Bloodhound LSR Thread As Requested...

Discussion

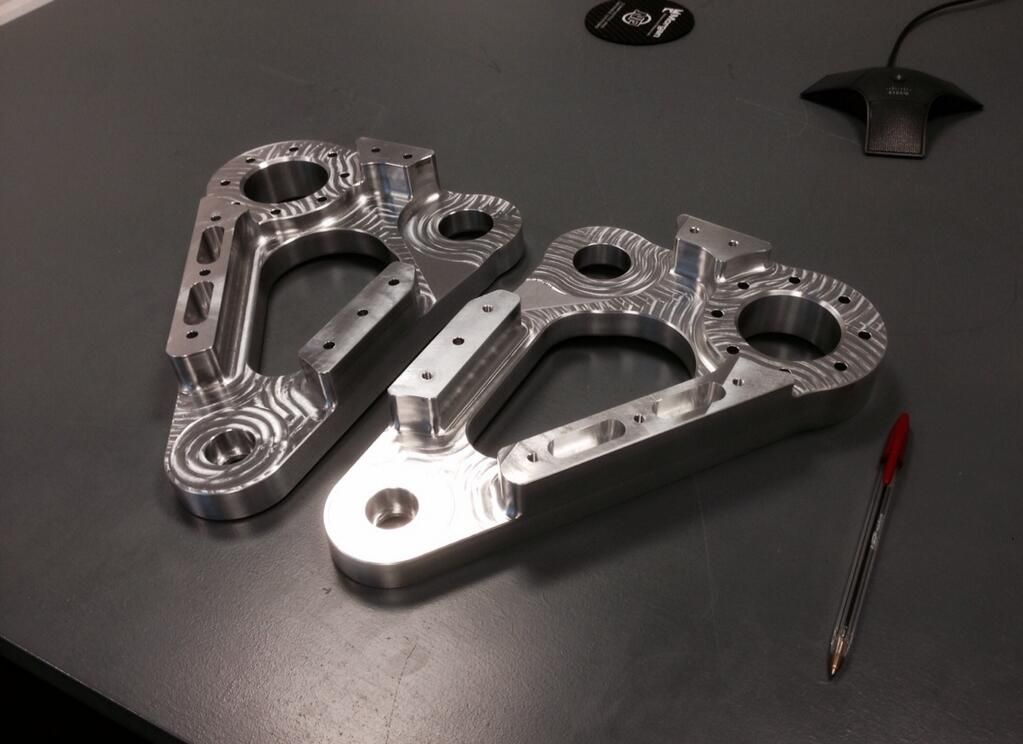

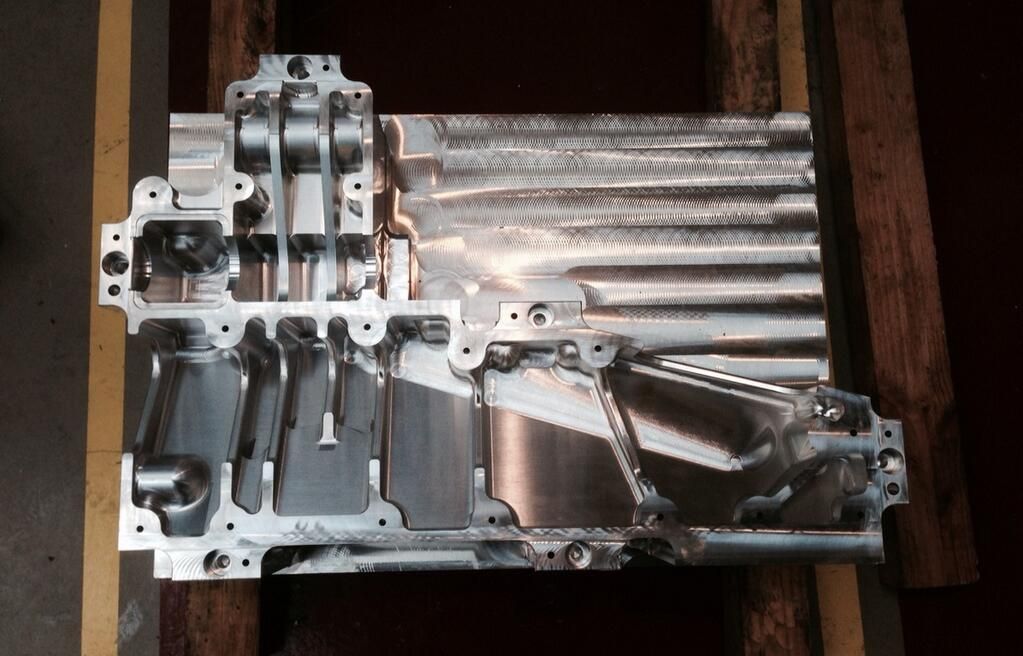

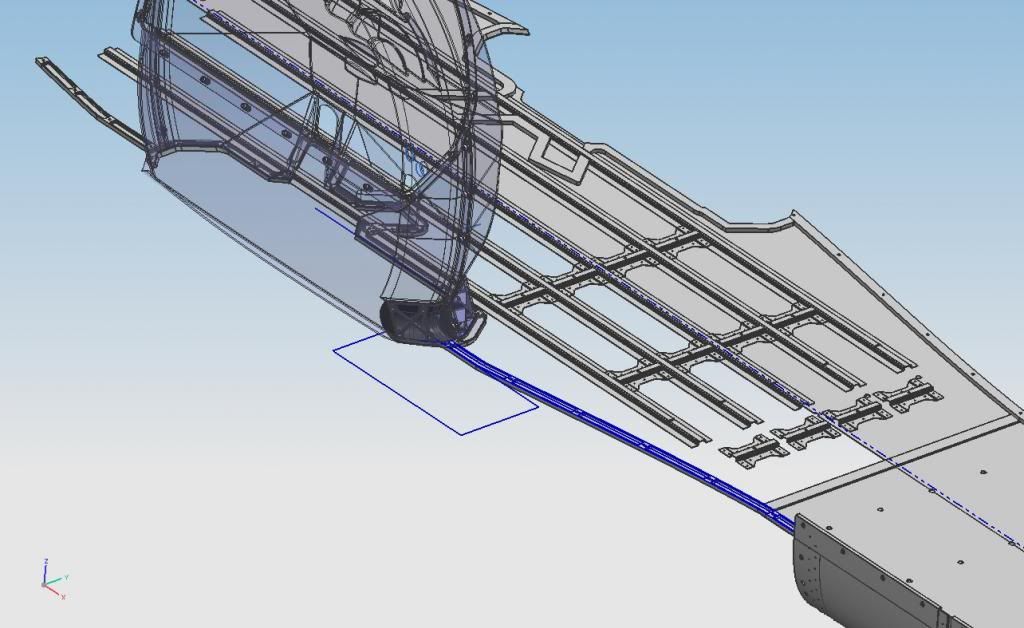

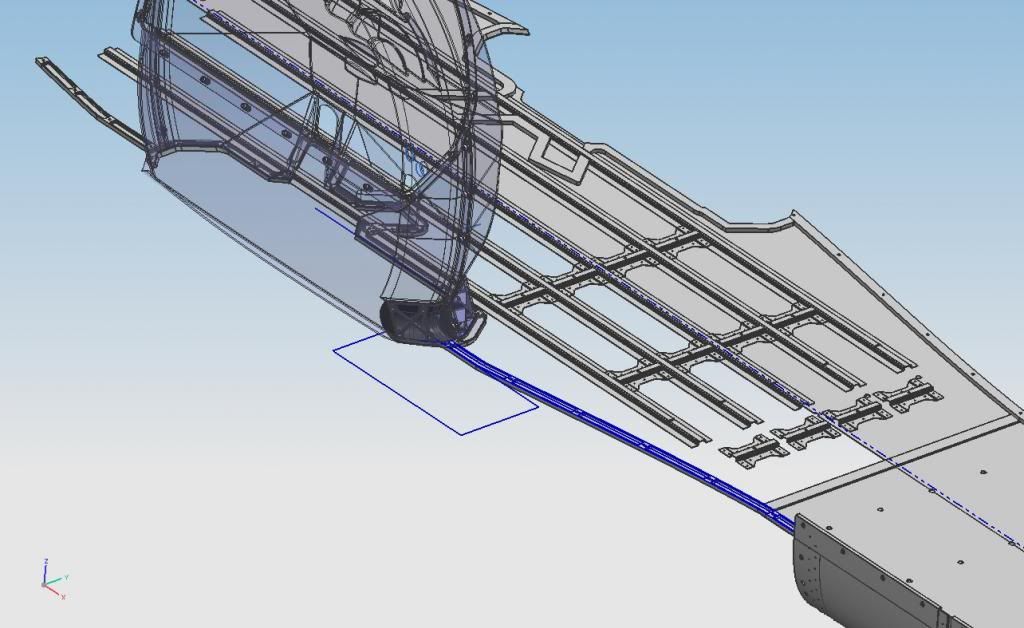

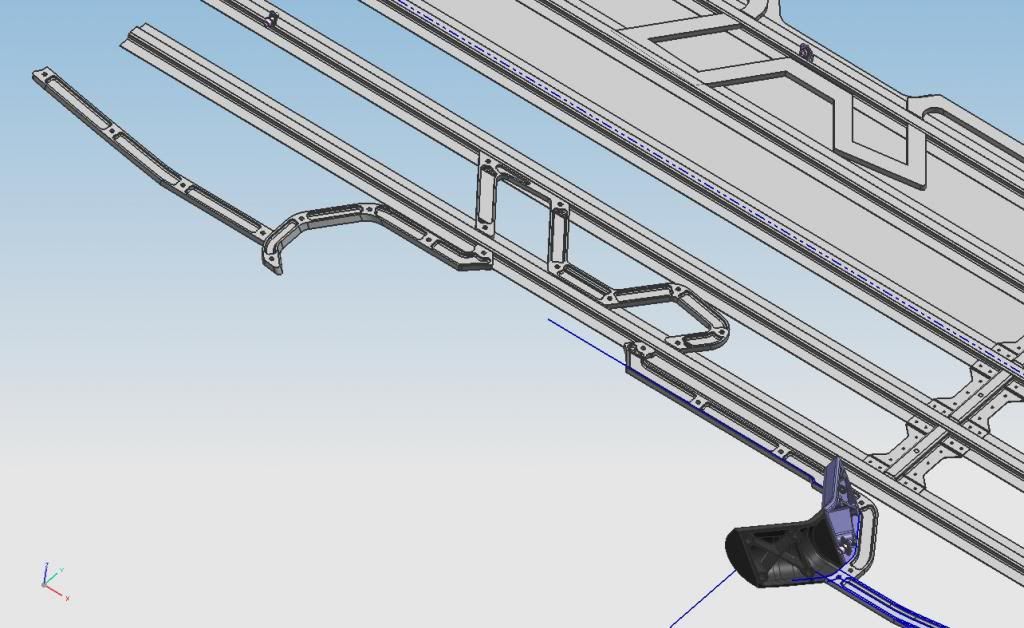

Today's job. Trying to fasten the twintex wheel pans to the steel floor.

Using 25mm aluminium edge members, riveted & bonded to the steel floor, these will have c/bore in from the underside & the anchor nuts on the wheel pan. That way we can remove the car floor without having to remove the side body panels.

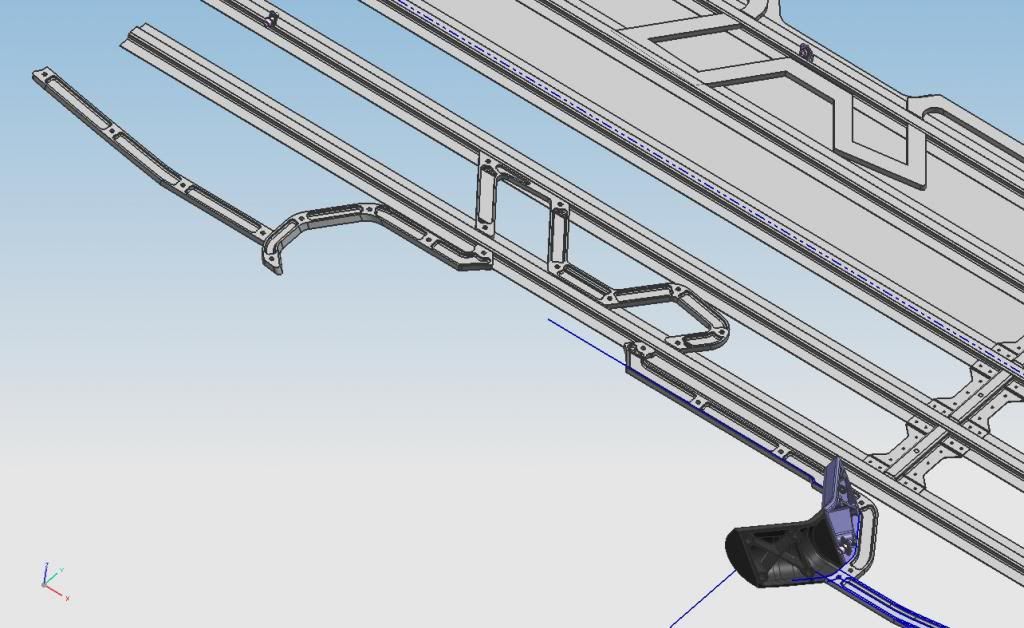

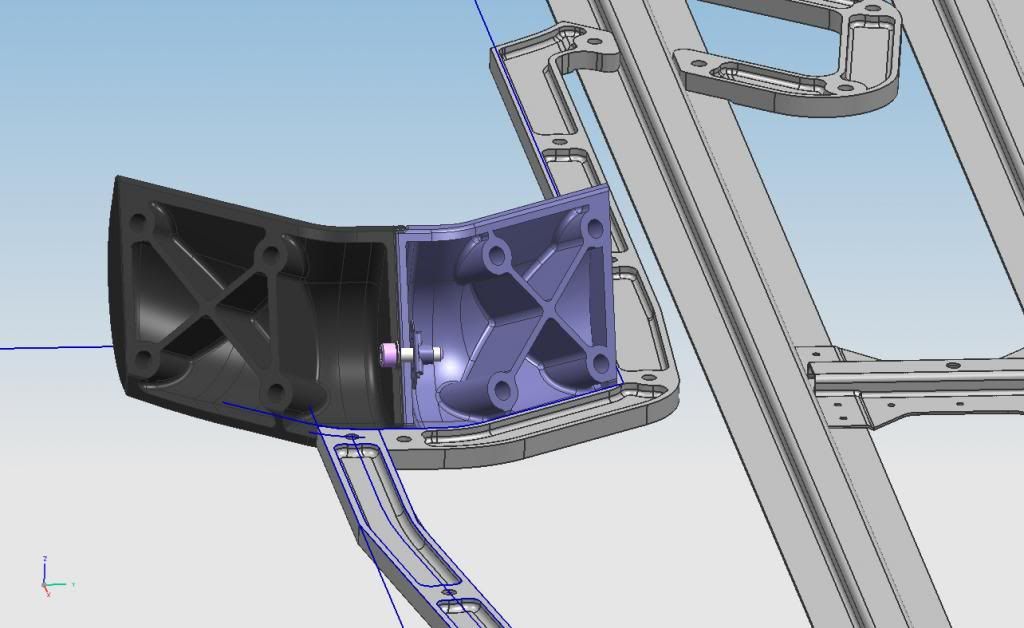

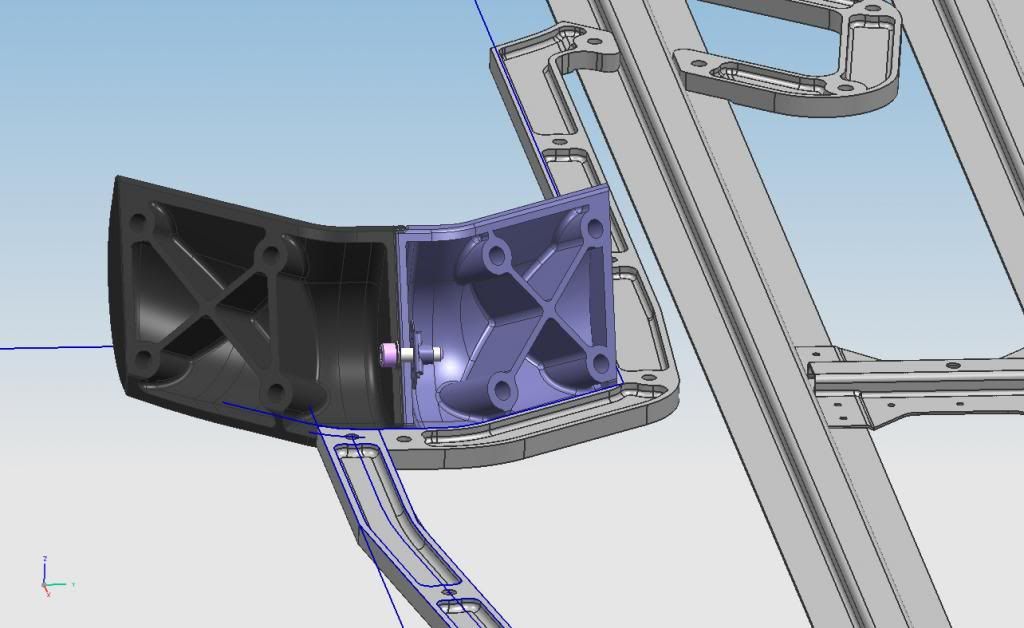

The two large block at the lower R/H side of the images are the erosion protection blocks, 3d printed Ti blocks attached to the wheel pans, nominal 4mm thickness. As a pair, they are 200mm x 90mm x 50mm, will weigh about 1.25kg for the pair, they will take quite a beating.

Last pic shows the back face of the erosion protection blocks.

Using 25mm aluminium edge members, riveted & bonded to the steel floor, these will have c/bore in from the underside & the anchor nuts on the wheel pan. That way we can remove the car floor without having to remove the side body panels.

The two large block at the lower R/H side of the images are the erosion protection blocks, 3d printed Ti blocks attached to the wheel pans, nominal 4mm thickness. As a pair, they are 200mm x 90mm x 50mm, will weigh about 1.25kg for the pair, they will take quite a beating.

Last pic shows the back face of the erosion protection blocks.

Edited by IN51GHT on Saturday 30th November 13:55

Silent1 said:

3d printed ti? why? surely just cnc'd would make more sense and also I didn't think there was a true 3d printing for metal yet, theres sintering IIRC but nothing that's as strong as cast.

Or am I a bit behind on that side of things?

Combination of factors really. But yes, rather than traditional printing, it is laser sintering (printing just being a generic term)Or am I a bit behind on that side of things?

1. Odd shape tricky tool holding for machining, thus possibly requiring tooling to be made, added cost.

2. We have access to laser printing Ti equipment FOC

3. It'll make a good story for the education programme.

El Guapo said:

Why have the large alloy components been machined from billet rather than forged? If I correctly remember the general principles, forged pieces would be easier & faster to make and would have better strength to weight.

That is correct, but tooling costs make it prohibitive for one off parts.Just another moody shot courtesy of Stefan Marjoram, upper chassis back on car ready for this weekends 1k Club event on Sunday.

Also, happy Christmas from all at Bloodhound SSC

http://youtu.be/YABsV2Zxvuo

Also, happy Christmas from all at Bloodhound SSC

http://youtu.be/YABsV2Zxvuo

rufusruffcutt said:

In5ight, are these beautifully machined parts going to be coated with anything, such as zinc chromate, to protect them? or are they going to be left as is due to the limited running of the car? Thanks

Just clear anodised to protect. Can't have them going furry when in a museum.Storer said:

I just love the detail needed for this monster. There has to be a good deal of confidence in your calculations for loadings and stresses on the components as you are entering the unknown!

The RF's we are working on are the same as those applied to a commercial airliner, the only difference is we've had to make certain "educated assumptions" as there is no precedent. We will compare real word figures from the various strain gauges, load cells, accelerometers, pressure tapping, thermocouples etc to make sure the correlate with the calculations. If they don't we need to find out why there is a discrepancy & assure ourselves 100% that it is safe to continue.Storer said:

Don't commercial airliners take off at less than 200mph?

Correct me if I am wrong but I think Andy wants to stay in touch with terra firma, albeit lightly, at 1000mph (that is an extraordinary number). I know you can use information from testing and previous record attempts but there has to be a large element of assumptions/guestimates because it hasn't been done before, or do you have info from unmanned high speed sledge runs?

Paul

Hence the phrase "educated assumptions"Correct me if I am wrong but I think Andy wants to stay in touch with terra firma, albeit lightly, at 1000mph (that is an extraordinary number). I know you can use information from testing and previous record attempts but there has to be a large element of assumptions/guestimates because it hasn't been done before, or do you have info from unmanned high speed sledge runs?

Paul

robinessex said:

You can be rest assured that just about every conceiveable calculation and assumption has been covered to make sure this beast says on tera firma! Exploring unknown territory is always a gamble. But maybe the guys (brains) involved have 'discovered' something new, and are keeping it to themsleves? Could have great commercial value!!!

Everything we discover along the way is shared with the outside world, it's part of the education programme, Bloodhound is a strictly not for profit organisation, every spare panny goes into the programme. Irrotational said:

Slightly OT but I'd highly recommend seeing the previous car at the Coventry car museum. It is awesome to stand next to it and try to imagine it at full chat!!

We (me, my wife & two daughters) have an open invite to go up to Coventry to see (& sit in) both LSR cars.Storer said:

I just hope your "education" was far better than mine (I'm sure it was and I admire the detail going into this project).

Paul

Left school with only a C in physics & geography to my name at GCSE level. Hated it with a passion, was bullied badly, generally had a torrid time. Even looking back now, 25 years on, it makes my blood run cold.Paul

Went to sixth form to do re-takes in Maths, English & Art, but they said I needed to do four subjects, so I chose an extra, new to me subject, called EWTP (Engineering Workshop Theory & Practice), which was normally a 3year course, but there were only 4 of us doing it so they agreed to do it over a year.

I flunked my English, Maths & Art but got an A* in EWTP, something just clicked, I really enjoyed it.

On the strength of that single good grade I got a 4 year aerospace craft apprenticeship at Westland helicopters, which during my placements involve me spending a 3month spell in the design office. At the end of the apprenticeship a handful of the original 30 or so were kept on, I was offered two positions, on in transmission R&O, one in the design office.

I went for the DO as I assumed the prospects would be better.

After several years working my way up the ladder in the DO we went to the motor show in 1999 at the NEC, we were given a Daily Telegraph, which we though would come in handy for lining the Guinea Pigs cage out when we cleaned them out.

So, we were cleaning the aforementioned Guinea Pigs out, when I noticed on the jobs page that Williams F1 were recruiting for Design Engineers with degree or equivalent. I wasn't going to bother applying, despite working for Williams very much being on my 'bucket list' SHMBO persuaded me, which took some doing.

As you can guess, I got the job, spent 6 years there, learning all of the time up to the point where I left due to family commitments.

After 5 years at Invensys Rail, in a job that required little brain work, I felt I was dying inside, then at exactly the right moment, the crazy house that is Bloodhounds came to my rescue, and here I am.

So my education has very much been career based, to the point where I'm going through the IMechE chartered application over the next month or so.

Edited by IN51GHT on Friday 13th December 07:16

Megaflow said:

IN51GHT said:

Problem is, some people actually think that, hence the IMechE chartered application.

I thought to be chartered a degree was a prerequisite?MarkGArgyle said:

Lucky to meet with Tony P from sponsor liaison for dinner last night who gave a cracking presentation (twice) to the guys here in Ireland. People still discussing it hours later.

Just wanted to say it is a fantastic project and we look forward to supporting it in the future.

Why not start a donation for the PH smiley - got to get it on the car somewhere

Tony the Tiger.Just wanted to say it is a fantastic project and we look forward to supporting it in the future.

Why not start a donation for the PH smiley - got to get it on the car somewhere

He rocked up at the party in a Tiger onesie, which I borrowed when I went for a midnight run around the zoo after it was closed!!

Gassing Station | General Gassing | Top of Page | What's New | My Stuff