Prying down lower suspension arm

Discussion

Just wondering if there are any particular tips to get lower control arms low enough to remove ball joints or struts? I've always used body weight to lean on the lower arm (sometimes with another helper), but it's a faff and always takes a while.

Any particular tips? It's easy raising the LCA, but getting it lower is a right pain!

Any particular tips? It's easy raising the LCA, but getting it lower is a right pain!

I do 4 to 6 lower arms a week and all i use is either a 24inch prybar or a 48 inch one, all done on a pair of axle stands, maybe 1 in 40 is a problem to find somewhere to pry against, usually fixed by removing some plastic shield somewhere, hitting the floor is solved by using a long crowbar with a steeper angle on the prying end and for the extream ones i have a 6ft solid weightlifting bar.

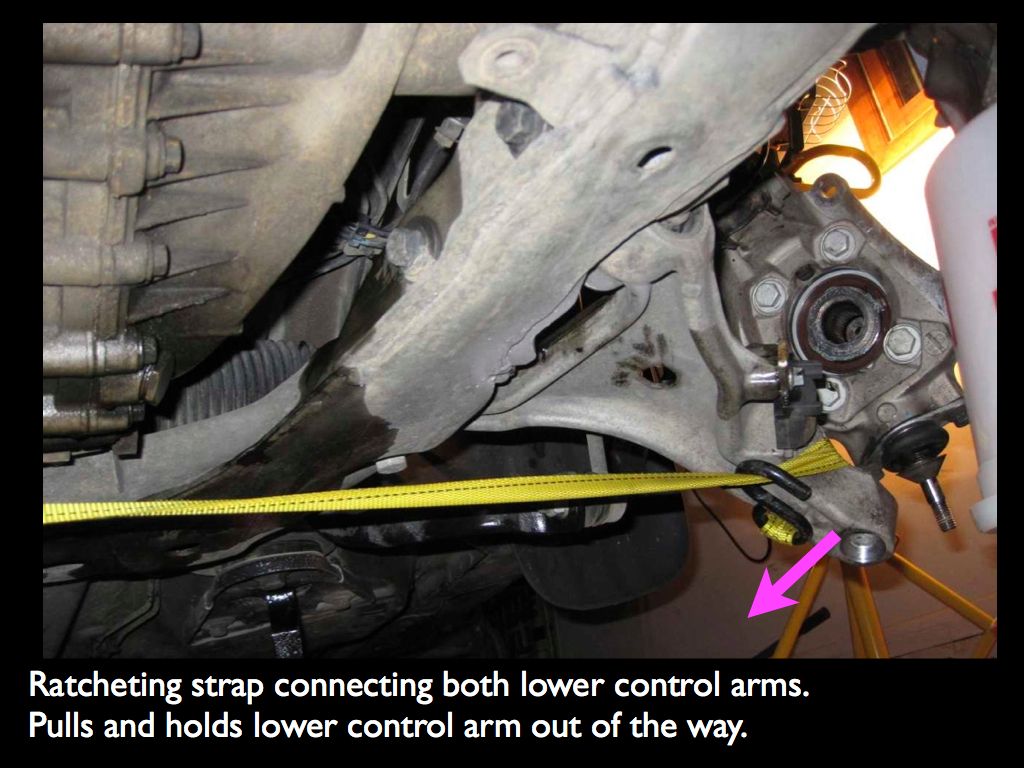

A length of chain circling the lower arm / wishbone (secured with a shackle or what have you..) and then a long prybar between the chain and the arm / wishbone, obviously on the underside. You could use a ratchet strap also I suppose instead of chain.

Assuming you have a bit of chain it takes seconds to set up and to remove.

Assuming you have a bit of chain it takes seconds to set up and to remove.

Spangles said:

Nice but a bit pricy for something most of us diy'ers would use once every few years.The chain round the prybar method I described above works the same way but that draper one be a whole lot less scratchy.

kev b said:

The chain or ratchet strap with a prybar or scaffold pole has always worked for me, sometimes use a block of wood to get more leverage.

Also if there is an anti roll bar attached then the opposite wheel should be off the ground.

Yeah, sounds good. Also, I've only got 1 side jacked-up, so will jack the other side so the wheel is off the ground on that side, too.Also if there is an anti roll bar attached then the opposite wheel should be off the ground.

I find it useful to turn the wheel to its full extent, and open the lower joint (where the pinch bolt sits) with a cold chisel. I usually then lever it down with a combination of ideas mentioned - the scaffolding bar being the most common. I also sometimes put a stilson wrench on the bar and lever the lower arm that way. But there's better ideas on here, especially the ratchet straps I think.

Gassing Station | Home Mechanics | Top of Page | What's New | My Stuff

(Jeep WK)

(Jeep WK)

Good tip, I learnt this the hard way.

Good tip, I learnt this the hard way.