RE: One-off Challenger Hellcat X announced

Discussion

wormus said:

R8VXF said:

Would prefer to go with a Maggie heartbeat 2300, much better cooling than the Eaton.

They're all Eaton TVS rotor packs. Just a different case and intercoolers on the Heartbeat. Truth is the 2300 will only make about 850hp no matter what version you use, not on pump fuel anyway. God knows I've tried! R8VXF said:

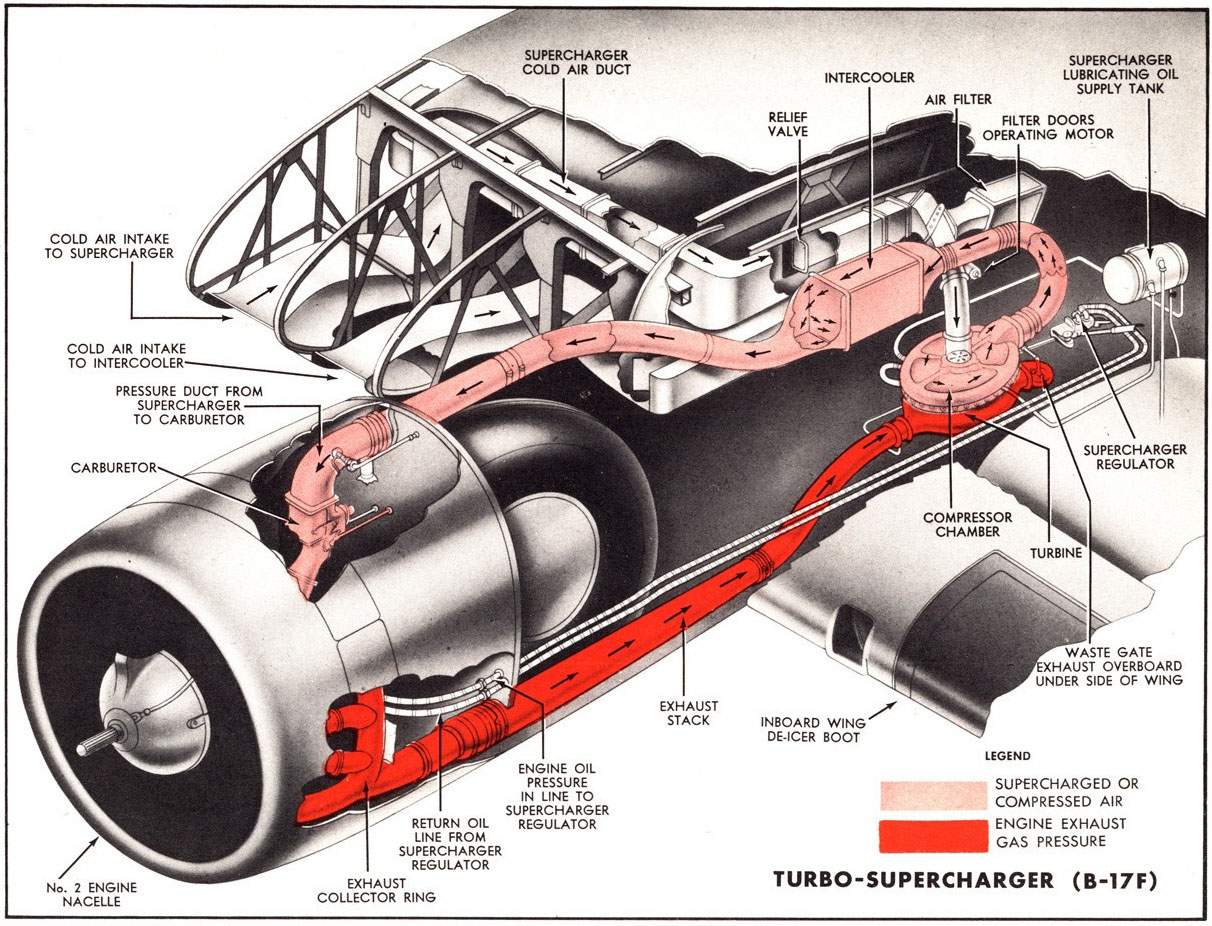

I believe the confusion may come from the fact that the aircraft in question had what is referred to as a turbo-supercharged engine (at least amongst what I have seen today). A Turbo-supercharger is the technical name for a turbo iirc

Its highly possible that that is the case (I have been educated today as I thought they were separate)

The P-47 had a similar system iirc.

Looks like a turbo to me

Sorry to wiki you but first sentence, second paragraph: https://en.wikipedia.org/wiki/Turbocharger

Sorry to wiki you but first sentence, second paragraph: https://en.wikipedia.org/wiki/Turbocharger

wiki said:

Turbochargers were originally known as turbosuperchargers when all forced induction devices were classified as superchargers. Nowadays the term "supercharger" is usually applied only to mechanically driven forced induction devices. The key difference between a turbocharger and a conventional supercharger is that a supercharger is mechanically driven by the engine, often through a belt connected to the crankshaft, whereas a turbocharger is powered by a turbine driven by the engine's exhaust gas.

R8VXF said:

Looks like a turbo to me

Sorry to wiki you but first sentence, second paragraph: https://en.wikipedia.org/wiki/Turbocharger

I was agreeing with you

Sorry to wiki you but first sentence, second paragraph: https://en.wikipedia.org/wiki/Turbocharger

wiki said:

Turbochargers were originally known as turbosuperchargers when all forced induction devices were classified as superchargers. Nowadays the term "supercharger" is usually applied only to mechanically driven forced induction devices. The key difference between a turbocharger and a conventional supercharger is that a supercharger is mechanically driven by the engine, often through a belt connected to the crankshaft, whereas a turbocharger is powered by a turbine driven by the engine's exhaust gas.

R8VXF said:

The Aussies have been getting higher out of the LSA without even going from a 1900 to a 2300. That 761 was without even any exhaust side mods and a very mild overdrive.

Sorry but you are wrong. One hero pull on a dyno on race gas does not count in my book. My 2300 was very overdriven at one point and every time I'd go WOT all it did was create heat. I have a custom built LSA with CNC ported heads, GT9 cam with lots of exhaust duration, 1 7/8" headers, dual 3" cat back, the lot. Engine was run on an engine dyno and it made 824hp, and that's all it would make on pump fuel. Don't believe what you read on the Internet and don't believe silly made up estimated flywheel power numbers, most of them are rubbish. In fact I've got one somewhere that says mine makes over 900hp which I know it doesn't. I would add I've studied this for so long I can tell you the sweet spot for a 2300 on a 6.2L engine is about 9psi boost which works out as about 670hp where it has about 74% isentropic efficiency. Spin it harder and it becomes less efficient, creating hot air instead. Take a look at the compressor maps for more info.

Edited by anonymous-user on Friday 24th July 08:11

Turbo-supercharger has various meanings. In the case of the Rolls-Royce Merlin, it's a shaft-driven centrifugal turbine supercharger attached directly to the back of the crankshaft.

All this talk of pushing Eaton Roots-type blowers to the limit makes me wonder why you wouldn't just upgrade to a Howden-Lysholm twin-screw compressor from Kenne Bell or Whipple (or whoever else makes them), they're much more efficient...

All this talk of pushing Eaton Roots-type blowers to the limit makes me wonder why you wouldn't just upgrade to a Howden-Lysholm twin-screw compressor from Kenne Bell or Whipple (or whoever else makes them), they're much more efficient...

RoverP6B said:

All this talk of pushing Eaton Roots-type blowers to the limit makes me wonder why you wouldn't just upgrade to a Howden-Lysholm twin-screw compressor from Kenne Bell or Whipple (or whoever else makes them), they're much more efficient...

Very good question. The answer is unless you want to cut a hole in the bonnet, you have to use the kits available and Whipple or Kenne Bell don't make one for my car. Also, twin screw compressors are still positive displacement and still suffer with heat issues, although less so than the older Eatons. The heartbeat TVS blowers are really good and very efficient (more so than the twin screws) but as yet they don't make one bigger than 2.3 litres. There is rumour of a 3.3 coming out but I'll believe it when I see it. There's also the question of traction and I have experimented with all sorts of combinations enough to know there is a compromise between power delivery and driveability. In the Monaro for example 650 whp is about as much as you can put on the road with the widest tyres you can fit on the car (285).

wormus said:

Very good question...

Understood. Considering my most powerful car is pushing 200whp and that can be a bit of a handful in the wet, on what I think are 255-section rear tyres, I could well imagine 650whp through 285s being distinctly hairy. As for twin-screw blowers, as I've always been led to believe that they are much less prone to heat-soak, is there actually much truth to that compared to the modern Eatons? Also, what alternatives to positive-displacement (if any) exist, other than turbocharging? Are centrifugal superchargers also considered to be PD?RoverP6B said:

Understood. Considering my most powerful car is pushing 200whp and that can be a bit of a handful in the wet, on what I think are 255-section rear tyres, I could well imagine 650whp through 285s being distinctly hairy. As for twin-screw blowers, as I've always been led to believe that they are much less prone to heat-soak, is there actually much truth to that compared to the modern Eatons? Also, what alternatives to positive-displacement (if any) exist, other than turbocharging? Are centrifugal superchargers also considered to be PD?

Twin screws do suffer with heat brought on by efficiency it's just the old Eaton blowers were so bad it made the twin screws look good! The TVS blowers are great in the right application and used in many modern performance cars including the Audi S4, Jag XFR and the supercharged Range Rovers. They also give you boost immediately off idle so a thump in the back you don't get from turbos and centrifugal superchargers. Centris do work well and give big HP gains whilst remaining efficient. They also do not suffer heat soak as they aren't attached to the engine which itself gets very hot. Downside is they make little boost below say 3000rpm so only work for half the rpm range, great for racing though, just not so good for the road.

Turbos are a mix of the two but are difficult to set up as they boost according to load x rpm so put your foot down and before you know it you've unstuck your tyres and heading for a hedge. They also require complex fabrication of pipe work etc which can lead to packaging issues.

Up to a point I think TVS superchargers are the best compromise for the road for bolt on power. In my case that takes a 400hp engine to over 800hp with a nice flat torque curve.

Just to add, the Eatons and Twin screws are both air pumps developed originally for pumping air into mines so the miners could breathe! The difference is the twin screw compresses the air within its own housing where the Eaton simply moves air from one side of the rotors to the other. Centrifugal pumps work in a different way altogether and aren't PD.

Edited by anonymous-user on Sunday 26th July 09:16

wormus said:

Centris do work well and give big HP gains whilst remaining efficient. They also do not suffer heat soak as they aren't attached to the engine which itself gets very hot. Downside is they make little boost below say 3000rpm so only work for half the rpm range, great for racing though, just not so good for the road.

You can achieve more boost at low-RPMs with a smaller pully and the addition of a restrictor plate. This is a solution that is close to ideal (in terms of performance / cost / packaging / heat / etc.)unsprung said:

You can achieve more boost at low-RPMs with a smaller pully and the addition of a restrictor plate. This is a solution that is close to ideal (in terms of performance / cost / packaging / heat / etc.)

Interesting although I'm not sure how you calculate the blower size vs the restriction? Just feels wrong. We all know what happens if you put your thumb over the end of a bicycle pump - it makes heat so I'm not so sure this would work at higher airflow levels.R8VXF said:

RoverP6B said:

Sorry - how can a centri lag when it's mechanically-driven, not exhaust-driven?

Not spinning fast enough to create boost at lower revs from what I understand.Centrifugal superchargers are like turbos except the latter will spin faster according to load x rpm. Centrifugal superchargers are still driven off the crank so boost builds according to rpm only (assuming no restriction of course) this means they have to be spinning at a certain rpm before any useful boost is made. Most modern PD blowers have a bypass valve which means they sap almost no power when cruising. It's this flexibility that makes them so popular in road cars.

RoverP6B said:

Understood. I wonder if perhaps a centrifugal (or PD) blower could be electrically driven to provide instant boost without sapping engine power, perhaps working off regenerative braking? Or would you then be better off just using the electrical power directly for traction?

I think there has been development in this area using an exhaust turbine (regenerative braking could work in addition, no reason why not) - AIUI the reason it's not got very far is due to the practicalities of running a 48 or 60V electrical system needed to get the compressor to spin fast enough.Gassing Station | General Gassing | Top of Page | What's New | My Stuff