Question about BHP + Torque

Discussion

Also, if you want another metric to compare different NASP engines, there is a 'Performance Index' discussed in this thread, and compared in this wiki

Torque at the wheels is power at the wheels / engine revs.

"Torque at the wheels" is a horrible name for "effective measured torque", but it's what people call it.

I would love a better name : feel free to invent a better name - it may catch on.

I would like to suggest "axle torque" to refer to the torque that is directly turning the wheels, to avoid confusion. It is a fairly useless measure, as you need to factor in rolling radius to get force / acceleration.

"Torque at the wheels" is a horrible name for "effective measured torque", but it's what people call it.

I would love a better name : feel free to invent a better name - it may catch on.

I would like to suggest "axle torque" to refer to the torque that is directly turning the wheels, to avoid confusion. It is a fairly useless measure, as you need to factor in rolling radius to get force / acceleration.

CrutyRammers said:

Mave said:

wedgeinald said:

This is VERY simplistic but here goes...

Torque is the ability to accelerate

Power is the ability to maintain speed

I hope this is of some help.....

Sorry, that's not simplistic, its plain wrong, and adds to the confusion.Torque is the ability to accelerate

Power is the ability to maintain speed

I hope this is of some help.....

Torque is how hard you accelerate in any given gear.

Power is how hard you accelerate at any given speed.

Kozy said:

The only accurate version of 'TI/PI' is this:

Torque is how hard you accelerate in any given gear.

Power is how hard you accelerate at any given speed.

This is correct though as with most generalisations it could be misinterpreted. Torque is how hard you accelerate in any given gear.

Power is how hard you accelerate at any given speed.

For those that don't understand the principle of torque, power and gearboxes it is useful to understand that gearboxes simply transform speed and torque. The power in and the power out are the same (ignoring losses).

Speed out = Speed in / Gear ratio

Torque out = Torque in * Gear ratio

Power in = Power out

Say I have a vehicle travelling at 10m/s on 1m diameter wheels which requires 200bhp to maintain this speed. The wheel rotational speed is therefore (10/pi)*60 = 191rpm or 20rads/s. The wheel torque is therefore (200*746)/20 = 7460Nm

- Case 1: This vehicle has a tractor engine producing 200bhp at 1000rpm. This engine is therefore producing (200*746)/(1000*2*pi/60) = 1425Nm of torque at this speed. The gearbox ratio required is 1000rpm/191rpm = 5.23. We note that the engines 1425Nm of torque multiplied by the gearing ratio of 5.23 gives the 7460Nm of wheel torque required to keep the vehicle moving

- Case 2: This vehicle has a motorbike engine producing 200bhp at 18000rpm. This engine is therefore producing (200*746)/(18000*2*pi/60) = 79.15Nm of torque at this speed. The gearbox ratio required is 18000rpm/191rpm = 94.24. We note that the engines 79.15Nm of torque multiplied by the gearing ratio of 94.24 gives the 7460Nm of wheel torque required to keep the vehicle moving

wormus said:

Mave said:

Mr2Mike said:

Don't be daft. How could a car move without a torque being applied to the driven wheels?

Read my post again. I didn't say wheel torque doesn't exist. I said the thing he is calling wheel torque doesn't exist. Because I don't think the graph actually shows torque at the wheel,

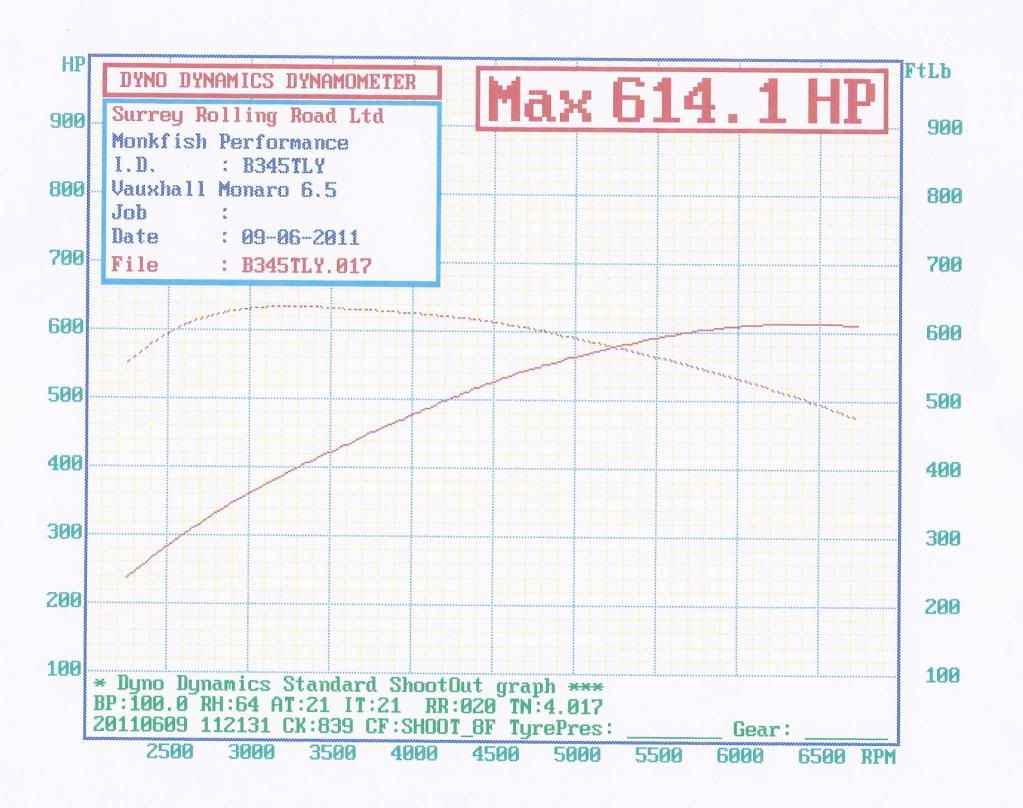

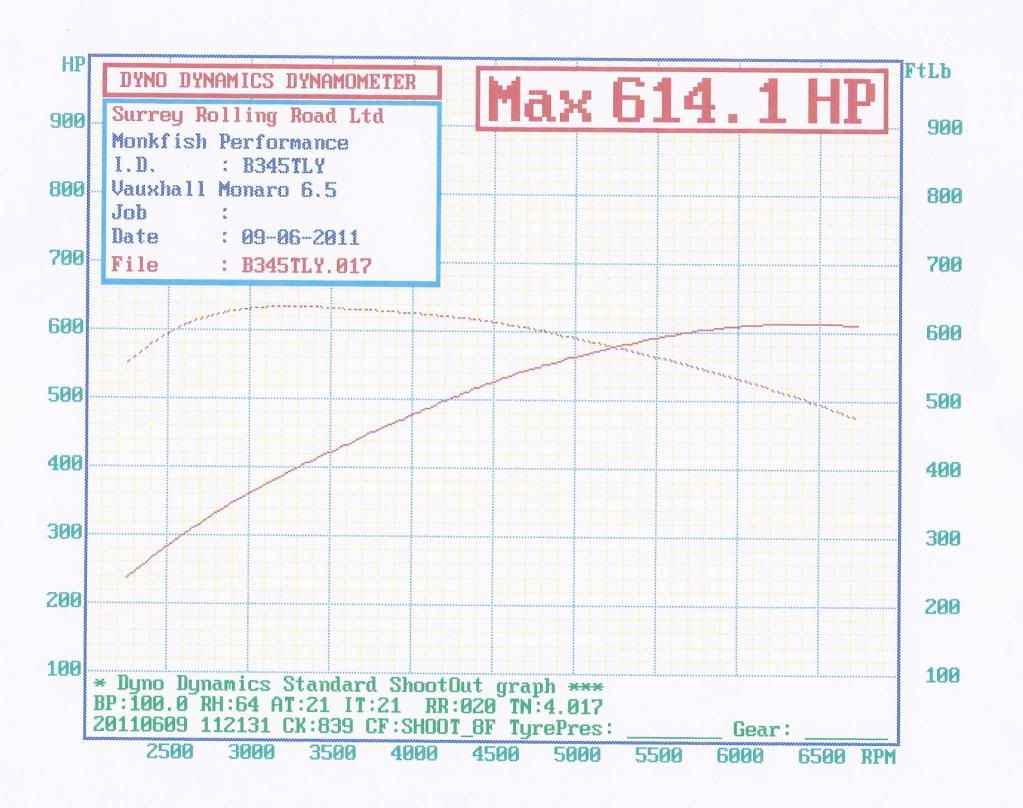

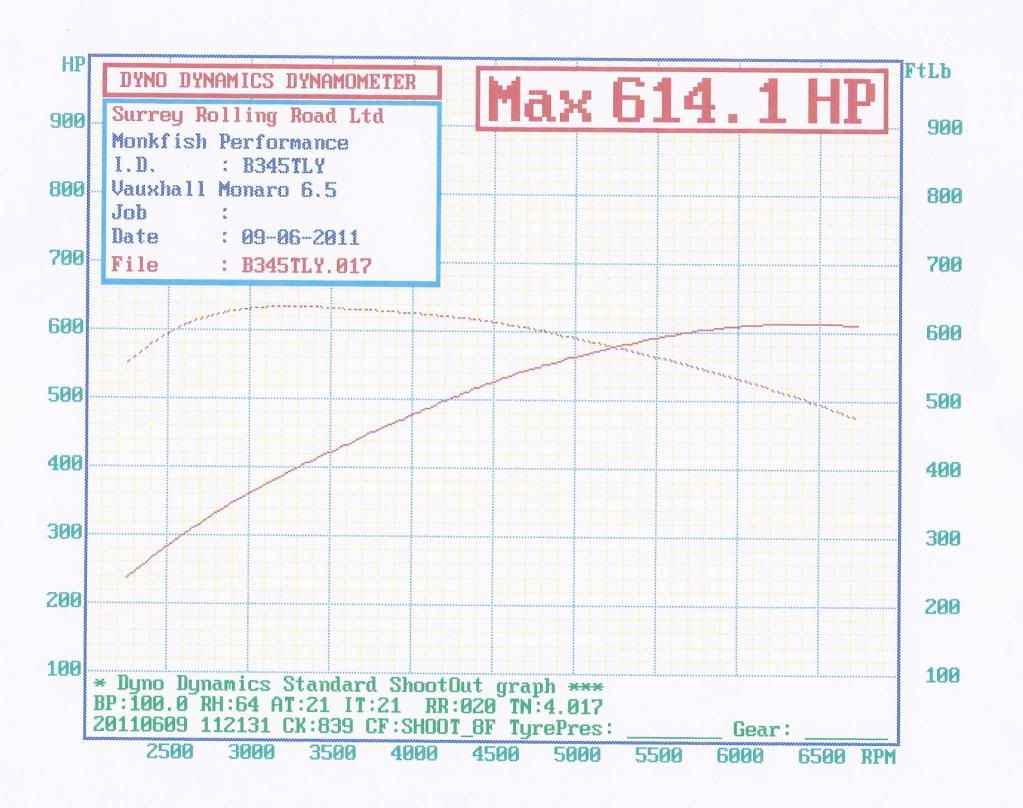

At 7000rpm it makes 614 wheel horsepower = 461*7000/5252. 461 lbs of what if not wheel torque?

You're just wrong. Tractive effort is what you're trying to calculate 'wheel torque' is nonsensical at 461lb.ft from a physical point of view as with your gear ratios would be about 200BHP. If that.

GroundEffect said:

So your back wheels are spinning at 7000rpm?

You're just wrong. Tractive effort is what you're trying to calculate 'wheel torque' is nonsensical at 461lb.ft from a physical point of view as with your gear ratios would be about 200BHP. If that.

No clearly it's engine RPM and you are being foolish. Christ, cannot wait until the schools go back! You're just wrong. Tractive effort is what you're trying to calculate 'wheel torque' is nonsensical at 461lb.ft from a physical point of view as with your gear ratios would be about 200BHP. If that.

wormus said:

GroundEffect said:

So your back wheels are spinning at 7000rpm?

You're just wrong. Tractive effort is what you're trying to calculate 'wheel torque' is nonsensical at 461lb.ft from a physical point of view as with your gear ratios would be about 200BHP. If that.

No clearly it's engine RPM and you are being foolish. Christ, cannot wait until the schools go back! You're just wrong. Tractive effort is what you're trying to calculate 'wheel torque' is nonsensical at 461lb.ft from a physical point of view as with your gear ratios would be about 200BHP. If that.

I'm not being foolish, you just don't make any physical sense. It can't be 'torque at the wheels' if no element of the wheel/tire/half shaft assembly ever sees that torque. Keep to reality.

wormus said:

GroundEffect said:

Check my Occupation.

Don't care what you do for a living TBH. You aren't arguing with me, you are arguing with my dyno graph. If you have something to explain, explain it. Perhaps you can explain my graph too? What they are calculating is power at the wheels through the torque at the wheels (the 'tractive effort' you keep mentioning) then multiplying this by a predefined factor - typically 85% efficiency - to calculate the power at the flywheel/crank.

To get the 'torque at the wheels' you want, they would just take the power they calculate at the wheels and do standard linear manipulation to turn it to a 'torque'...but it actually doesn't mean anything. No part of your drivetrain will ever see it.

What you should care about:

1) Engine torque curve

2) Driveline efficiency

3) Trans/DL ratios

With the above you can basically work out all your performance metrics...assuming wheel slip etc is known.

Torque is the entire game. That's the closest to base unit there is.

wormus said:

Well it says something:

At 7000rpm it makes 614 wheel horsepower = 461*7000/5252. 461 lbs of what if not wheel torque?

It looks like you are making 614 bhp up to about 6500rpm not 7000rpm so the calculated torque is is 496ftlb, which matches your graph.

At 7000rpm it makes 614 wheel horsepower = 461*7000/5252. 461 lbs of what if not wheel torque?

This is not the measured torque at the wheels however, it is a calculated figure which is equivalent to the torque produced at the engine rpm for the delivered power if there are no drivetrain losses. This is what Mave said earlier.

If you were to have a wheels rpm scale across the top of the graph then you could plot the calculated wheel torque. This would mean that the torque scale would be different from the power scale. When using bhp and ftlb it is quite convenient that the same scale values can be used and have the traces occupy the same area of the graph.

Speedy11 said:

wormus said:

It was your excessive trolling that killed the Mark Higgings/IOM TT thread. Shame.

Pointing out in that thread that you and ZX10R NIN didn't understand torque or that his claimed figures for his engine are impossible is not trolling.wormus said:

Don't care what you do for a living TBH. You aren't arguing with me, you are arguing with my dyno graph. If you have something to explain, explain it. Perhaps you can explain my graph too?

I suspect this is going to be like banging my head on a brick wall but here goes:Torque is an angular moment, a force multiplied by the distance from the axis of rotation that the force is applied.

Tractive effort in this case is the linear force between the tyres and the road acting on the mass of the vehicle to accelerate it. This linear force is calculated from the angular moment on the wheels divided by the radius of the wheels. The tractive effort is therefore proportional to the torque at the driveshafts.

Gear ratios multiply torque and divide speed thus maintaining the same output power. Successive gearing stages in a drivetrain multiply together to give one total gear ratio between the engine crankshaft and the driveshafts.

What a dyno actually measures is the torque and speed of its rollers not the axle of the car.

- If your wheels are the same diameter as the rollers the torque and speed of the rollers will be same as the cars axle.

- If your wheels are half the diameter of the rollers the torque on the rollers will be double and the speed half that of the cars axle.

- If your wheels are double the diameter of the rollers the torque on the rollers will be half and the speed double that of the cars axle.

For every gradation of speed the dyno calculates the measured power (roller torque * roller speed) and logs the actual engine speed. After the run it plots the measured power directly against the logged engine speed. The torque plot is derived by dividing each value of power by its respective logged engine speed. At no point does the dyno actually know what the torque at the axle/wheels is.

The phrase 'Torque at the wheels' is therefore misleading. What it actually means is 'Torque at the crankshaft adjusted for drivetrain losses'. The 'power at the wheels' on the other hand is absolutely correct.

Edited by TurboHatchback on Tuesday 29th July 17:22

wormus said:

Irrespective of the fact the man you are arguing with about the TT is a TT racer who had put in a 127mph lap? I'm surprised he was as patient as he was TBH.

What has that got to do with the fact he was wrong? An engine can't make 90bhp @ 9700 rpm with only 37 lb-ft. So either he made them up or his dyno was broken.GroundEffect said:

I can make a graph. It will take me about 30 seconds in Excel. Doesn't mean it actually represents anything that the rollers are feeling as a torque.

What they are calculating is power at the wheels through the torque at the wheels (the 'tractive effort' you keep mentioning) then multiplying this by a predefined factor - typically 85% efficiency - to calculate the power at the flywheel/crank.

To get the 'torque at the wheels' you want, they would just take the power they calculate at the wheels and do standard linear manipulation to turn it to a 'torque'...but it actually doesn't mean anything. No part of your drivetrain will ever see it.

What you should care about:

1) Engine torque curve

2) Driveline efficiency

3) Trans/DL ratios

With the above you can basically work out all your performance metrics...assuming wheel slip etc is known.

Torque is the entire game. That's the closest to base unit there is.

Thanks for taking the time to explain. I'm not sure how this thread escalated. I was referring to a number on a graph, I have had many numbers on similar graphs to compare to to know 770lbs "at the wheels" is too much while 600lbs is about right to avoid constant loss of traction. As many of you don't own a Monaro, with my combination of engine, power, diff or gearbox the whole discusiion seems a little ridiculous.What they are calculating is power at the wheels through the torque at the wheels (the 'tractive effort' you keep mentioning) then multiplying this by a predefined factor - typically 85% efficiency - to calculate the power at the flywheel/crank.

To get the 'torque at the wheels' you want, they would just take the power they calculate at the wheels and do standard linear manipulation to turn it to a 'torque'...but it actually doesn't mean anything. No part of your drivetrain will ever see it.

What you should care about:

1) Engine torque curve

2) Driveline efficiency

3) Trans/DL ratios

With the above you can basically work out all your performance metrics...assuming wheel slip etc is known.

Torque is the entire game. That's the closest to base unit there is.

Gassing Station | General Gassing | Top of Page | What's New | My Stuff