Our Victorian/industrial/canalside new build thread...

Discussion

House starting to catch up with the garage!

Living room from the patio...

Kitchen/diner from the patio...

Garage awaiting lintels and trusses...

Utility room...comparison between the lightweight "thin joint" external wall and the traditional block internal wall...

First floor joists should be in next week!

Living room from the patio...

Kitchen/diner from the patio...

Garage awaiting lintels and trusses...

Utility room...comparison between the lightweight "thin joint" external wall and the traditional block internal wall...

First floor joists should be in next week!

sealtt said:

Enjoying watching the progress.

I had a look for the USB wall sockets with switches but could only find them for the US, I'm sure they are out there just I can't find them.

Boo! But thanks for the info...no doubt they will be an easy retro fit, or possibly available in a few months time when we're needing them.I had a look for the USB wall sockets with switches but could only find them for the US, I'm sure they are out there just I can't find them.

jhfozzy said:

Hard-Drive said:

Utility room...comparison between the lightweight "thin joint" external wall and the traditional block internal wall...

Loving the thread, build threads are fantastic reading and give me great ideas, to my wife's dismay.IANAB*, but are you sure you mean "thin joint"? They look like thinsulate (Celcon) blocks to my untrained eye?

- I am not a brickie

From the web...

"The H+H Thin-Joint system combines the Celcon Plus, Jumbo Blok or MultiPlate ranges of high quality, accurately dimensioned aircrete blocks with a specially developed Thin-Joint mortar (called Celfix).

Thin-Joint blockwork enables walls to be built very quickly without having to wait the conventional 24 hours for the mortar to set before further loading can be applied.

Celfix Mortar is cement based and supplied as a dry, pre-mixed powder in 25kg bags. It has been designed to replace the traditional sand:cement mortar. Celfix Mortar starts to set within 10 minutes of application and approaches full design strength in just 1 to 2 hours. This enables blockwork to be built extremely quickly, and in the case of cavity wall construction independently of the outer leaf, which is normally brickwork.

Celfix Mortar is easily mixed on site by adding the appropriate quantities of water. It is applied with a proprietary scoop or sledge, which will create a consistent joint thickness of 2mm.

The Thin-Joint system enables the structure of a building to be built faster and to a better quality, allowing follow-on trades to start work sooner in a weatherproof environment, whilst retaining the flexibility of on-site construction.

Fully adopted as the preferred method of wall construction throughout most of Europe, this innovative and award-winning system is now firmly established within the UK. The Thin-joint system can also be used successfully for commercial projects"

TA14 said:

Gingerbread Man said:

herewego said:

Are the inner and outer walls not tied together?

My thoughts too. Not sure I've seen the thin joint before. I would have thought that the courses being staggered would have caused issues.hhcelcon said:

Helical wall ties are later driven in through insulation as the external brickwork is installed.

"IANAB" to use a previous comment, however looking at the guys who were doing the garage out of conventional blocks and cement, and the guys doing the house using the thin joint methods at the same time, it does seem like a bit of a no brainer. The "ice cream scoop" thing delivers a measured amount of celfix for one block, the scoop is then flipped over to the serrated side (working like a tile grout spreader), the block goes on and it's onto the next one. The wall goes up really fast. The glue is formulated to stay fairly liquid in the bucket, but dries very quickly once applied (and very very quickly if it's a warm day!) There's a lot more block per given area of wall, which I guess is stronger and also more thermally efficient.

Garage scaffolding up, ready for roof joists later this week (weather permitting!)

View from "patio"...lounge on left, kitchen on right, going to work really well with both bifolds open...

First floor joists in and brickwork progressing nicely. Window apertures look a bit odd at the bottom...the extra bricks will be removed when the stone window sills go in.

Feels weird being able to walk around the ground floor and see the actual room sizes!

View from "patio"...lounge on left, kitchen on right, going to work really well with both bifolds open...

First floor joists in and brickwork progressing nicely. Window apertures look a bit odd at the bottom...the extra bricks will be removed when the stone window sills go in.

Feels weird being able to walk around the ground floor and see the actual room sizes!

Garage roof trusses up and house brickwork progressing well...

View from porch, through hallway and into kitchen/diner...

I've decided to go for the full PH garage treatment, so the whole lot will be plasterboarded/skimmed, with a plasterboard ceiling and downlighters, it really isn't much additional cost in the grand scheme of things and it's much easier to do it now.

I'm also going to ply board this central area (scale wise you'd need to stoop but you can walk along it) with a large access hatch for storing long, lightweight things (sails etc). I'll insulate it too.

Living room with beginnings of the fire place. Sun coming in nicely through what will be the bifold...

[/url]

[/url]

This will be the patio, and a great little sun-trap it is too. Garage wall on the left, living room bifold centre, kitchen/diner and bifold to the right.

View from porch, through hallway and into kitchen/diner...

I've decided to go for the full PH garage treatment, so the whole lot will be plasterboarded/skimmed, with a plasterboard ceiling and downlighters, it really isn't much additional cost in the grand scheme of things and it's much easier to do it now.

I'm also going to ply board this central area (scale wise you'd need to stoop but you can walk along it) with a large access hatch for storing long, lightweight things (sails etc). I'll insulate it too.

Living room with beginnings of the fire place. Sun coming in nicely through what will be the bifold...

[/url]

[/url]This will be the patio, and a great little sun-trap it is too. Garage wall on the left, living room bifold centre, kitchen/diner and bifold to the right.

Edited by Hard-Drive on Sunday 25th October 12:28

Man-Cave block/brickwork (gable ends, corbeling, arches) done. Just needs slate roof, doors, windows and guttering fitting. Weather been pretty crap this week unfortunately.

Oh, and that's not an ornamental breeze block, I have a stonemason turning up next week with an "MMXVI" date stone. Found him on eBay, hand delivered, hand carved, for about half the price of a mass produced cast one. Block out, stone in, jobs a good'un.

Oh, and that's not an ornamental breeze block, I have a stonemason turning up next week with an "MMXVI" date stone. Found him on eBay, hand delivered, hand carved, for about half the price of a mass produced cast one. Block out, stone in, jobs a good'un.

Blockwork pretty much to full height now, brickwork catching up too...

Scaffolding down on garage...just awaiting the doors.

Meanwhile the scaffolding is going up a level on the house and the roof trusses have arrived. Weather looking a bit moist next week though so we shall see if that halts progress a bit!

Scaffolding down on garage...just awaiting the doors.

Meanwhile the scaffolding is going up a level on the house and the roof trusses have arrived. Weather looking a bit moist next week though so we shall see if that halts progress a bit!

It's fixable... said:

Loving this project - just a quick question about the back gable of the garage - you said you wanted to store long things in there, but no high level access door in the rear gable to let you lean them up against the back of the garage and then draw them in from inside? No trying to be a smart arse just wondering why no door....

That's a fair point and in hindsight we could have done it. To be honest though, the only really long stuff that will go up there is probably dinghy sails, and rolled up they are flexible enough to go through a standard loft style hatch.More progress...up to wall plate height now on the house. Roof trusses now in despite the wind and the gable ends are taking shape. Brick arches in place above all the upstairs windows. Fingers crossed for the roof to be finished by the end of November, and the house to be watertight by Christmas.

View from the road...

Front of the house. The blue brick bases either side of the front door will be for the supporting posts for the porch canopy.

Back view...

[/url]

[/url]

Side view...

Teleporter for getting the materials up high...

First floor joists from the kitchen looking up through the master bedroom...

iPhone pano view from the scaffolding on the side of the house, which will also be the view from the main bathroom and the ensuite. Going to throw caution to the winds and we're just having plain, not frosted glass. We can always apply a privacy film on the onside of the glass if needed.

Hard to see it now but this will one day be the back garden. We dug half of it out flat, and the gradient change will be retained by gabian baskets sunk into the ground following the slope. This "wall" will run out of shot to the left, before running down the side of the house for 30 metres. The upside down boat is in our very tumbled down barn...and will be the "going to the pub boat" at some point!

View from the road...

Front of the house. The blue brick bases either side of the front door will be for the supporting posts for the porch canopy.

Back view...

[/url]

[/url]Side view...

Teleporter for getting the materials up high...

First floor joists from the kitchen looking up through the master bedroom...

iPhone pano view from the scaffolding on the side of the house, which will also be the view from the main bathroom and the ensuite. Going to throw caution to the winds and we're just having plain, not frosted glass. We can always apply a privacy film on the onside of the glass if needed.

Hard to see it now but this will one day be the back garden. We dug half of it out flat, and the gradient change will be retained by gabian baskets sunk into the ground following the slope. This "wall" will run out of shot to the left, before running down the side of the house for 30 metres. The upside down boat is in our very tumbled down barn...and will be the "going to the pub boat" at some point!

^Yikes! That's a bit of a nightmare...but it has been seriously windy!

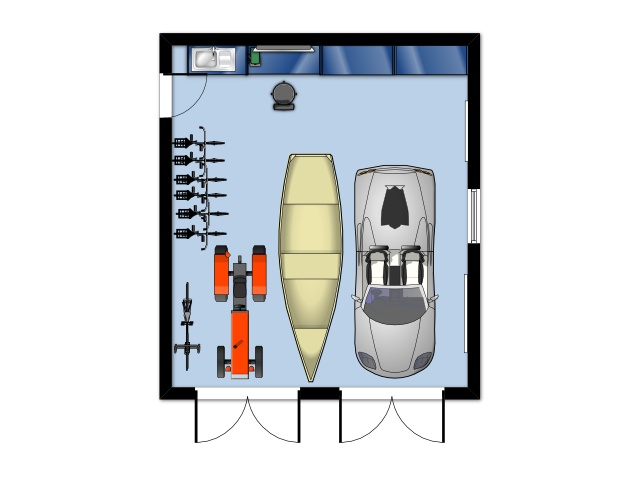

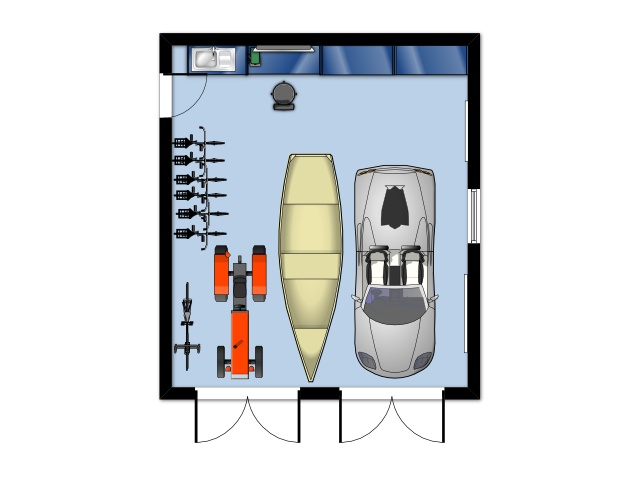

I started messing around with a basic CAD program called Floorplanner tonight just to plan the garage. It has some limitations, for example the car changes colour if you switch from 2d to 3d renders, but it gives me an idea of the layout and I now know which "BiGDUG" storage units to order! Another issue is the row of very high, but very short wheelbase bikes which are actually representing the space taken up by vertically hanging bikes but you get the idea. The generic tractor, rowing boat and Ferrari are actually a Countax ride-on mower, Fireball sailing dinghy and a Porsche Boxster, to scale. So there's plenty room, and for most of the time the boat won't be there.

I want to do the floor in those black vinyl interlocking floor tiles, but they are eye-wateringly expensive...reckon it's going to be circa £850 to do. Anyone know of any cheaper alternatives?

I started messing around with a basic CAD program called Floorplanner tonight just to plan the garage. It has some limitations, for example the car changes colour if you switch from 2d to 3d renders, but it gives me an idea of the layout and I now know which "BiGDUG" storage units to order! Another issue is the row of very high, but very short wheelbase bikes which are actually representing the space taken up by vertically hanging bikes but you get the idea. The generic tractor, rowing boat and Ferrari are actually a Countax ride-on mower, Fireball sailing dinghy and a Porsche Boxster, to scale. So there's plenty room, and for most of the time the boat won't be there.

I want to do the floor in those black vinyl interlocking floor tiles, but they are eye-wateringly expensive...reckon it's going to be circa £850 to do. Anyone know of any cheaper alternatives?

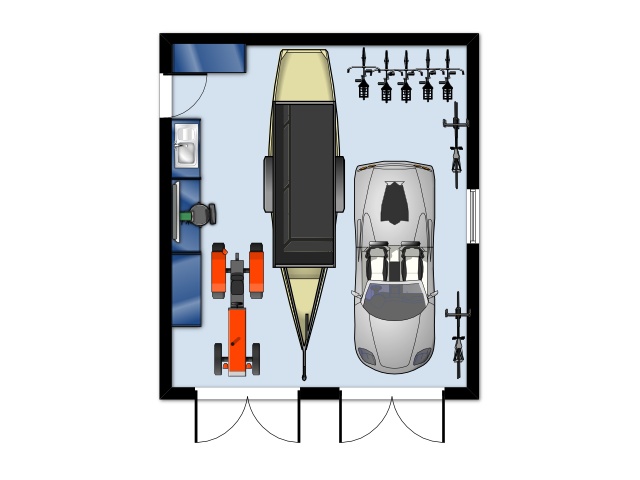

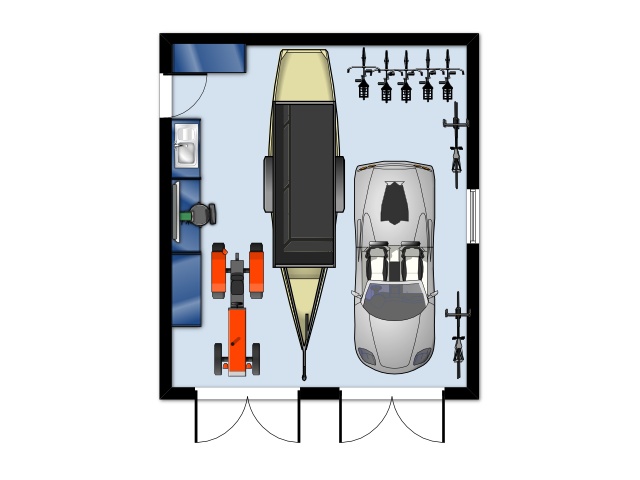

Or, with a bit of jiggery pokery I can fit my 50 year old Flying Fifteen keelboat in there too...

I rescued this boat off the sailing club bonfire pile as a total basket case a few years ago and spent ages rebuilding/redecking her...she's all wood and although she ended up looking like this after the rebuild, the past few winters outside have not been kind to the varnish and she badly needs to get indoors and under cover.

I rescued this boat off the sailing club bonfire pile as a total basket case a few years ago and spent ages rebuilding/redecking her...she's all wood and although she ended up looking like this after the rebuild, the past few winters outside have not been kind to the varnish and she badly needs to get indoors and under cover.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff

[/url]

[/url]