My V8 powered TVR Vixen

Discussion

A strong alloy, that is commonly available, over here, is 6063. I would use that, in the T6 temper, in at least 3/8" thickness, if it is going to be providing support, for the starter. I am totally guessing, but I would think, that 1/4" is too thin, and the bolt would soon come loose.

Best regards,

Bernard.

Best regards,

Bernard.

Slow M said:

A strong alloy, that is commonly available, over here, is 6063. I would use that, in the T6 temper, in at least 3/8" thickness, if it is going to be providing support, for the starter. I am totally guessing, but I would think, that 1/4" is too thin, and the bolt would soon come loose.

Best regards,

Bernard.

I spoke to my local machine shop yesterday and they said 1/4" aluminum in 5000-series should be plenty strong enough. The one bolt will be threaded through the aluminum (not just pushed through) and then I'll use thread lock as well (or maybe the galvanic reaction between galvanized steel and aluminum will take care of that?).Best regards,

Bernard.

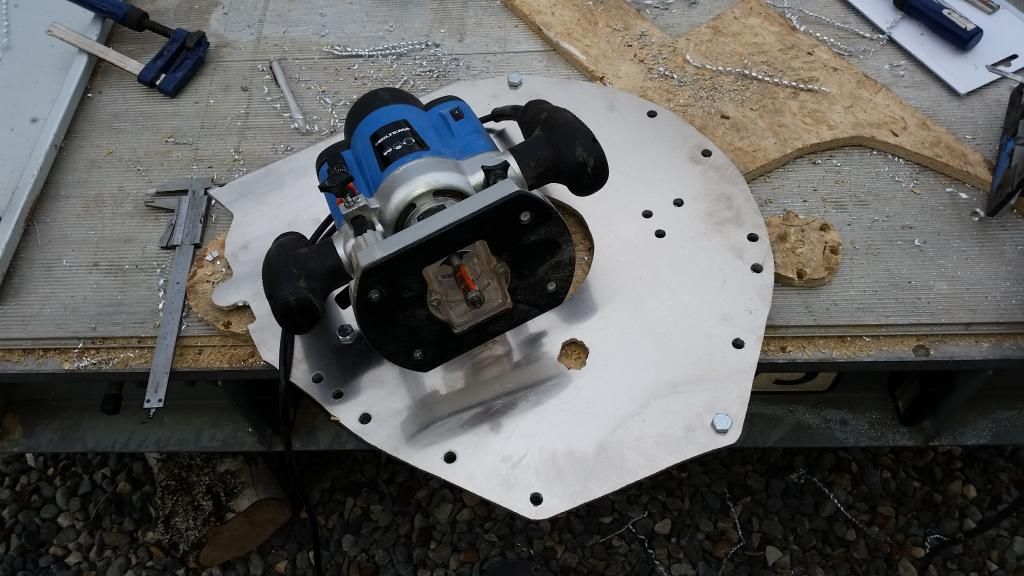

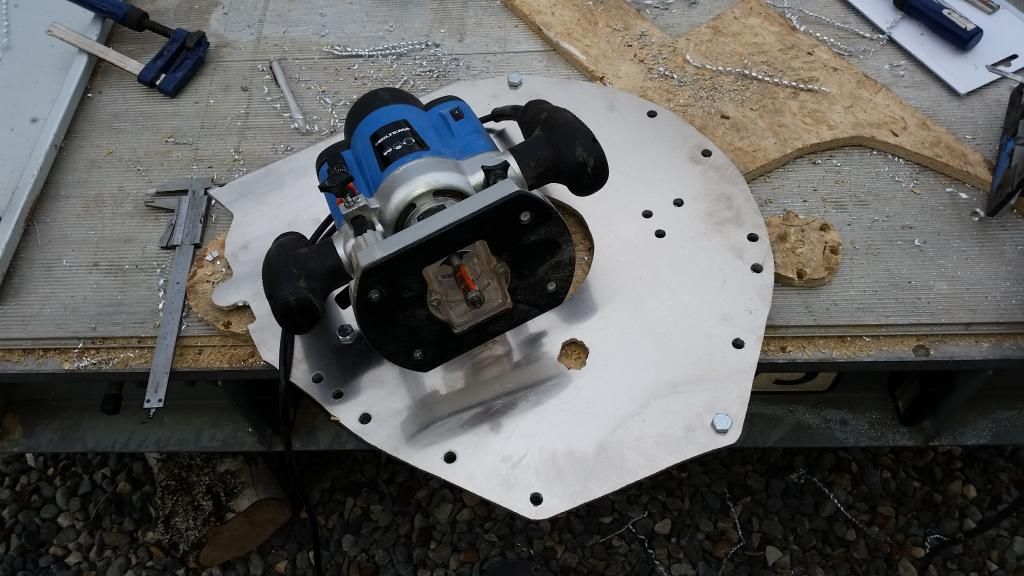

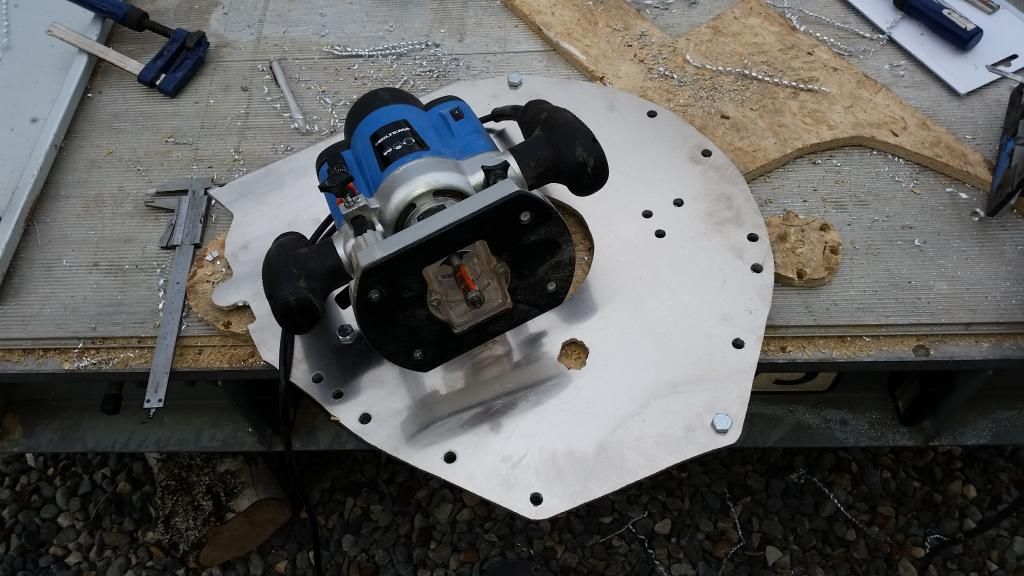

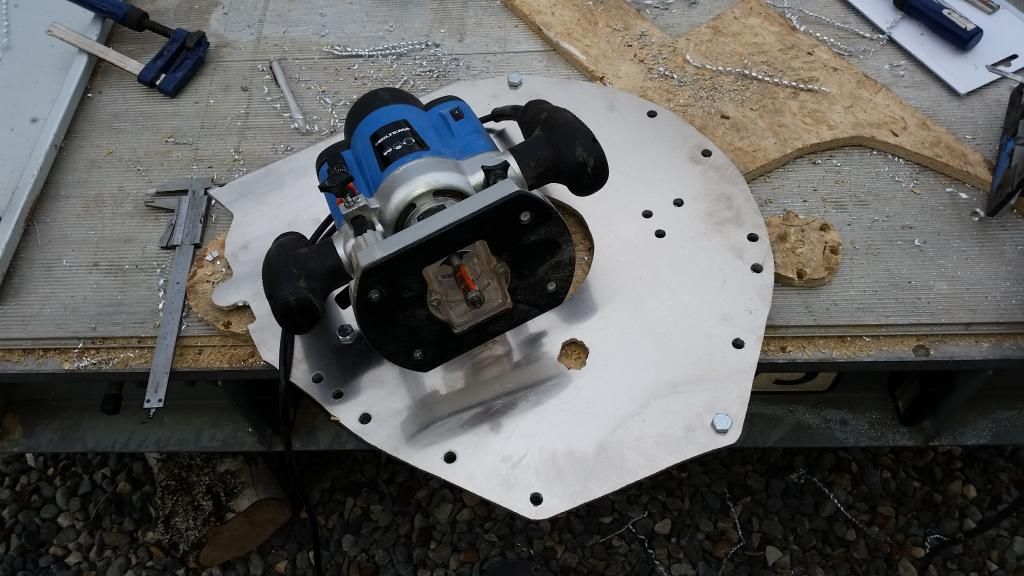

They also agreed to my idea of me milling the backplate with my router with a copy carbide bit with a roller bearing on the bottom

So I've finished the engine backplate.

I started of with a 6mm aluminum plate that I cut to a rough shape with my jigsaw equiped with a aluminum blade

I then used my router with a flush cut router bit

And ended up with a combination of the original Daimler and bespoke Ford engine backplate

Trial fitted to the engine to make sure the starter ended up in the correct position

Now I need to order a hydraulic concentric clutch release bearing. Looks like I might go for a Tilton 6000 unit.

Also need to have my prop modified.

I started of with a 6mm aluminum plate that I cut to a rough shape with my jigsaw equiped with a aluminum blade

I then used my router with a flush cut router bit

And ended up with a combination of the original Daimler and bespoke Ford engine backplate

Trial fitted to the engine to make sure the starter ended up in the correct position

Now I need to order a hydraulic concentric clutch release bearing. Looks like I might go for a Tilton 6000 unit.

Also need to have my prop modified.

Sonus said:

So I've finished the engine backplate.

I started of with a 6mm aluminum plate that I cut to a rough shape with my jigsaw equiped with a aluminum blade

I then used my router with a flush cut router bit

And ended up with a combination of the original Daimler and bespoke Ford engine backplate

Trial fitted to the engine to make sure the starter ended up in the correct position

Now I need to order a hydraulic concentric clutch release bearing. Looks like I might go for a Tilton 6000 unit.

Also need to have my prop modified.

Howe Racing do one for the T5 and T10;s I have one in mine.I started of with a 6mm aluminum plate that I cut to a rough shape with my jigsaw equiped with a aluminum blade

I then used my router with a flush cut router bit

And ended up with a combination of the original Daimler and bespoke Ford engine backplate

Trial fitted to the engine to make sure the starter ended up in the correct position

Now I need to order a hydraulic concentric clutch release bearing. Looks like I might go for a Tilton 6000 unit.

Also need to have my prop modified.

http://www.ebay.com/bhp/hydraulic-throwout-bearing

N

Edited by Dollyman1850 on Sunday 1st March 13:46

Edited by Dollyman1850 on Sunday 1st March 13:46

Dollyman1850 said:

Howe Racing do one for the T5 and T10;s I have one in mine.

http://www.ebay.com/bhp/hydraulic-throwout-bearing

N

Has the Howe been reliable? I've read a lot of stories about Mcloed and Ram units leakinghttp://www.ebay.com/bhp/hydraulic-throwout-bearing

N

Edited by Dollyman1850 on Sunday 1st March 13:46

Edited by Dollyman1850 on Sunday 1st March 13:46

I'd rather not remove the engine and box again anytime soon

Sonus said:

Has the Howe been reliable? I've read a lot of stories about Mcloed and Ram units leaking

I'd rather not remove the engine and box again anytime soon

Its sat around in the racer for about 3 years now and not leaked!I'd rather not remove the engine and box again anytime soon

It will most likely suit your install since it comes with circular shims to allow easy set up of travel..Thus any tolerance issues on your conversion will be easily adjusted out.

Its also much cheaper than the Tilton set up.

N.

Dollyman1850 said:

Its sat around in the racer for about 3 years now and not leaked!

It will most likely suit your install since it comes with circular shims to allow easy set up of travel..Thus any tolerance issues on your conversion will be easily adjusted out.

Its also much cheaper than the Tilton set up.

N.

How do you stop the HOWE HTB from rotating on the bearing retainer? I'd be worried that it could start rotating and start bashing one of either the bleed or supply ears on the "spigot"?It will most likely suit your install since it comes with circular shims to allow easy set up of travel..Thus any tolerance issues on your conversion will be easily adjusted out.

Its also much cheaper than the Tilton set up.

N.

It's very tempting to go for the HOWE compared to the Tilton when you look at the price.

Hansoplast said:

Nice story telling with the pics.

Looks easy ( is not) but helps the faint hearted to do fine works to their classics. Or at least try.

Good luck with this item.

Hans

Thanks HansoplastLooks easy ( is not) but helps the faint hearted to do fine works to their classics. Or at least try.

Good luck with this item.

Hans

It's not that hard as long as you don't rush it and try a few times on a scrap piece first.

The important part when milling aluminum with a router I've found is to move the router in the correct direction compared to the rotational direction of the bit. Do it the wrong way often ends with the router running away from you.

Wear protective glasses!

Sonus said:

How do you stop the HOWE HTB from rotating on the bearing retainer? I'd be worried that it could start rotating and start bashing one of either the bleed or supply ears on the "spigot"?

It's very tempting to go for the HOWE compared to the Tilton when you look at the price.

Sorry Sonus. I haven't been ignoring you..I have looked for a pic but cannot find one.It's very tempting to go for the HOWE compared to the Tilton when you look at the price.

In answer to your question there are many hundreds of these fitted in the states and mine works fine, they are designed to move on the shaft and are retained by a location dowel which is bolted onto one of the gearbox / bell housing bolts. It is important to follow the set up instructions regarding free length and pre-loading, also to use the correct clutch cylinder. They only turn 1 way so once sitting against the dowel it doesn't move any further.

There will always be the possibility of a leak and that is the disadvantage with one. they do however have many advantages over all of the externally mounted mess with an external slave, operating arm, clutch fork and std bearing.

Mine has been fine, doubtless thousands of others in normal service will similarly be ok.

N.

Edited by Dollyman1850 on Friday 6th March 18:37

Dollyman1850 said:

Sorry Sonus. I haven't been ignoring you..I have looked for a pic but cannot find one.

In answer to your question there are many hundreds of these fitted in the states and mine works fine, they are designed to move on the shaft and are retained by a location dowel which is bolted onto one of the gearbox / bell housing bolts. It is important to follow the set up instructions regarding free length and pre-loading, also to use the correct clutch cylinder. They only turn 1 way so once sitting against the dowel it doesn't move any further.

There will always be the possibility of a leak and that is the disadvantage with one. they do however have many advantages over all of the externally mounted mess with an external slave, operating arm, clutch fork and std bearing.

Mine has been fine, doubtless thousands of others in normal service will similarly be ok.

N.

Thanks! I've been reading up and it looks lkke the Howe one is the better of the less expensive ones. I think I'll order one today In answer to your question there are many hundreds of these fitted in the states and mine works fine, they are designed to move on the shaft and are retained by a location dowel which is bolted onto one of the gearbox / bell housing bolts. It is important to follow the set up instructions regarding free length and pre-loading, also to use the correct clutch cylinder. They only turn 1 way so once sitting against the dowel it doesn't move any further.

There will always be the possibility of a leak and that is the disadvantage with one. they do however have many advantages over all of the externally mounted mess with an external slave, operating arm, clutch fork and std bearing.

Mine has been fine, doubtless thousands of others in normal service will similarly be ok.

N.

Edited by Dollyman1850 on Friday 6th March 18:38

Slow M said:

Having heard enough nightmare tales of leaking slaves, I opted to place a puller slave alongside the bellhousing, with the telescoping shaft pointed backward.

It's light, cheap, and easy to reach.

Best regards,

Bernard.

Since I am using an auto bellhousing there is no fork to operate so I am 'stuck' with using a concengric hydraulic one.It's light, cheap, and easy to reach.

Best regards,

Bernard.

Gassing Station | TVR Classics | Top of Page | What's New | My Stuff