Errr, my bell housing doesnt fit

Discussion

phillpot said:

One of these ?

I think I sort of get the idea that the angle on each UJ should be equal? But would be grateful if you could take a minute or two to explain what or where you are measuring from?

Thats the puppy.

I think I sort of get the idea that the angle on each UJ should be equal? But would be grateful if you could take a minute or two to explain what or where you are measuring from?

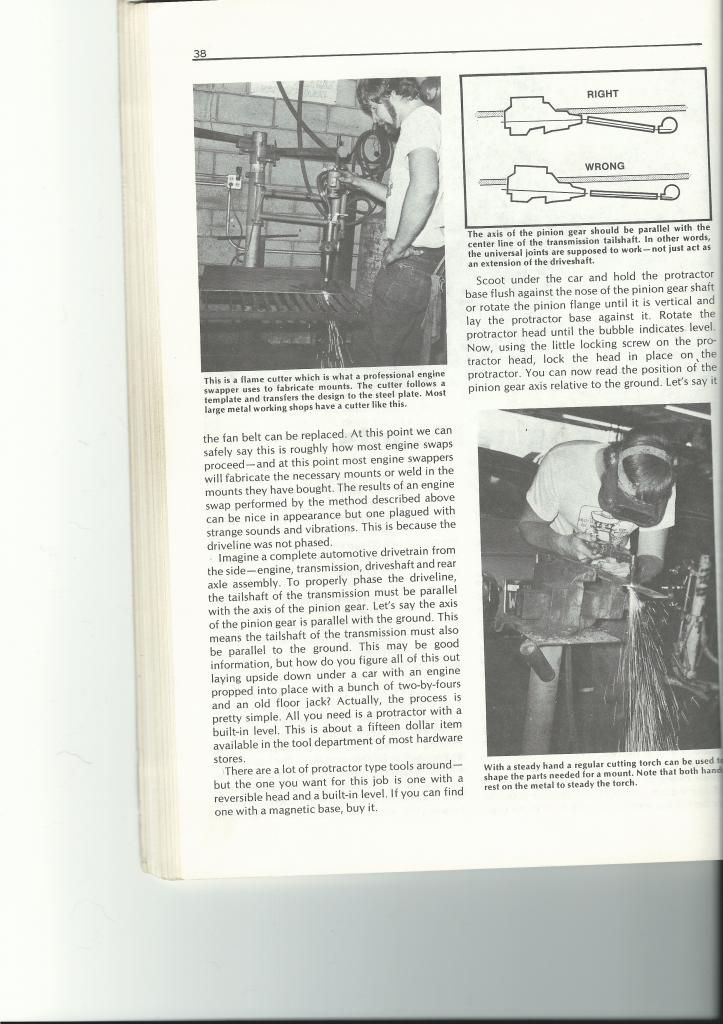

To have the driveline in phase the respective angles should add up to 180 degrees;

The 2 datum measures are taken from the front of the diff output flange and the rear of the gearbox output shaft (the end casing is usually flat enough to lay the level against..

so you take the diff flange and lets say it points upward by 2 degrees that would be an angle of 88 degrees. The gearbox angle will therefore need to point downward by 2 degrees or 268 degrees of angle…Take one from the other and you get 180 degrees..

In simpler terms if diff flange level then gearbox flange level…

If diff points up x degrees from horizontal then gearbox flange points downwards by X degrees

The relative heights of diff and gearbox flanges are not important but obviously good practise should dictate that they are not so far out of whack that the prop runs at an angle greater than about 8 degrees..

I will scan and post up a pic.

The theory is sound and allows u/j's to work at either end of the shaft in phase to ensure you don't get driveline vibration.

N.

Well, I am shocked at the dates on this thread!

Just to bring the thread up to date, I took the rolling chassis up to Duncan Reuben last year so he could check the dimensions on his chassis jig. Several areas were well and truly "out". The engine mounting brackets were in the wrong place and a lot of work was needed to get the rear suspension pick-ups replaced and the rear diff bottom mounts in the right place, but it is now all done and back in my garage. First job was obviously to put it all back together and take a few snaps.

Now its ready for the next stage, which has absolutely got to be getting the engine running (broom Broom!)

:thumbsup:

Huge thanks to Duncan for spending the time to sort it all out.

Just to bring the thread up to date, I took the rolling chassis up to Duncan Reuben last year so he could check the dimensions on his chassis jig. Several areas were well and truly "out". The engine mounting brackets were in the wrong place and a lot of work was needed to get the rear suspension pick-ups replaced and the rear diff bottom mounts in the right place, but it is now all done and back in my garage. First job was obviously to put it all back together and take a few snaps.

Now its ready for the next stage, which has absolutely got to be getting the engine running (broom Broom!)

:thumbsup:

Huge thanks to Duncan for spending the time to sort it all out.

Edited by Astacus on Saturday 14th January 14:27

Looking really really good!

Could I ask for even more measurements? If you wouldn't mind measuring the following I would be truly thankfull;

1. Height from center of crankshaft to top of upper frame tubes

2. Height from center (top of sliding bit on prop is fine) propshaft to top frame tube just aft of the gearbox

Could I ask for even more measurements? If you wouldn't mind measuring the following I would be truly thankfull;

1. Height from center of crankshaft to top of upper frame tubes

2. Height from center (top of sliding bit on prop is fine) propshaft to top frame tube just aft of the gearbox

Gassing Station | TVR Classics | Top of Page | What's New | My Stuff