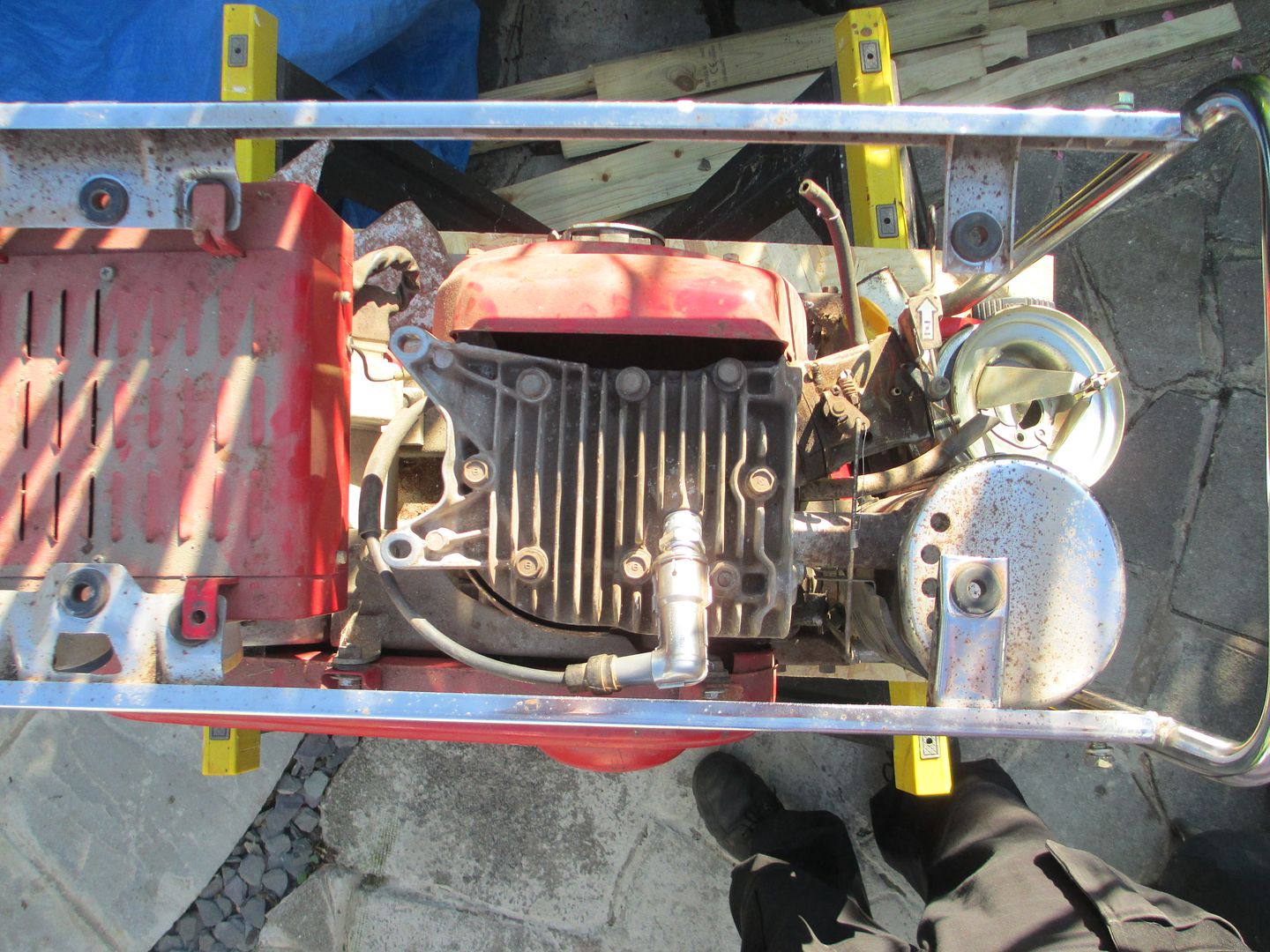

This one was described as was running then put into storage and is now seized. When we started looking at it we found the engine would turn for about ¾ of a revolution before hitting something. We thought maybe a valve was either stuck or broken so started disassembly.

Need to add an exhaust to the parts list..

Exhaust and carburettor removed

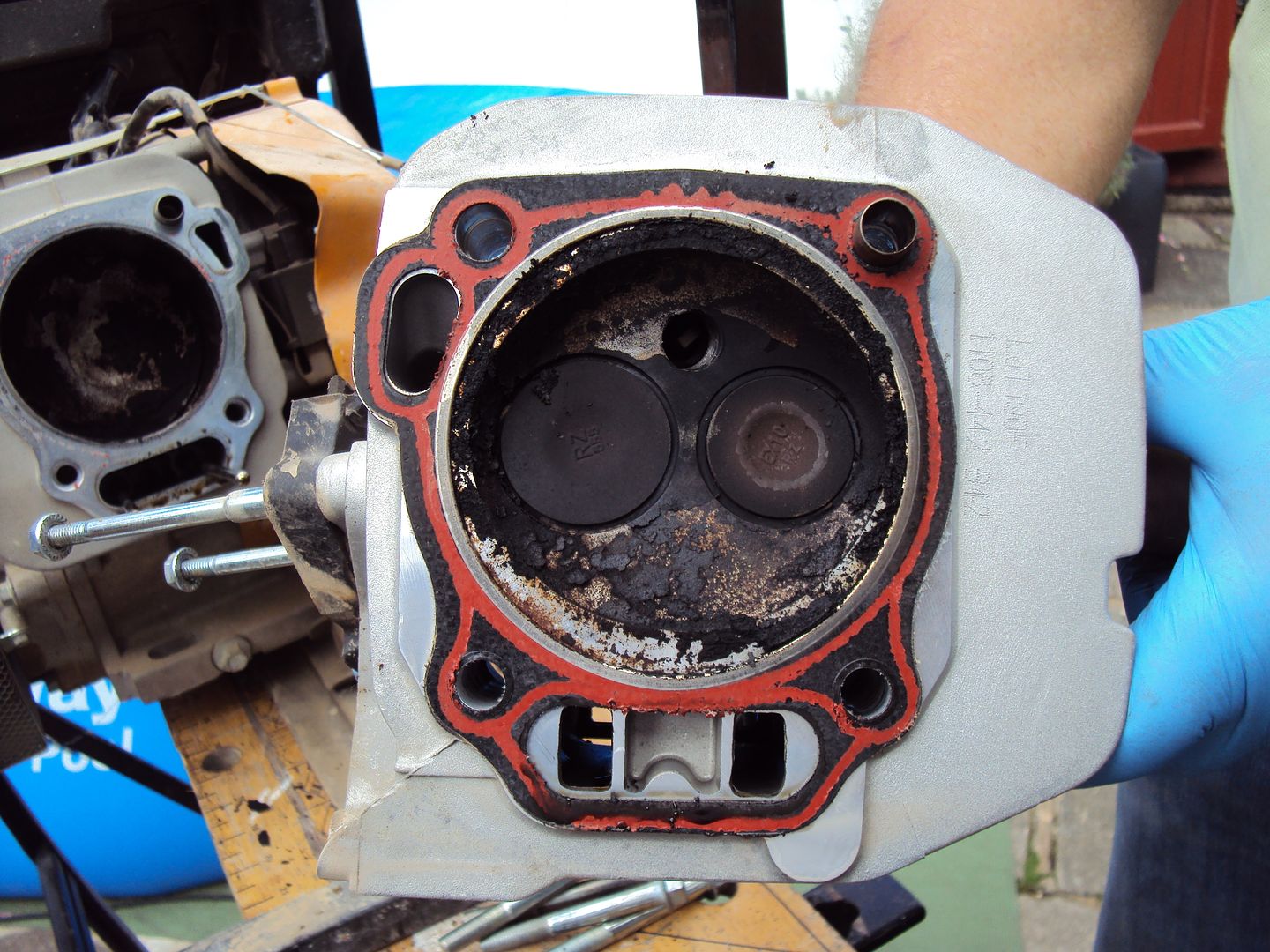

Head off, valves look ok

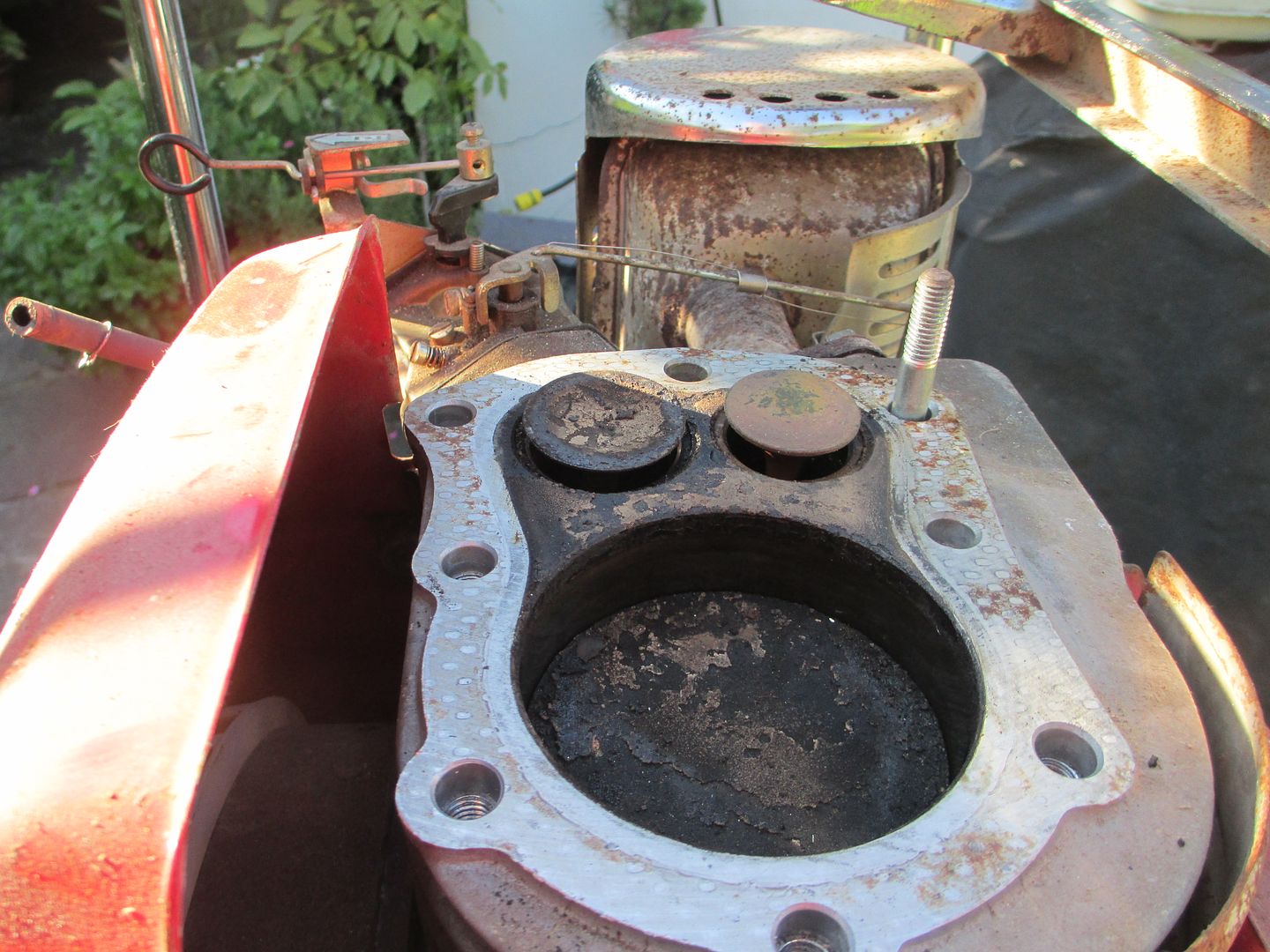

Piston

The engine turned freely with the head removed, so we guessed it was all the carbon stopping the piston from going all the way to the top.

We cleaned all the carbon from the head and piston and reassembled the engine, (sorry forgot to take pictures) and got it running.

Just need to find someone to weld the exhaust, all though I am looking at the possibility of buying a MIG or TIG welder.

If there are any PH’rs in the Orpington/ Chislehurst area that fancy practising their welding skills in exchange for beer/beer tokens drop me a pm .

.

“Engine will not run. It starts, splutters and stops - and very often will not start at all. I have no idea what is wrong, nor if it will generate once the engine is running.”

I took a chance thinking it was the stepper motor which operates the throttle as this is the most likely cause.

On disassembly we found the fuel pipe from the tank had a kink preventing the fuel from flowing

And that the ignition control unit was unplugged.

As soon as these were rectified, it started straight away, however it wasn’t outputting any power. After some further testing we determined the inverter unit was at fault.

I thought there might be an easy fix as the capacitor wasn’t looking too healthy as it was bulging

After a quick test the capacitor was found to be ok, so it looks like the fault is inside the inverter unit with no chance if repair as it is all potted.

I’m currently deciding how to proceed with this one as the replacement inverter costs nearly as much as a working unit sells for.

On to the second one we bought.

This one was described as was running then put into storage and is now seized. When we started looking at it we found the engine would turn for about ¾ of a revolution before hitting something. We thought maybe a valve was either stuck or broken so started disassembly.

Need to add an exhaust to the parts list..

Exhaust and carburettor removed

Head off, valves look ok

Piston

The engine turned freely with the head removed, so we guessed it was all the carbon stopping the piston from going all the way to the top.

We cleaned all the carbon from the head and piston and reassembled the engine, (sorry forgot to take pictures) and got it running.

Just need to find someone to weld the exhaust, all though I am looking at the possibility of buying a MIG or TIG welder.

If there are any PH’rs in the Orpington/ Chislehurst area that fancy practising their welding skills in exchange for beer/beer tokens drop me a pm

.

. Blue32 said:

Just need to find someone to weld the exhaust, all though I am looking at the possibility of buying a MIG or TIG welder.

If there are any PH’rs in the Orpington/ Chislehurst area that fancy practising their welding skills in exchange for beer/beer tokens drop me a pm .

.

I know just the place - though I dont know the telephone number. - will PM you - let me know if it doesnt get to you.If there are any PH’rs in the Orpington/ Chislehurst area that fancy practising their welding skills in exchange for beer/beer tokens drop me a pm

.

. paolow said:

PM sent

Thanks, I will give them a try

creationracing said:

Interesting forum post here - could you retrofit a Honda unit if you can find one at a good price?

I looked at the Honda inverter, the replacement Kipor inverter is around £250. The equivalent Honda is £900+ !!I believe this particular series of generator was subject to a patent dispute as it appears to be a direct copy of a Honda EU series(Kipor manufactured for Honda)so parts are supposedly interchangeable there is a photo somewhere of a skip full of generators which had been taken from the importer.

creationracing said:

Are there any commercially available inverter units that you can buy off the shelf instead of spending a fortune on the genuine Kipor replacement?

PS I used to work in a repairs lab - potting compound was often the bane of our lives! Of course as a mere graduate I was made to de-pot a power supply. It was something of a right of passage. Whether or not you could fix the thing was irrelevant...

I've done a few bits of potting archaeology, some successful some not; you definitely need to be slightly OCD to complete it. PS I used to work in a repairs lab - potting compound was often the bane of our lives! Of course as a mere graduate I was made to de-pot a power supply. It was something of a right of passage. Whether or not you could fix the thing was irrelevant...

hidetheelephants said:

I've done a few bits of potting archaeology, some successful some not; you definitely need to be slightly OCD to complete it.

Me too, I have spent many happy hours with a scalpel and Dremel removing the stuff. There are some acids which will remove the potting compound, but they will also remove markings from components and damage the PCB.

The Wolf went to a new home last week and I decided to order a inverter for the dead Kippor which should turn up in the next few days.

During the week we picked up another Honda, this one dates back to the late 60s/ early 70s!

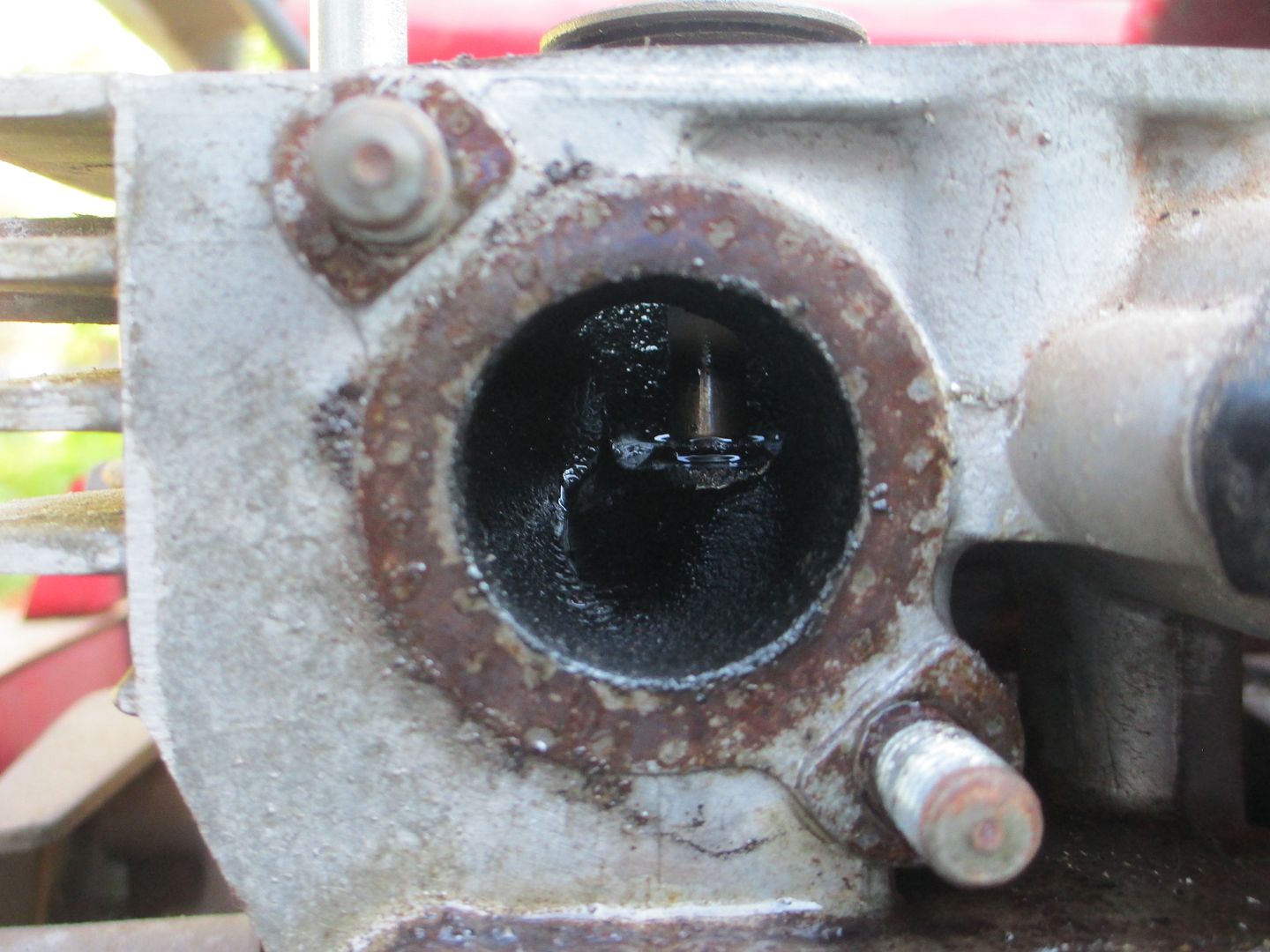

The fault is that it won’t start, we quickly found it had no compression as when the pull start was pulled the engine would turn with no resistance so started the strip down.

Valves and piston are present look ok.

Pretty sure both valves shouldn’t be open at the same time.

Looks like the exhaust valve is stuck open.

We tried putting some oil on the valve stem too see if it would free up.

The valve would close with a gentle tap

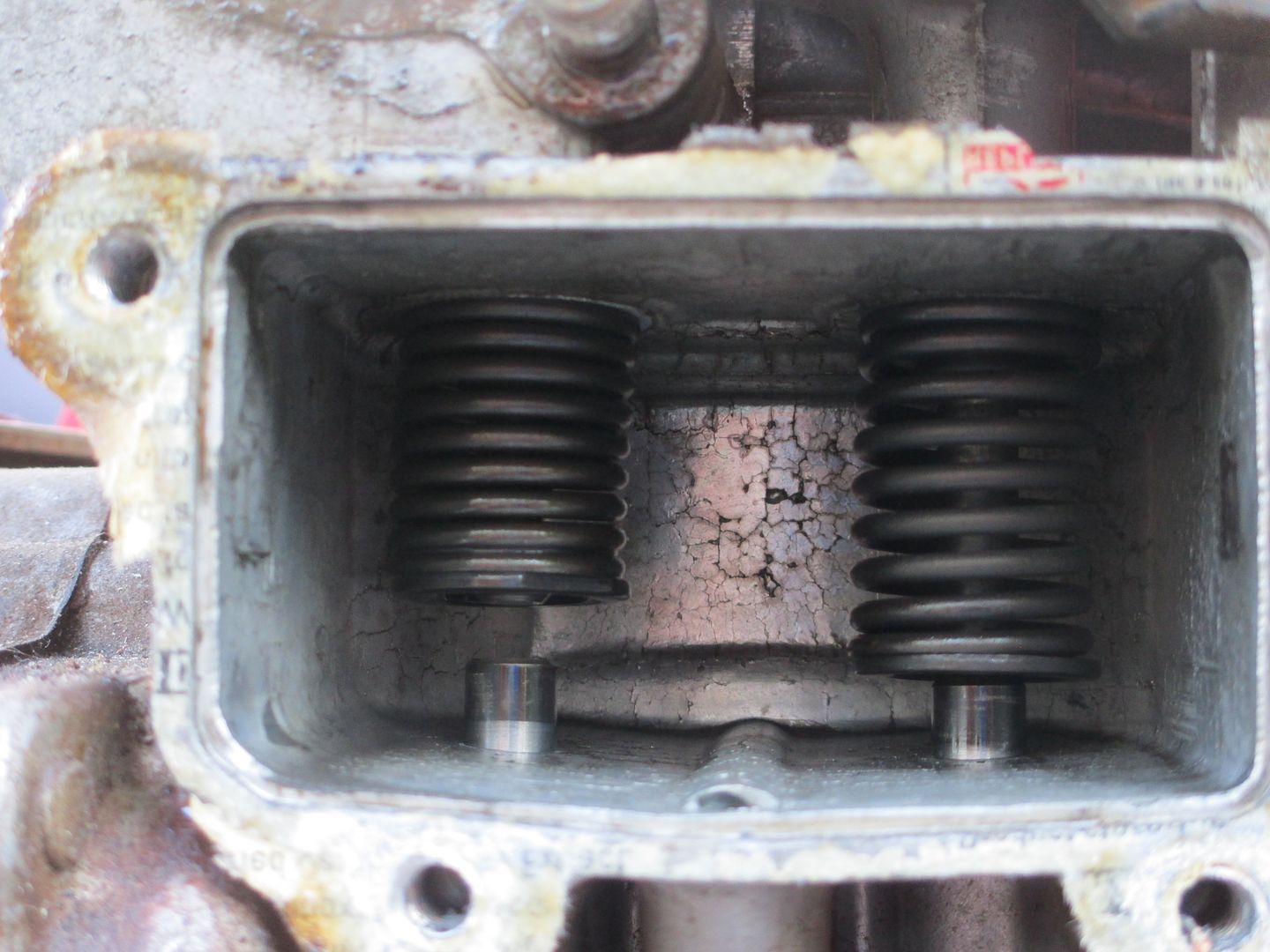

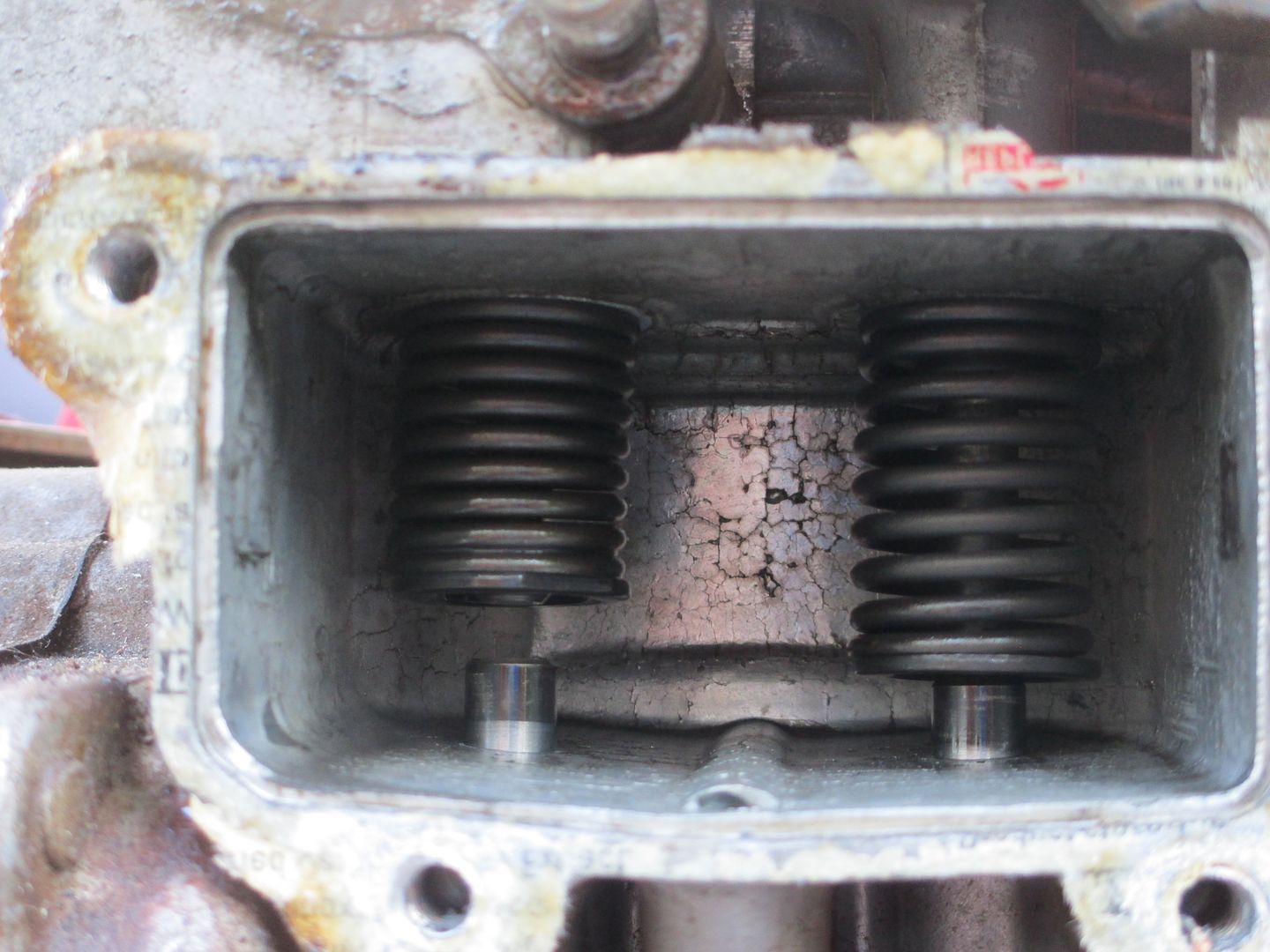

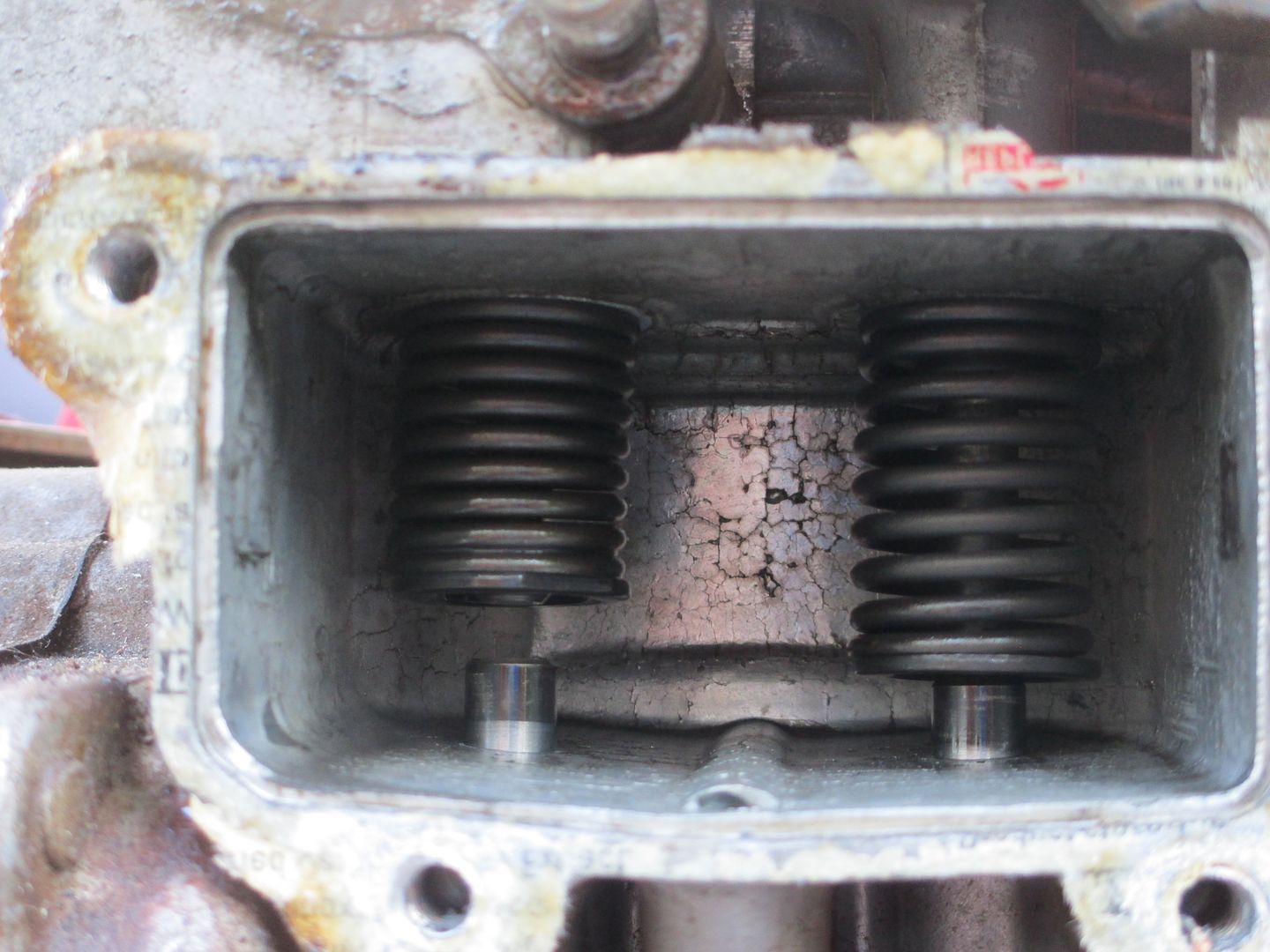

Opened up the valve chest to check the valve springs were ok.

There shouldn’t be a gap between the valve stem and the tappet.

Recipes on the valve chest gasket!

We managed to get the valve freed up, so cleaned all the carbon off the piston and out of the cylinder head.

Once reassembled it fired up on the second pull and made power.

I couldn’t resist trying some metal polish on the exhaust heat shield

And some Autoglym on the belt cover, 50/50 for the detailing geeks

I gave the rest of the exhaust heat shield a polish along with the air filter housing.

We just need to get a new pull start as the current one has a broken spring which makes it a bit temperamental.

Blue32 said:

Me too, I have spent many happy hours with a scalpel and Dremel removing the stuff. There are some acids which will remove the potting compound, but they will also remove markings from components and damage the PCB.

The Wolf went to a new home last week and I decided to order a inverter for the dead Kippor which should turn up in the next few days.

During the week we picked up another Honda, this one dates back to the late 60s/ early 70s!

Opened up the valve chest to check the valve springs were ok.

There shouldn’t be a gap between the valve stem and the tappet.

Amazing - both that it is still going strong 50 years later but also the design of the valve assembly. Presumably it uses a vertical pushrod directly on the valve stem? Must have made getting the colletts off to lessen the spring tension and lap the valves a breeze - or maybe not given it is all recessed? Any real wear after all these years? Also do things like the springs still, well stay 'sprung' after such a period?The Wolf went to a new home last week and I decided to order a inverter for the dead Kippor which should turn up in the next few days.

During the week we picked up another Honda, this one dates back to the late 60s/ early 70s!

Opened up the valve chest to check the valve springs were ok.

There shouldn’t be a gap between the valve stem and the tappet.

Thinking about it I had a Capri that had 2 lay up periods of about 4 years a piece in its history and seemed fine so why not?

paolow said:

Amazing - both that it is still going strong 50 years later but also the design of the valve assembly. Presumably it uses a vertical pushrod directly on the valve stem? Must have made getting the colletts off to lessen the spring tension and lap the valves a breeze - or maybe not given it is all recessed? Any real wear after all these years? Also do things like the springs still, well stay 'sprung' after such a period?

Thinking about it I had a Capri that had 2 lay up periods of about 4 years a piece in its history and seemed fine so why not?

Yes the push rod runs directly on the cam and pushes against the valve stem. We were planning to remove and lap the valves, but couldn’t release the collets to free the springs so decide to leave it. The springs were fine, when we tapped the exhaust valve it would snap shut. Thinking about it I had a Capri that had 2 lay up periods of about 4 years a piece in its history and seemed fine so why not?

There was just some stiction in the valve guide, presumably through lack of use. Once we got the oil worked in to it, the valve moved freely.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff