Mac#1 Motorsport Worx Build

Discussion

Aftermarket management would be nice, probably make the car drive a bit more smoothly too, but it still wouldn't alter the fact that the manual boost controller wasn't working. When the car was at BigCC last year, the boost controller was working and the car made 297bhp@wheels on the high boost setting, that was before the ignition module was fitted, proving that it's not the Power Commander setup holding the car back in this instance.

Well I bought an electronic boost controller this afternoon, the Turbosmart E-Boost Street from Motorsport Developments.

http://shop.motorsport-developments.co.uk/turbosma...

Now i need a 4psi or 6psi spring for the wastegate and something to replace my 52mm boost gauge.

http://shop.motorsport-developments.co.uk/turbosma...

Now i need a 4psi or 6psi spring for the wastegate and something to replace my 52mm boost gauge.

Red16 said:

Well I bought an electronic boosthttp://www.pistonheads.com/gassing/imgs/6.gif controller this afternoon, the Turbosmart E-Boost Street from Motorsport Developments.

http://shop.motorsport-developments.co.uk/turbosma...

Now i need a 4psi or 6psi spring for the wastegate and something to replace my 52mm boost gauge.

"something to replace my 52mm boost gauge"

http://shop.motorsport-developments.co.uk/turbosma...

Now i need a 4psi or 6psi spring for the wastegate and something to replace my 52mm boost gauge.

Can I suggest a toilet roll holder!

Trophy200

Red16 said:

A bit of an update...

Unfortunately the new clutch puller pin has broke, looks like the stainless steel was too brittle and has sheared.

A new puller pin has been made up from EN24t steel, it has an extra shoulder in the centre to locate in the original clutch cover bearing, and here she is...

In a bid to stop breaking puller pins, I've removed the weighted arms from the lockup clutch plate, so the clutch now operates as a standard clutch. The car now drives a lot better than it did with the lockup working, but the problem is the clutch now slips while using high boost.

To try and combat the clutch slippage I've bought an EBC heavy duty clutch kit with uprated springs, this will give more friction and more clamping force, so hopefully do the trick.

If the clutch still slips while running the EBC kit, it'll be a case of fitting the weighted arms to the lockup plate with no weights, try it and if required add weights until the clutch does not slip, trial and error stylee, trying to use as little a weight as possible to allow the clutch to grip.

A couple of things I hope you find useful. Not meaning to be critical of the build as it looks like you've done a very thorough job!Unfortunately the new clutch puller pin has broke, looks like the stainless steel was too brittle and has sheared.

A new puller pin has been made up from EN24t steel, it has an extra shoulder in the centre to locate in the original clutch cover bearing, and here she is...

In a bid to stop breaking puller pins, I've removed the weighted arms from the lockup clutch plate, so the clutch now operates as a standard clutch. The car now drives a lot better than it did with the lockup working, but the problem is the clutch now slips while using high boost.

To try and combat the clutch slippage I've bought an EBC heavy duty clutch kit with uprated springs, this will give more friction and more clamping force, so hopefully do the trick.

If the clutch still slips while running the EBC kit, it'll be a case of fitting the weighted arms to the lockup plate with no weights, try it and if required add weights until the clutch does not slip, trial and error stylee, trying to use as little a weight as possible to allow the clutch to grip.

The reason the pin broke there is due to the massive stress raiser at that corner. I bet that's a 0.2mm rad in there, really it needs to be 0.8mm min. Also, have you got a clutch stop on the pedal or are you relying on the pin to stop it?

I have been advised by the guys who built my engine (who deal with a lot of turbo bike engines) that EBC clutch plates tend to disintegrate with clutch slip and within a short period of time you will end up with chunks of clutch material floating around in your oil. Not nice!

Thanks for the pointers, criticism is welcomed as long as it is constructive, and you definitely make a good point regarding the larger radius being stronger, something to bare in mind if there is a next time.

You'll be pleased to know there is a stop fitted to the clutch pedal.

I've heard those stories about Barnett clutch plates but never EBC, they're fitted now so i'll be keeping an eye on what comes out when i do my regular oil changes. On a positive note, with the lock up clutch and the flatshifter fitted, the clutch is rarely used and slipped now, so theoretically i shouldn't get a lot of clutch material in my oil.

You'll be pleased to know there is a stop fitted to the clutch pedal.

I've heard those stories about Barnett clutch plates but never EBC, they're fitted now so i'll be keeping an eye on what comes out when i do my regular oil changes. On a positive note, with the lock up clutch and the flatshifter fitted, the clutch is rarely used and slipped now, so theoretically i shouldn't get a lot of clutch material in my oil.

The electronic boost controller is now fitted and seems to be working nicely, the lower boost set point is programmed up and it is holding 8.5psi on the low setting.

Unfortunately the setting up of the boost controller was cut short as I've encountered a problem which I think may be tranmission related. While driving the car there is a noise which sounds like something rattling around inside the engine, this noise is non existant if the car is sat at idle, the clutch is fully functional and the car drives ok (if the noise was not present).

So without further ado I've pulled the engine out of the car

The engine was turned upside down and the sump removed, some metallic particles were found in the sump

More metallic particles evident on the sump gasket

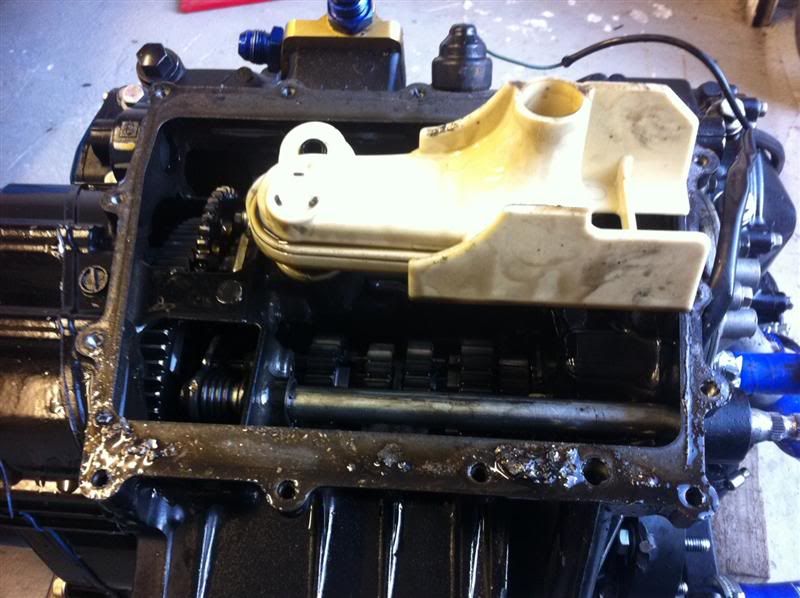

With the oil pickup and clutch cover removed the engine looks like this

Removed the covers and idler gear from the starter motor assembly

Crank position sensor cover and clutch plates removed

Clutch basket taken off

Clutch basket assembly

Remove this circlip from the gear selector shaft, then it can be slid out of the transmission casing

With the selector shaft removed, things look like this inside

Starter motor removed which gives access to the generator cover

Generator assembly removed

Big hole where the generator lives

Sprocket adaptor and water pump removed

Oil pump drive gear removed

Lower gear selector fork shaft being withdrawn

Lower selector and shaft

Unfortunately the setting up of the boost controller was cut short as I've encountered a problem which I think may be tranmission related. While driving the car there is a noise which sounds like something rattling around inside the engine, this noise is non existant if the car is sat at idle, the clutch is fully functional and the car drives ok (if the noise was not present).

So without further ado I've pulled the engine out of the car

The engine was turned upside down and the sump removed, some metallic particles were found in the sump

More metallic particles evident on the sump gasket

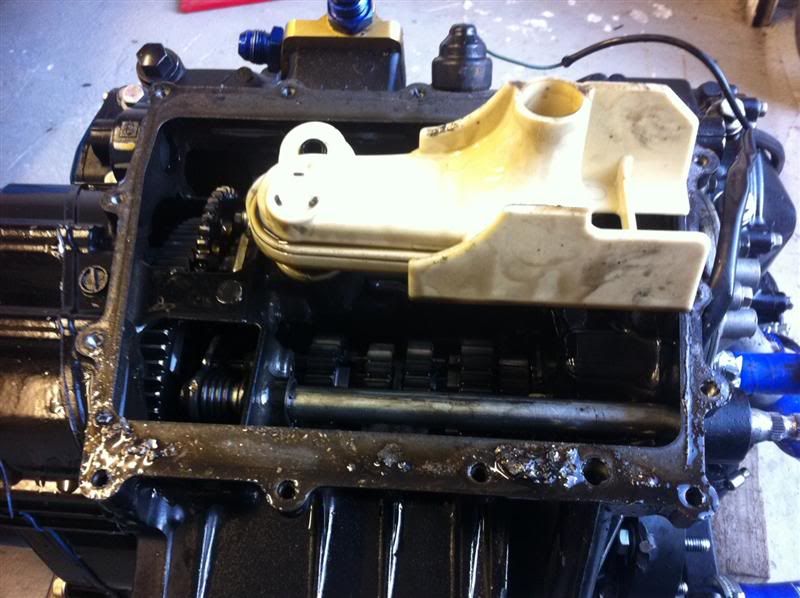

With the oil pickup and clutch cover removed the engine looks like this

Removed the covers and idler gear from the starter motor assembly

Crank position sensor cover and clutch plates removed

Clutch basket taken off

Clutch basket assembly

Remove this circlip from the gear selector shaft, then it can be slid out of the transmission casing

With the selector shaft removed, things look like this inside

Starter motor removed which gives access to the generator cover

Generator assembly removed

Big hole where the generator lives

Sprocket adaptor and water pump removed

Oil pump drive gear removed

Lower gear selector fork shaft being withdrawn

Lower selector and shaft

Edited by Red16 on Friday 2nd March 11:34

Upper selector fork shaft being withdrawn

Gear selector drum being withdrawn

Gear selector drum assembly

Selector fork shafts and drum removed but upper selector forks still in position

Upper selector forks

Oil pump

Oil pump housing

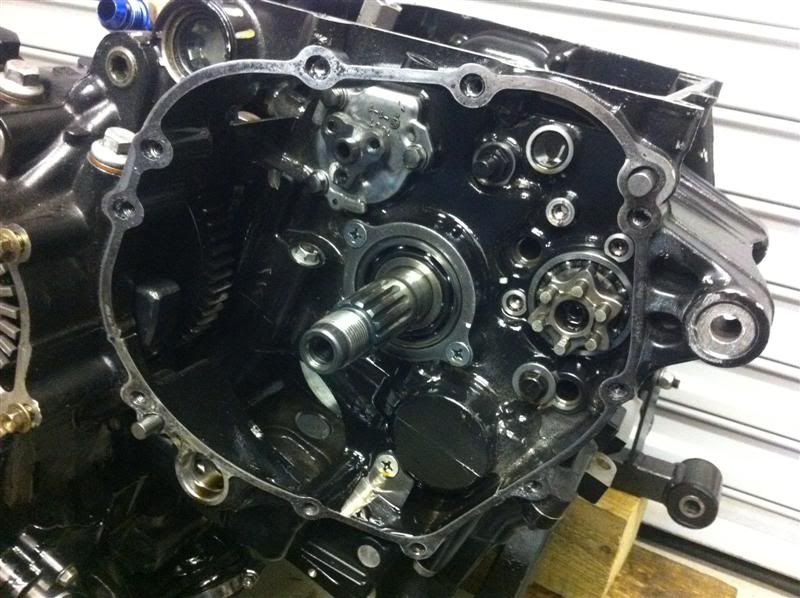

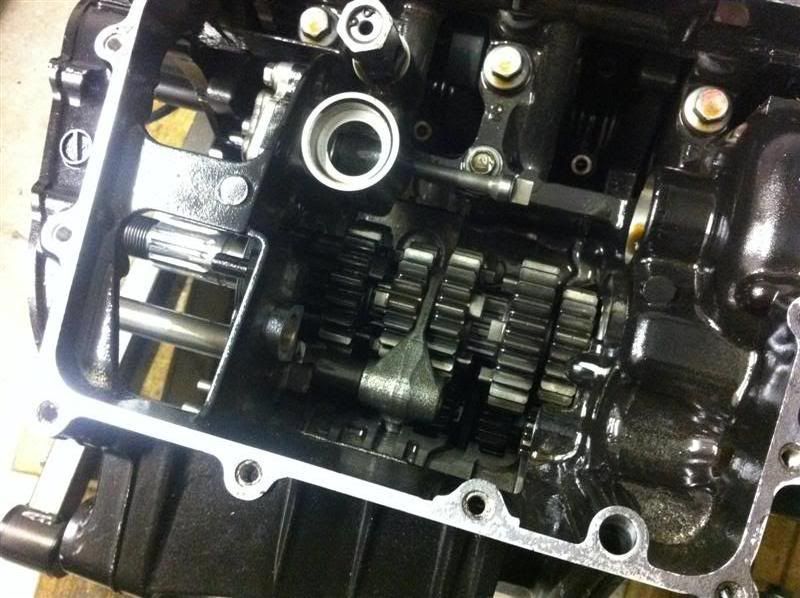

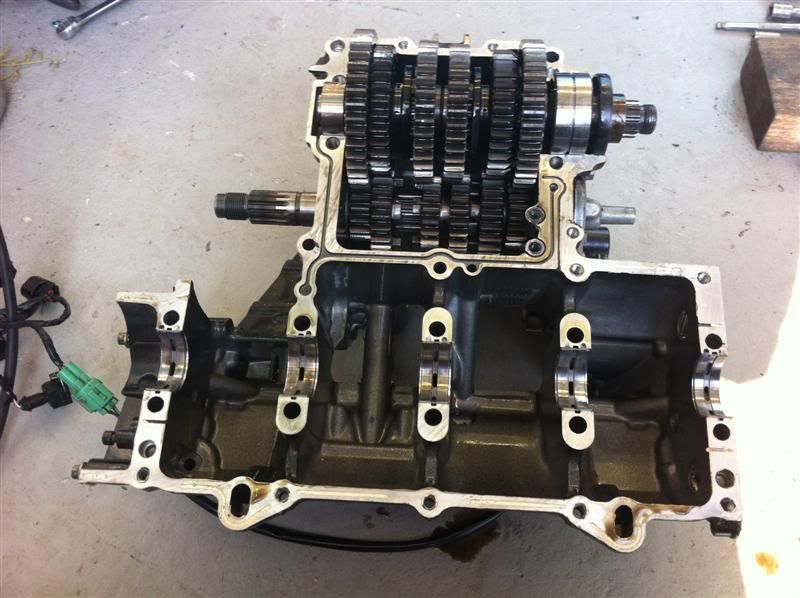

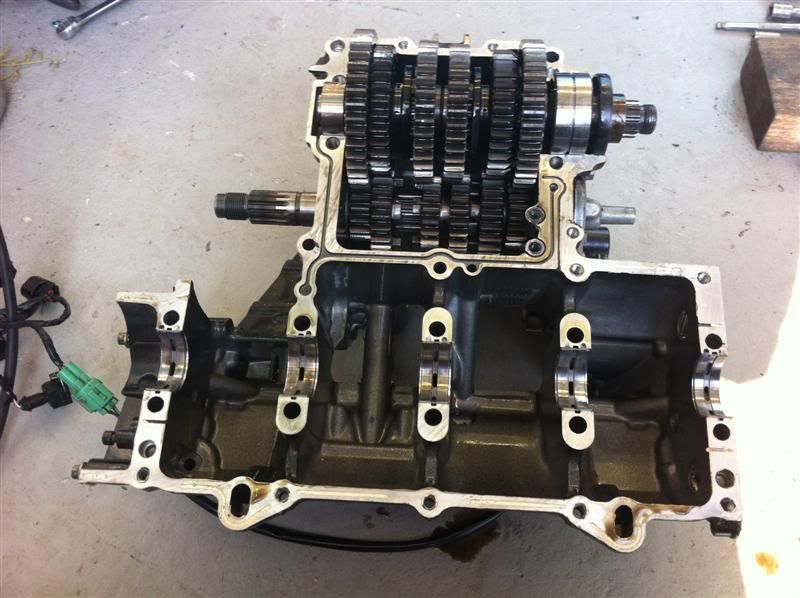

Engine casing split and the transmission removed

Transmission

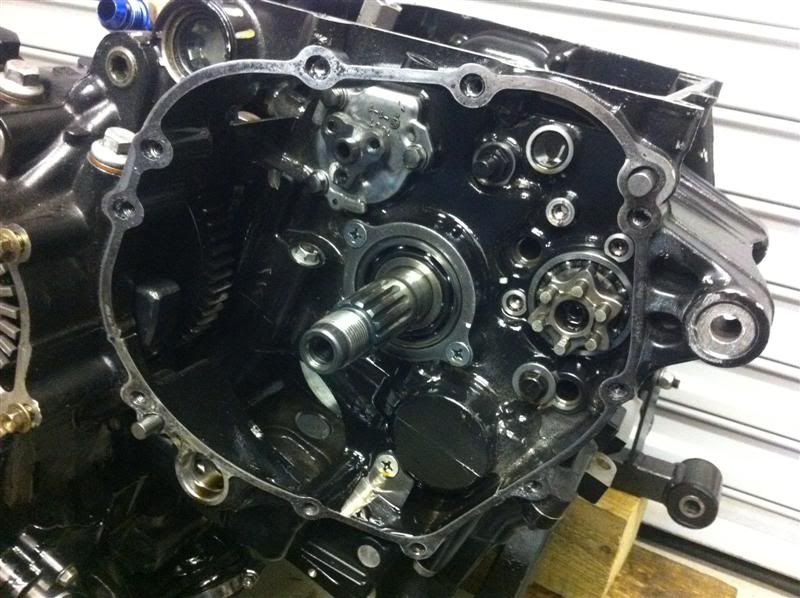

Transmission output shaft removed

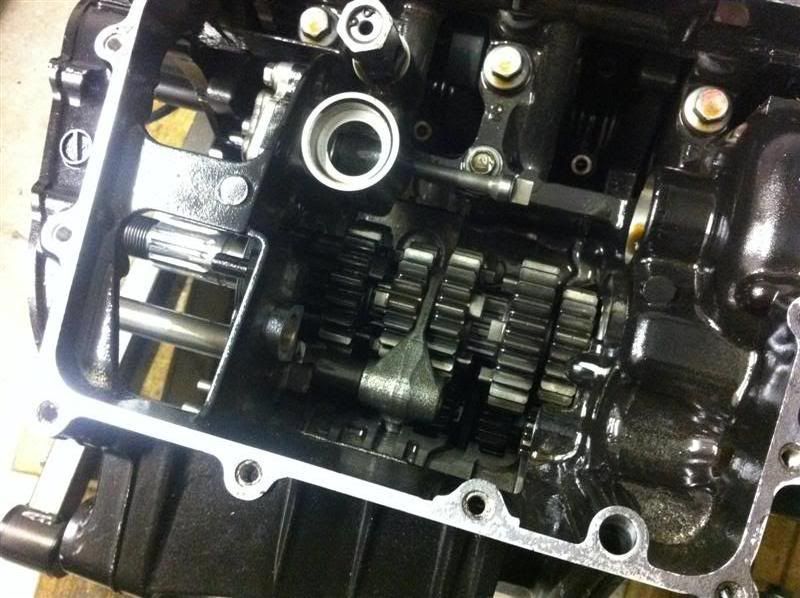

Transmission shafts

Having got to this stage of the stripdown and not found anything obvious wrong I was getting a bit concerned, due the large pieces of debris in the sump it had to be something fairly sizeable and obvious which had gone wrong, the issue turned out to be a damaged big end shell.

As you can see here, the big end shell isn't in great shape and the rod cap appears to be scored

Hopefully the rod will be able to be salvaged, but that can't be ascertained until it it cleaned up and measured.

I'm very suprised that with the big end fault I have found that there was no excess noise/vibration while the engine was idling.

On a positive note, the problem has been found and can therefore now be rectified.

Gear selector drum being withdrawn

Gear selector drum assembly

Selector fork shafts and drum removed but upper selector forks still in position

Upper selector forks

Oil pump

Oil pump housing

Engine casing split and the transmission removed

Transmission

Transmission output shaft removed

Transmission shafts

Having got to this stage of the stripdown and not found anything obvious wrong I was getting a bit concerned, due the large pieces of debris in the sump it had to be something fairly sizeable and obvious which had gone wrong, the issue turned out to be a damaged big end shell.

As you can see here, the big end shell isn't in great shape and the rod cap appears to be scored

Hopefully the rod will be able to be salvaged, but that can't be ascertained until it it cleaned up and measured.

I'm very suprised that with the big end fault I have found that there was no excess noise/vibration while the engine was idling.

On a positive note, the problem has been found and can therefore now be rectified.

Turn7 said:

Sorry to see this. However, I would be more concerned in finding the reason for this now you have found the fault.

Oiling issues ?

I completely agree, further investigation is needed to see if there are any signs as to why this happened, it'd be devastating to rebuild the engine and have the same thing happen again!Oiling issues ?

Oil level was ok, oil pump looks good, no low oil pressure warning, still need to check oil galleries when the engine is bare. The only damage I've found so far is the two centre big end shells, number 2 is scored but number 3 has span and is destroyed, all the other big end and main bearing shells look to be in good condition.

This afternoon I gave the garage a tidy up to make some decent workspace to progress the engine overhaul

Removed the cam chain tensioner

Cam chain tensioner

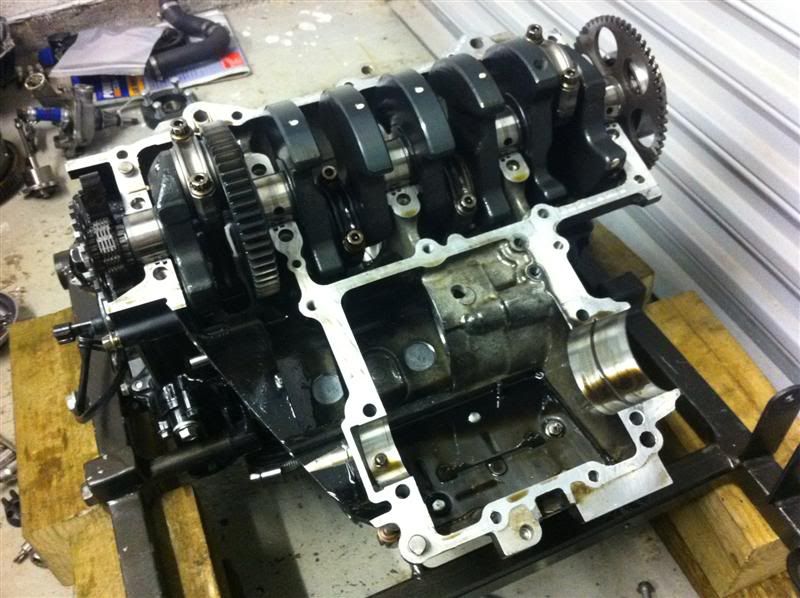

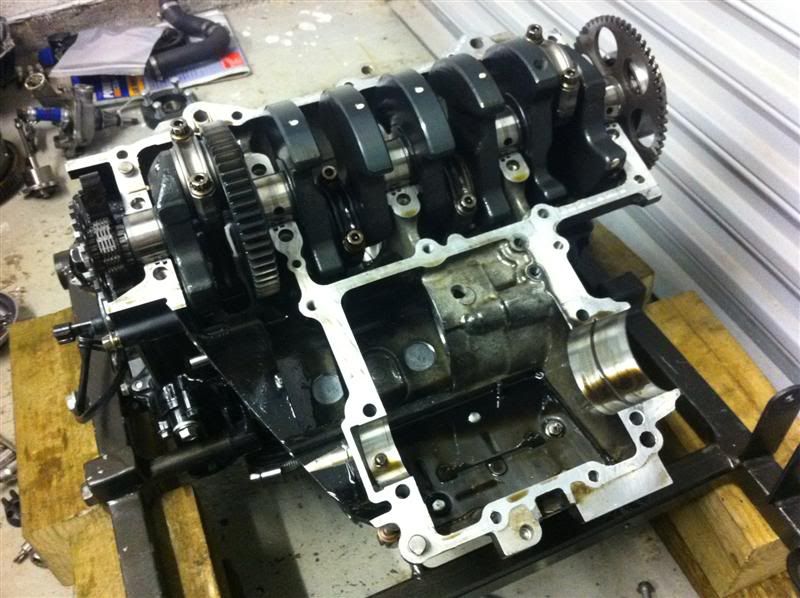

Cam cover removed, exposing the cams

Camshaft retainer caps, camshafts and followers.

Cylinder head without camshafts and followers.

With the camshafts removed the crank was then pulled out the bottom of the engine.

Crankshaft and cam chain.

Removed the cam chain tensioner

Cam chain tensioner

Cam cover removed, exposing the cams

Camshaft retainer caps, camshafts and followers.

Cylinder head without camshafts and followers.

With the camshafts removed the crank was then pulled out the bottom of the engine.

Crankshaft and cam chain.

teabagger said:

Do you use a baffled sump or a is the engine running a dry sump setup?

It's the standard sump and pickup, same as all the other ZX10R cars are using.eliot said:

I think thats the worst big end i've ever seen

I know, it's definitely not in the best condition.

turbo9111 said:

Bloody hell u have been busy did you consider just buying a replacement engine ????

That was an option but if I went down that route I'd still need to strip the new engine and rebuild it with forged rods and pistons, as my engine is not a standard one, so unless the engine casing/bores etc are damaged then i'll be using my original engine.Gassing Station | Kit Cars | Top of Page | What's New | My Stuff