Discussion

Got some bits done over the weekend, uprights painted and rebuilt, new balljoints. Driveshafts cleaned up and painted and all the wishbones, cradle etc blasted and POR15'd. If it sticks to them as well as it's sticking to my skin I think we're in business.

Had a mare with the shotblaster so was a bit behind schedule from where I planned to be, going to have to give some bits another coat tonight, but it won't be long still the wishbones and new shocks are on. Would be nice to get it back on it's wheels this week but will be much easier to get the motor and driveshafts in first before fitting the rear uprights so that can wait, should get the rest fitted though. Not making bad progress

I have had a think and I'm not going to use the Exige exhaust, going to get a normal 2.5in silencer and keep the exit where it's supposed to be, means no messing with the clam and to be honest I was shocked at the weight of the exige system.

Have offered the B16a2 bottom end on locostbuilders and EK9 Honda forum for free but no takers, shame but it might be going to the tip as it's just in the way...

Had a mare with the shotblaster so was a bit behind schedule from where I planned to be, going to have to give some bits another coat tonight, but it won't be long still the wishbones and new shocks are on. Would be nice to get it back on it's wheels this week but will be much easier to get the motor and driveshafts in first before fitting the rear uprights so that can wait, should get the rest fitted though. Not making bad progress

I have had a think and I'm not going to use the Exige exhaust, going to get a normal 2.5in silencer and keep the exit where it's supposed to be, means no messing with the clam and to be honest I was shocked at the weight of the exige system.

Have offered the B16a2 bottom end on locostbuilders and EK9 Honda forum for free but no takers, shame but it might be going to the tip as it's just in the way...

Done some bits over the weekend, given the block a clean and re honed it ready for assembly.

Built myself a good gearbox out of the S80 LSD integra type R box and S4C 1.6 civic box.

Used the best gears, synchros and hubs out of the two and swapped 4th gear so there will be less of a gap from 3rd - 4th. So I have a really sought-after box now with better ratios than any of he standard boxes and with the factory LSD and 4.78 FD Could have swapped 5th too but don't want it revving any higher than it already will be on the motorway.

Could have swapped 5th too but don't want it revving any higher than it already will be on the motorway.

Also fitted the drivers side front wishbones which were a pig to do, ran out of time after that but the passenger side should be easier with no steering rack/pedal box in the way when reaching through the monocoque.

Built myself a good gearbox out of the S80 LSD integra type R box and S4C 1.6 civic box.

Used the best gears, synchros and hubs out of the two and swapped 4th gear so there will be less of a gap from 3rd - 4th. So I have a really sought-after box now with better ratios than any of he standard boxes and with the factory LSD and 4.78 FD

Could have swapped 5th too but don't want it revving any higher than it already will be on the motorway.

Could have swapped 5th too but don't want it revving any higher than it already will be on the motorway.Also fitted the drivers side front wishbones which were a pig to do, ran out of time after that but the passenger side should be easier with no steering rack/pedal box in the way when reaching through the monocoque.

Still plodding on, haven't bothered updating much as nothing particularly interesting to show yet, I've fitted all the wishbones etc. got my arm stuck in the car whilst doing the rear wishbone mounts  front end is built up new shocks etc

front end is built up new shocks etc

Just in the process of sorting the engine bits out and hopefully next weekend it'll be going back in. I could quite easily have the thing built as a rolling car this weekend but it'll be much easier to wait until the engine is ready and jack the whole engine/box/cradle assembly up to the back of the car an bolt to the lot to the tub than trying to crane the thing in. That's how I removed it anyway and it was dead easy. So hopefully some more exciting updates in a week or so...!

front end is built up new shocks etc

front end is built up new shocks etcJust in the process of sorting the engine bits out and hopefully next weekend it'll be going back in. I could quite easily have the thing built as a rolling car this weekend but it'll be much easier to wait until the engine is ready and jack the whole engine/box/cradle assembly up to the back of the car an bolt to the lot to the tub than trying to crane the thing in. That's how I removed it anyway and it was dead easy. So hopefully some more exciting updates in a week or so...!

Edited by Yazza54 on Wednesday 6th April 10:30

Finally got my head built up on Saturday.

I decided it would be criminal to fit it without doing some mild porting first, by that I just mean basically copying what mr Honda did... The head I have is exactly the same casting but Honda blended behind the valve on the type R heads. Having seen it, it's a basic clean up not the "factory port job" some would have you believe. As I found on mine there's a fairly pronounced ridge just before the valve which can't help flow at all so I blended that out on all of them as well as removing any nasty casting marks and gave the exhaust ports a good clean up. I don't profess to be particularly good at this kinda thing but I'm happy with the job I did and theres logic behind it rather than just mindlessly attacking it with a burr! I used a flap wheel to avoid removing any more material than necessary.

Lapped the type R valves in, built back up with type r dual springs and new collets Then later on I finally finished plastigauging the rods which were all good so torqued them all up and all the main caps.

Then later on I finally finished plastigauging the rods which were all good so torqued them all up and all the main caps.

Built the motor up yesterday, note that I am a keen fan of recycling so I re used my pizza hut boxes as protection for the block ... The mrs said I should spend more time with her so I built it up in the dining room, hahahhaa

Buttoned all the bottom end up, fidanza flywheel and new clutch

Knew I kept the shaft from my old gearbox for a reason, made aligning the clutch dead easy

Flipped it over and dropped the head on and new gasket, then dropped the cams in.

At this point I had a ******* major ordeal with some JUNK 2 (or skunk2 as they're also known) low profile valve cover bolts. Two of the 4No. that replace the OEM posts on the cam caps snapped at not even 10ftlb. Now I know they probably would've been OK just nipped down but at the end of the day they bolt through the cam caps so everything IMO should be torqued to spec. These couldn't even manage half the specified torque. Utter s te. One was dead easy to get out having snapped just below the head of the bolt, the other snapped flush with the head so yep you guessed it, frigging cam had to come out, cap off and just about managed to tap the bolt round with a punch and get it out.

te. One was dead easy to get out having snapped just below the head of the bolt, the other snapped flush with the head so yep you guessed it, frigging cam had to come out, cap off and just about managed to tap the bolt round with a punch and get it out.

Put the cam back in and fitted the OEM ones.

Then finally got onto getting the belt on, new gates belt, koyo tensioner and new water pump installed. I don't like how close the GTM engine mount is to the tensioner/belt so will be grinding that down a bit, although the tensioner is all the way back in the photo, there is a gap but very close... Hopefully I'll get that done tonight and maybe get it mated up to the box. Then I'll see about getting the lump back in the car.

I decided it would be criminal to fit it without doing some mild porting first, by that I just mean basically copying what mr Honda did... The head I have is exactly the same casting but Honda blended behind the valve on the type R heads. Having seen it, it's a basic clean up not the "factory port job" some would have you believe. As I found on mine there's a fairly pronounced ridge just before the valve which can't help flow at all so I blended that out on all of them as well as removing any nasty casting marks and gave the exhaust ports a good clean up. I don't profess to be particularly good at this kinda thing but I'm happy with the job I did and theres logic behind it rather than just mindlessly attacking it with a burr! I used a flap wheel to avoid removing any more material than necessary.

Lapped the type R valves in, built back up with type r dual springs and new collets

Then later on I finally finished plastigauging the rods which were all good so torqued them all up and all the main caps.

Then later on I finally finished plastigauging the rods which were all good so torqued them all up and all the main caps.Built the motor up yesterday, note that I am a keen fan of recycling so I re used my pizza hut boxes as protection for the block ... The mrs said I should spend more time with her so I built it up in the dining room, hahahhaa

Buttoned all the bottom end up, fidanza flywheel and new clutch

Knew I kept the shaft from my old gearbox for a reason, made aligning the clutch dead easy

Flipped it over and dropped the head on and new gasket, then dropped the cams in.

At this point I had a ******* major ordeal with some JUNK 2 (or skunk2 as they're also known) low profile valve cover bolts. Two of the 4No. that replace the OEM posts on the cam caps snapped at not even 10ftlb. Now I know they probably would've been OK just nipped down but at the end of the day they bolt through the cam caps so everything IMO should be torqued to spec. These couldn't even manage half the specified torque. Utter s

te. One was dead easy to get out having snapped just below the head of the bolt, the other snapped flush with the head so yep you guessed it, frigging cam had to come out, cap off and just about managed to tap the bolt round with a punch and get it out.

te. One was dead easy to get out having snapped just below the head of the bolt, the other snapped flush with the head so yep you guessed it, frigging cam had to come out, cap off and just about managed to tap the bolt round with a punch and get it out.

Put the cam back in and fitted the OEM ones.

Then finally got onto getting the belt on, new gates belt, koyo tensioner and new water pump installed. I don't like how close the GTM engine mount is to the tensioner/belt so will be grinding that down a bit, although the tensioner is all the way back in the photo, there is a gap but very close... Hopefully I'll get that done tonight and maybe get it mated up to the box. Then I'll see about getting the lump back in the car.

Edited by Yazza54 on Monday 18th April 13:48

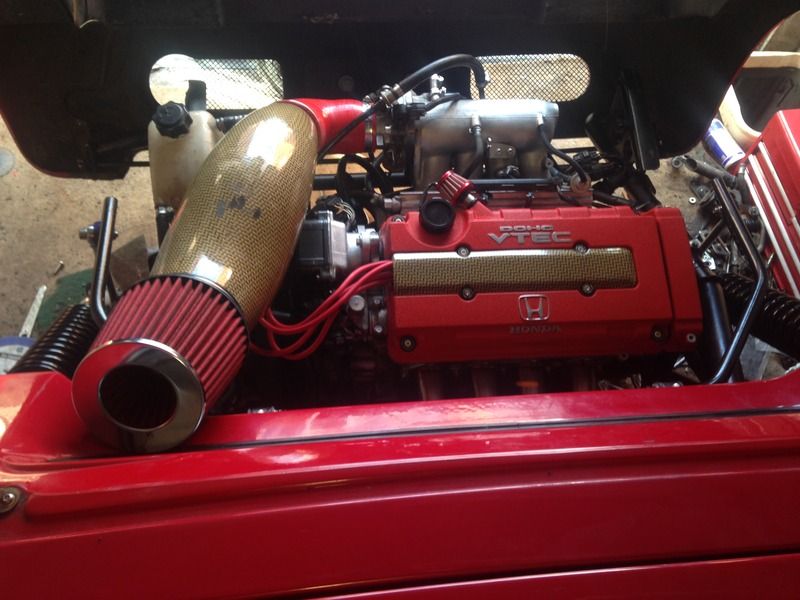

Got the engine back in over the weekend, few bits of plumbing left to do but mostly done. Need to fit the gear linkage back up and fit the rose joints I've sourced instead of the old rubber ball joint type ends on the gear change cables.

Going to do the valve clearances tonight and fit my valve cover I think. Then I'll get some pics of that. New shocks are on the back etc..

Rear ARB is back on was cleaning the drop links up last night. Even after 3 lots of paint strupper it just didn't want to come off fully and they seemed a little stained by the paint so out came the grit paper.

Was quite difficult until I realised I could just about fit them in my drill chuck

40 odd quid worth of the best rose joints I could get from McGill motorsports later

Going to do the valve clearances tonight and fit my valve cover I think. Then I'll get some pics of that. New shocks are on the back etc..

Rear ARB is back on was cleaning the drop links up last night. Even after 3 lots of paint strupper it just didn't want to come off fully and they seemed a little stained by the paint so out came the grit paper.

Was quite difficult until I realised I could just about fit them in my drill chuck

40 odd quid worth of the best rose joints I could get from McGill motorsports later

Edited by Yazza54 on Wednesday 27th April 11:54

I like it ..

Gonna open up the top side vent too as it sits just behind it. I need to make some form of support for it so it looks a bit more finished. It's the only way you can get any kind of decent system on it as all there's room for is a bend or a cone filter straight on the TB surrounded by the clam so this way at least it's out of the way and near a opening.

Gonna open up the top side vent too as it sits just behind it. I need to make some form of support for it so it looks a bit more finished. It's the only way you can get any kind of decent system on it as all there's room for is a bend or a cone filter straight on the TB surrounded by the clam so this way at least it's out of the way and near a opening.

Not sure. Need to make the exhaust which I'll get on with in the week, all the carpets etc need to go back stuff like that, then it needs the wheels powder coating and the car wants painting really to do it justice and I don't like half arsing stuff like that I want it to look as good as it can the first time it gets driven. Couple months maybe..??

I got the new slave cylinder fitted and bled last night, thankfully once the clutch was depressed all gears selected nicely and I was pleasantly surprised that the rose joined linkage does seem to have improved the feel quite a lot. I wasn't expecting it to make much difference, I think once the linkage is all greased up and I've replaced the springs to centre the lever it should feel much better. But the slop when selecting gear has pretty much gone  Was a relief as I was struggling to select any gears the other day but was just because the clutch hadn't been released since fitting.

Was a relief as I was struggling to select any gears the other day but was just because the clutch hadn't been released since fitting.

Main job for the rest of the week is sorting the exhaust out, I've got the mandrel bends, 200cpsi magnaflow cat, new oval silencer all 2.5inch stainless.. borrowed a welder off a mate to tack it up on the car but will hopefully be getting a fella who works with my dad to tig it all up neatly to finish it off. The cat won't be removable but considering its a sports cat and the piping is 2.5inch all the way through and quite a short system I doubt it will be particularly restrictive.

Was a relief as I was struggling to select any gears the other day but was just because the clutch hadn't been released since fitting.

Was a relief as I was struggling to select any gears the other day but was just because the clutch hadn't been released since fitting. Main job for the rest of the week is sorting the exhaust out, I've got the mandrel bends, 200cpsi magnaflow cat, new oval silencer all 2.5inch stainless.. borrowed a welder off a mate to tack it up on the car but will hopefully be getting a fella who works with my dad to tig it all up neatly to finish it off. The cat won't be removable but considering its a sports cat and the piping is 2.5inch all the way through and quite a short system I doubt it will be particularly restrictive.

Home made exhaust is done, changed my mind a few times along the way but all fits well now. Forgive the bad pic it was fairly late last night when I threw it all together.

In other news it should really be running by now but I have no spark. Checked all the wiring, earths etc. Spins over well and is injecting so the only thing I've re used that could cause this is the distributor. The old engine struggled to start and ran a bit rough so that was probably why. Have some bits on the way to rebuild the dizzy which will obviously take longer than just buying an aftermarket one but will be better ok the long run. Apparently they are renowned for giving up at least once in the engines life time and this dizzy is fairly old.

In other news it should really be running by now but I have no spark. Checked all the wiring, earths etc. Spins over well and is injecting so the only thing I've re used that could cause this is the distributor. The old engine struggled to start and ran a bit rough so that was probably why. Have some bits on the way to rebuild the dizzy which will obviously take longer than just buying an aftermarket one but will be better ok the long run. Apparently they are renowned for giving up at least once in the engines life time and this dizzy is fairly old.

Got the dizzy opened up today and as expected the coil was absolutely knackered. So out that came, new coil, ignition module and rotor arm.

Ignition module comes with thermal paste to be applied between it and the heat sink which is removed from the old module.

New rotor arm. You may or may not notice that the dust cover behind the rotor arm is missing, I had to break it to get the old rotor off which was totally corroded on the shaft. All cleaned up and greased before fitting new one. And Allen keys instead of the s tty JIS screws.

tty JIS screws.

Have a new dust cover and dizzy cap on the way but the above cured the problem and it fired up straight away. No videos or anything as I was somewhat pre occupied, got the timing light on it and set the dizzy up to 16 degrees.

Runs really nice, not too loud more induction than anything. First time out of the garage under its own steam ...

Clutch feels good and it's not too difficult pulling away with such a light flywheel on.

Just need to get the bloody coolant system bled now, it's taken 7.5 litres but Google tells me an MGF holds about 10.5... So based on that loose nugget of info with it being a similar layout, there's still a lot of air in there!! Any tips???

Ignition module comes with thermal paste to be applied between it and the heat sink which is removed from the old module.

New rotor arm. You may or may not notice that the dust cover behind the rotor arm is missing, I had to break it to get the old rotor off which was totally corroded on the shaft. All cleaned up and greased before fitting new one. And Allen keys instead of the s

tty JIS screws.

tty JIS screws.

Have a new dust cover and dizzy cap on the way but the above cured the problem and it fired up straight away. No videos or anything as I was somewhat pre occupied, got the timing light on it and set the dizzy up to 16 degrees.

Runs really nice, not too loud more induction than anything. First time out of the garage under its own steam ...

Clutch feels good and it's not too difficult pulling away with such a light flywheel on.

Just need to get the bloody coolant system bled now, it's taken 7.5 litres but Google tells me an MGF holds about 10.5... So based on that loose nugget of info with it being a similar layout, there's still a lot of air in there!! Any tips???

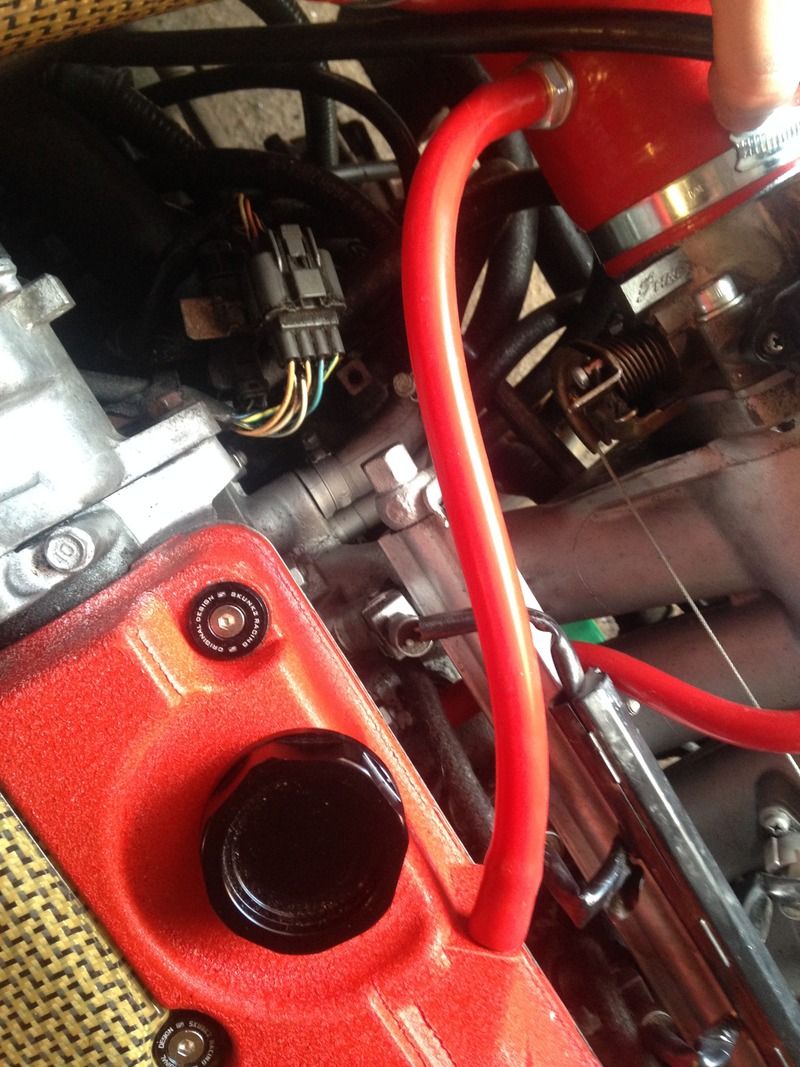

Changed the pcv one way valve and hose - the old one wasn't sealing when I blew down it and the hose was collapsing from the vacuum.

Also got rid of the breather filter on valve cover and took a hose to my induction like it should be, using a neat little billet hose take off. Dunno if it's just a placebo effect or what but I swear it runs steadier and is slightly more responsive now. Either way the breathing system is plumbed properly now.

Also got rid of the breather filter on valve cover and took a hose to my induction like it should be, using a neat little billet hose take off. Dunno if it's just a placebo effect or what but I swear it runs steadier and is slightly more responsive now. Either way the breathing system is plumbed properly now.

Right car was driven for the first time on Saturday and passed it's MOT OK  (after a long fast idle to get the new CAT working, was worried at first as it just wasn't doing anything!) Was a rubbish day for it..!

(after a long fast idle to get the new CAT working, was worried at first as it just wasn't doing anything!) Was a rubbish day for it..!

First off, the engine desperately needs additional steady bars. It doesn't half rock about under power/gearchanges, I can't believe he drove this car all that time like that, even with the old B16 motor it must have been bad! So straight off that's kinda ruining the driving experience for me, so first thing on the to do list.

Gear change - it's quite poor. The play has gone and the gearbox itself feels nice slotting into gears but the actual lever arrangement feels horrible. Again this detracts significantly to the driving enjoyment, I may have to buy a Mike satur shift kit to replace the MGF gear change.

Handling - at first it was displaying some dodgy handling and I was getting a slight knock from the passenger rear, my fault I had it set up all wrong, feels fairly planted now.

Aaaaand I broke down - luckily pulling onto my drive! It seems the slave cylinder piston was travelling too far out of the slave cylinder and it has cocked, then when releasing it the clutch fork has forced it back at an angle and cracked the slave. The Honda slave cylinder rod isn't adjustable so I'm hoping there is some adjustment at the clutch master to reduce the travel

So all in all, good that its legally on the road but plenty to work through. The engine is nice and it goes well, the potential is there.. sounds good too.

(after a long fast idle to get the new CAT working, was worried at first as it just wasn't doing anything!) Was a rubbish day for it..!

(after a long fast idle to get the new CAT working, was worried at first as it just wasn't doing anything!) Was a rubbish day for it..!

First off, the engine desperately needs additional steady bars. It doesn't half rock about under power/gearchanges, I can't believe he drove this car all that time like that, even with the old B16 motor it must have been bad! So straight off that's kinda ruining the driving experience for me, so first thing on the to do list.

Gear change - it's quite poor. The play has gone and the gearbox itself feels nice slotting into gears but the actual lever arrangement feels horrible. Again this detracts significantly to the driving enjoyment, I may have to buy a Mike satur shift kit to replace the MGF gear change.

Handling - at first it was displaying some dodgy handling and I was getting a slight knock from the passenger rear, my fault I had it set up all wrong, feels fairly planted now.

Aaaaand I broke down - luckily pulling onto my drive! It seems the slave cylinder piston was travelling too far out of the slave cylinder and it has cocked, then when releasing it the clutch fork has forced it back at an angle and cracked the slave. The Honda slave cylinder rod isn't adjustable so I'm hoping there is some adjustment at the clutch master to reduce the travel

So all in all, good that its legally on the road but plenty to work through. The engine is nice and it goes well, the potential is there.. sounds good too.

Gassing Station | Kit Cars | Top of Page | What's New | My Stuff