Discussion

I got the new slave cylinder fitted and bled last night, thankfully once the clutch was depressed all gears selected nicely and I was pleasantly surprised that the rose joined linkage does seem to have improved the feel quite a lot. I wasn't expecting it to make much difference, I think once the linkage is all greased up and I've replaced the springs to centre the lever it should feel much better. But the slop when selecting gear has pretty much gone  Was a relief as I was struggling to select any gears the other day but was just because the clutch hadn't been released since fitting.

Was a relief as I was struggling to select any gears the other day but was just because the clutch hadn't been released since fitting.

Main job for the rest of the week is sorting the exhaust out, I've got the mandrel bends, 200cpsi magnaflow cat, new oval silencer all 2.5inch stainless.. borrowed a welder off a mate to tack it up on the car but will hopefully be getting a fella who works with my dad to tig it all up neatly to finish it off. The cat won't be removable but considering its a sports cat and the piping is 2.5inch all the way through and quite a short system I doubt it will be particularly restrictive.

Was a relief as I was struggling to select any gears the other day but was just because the clutch hadn't been released since fitting.

Was a relief as I was struggling to select any gears the other day but was just because the clutch hadn't been released since fitting. Main job for the rest of the week is sorting the exhaust out, I've got the mandrel bends, 200cpsi magnaflow cat, new oval silencer all 2.5inch stainless.. borrowed a welder off a mate to tack it up on the car but will hopefully be getting a fella who works with my dad to tig it all up neatly to finish it off. The cat won't be removable but considering its a sports cat and the piping is 2.5inch all the way through and quite a short system I doubt it will be particularly restrictive.

Home made exhaust is done, changed my mind a few times along the way but all fits well now. Forgive the bad pic it was fairly late last night when I threw it all together.

In other news it should really be running by now but I have no spark. Checked all the wiring, earths etc. Spins over well and is injecting so the only thing I've re used that could cause this is the distributor. The old engine struggled to start and ran a bit rough so that was probably why. Have some bits on the way to rebuild the dizzy which will obviously take longer than just buying an aftermarket one but will be better ok the long run. Apparently they are renowned for giving up at least once in the engines life time and this dizzy is fairly old.

In other news it should really be running by now but I have no spark. Checked all the wiring, earths etc. Spins over well and is injecting so the only thing I've re used that could cause this is the distributor. The old engine struggled to start and ran a bit rough so that was probably why. Have some bits on the way to rebuild the dizzy which will obviously take longer than just buying an aftermarket one but will be better ok the long run. Apparently they are renowned for giving up at least once in the engines life time and this dizzy is fairly old.

Got the dizzy opened up today and as expected the coil was absolutely knackered. So out that came, new coil, ignition module and rotor arm.

Ignition module comes with thermal paste to be applied between it and the heat sink which is removed from the old module.

New rotor arm. You may or may not notice that the dust cover behind the rotor arm is missing, I had to break it to get the old rotor off which was totally corroded on the shaft. All cleaned up and greased before fitting new one. And Allen keys instead of the s tty JIS screws.

tty JIS screws.

Have a new dust cover and dizzy cap on the way but the above cured the problem and it fired up straight away. No videos or anything as I was somewhat pre occupied, got the timing light on it and set the dizzy up to 16 degrees.

Runs really nice, not too loud more induction than anything. First time out of the garage under its own steam ...

Clutch feels good and it's not too difficult pulling away with such a light flywheel on.

Just need to get the bloody coolant system bled now, it's taken 7.5 litres but Google tells me an MGF holds about 10.5... So based on that loose nugget of info with it being a similar layout, there's still a lot of air in there!! Any tips???

Ignition module comes with thermal paste to be applied between it and the heat sink which is removed from the old module.

New rotor arm. You may or may not notice that the dust cover behind the rotor arm is missing, I had to break it to get the old rotor off which was totally corroded on the shaft. All cleaned up and greased before fitting new one. And Allen keys instead of the s

tty JIS screws.

tty JIS screws.

Have a new dust cover and dizzy cap on the way but the above cured the problem and it fired up straight away. No videos or anything as I was somewhat pre occupied, got the timing light on it and set the dizzy up to 16 degrees.

Runs really nice, not too loud more induction than anything. First time out of the garage under its own steam ...

Clutch feels good and it's not too difficult pulling away with such a light flywheel on.

Just need to get the bloody coolant system bled now, it's taken 7.5 litres but Google tells me an MGF holds about 10.5... So based on that loose nugget of info with it being a similar layout, there's still a lot of air in there!! Any tips???

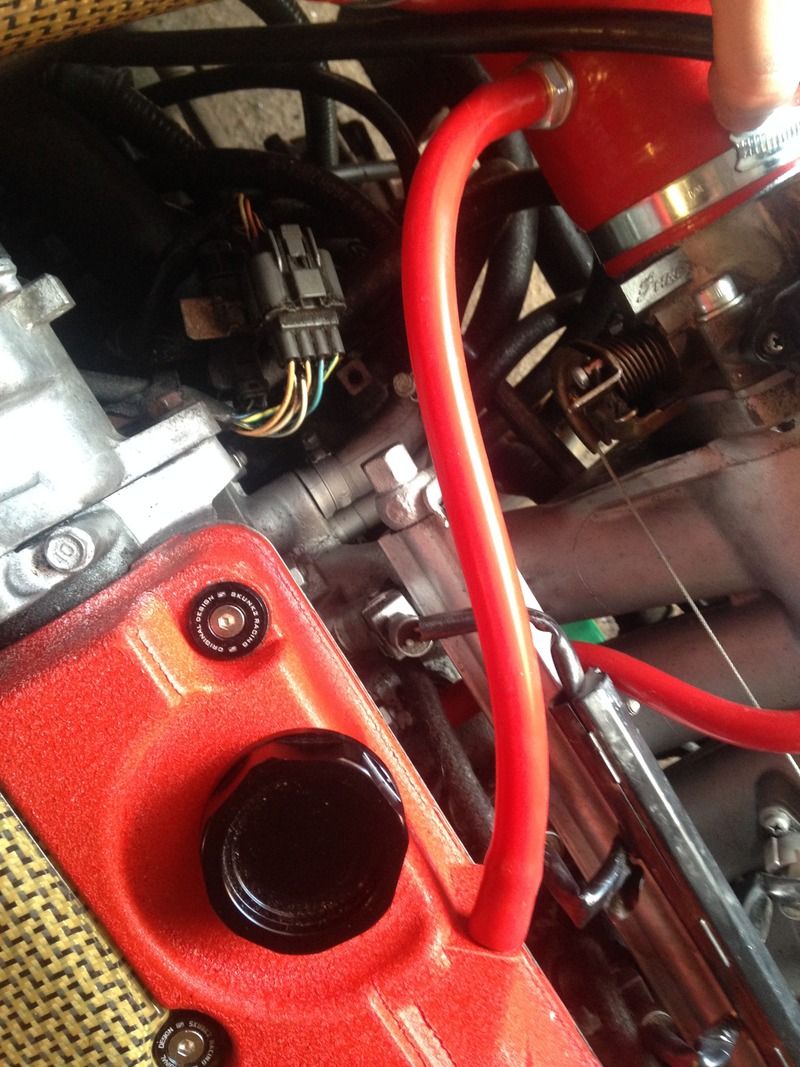

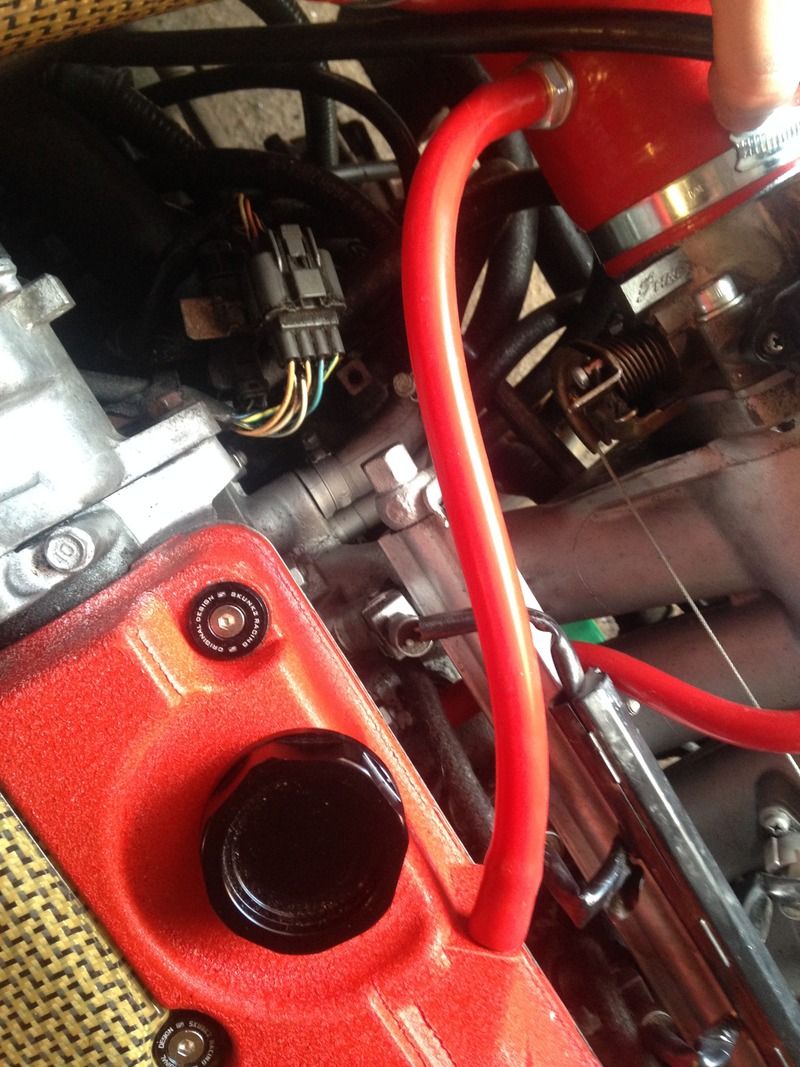

Changed the pcv one way valve and hose - the old one wasn't sealing when I blew down it and the hose was collapsing from the vacuum.

Also got rid of the breather filter on valve cover and took a hose to my induction like it should be, using a neat little billet hose take off. Dunno if it's just a placebo effect or what but I swear it runs steadier and is slightly more responsive now. Either way the breathing system is plumbed properly now.

Also got rid of the breather filter on valve cover and took a hose to my induction like it should be, using a neat little billet hose take off. Dunno if it's just a placebo effect or what but I swear it runs steadier and is slightly more responsive now. Either way the breathing system is plumbed properly now.

Right car was driven for the first time on Saturday and passed it's MOT OK  (after a long fast idle to get the new CAT working, was worried at first as it just wasn't doing anything!) Was a rubbish day for it..!

(after a long fast idle to get the new CAT working, was worried at first as it just wasn't doing anything!) Was a rubbish day for it..!

First off, the engine desperately needs additional steady bars. It doesn't half rock about under power/gearchanges, I can't believe he drove this car all that time like that, even with the old B16 motor it must have been bad! So straight off that's kinda ruining the driving experience for me, so first thing on the to do list.

Gear change - it's quite poor. The play has gone and the gearbox itself feels nice slotting into gears but the actual lever arrangement feels horrible. Again this detracts significantly to the driving enjoyment, I may have to buy a Mike satur shift kit to replace the MGF gear change.

Handling - at first it was displaying some dodgy handling and I was getting a slight knock from the passenger rear, my fault I had it set up all wrong, feels fairly planted now.

Aaaaand I broke down - luckily pulling onto my drive! It seems the slave cylinder piston was travelling too far out of the slave cylinder and it has cocked, then when releasing it the clutch fork has forced it back at an angle and cracked the slave. The Honda slave cylinder rod isn't adjustable so I'm hoping there is some adjustment at the clutch master to reduce the travel

So all in all, good that its legally on the road but plenty to work through. The engine is nice and it goes well, the potential is there.. sounds good too.

(after a long fast idle to get the new CAT working, was worried at first as it just wasn't doing anything!) Was a rubbish day for it..!

(after a long fast idle to get the new CAT working, was worried at first as it just wasn't doing anything!) Was a rubbish day for it..!

First off, the engine desperately needs additional steady bars. It doesn't half rock about under power/gearchanges, I can't believe he drove this car all that time like that, even with the old B16 motor it must have been bad! So straight off that's kinda ruining the driving experience for me, so first thing on the to do list.

Gear change - it's quite poor. The play has gone and the gearbox itself feels nice slotting into gears but the actual lever arrangement feels horrible. Again this detracts significantly to the driving enjoyment, I may have to buy a Mike satur shift kit to replace the MGF gear change.

Handling - at first it was displaying some dodgy handling and I was getting a slight knock from the passenger rear, my fault I had it set up all wrong, feels fairly planted now.

Aaaaand I broke down - luckily pulling onto my drive! It seems the slave cylinder piston was travelling too far out of the slave cylinder and it has cocked, then when releasing it the clutch fork has forced it back at an angle and cracked the slave. The Honda slave cylinder rod isn't adjustable so I'm hoping there is some adjustment at the clutch master to reduce the travel

So all in all, good that its legally on the road but plenty to work through. The engine is nice and it goes well, the potential is there.. sounds good too.

How's this for weird, I'm pretty sure my new slave cylinder was assembled wrong at the factory, at one end of the piston is a cup and the other a nipple/pin

I would have thought that the rod would sit in the cup but in this is looks like it's been the other way round, worn a groove in the nipple and eventually gone bang - wtf

I would have thought that the rod would sit in the cup but in this is looks like it's been the other way round, worn a groove in the nipple and eventually gone bang - wtf

He's agreed to refund me and I've ordered another through jap service parts which have always been good

This might be why the gear change felt awful too as with it removed the gear change feels quite good again apart from the fact it doesn't centre well, still has the springs missing need to get it on the ramp and do that this weekend

This might be why the gear change felt awful too as with it removed the gear change feels quite good again apart from the fact it doesn't centre well, still has the springs missing need to get it on the ramp and do that this weekend

I got my new slave cylinder in the post, fitted and bled and it's so much nicer - unsurprisingly!!

Also got the poly inserts for the gearbox mount, which is the opposite side to the engine steady currently fitted, they are very stiff mouldings that press into the gaps in the OEM rubber mount

So out came the jack and removed all nuts and bolts and lowered that side to get the mount out, pressed them in and re fitted, quite a tight fit. Hopefully this will reduce some movement, but I'm still looking at the best way to add another steady bar.

Also got the poly inserts for the gearbox mount, which is the opposite side to the engine steady currently fitted, they are very stiff mouldings that press into the gaps in the OEM rubber mount

So out came the jack and removed all nuts and bolts and lowered that side to get the mount out, pressed them in and re fitted, quite a tight fit. Hopefully this will reduce some movement, but I'm still looking at the best way to add another steady bar.

Ryan, somewhere (still searching) there's a post about how I fitted the Mk2 Elise shift to my Libra. The back end is irrelevant with your Honda box, but I had new cables made up, used the ball joints from an Elise mod.

The lever mech. I mounted on top of the tunnel, this brought the actual lever up and forward so that it was less than a handspan away from the steering wheel. Even with the MGF box, it was a cracking gear change.

Found a couple of pics:

The cables go back into the tunnel just in front of the handbrake.

The new cables I had made were 100mm longer than the original elise ones.

The lever mech. I mounted on top of the tunnel, this brought the actual lever up and forward so that it was less than a handspan away from the steering wheel. Even with the MGF box, it was a cracking gear change.

Found a couple of pics:

The cables go back into the tunnel just in front of the handbrake.

The new cables I had made were 100mm longer than the original elise ones.

Edited by Paul Drawmer on Wednesday 1st June 09:51

Hi Paul

I have been reading some of the old Team GTM posts on this very subject, I am quite tempted to try the Toyota Starlet gearchange like Bertrams as it looks very compact and I think I could easily retrofit it without disturbing too much in the tunnel, it should be cheap too. Otherwise it's the elise or Satur route but the prices are making my eyes water...! The height of yours looks much better. I find it quite awkward as I have the seat as far back as it can go to get in the car, so it feels a little too low and too far away. I have replaced some bushes that were heavily worn, Roger had a spare he kindly gave me, and heavier springs in the MGF change but it's still not very good.

Cheers

I have been reading some of the old Team GTM posts on this very subject, I am quite tempted to try the Toyota Starlet gearchange like Bertrams as it looks very compact and I think I could easily retrofit it without disturbing too much in the tunnel, it should be cheap too. Otherwise it's the elise or Satur route but the prices are making my eyes water...! The height of yours looks much better. I find it quite awkward as I have the seat as far back as it can go to get in the car, so it feels a little too low and too far away. I have replaced some bushes that were heavily worn, Roger had a spare he kindly gave me, and heavier springs in the MGF change but it's still not very good.

Cheers

Edited by Yazza54 on Wednesday 1st June 11:05

The MGF gear change is mucked up by the whole spring thing at the lever end. The Elise shift is much more precise, as it only uses the springing in the 'box itself. The cables and rod ends must be free though.

I went back to old forum listing to get the photos - quite trip down memory lane!

My old car is now owned by Colin who lives in Wales - he has put a supercharged Honda in it!

https://www.youtube.com/watch?v=mQ4WX2jDwLc

I went back to old forum listing to get the photos - quite trip down memory lane!

My old car is now owned by Colin who lives in Wales - he has put a supercharged Honda in it!

https://www.youtube.com/watch?v=mQ4WX2jDwLc

Been doing some more bits, have figured out a way forward on the gear change mechanism. Going to use a focus ST170 set up as the mechanism is very compact and detaches from the main gearchange frame. That can be bolted to the tunnel on a bracket and then I can adjust the cables as necessary and re fit. So the linkage will drop through the hole into the tunnel, similar to how Bertram made use of the starlet set up. I am planning on completely gutting the MGF gearchange innards but leaving the outer frame attached in the tunnel as it holds the cables and they should be near enough in the right place already.

My clutch seems to be travelling too far, it's odd. 3/4 travel is perfect and I can select all gears, clutch fully depressed and it actually struggles to get gears and if in gear will begin to creep, so the clutch is dragging. Problem is that there is no adjustment on the slave or master so I could either put a stop on the pedal or cut down the slave push rod slightly. No doubt that with that and the gearchange mods it should be a considerable improvement.

Still need to make an additional engine steady but the mount inserts definitely helped.

Car needs some tweaking handling wise, feels a little vague and light at the front.

Also it's struggling to get properly warm. I seem to get to 60-65 degrees and stabilise. I will admit that I put 1 small hole in the thermostat as I was struggling to bleed the system, can't imagine that one little hole causing it to run 10-15 degrees cooler than it should though...!?

Went out in it after work and got this little sound clip. It's bloody quick I will say that. I can't wait until I've got all these little bits sorted.

https://youtu.be/kSMUkrzgOeM

My clutch seems to be travelling too far, it's odd. 3/4 travel is perfect and I can select all gears, clutch fully depressed and it actually struggles to get gears and if in gear will begin to creep, so the clutch is dragging. Problem is that there is no adjustment on the slave or master so I could either put a stop on the pedal or cut down the slave push rod slightly. No doubt that with that and the gearchange mods it should be a considerable improvement.

Still need to make an additional engine steady but the mount inserts definitely helped.

Car needs some tweaking handling wise, feels a little vague and light at the front.

Also it's struggling to get properly warm. I seem to get to 60-65 degrees and stabilise. I will admit that I put 1 small hole in the thermostat as I was struggling to bleed the system, can't imagine that one little hole causing it to run 10-15 degrees cooler than it should though...!?

Went out in it after work and got this little sound clip. It's bloody quick I will say that. I can't wait until I've got all these little bits sorted.

https://youtu.be/kSMUkrzgOeM

Now you mention it I recall seeing a post about your dads Ultima before.

Clutch issue sounds like classic overthrow. I think you have three options; Either a smaller bore master cylinder or a bigger bore slave (both result in less throw) or a stop on the clutch pedal. Shortening the slave push rod will just result in the piston coming further out (see your previous issue).

A small bleed hole in a stat can have a surprisingly large effect. They need to be tiny rather than small. Have you checked the temp reading is true? A digital IR thermometer will tell you.

Clutch issue sounds like classic overthrow. I think you have three options; Either a smaller bore master cylinder or a bigger bore slave (both result in less throw) or a stop on the clutch pedal. Shortening the slave push rod will just result in the piston coming further out (see your previous issue).

A small bleed hole in a stat can have a surprisingly large effect. They need to be tiny rather than small. Have you checked the temp reading is true? A digital IR thermometer will tell you.

Edited by AdiT on Thursday 2nd June 22:57

You are of course correct I was thinking about it last night and shortening the rod wouldn't be a good idea. I'm sure I can make some sort of stop for the pedal.

I have another standard thermostat, might as well throw that in and see what it does. I haven't done that but I believe it to be fairly accurate as the fan comes on at the correct temp etc. But that's only ever happened once when I was bleeding it and it had been running on my drive for a long time.

Yeah he's been at it some time but it is coming together

https://youtu.be/btpLtrcrms8

I have another standard thermostat, might as well throw that in and see what it does. I haven't done that but I believe it to be fairly accurate as the fan comes on at the correct temp etc. But that's only ever happened once when I was bleeding it and it had been running on my drive for a long time.

Yeah he's been at it some time but it is coming together

https://youtu.be/btpLtrcrms8

Edited by Yazza54 on Friday 3rd June 06:21

Gassing Station | Kit Cars | Top of Page | What's New | My Stuff