RE: VW's VAQ 'diff' explained

Discussion

P4GNO said:

This system appears to do something very similar but applying it after the diff.

The "Cleverness" of this new system is that it allows VW to use one single mains gearbox for ALL of their models (which reduces costs and parts count / build differences) and then just bolt on the appropriate system. (be that a blanking plate for no LSD, a Bevel gearbox for the 4wd cars, or this new "LSD" for the hot front drivers).The fact that the clutches are "external" to the diff cage is really irrelevant in terms of operation, they still act to control the differential speed (slip) between the halfshafts and the Crownwheel/diffcage, just like a conventional LSD does.

The benefits of this "external" packaging come at build time and to reduce production costs by lowering parts count differences between models, and this makes for a high volume for any given part and hence a lower piece cost!

Regarding front to rear torque splitting systems like Haldex Et-al, the important thing that people tend to forget is that to modify the yaw of a vehicle, you need to modify the mean tyre slip and NOT the mean drive torque at each end of the car!!

The following graph is important:

And the following statement is CRITICAL:

"A tyre can supply a maximum force vector at its contact patch for any given vertical load. That vector is the summation of the Lateral and Longitudinal forces acting on that tyre"

What that means is that increasing one component of the total force vector, say the lateral load, MUST necessarily reduce the other component of that vector so as not to exceed the magnitude of the total force vector available.

"So what" i hear you say! Well, the reason we can "drift" a rwd car round a bend is precisely because of the fact that by applying excess wheel speed to the rear axle, increasing longitudinal load, the lateral load capability of the tyre falls, and the tyre "slips sideways" on the road, and bingo, drift city (or an ungainly and embarrassing exit into a hedge/ditch/bus-stop depending on your skills...... ;-)

So, to control vehicle yaw, any front/rear torque biasing system must be able to vary the driven SPEED of it's axles independently and NOT just the driven Torque of those axles. This is because the front and rear axles are linked by the vehicle body, and so more longitudinal load at EITHER end results in a vehicle acceleration!

The corollary of this is that to provide full yaw control, any torque vectoring system must be able to REDUCE the drive torque at the opposite end from which it is apply it. "Clutch based" systems without epicyclic differentials CANNOT do this, and so can never approach the yaw authority of either a rwd or proper torque vectoring system.

The following graph is important:

And the following statement is CRITICAL:

"A tyre can supply a maximum force vector at its contact patch for any given vertical load. That vector is the summation of the Lateral and Longitudinal forces acting on that tyre"

What that means is that increasing one component of the total force vector, say the lateral load, MUST necessarily reduce the other component of that vector so as not to exceed the magnitude of the total force vector available.

"So what" i hear you say! Well, the reason we can "drift" a rwd car round a bend is precisely because of the fact that by applying excess wheel speed to the rear axle, increasing longitudinal load, the lateral load capability of the tyre falls, and the tyre "slips sideways" on the road, and bingo, drift city (or an ungainly and embarrassing exit into a hedge/ditch/bus-stop depending on your skills...... ;-)

So, to control vehicle yaw, any front/rear torque biasing system must be able to vary the driven SPEED of it's axles independently and NOT just the driven Torque of those axles. This is because the front and rear axles are linked by the vehicle body, and so more longitudinal load at EITHER end results in a vehicle acceleration!

The corollary of this is that to provide full yaw control, any torque vectoring system must be able to REDUCE the drive torque at the opposite end from which it is apply it. "Clutch based" systems without epicyclic differentials CANNOT do this, and so can never approach the yaw authority of either a rwd or proper torque vectoring system.

RacerMike said:

I don't believe that's Haldex though. Certainly not if it's got a separate rear diff. The Haldex system has no center diff and hence cannot split torque between front and rear. It can only add torque to the rear as a proportion of what's coming from the front.

The Insignia shares Saab's XWD system; details in the link.

Clivey said:

The Insignia shares Saab's XWD system; details in the link.

That would tie in with what I was surmising.

Wikipedia said:

using the two couplings the XWD system can send 85% of available torque to a single rear wheel

If it is Haldex it's only possible to send a proportion of the available torque from the front to the back. In the Haldex 4 application, this was limited to 85% of the available torque (i.e. it would be a 57:43 split front to back) and Gen 5 can send 100% of the available torque to the back resulting in a 50:50 split.It's all just very careful wording. No 4WD system that takes it's drive from the diff cage on the front axle will be able to remove drive from the front axle. This then leads on to what Max_Torque was explaining above.

xRIEx said:

TooMany2cvs said:

Basically, AIUI, there's no diff at all in the gearbox - just a single output shaft.

I don't think so: article said:

but is actually entirely independent of the diff cage

I read it as it transmits torque from one drive shaft to the other, completely external from the diff (so like a torsen effect, but with greater torque bias (and not contained in the diff)).TooMany2cvs said:

xRIEx said:

TooMany2cvs said:

Basically, AIUI, there's no diff at all in the gearbox - just a single output shaft.

I don't think so: article said:

but is actually entirely independent of the diff cage

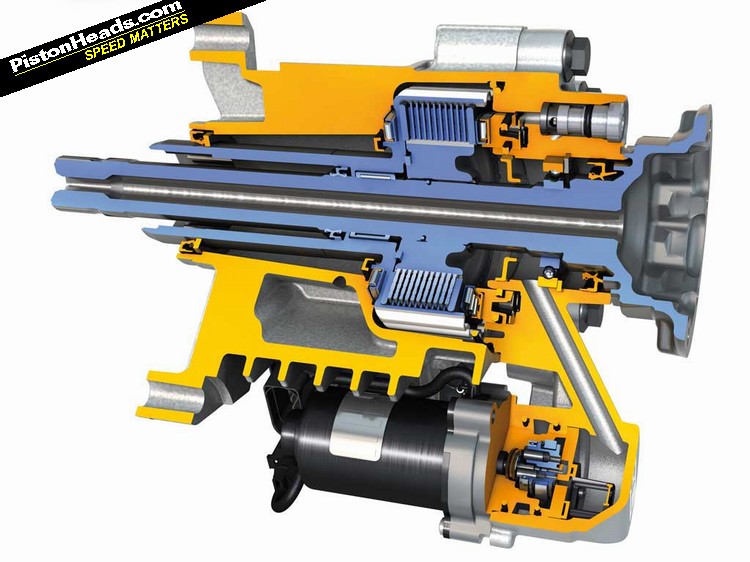

I read it as it transmits torque from one drive shaft to the other, completely external from the diff (so like a torsen effect, but with greater torque bias (and not contained in the diff)).It's very clear from this pic:

that the unit just "plugs in" to the offside of the transmission casing, just like the 4wd spur gearbox does on the 4wd variants). The clutch plates are then interposed between the larger outer splied coupling to the diff cage and the inner "halfshaft" that then goes on to drive the offside front wheel.

This is identical to the 4wd spur box that has to allow the offside front halfshaft to get out of the front diff whilst taking drive power off the diff cage!

Edited by anonymous-user on Wednesday 30th July 14:03

So am I right in thinking its just like a Viscous unit in a diff, ie its mounted on one drive flange & the to the crownwheel that only slows down the difference in wheel speeds, except its an electronically controlled clutch pack instead of goo.

Edited by cptsideways on Wednesday 30th July 14:19

vrooom said:

It look heavy... really heavy...

Not sure it does really. You have to have the halfshaft their anway, and the bearing support / housing for that shaft. So we are adding a bit more ally housing, a clutch pack and a 'lecy motor and pump. I'd guess at <8Kg additional weight. So sure, on a Caterham that would be heavy, but on a Mk7 Golf?Mr2Mike said:

cptsideways said:

So am I right in thinking its just like a Viscous unit in a diff, ie its mounted on one drive flange & the to the crownwheel that only slows down the difference in wheel speeds, except its an electronically controlled clutch pack instead of goo.

Exactly like this.I think I'd prefer a viscous diff thanks

cptsideways said:

Mr2Mike said:

cptsideways said:

So am I right in thinking its just like a Viscous unit in a diff, ie its mounted on one drive flange & the to the crownwheel that only slows down the difference in wheel speeds, except its an electronically controlled clutch pack instead of goo.

Exactly like this.I think I'd prefer a viscous diff thanks

So you cant drift a 4WD then?

Fine for talking straight line, and relatively true you cant fully torque vector without speed delta as well as torque, but when your cornering you do have a speed delta between front and rear axles

So if you change the torque while cornering you are partially ( i call it passive) torque vectoring, especially when your in proper understeer or oversteering where you do have greater speed deltas. Hence with decent 4x4 systems you can drift, especially the torque on demand types

Same principal works cross axle too, and is the reason active torque vectoring systems are so rare, is 80& of the benefits are no possible with active locking diffs and 'brake' based torque vectoring systems, and they are much cheaper and lighter.

Fine for talking straight line, and relatively true you cant fully torque vector without speed delta as well as torque, but when your cornering you do have a speed delta between front and rear axles

So if you change the torque while cornering you are partially ( i call it passive) torque vectoring, especially when your in proper understeer or oversteering where you do have greater speed deltas. Hence with decent 4x4 systems you can drift, especially the torque on demand types

Same principal works cross axle too, and is the reason active torque vectoring systems are so rare, is 80& of the benefits are no possible with active locking diffs and 'brake' based torque vectoring systems, and they are much cheaper and lighter.

Max_Torque said:

Regarding front to rear torque splitting systems like Haldex Et-al, the important thing that people tend to forget is that to modify the yaw of a vehicle, you need to modify the mean tyre slip and NOT the mean drive torque at each end of the car!!

The following graph is important:

And the following statement is CRITICAL:

"A tyre can supply a maximum force vector at its contact patch for any given vertical load. That vector is the summation of the Lateral and Longitudinal forces acting on that tyre"

What that means is that increasing one component of the total force vector, say the lateral load, MUST necessarily reduce the other component of that vector so as not to exceed the magnitude of the total force vector available.

"So what" i hear you say! Well, the reason we can "drift" a rwd car round a bend is precisely because of the fact that by applying excess wheel speed to the rear axle, increasing longitudinal load, the lateral load capability of the tyre falls, and the tyre "slips sideways" on the road, and bingo, drift city (or an ungainly and embarrassing exit into a hedge/ditch/bus-stop depending on your skills...... ;-)

So, to control vehicle yaw, any front/rear torque biasing system must be able to vary the driven SPEED of it's axles independently and NOT just the driven Torque of those axles. This is because the front and rear axles are linked by the vehicle body, and so more longitudinal load at EITHER end results in a vehicle acceleration!

The corollary of this is that to provide full yaw control, any torque vectoring system must be able to REDUCE the drive torque at the opposite end from which it is apply it. "Clutch based" systems without epicyclic differentials CANNOT do this, and so can never approach the yaw authority of either a rwd or proper torque vectoring system.

The following graph is important:

And the following statement is CRITICAL:

"A tyre can supply a maximum force vector at its contact patch for any given vertical load. That vector is the summation of the Lateral and Longitudinal forces acting on that tyre"

What that means is that increasing one component of the total force vector, say the lateral load, MUST necessarily reduce the other component of that vector so as not to exceed the magnitude of the total force vector available.

"So what" i hear you say! Well, the reason we can "drift" a rwd car round a bend is precisely because of the fact that by applying excess wheel speed to the rear axle, increasing longitudinal load, the lateral load capability of the tyre falls, and the tyre "slips sideways" on the road, and bingo, drift city (or an ungainly and embarrassing exit into a hedge/ditch/bus-stop depending on your skills...... ;-)

So, to control vehicle yaw, any front/rear torque biasing system must be able to vary the driven SPEED of it's axles independently and NOT just the driven Torque of those axles. This is because the front and rear axles are linked by the vehicle body, and so more longitudinal load at EITHER end results in a vehicle acceleration!

The corollary of this is that to provide full yaw control, any torque vectoring system must be able to REDUCE the drive torque at the opposite end from which it is apply it. "Clutch based" systems without epicyclic differentials CANNOT do this, and so can never approach the yaw authority of either a rwd or proper torque vectoring system.

cptsideways said:

So its an overly complicated electro hydraulic system replacing a simple mechanical device that has previously done its job fine for 1000's of miles without any intervention. Plus the new fangled thing is made by a company no longer renowned for making electrical complicated engineery things reliable any more.

I think I'd prefer a viscous diff thanks

As Max has said you are missing the point a bit. The clutch allows the diff to be adjusted all the way from completely open to completely locked, and it's not limited by only being actuated on torque or wheel speed difference. e.g. this could offer the traction benefits of a really stiff plate diff without all the numerous disadvantages.I think I'd prefer a viscous diff thanks

scherzkeks said:

All generations of Haldex from II to V can do a 50/50 mechanical split and can send up to 100% to the rear based on available torque during axle slip. The improvement in IV and V is that no slip is required to lock the clutch pack at 50/50 -- the ECU can do it whenever it wants.

When the Haldex coupling is locked up and the front axle speed happens to be greater than the rear (slip), proportional torque flows rearward until grip is restored on the front and axle speeds are matched again. On acceleration, at typical torque measure would be a rear-biased 30/70 F/R, as the front end lifts on acceleration, creating slip and a speed difference in the shafts. This is not overdrive on the rear, but it is what the actual torque distribution can look like.

Compare this to an older 50/50 Torsen (pre asymmetric 40/60): when one axle spins faster than the other (slip), the Torsen center diff shifts the available torque to the slower axle to restore traction and even out axle speeds. In this area, the Haldex actually has a plus, as it can shift nearly 100% of available torque, whereas the T2 Torsen can only shift as much as the bias ratio allows (in old stock B6 A4s, the amt. was 66%, for example).

But the wording implies (or at least gives the impression in the VW marketing literature) that you can have a 0:100 split. Whilst I agree that this is theoretically possible if you lose traction on the front two wheels, it's still only a 'hang on' rear end. A true 4WD coupling with a centre diff can permanently modify the torque split to the rear or front. Ultimately, all 4WD systems have some advantages and disadvantages (Torsen being next to useless when stuck for instance), but my comments were directed at the implication from VW that the Haldex is able to make the car 'rear wheel drive' which whilst technically true, is the same as saying that a Golf GTI can be '1 wheel drive'. True, but only because of the natural loss of traction and inherent behaviour of an open diff, active or not.When the Haldex coupling is locked up and the front axle speed happens to be greater than the rear (slip), proportional torque flows rearward until grip is restored on the front and axle speeds are matched again. On acceleration, at typical torque measure would be a rear-biased 30/70 F/R, as the front end lifts on acceleration, creating slip and a speed difference in the shafts. This is not overdrive on the rear, but it is what the actual torque distribution can look like.

Compare this to an older 50/50 Torsen (pre asymmetric 40/60): when one axle spins faster than the other (slip), the Torsen center diff shifts the available torque to the slower axle to restore traction and even out axle speeds. In this area, the Haldex actually has a plus, as it can shift nearly 100% of available torque, whereas the T2 Torsen can only shift as much as the bias ratio allows (in old stock B6 A4s, the amt. was 66%, for example).

When I test drove the new Golf R, I described it as 'my Mk5 GTI with another 30bhp and loads of traction'. It never feels anything other than FWD.....which makes me wonder whether there's really much point when you an have this VAQ diff.....

RacerMike said:

But the wording implies (or at least gives the impression in the VW marketing literature) that you can have a 0:100 split. Whilst I agree that this is theoretically possible if you lose traction on the front two wheels, it's still only a 'hang on' rear end. A true 4WD coupling with a centre diff can permanently modify the torque split to the rear or front.

Not sure what you mean here. In a 50/50 Torsen setup, if slip is registered on an axle, the Torsen can shift proportional torque to quell the slip and restore grip (but is limited, unlike Haldex, by the bias ratio). The 40/60 setup is the same, but uses planetary gearing for a slight (true) overdrive on the rear. The latest Haldex cars lock the clutch pack fully on command and any slip on an axle is compensated by a torque shift to the slower, grippier axle. So the systems do the same job but employ different methods. RacerMike said:

Ultimately, all 4WD systems have some advantages and disadvantages (Torsen being next to useless when stuck for instance), but my comments were directed at the implication from VW that the Haldex is able to make the car 'rear wheel drive' which whilst technically true, is the same as saying that a Golf GTI can be '1 wheel drive'. True, but only because of the natural loss of traction and inherent behaviour of an open diff, active or not.

When I test drove the new Golf R, I described it as 'my Mk5 GTI with another 30bhp and loads of traction'. It never feels anything other than FWD.....which makes me wonder whether there's really much point when you an have this VAQ diff.....

No Haldex system has ever felt anything other than AWD to me, which by nature/design has both FWD and RWD characteristics when cornering. The driving style employed isn't the same on the road or circuit as a purely FWD or RWD car. When I test drove the new Golf R, I described it as 'my Mk5 GTI with another 30bhp and loads of traction'. It never feels anything other than FWD.....which makes me wonder whether there's really much point when you an have this VAQ diff.....

I also don't find the literature misleading, as it accurately describes the capabilities of the system in a soundbite. The only Audi that feels RWD to me is the R8 -- because it basically is. Even on slip, it pushes so little power to the fronts that I wonder why they don't just make it RWD, since the whole point of AWD is even power distribution for superior traction on mixed surfaces. My only wishes from Audi from a pure performance perspective (and it is probably overkill for most users) is that they would dial out a bit more understeer in their suspension setups and that they'd just employ two mech. LSDs on all the road systems and be done with it. I have not had a chance to try the latest e-diffs, though, so maybe they really are as good as some say.

Gassing Station | General Gassing | Top of Page | What's New | My Stuff