Bloodhound LSR Thread As Requested...

Discussion

There is no doubt that there are a number of factors that can only be guessed (highly educated guesses) at, currently.

When the car gets to SA next year, puts in some supersonic runs and gathers some data then many questions will have information that helps to extrapolate the effect of another 200 to 250mph.

The more information the less the (informed) guess work.

Paul

When the car gets to SA next year, puts in some supersonic runs and gathers some data then many questions will have information that helps to extrapolate the effect of another 200 to 250mph.

The more information the less the (informed) guess work.

Paul

wst said:

Will there be any data logging stuff in the point like a pitot tube?

I'm presuming of course that the rumbling through the ground doesn't shake up a layer of pitot-clogging dust just barely ahead of the vehicle (what with how sound through the ground travels faster than sound through the air)...

Pitot is mounted way up on the fin leading edge away from any of the shockwaves. I'm presuming of course that the rumbling through the ground doesn't shake up a layer of pitot-clogging dust just barely ahead of the vehicle (what with how sound through the ground travels faster than sound through the air)...

mcdjl said:

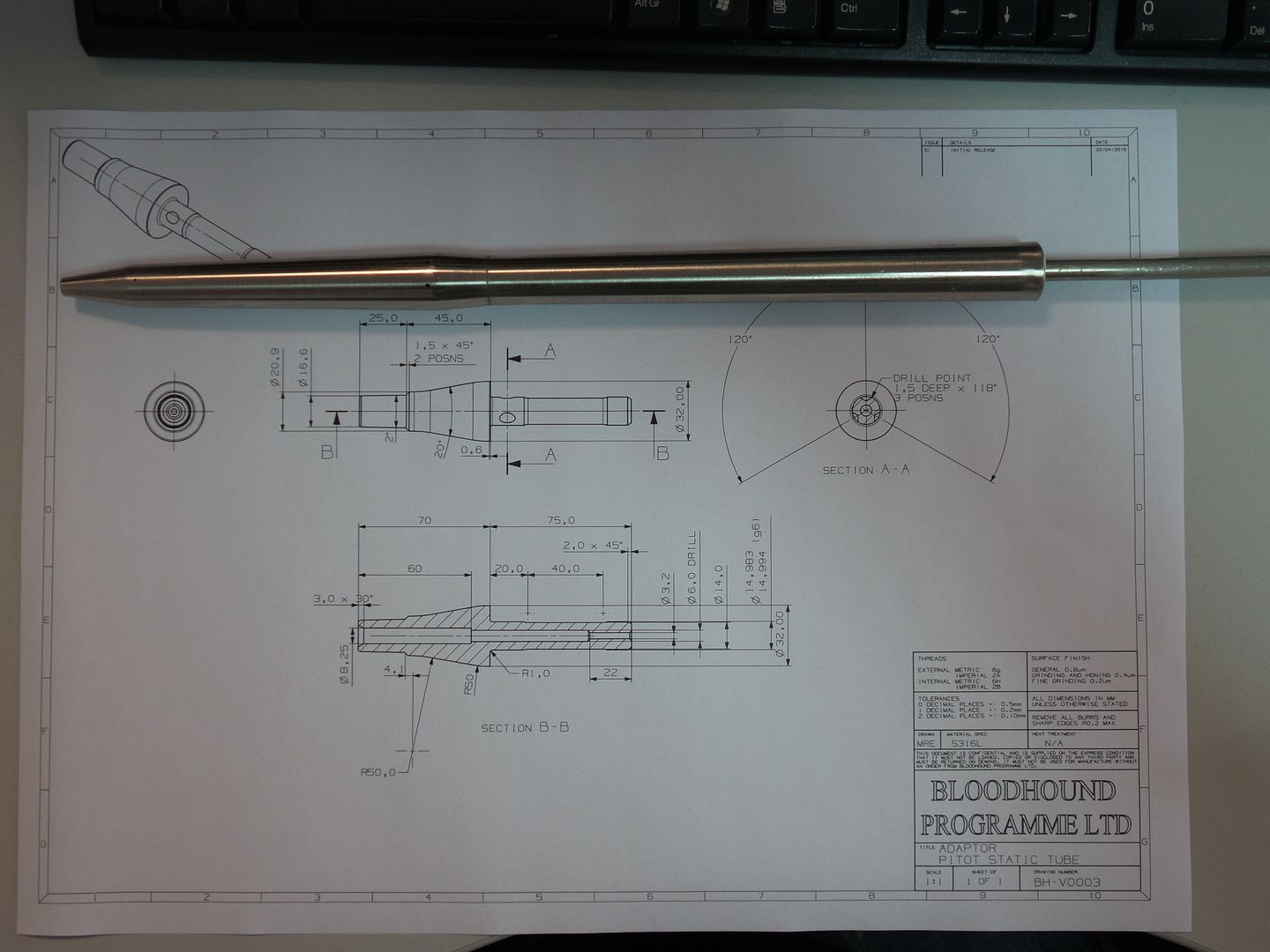

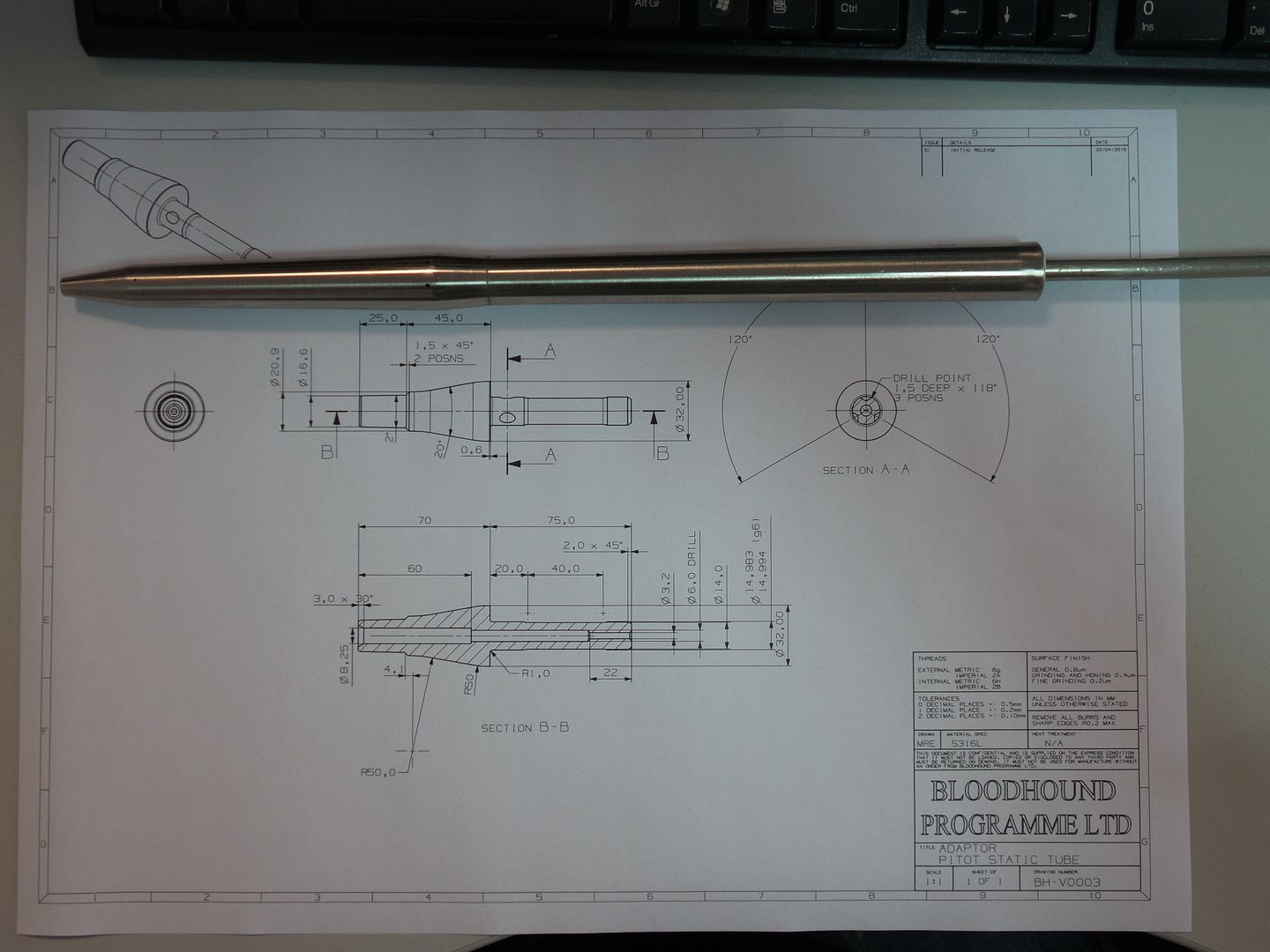

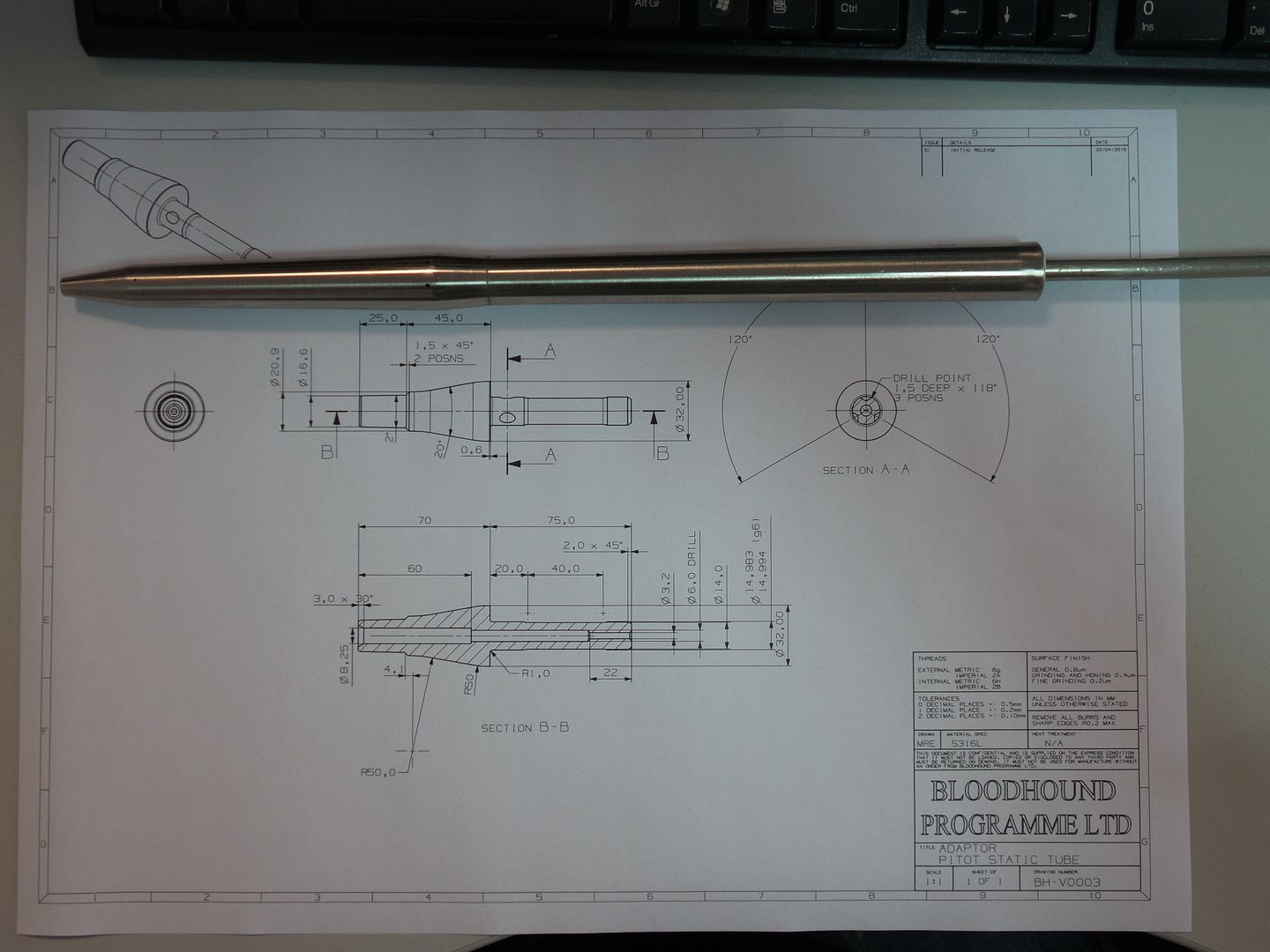

Er, that's actually what our pitot is from, here it is pre attachment. We're only using the dynamic pressure reading, taking static from a point reading at the moment the brakes are released at the beginning of a run.

iiyama said:

What exactly are all those black T shaped fittings within the fin? They look to have a thread on one end, so I assuming some kind of bolt? If this is the case what is the reasoning behind the T shape?

Ta!

Tooling pins to hold the intercostal ribs in the correct posn until the fin is ready to be stitched up.Ta!

IN51GHT said:

Er, that's actually what our pitot is from, here it is pre attachment. We're only using the dynamic pressure reading, taking static from a point reading at the moment the brakes are released at the beginning of a run.

Yeah but you're putting it in the wrong place!

That does look cool though.... Where can I get one....?

IN51GHT said:

iiyama said:

What exactly are all those black T shaped fittings within the fin? They look to have a thread on one end, so I assuming some kind of bolt? If this is the case what is the reasoning behind the T shape?

Ta!

Tooling pins to hold the intercostal ribs in the correct posn until the fin is ready to be stitched up.Ta!

IN51GHT said:

iiyama said:

So why these rather than skin pins? What's the advantage of them?

Skin pins hold the skin to the structure, the tooling pins hold the structure to the assy fixture, they are a ground pin, so a very good fit in the 6mm reamed tooling holes in the structure.Gassing Station | General Gassing | Top of Page | What's New | My Stuff