99t's Saab 99 Turbo

Discussion

I love this thread! Please come and sort out my 900T when you are done with yours!

They did a 3 door "combi coupe" in the traditional Saab fastback style, and a booted 2 door that was much stiffer.

deltashad said:

I used to pass a gorgeous black 900 turbo on my walk home from school. It had an APC badge on the back, I think they liked the three extra letter designations. Never knew what it meant...

On another note my dentist had a bright red 99 turbo, must have been about an X-reg, not as pretty a shape as yours. Was this a standard colour?

Loving the car and the work op. I started and gave up on my Lancia, reading threads like this would get me started again, unfortunately I have no real skills and the extent and compications of the work have led me to bite the bullet and give it to a specialist to complete.

APC = automatic performance control. Basically electronic boost control with a knock sensor. In 1980!On another note my dentist had a bright red 99 turbo, must have been about an X-reg, not as pretty a shape as yours. Was this a standard colour?

Loving the car and the work op. I started and gave up on my Lancia, reading threads like this would get me started again, unfortunately I have no real skills and the extent and compications of the work have led me to bite the bullet and give it to a specialist to complete.

They did a 3 door "combi coupe" in the traditional Saab fastback style, and a booted 2 door that was much stiffer.

As the year nears its conclusion, I thought I'd best detail the progress made in 2014.

Sorry to say this won't take long...

I assumed the fuel accumulator was beyond salvation and dipped it in acid for several days - initially just to help to get the unions undone (and save the moulded fuel lines).

However whilst slightly surprised that it cleaned up so well, I was genuinely amazed that it also pressure tested ok.

Still not entirely sure I want to reuse it, but it may just suffice if a correct replacement proves impossible to obtain.

I also started on the doors. As this work progresses you may well wonder why I didn't just replace the doors with better ones (and in fact I even have a much better pair "in stock"!)

Originality is the answer. I want to end up with a 99 Turbo that retains all of its original panels (or as much of them as possible) even though it would be far quicker and easier to replace in most cases.

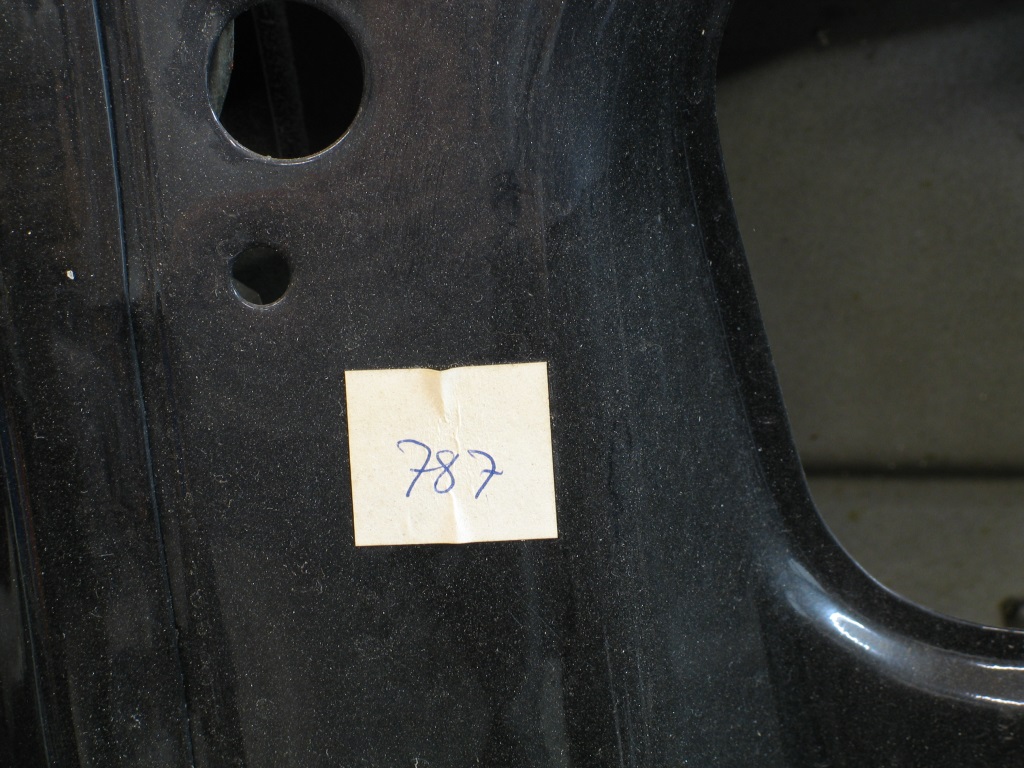

The Geek in me likes that the original doors retain some nice factory information under the trim panels

and

which might not mean much without this

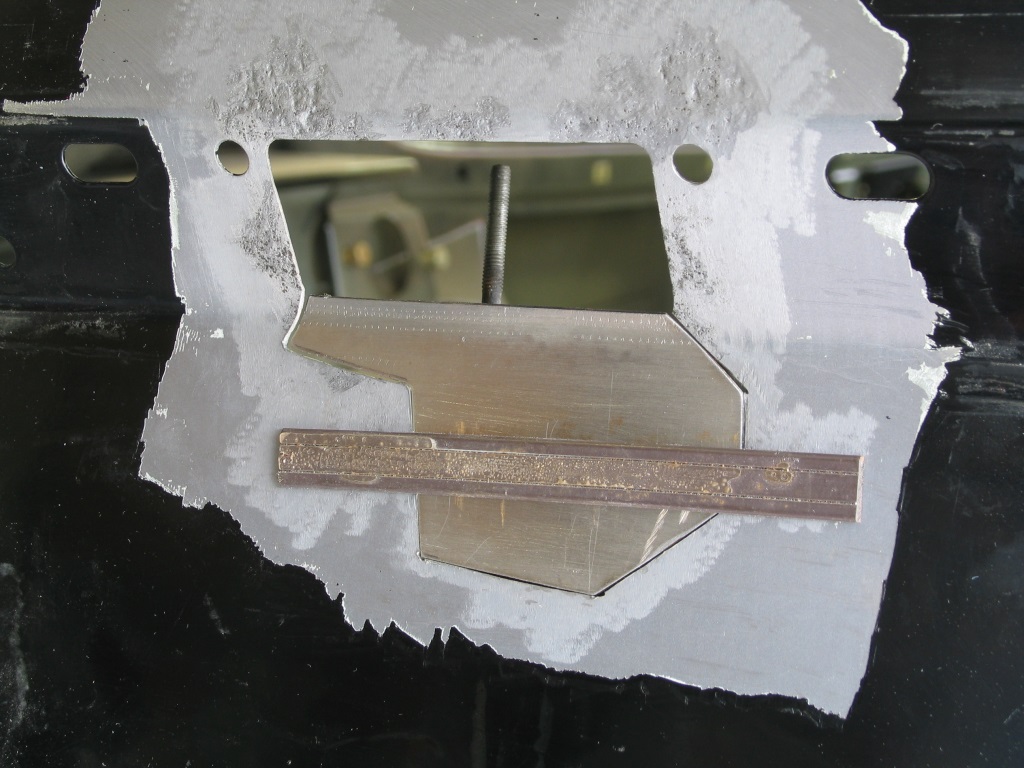

So, deep breath... and cut some rust out of the bottom of the driver's door...

...and started tacking new sections in.

Besides the rotten bottoms, the other major issue with the doors is badly rusty window channels (which guide the glass when wound down into the door).

As the channel rusts the metal expands and compresses the rubber / felt liner that the glass slides in, making it excessively tight and making window winding difficult. People often blame the winder mechanism for stiff windows, but in my experience the mechanism is rarely the culprit in a Saab 99.

Mine were pretty bad in places. The channels are welded into the very ends of the door so access is really poor, so painstaking removal is the only option.

The top lip of the door skin is also rusty and badly repaired previously so decision where to cut into the door frame was made easier.

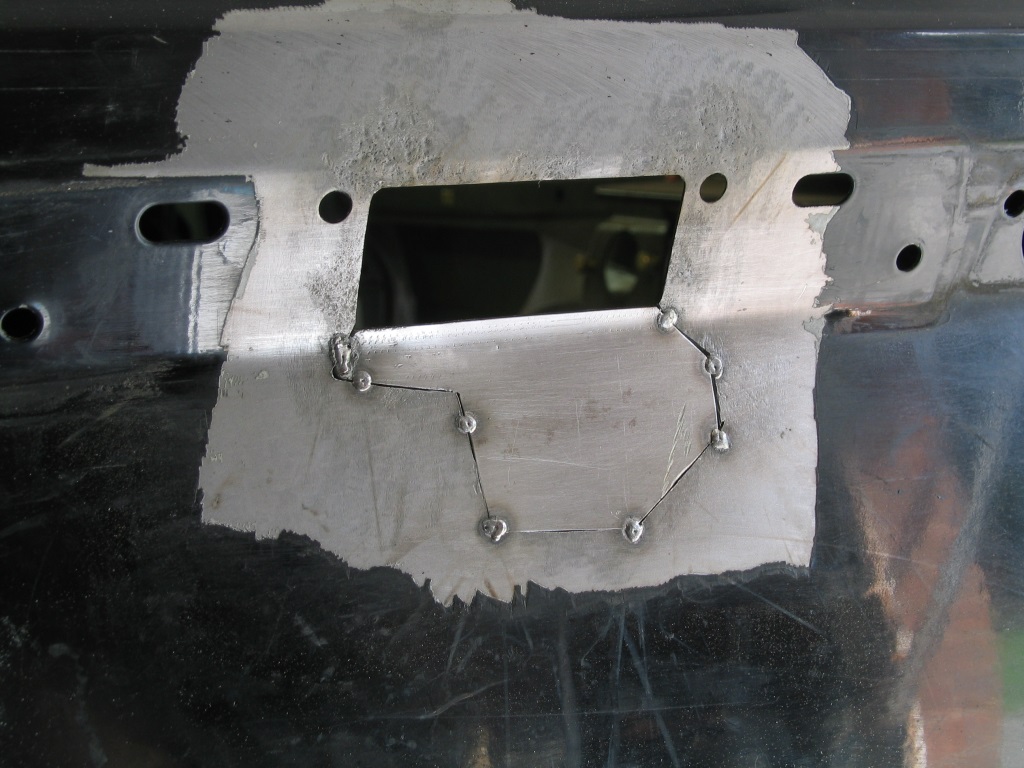

The U-section channel has a curve along its length so not easy to make a replacement with the facilities I have, so elected to repair.

De-rusted

Patched (about 8 small patches in total), treated and epoxy coated, ready to weld back into the door.

And that's about it in terms of actual work!

Earlier in the year I tracked down a few more NOS parts in Tenerife of all places!

Then just after Christmas the postman arrived with a genuine exhaust tailpipe poking out of his sack!

Happy New Year to All and here's to a productive 2015

Sorry to say this won't take long...

I assumed the fuel accumulator was beyond salvation and dipped it in acid for several days - initially just to help to get the unions undone (and save the moulded fuel lines).

However whilst slightly surprised that it cleaned up so well, I was genuinely amazed that it also pressure tested ok.

Still not entirely sure I want to reuse it, but it may just suffice if a correct replacement proves impossible to obtain.

I also started on the doors. As this work progresses you may well wonder why I didn't just replace the doors with better ones (and in fact I even have a much better pair "in stock"!)

Originality is the answer. I want to end up with a 99 Turbo that retains all of its original panels (or as much of them as possible) even though it would be far quicker and easier to replace in most cases.

The Geek in me likes that the original doors retain some nice factory information under the trim panels

and

which might not mean much without this

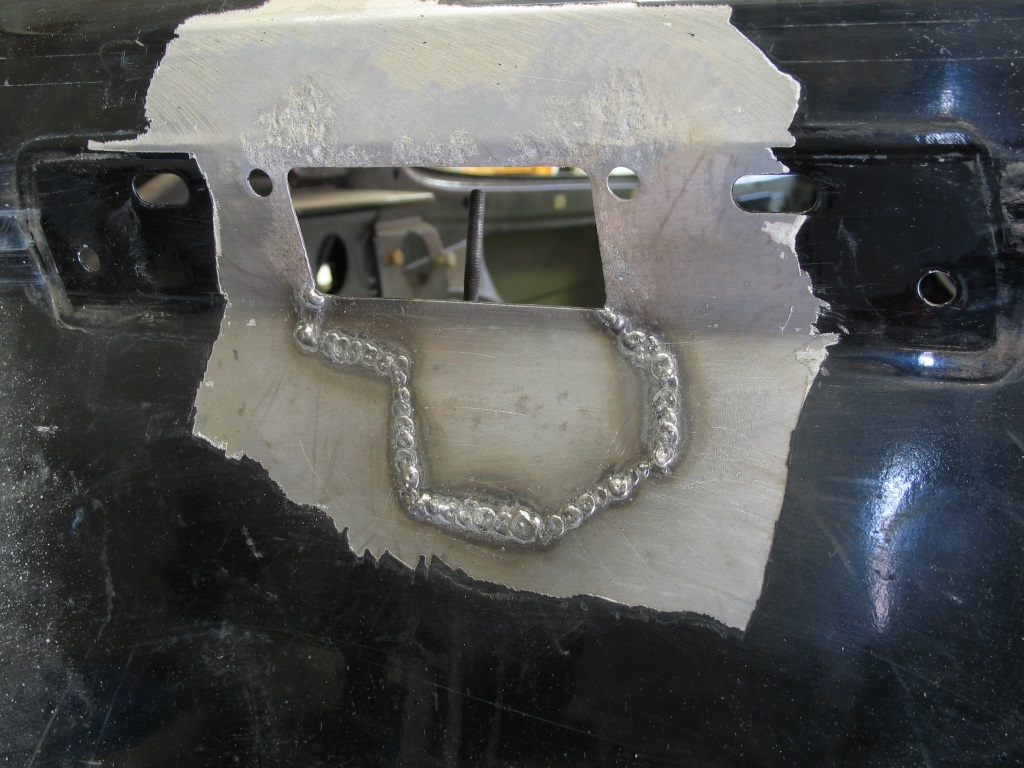

So, deep breath... and cut some rust out of the bottom of the driver's door...

...and started tacking new sections in.

Besides the rotten bottoms, the other major issue with the doors is badly rusty window channels (which guide the glass when wound down into the door).

As the channel rusts the metal expands and compresses the rubber / felt liner that the glass slides in, making it excessively tight and making window winding difficult. People often blame the winder mechanism for stiff windows, but in my experience the mechanism is rarely the culprit in a Saab 99.

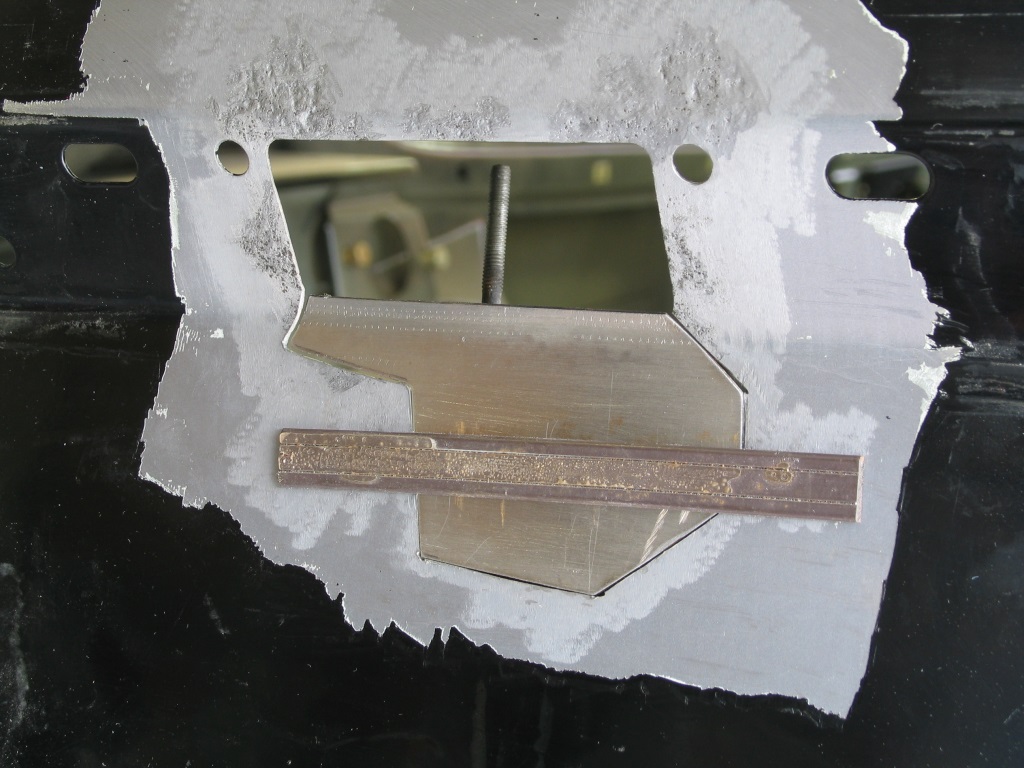

Mine were pretty bad in places. The channels are welded into the very ends of the door so access is really poor, so painstaking removal is the only option.

The top lip of the door skin is also rusty and badly repaired previously so decision where to cut into the door frame was made easier.

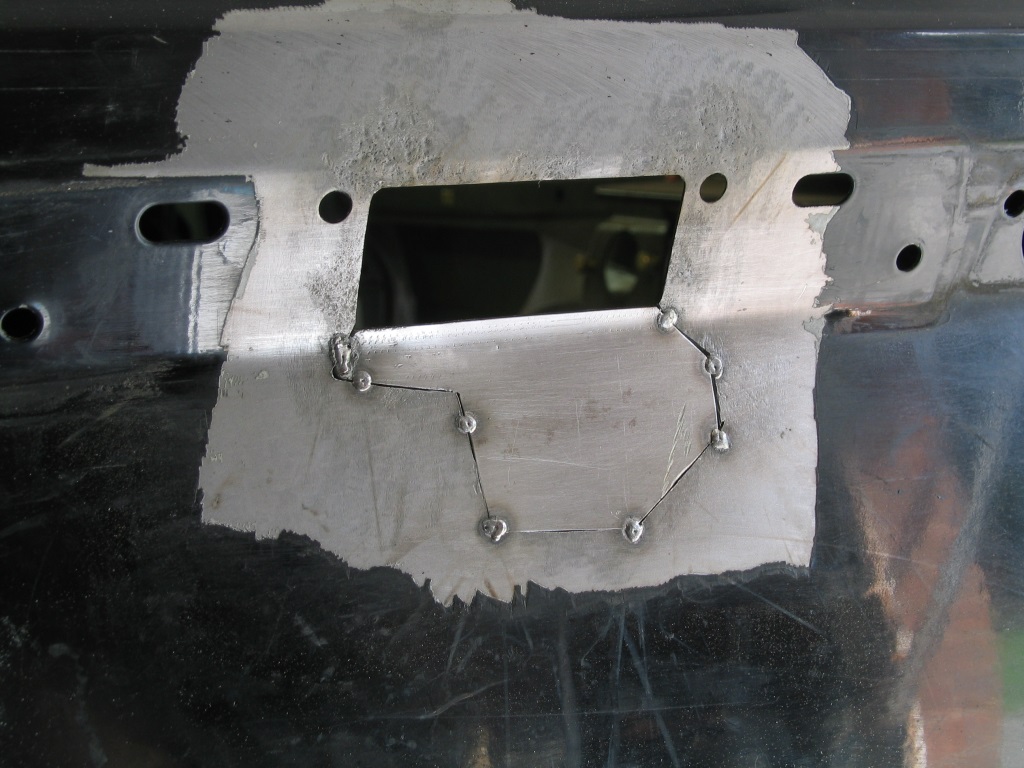

The U-section channel has a curve along its length so not easy to make a replacement with the facilities I have, so elected to repair.

De-rusted

Patched (about 8 small patches in total), treated and epoxy coated, ready to weld back into the door.

And that's about it in terms of actual work!

Earlier in the year I tracked down a few more NOS parts in Tenerife of all places!

Then just after Christmas the postman arrived with a genuine exhaust tailpipe poking out of his sack!

Happy New Year to All and here's to a productive 2015

Ok, going to try to update more regularly this year.

One of the reasons I hadn't done much towards the latter end of last year is because I decided to give up another one of my other long-term projects, a slightly later two-door 99 turbo.

I had purchased this as a parts car, then given it a reprieve as it drove well. When I started welding however, I wished I hadn't bothered. It was far rustier than the three-door, also high mileage and badly (MOT) rust repaired previously. Stored for the last few years whilst I pondered its future, I finally, reluctantly accepted that life is too short and it would take more time than I was prepared to invest to even make an even half-decent car of it.

Decision made I stripped it, keeping anything that could be of future use. All the saved parts meant that I couldn't even get into the garage until I built a new shed to store all the parts. The only space Mrs 99t would allocate me for this was behind the garage - about three feet wide and twenty something feet long!

Still a work in progress but this is what it looked like before I put the stripped parts in it! Rather fuller now but at least I can get into the garage again!

Shell gone, shed built and (over)filled and I can finally get back to this project...

Work on the tailgate continues. Really and honestly I should admit at this point that it was beyond sensible repair and I could have saved many, many hours by replacing it. My obsession with retaining all the original panels remains intact however, so onwards and upwards...

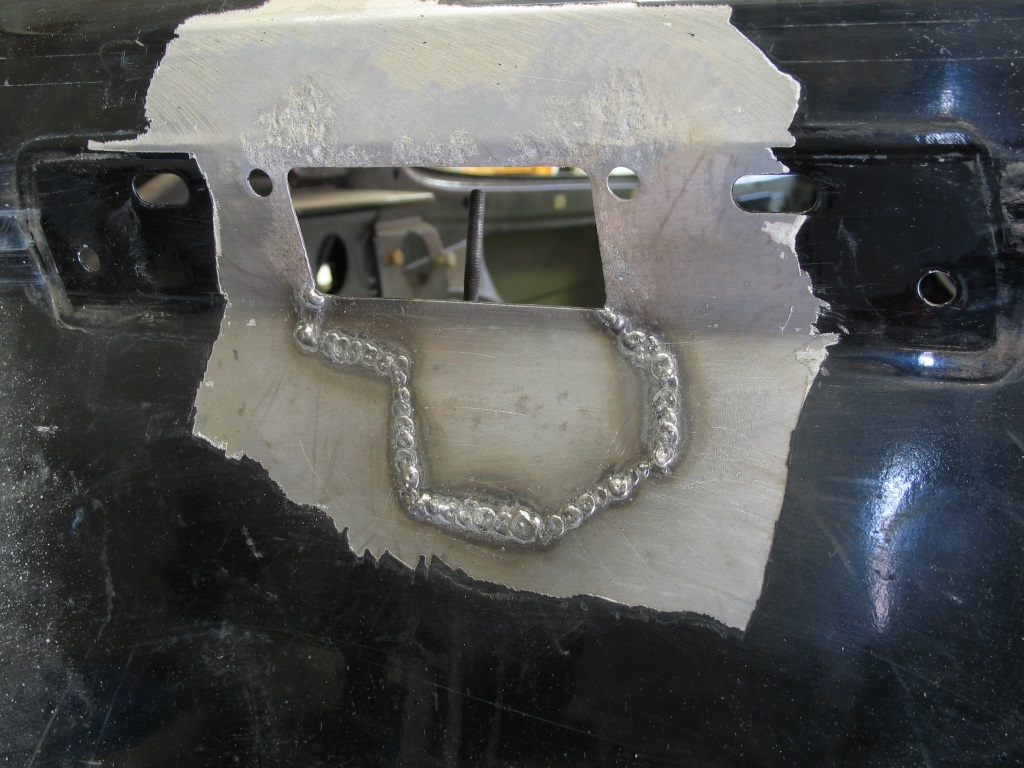

Areas around number plate fixings well corroded.

The nearside cleaned up ok as pits weren't too deep but the offside was worse and needed a patch.

Area around hatch release with the mechanism removed

Rust above will clean up, but again metal below too thin.

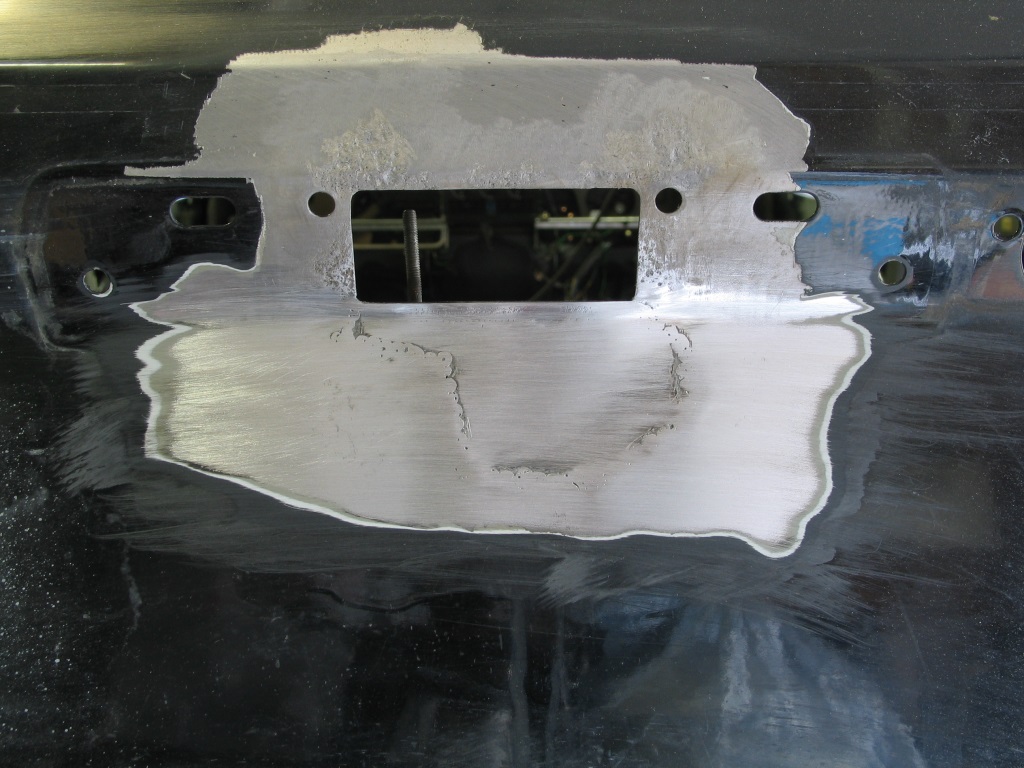

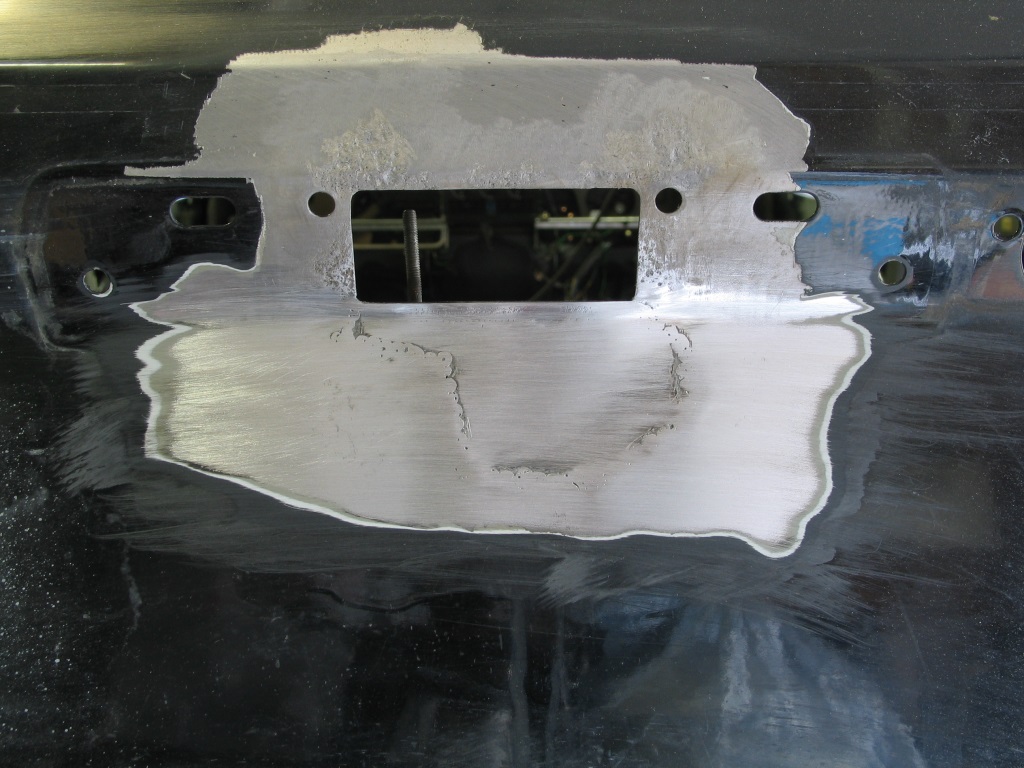

Lots of spot welds, alternating welding and quenching which results in this, not pretty but hopefully little or no distortion

After a quick dress to the welds

Very difficult to take a picture of an expanse of grey primer and make it show anything meaningful!! You'll have to take my word for it that with the lightest skim of filler (less than 1mm I reckon) it passes the palm of the hand test

Bored of the tailgate for now I attacked the bubbling paint around the nearside front indicator / sidelight aperture...

Rust spiders alive and well

Initial pass with wet and dry to remove lightest corrosion and staining.

Removing the heavier rust deposits and pits at the bottom of the aperture via mix of mechanical removal (tiny diamond bit on Dremel) and soaking in Phosphoric acid, repeat as necessary until all clean. Fortunately the Swedes used thick steel and even the deepest pits have cleaned up without going through the metal.

Then coat with Hydrate 80 (and later Electrox) which will keep moisture out until I'm ready to start painting (which certainly isn't going to be any time soon!!)

One of the reasons I hadn't done much towards the latter end of last year is because I decided to give up another one of my other long-term projects, a slightly later two-door 99 turbo.

I had purchased this as a parts car, then given it a reprieve as it drove well. When I started welding however, I wished I hadn't bothered. It was far rustier than the three-door, also high mileage and badly (MOT) rust repaired previously. Stored for the last few years whilst I pondered its future, I finally, reluctantly accepted that life is too short and it would take more time than I was prepared to invest to even make an even half-decent car of it.

Decision made I stripped it, keeping anything that could be of future use. All the saved parts meant that I couldn't even get into the garage until I built a new shed to store all the parts. The only space Mrs 99t would allocate me for this was behind the garage - about three feet wide and twenty something feet long!

Still a work in progress but this is what it looked like before I put the stripped parts in it! Rather fuller now but at least I can get into the garage again!

Shell gone, shed built and (over)filled and I can finally get back to this project...

Work on the tailgate continues. Really and honestly I should admit at this point that it was beyond sensible repair and I could have saved many, many hours by replacing it. My obsession with retaining all the original panels remains intact however, so onwards and upwards...

Areas around number plate fixings well corroded.

The nearside cleaned up ok as pits weren't too deep but the offside was worse and needed a patch.

Area around hatch release with the mechanism removed

Rust above will clean up, but again metal below too thin.

Lots of spot welds, alternating welding and quenching which results in this, not pretty but hopefully little or no distortion

After a quick dress to the welds

Very difficult to take a picture of an expanse of grey primer and make it show anything meaningful!! You'll have to take my word for it that with the lightest skim of filler (less than 1mm I reckon) it passes the palm of the hand test

Bored of the tailgate for now I attacked the bubbling paint around the nearside front indicator / sidelight aperture...

Rust spiders alive and well

Initial pass with wet and dry to remove lightest corrosion and staining.

Removing the heavier rust deposits and pits at the bottom of the aperture via mix of mechanical removal (tiny diamond bit on Dremel) and soaking in Phosphoric acid, repeat as necessary until all clean. Fortunately the Swedes used thick steel and even the deepest pits have cleaned up without going through the metal.

Then coat with Hydrate 80 (and later Electrox) which will keep moisture out until I'm ready to start painting (which certainly isn't going to be any time soon!!)

appletonn said:

99t said:

Cardinal Red (ok on a Turbo not an EMS)

EMS = Electronic Manual Special I believe, or the Swedish equivalent perhaps?

Old thread but OMG that is lovely in that colour!

EMS = Electronic Manual Special I believe, or the Swedish equivalent perhaps?

They did sell 100 or so five door Cardinal versions here, uber, uber-rare now. One just happens to be for sale - no affiliation but it looks a cracker...

http://www.carandclassic.co.uk/car/C454182

Shadow R1 said:

He is still around, posted on the high miles monaro thread not long ago.

Sorry chaps, hadn't seen the question.Work on the 99 paused around the time of my last post when other projects (but specifically my '66 El Camino) came along.

The shell is still living happily on the spit in the dehumidified garage and all the trim and mechanical bits are safely stored away, individually bubble wrapped and labelled in the majority of cases!

There is an awful lot of de-rusting and welding still to do on the shell, work that I think I had become sick of doing by 2015. I've not done much welding since then so feel better about cracking on with it some time in the not-too-distant future.

The time since I last worked on the Saab hasn't been wasted though - I now have the proper air-fed painting gear which means I can spray 2K without killing myself, and the challenges presented by the roof on the Elk, which I believe I have now overcome, have forced me to become substantially more accomplished at bodywork prep than I was four years ago - which will be necessary when I come to paint the Saab in unforgiving gloss black..

TL:DR - thanks for the interest in progress, there won't be any updates on this for a while yet but I consider work to be paused rather than stopped.

Good thread.

I had a black S reg 99 Turbo 3 door and hate to think how many years it spent in the garage before being sold on. It had an overheating problem and the new owner found that the water pump drive shaft had broken - apparently a common problem.

I used to work in a Saab dealer in 1979 - remember the first blue 900's with powder blue interior - aren't interior colours these days so boring? The first 900's came with transit protection wax that was very hard to shift off the paintwork - ended up trying petrol(!) and then they were sent off for steam cleaning - can't have done the long term durability much good....

We had a 99 5 door shell round the back being stripped for spares - apparently the car hit a kerb at 90mph and rolled but true to Saab's solidity all the doors still opened perfectly.

Have you considered trying TIG welding on bodywork patching - kit is cheap these days and quicker than spotwelding/easier to control?

Interested to see how well dilute phosphoric acid works - citric acid is also apparently good at rust removal.

I had a black S reg 99 Turbo 3 door and hate to think how many years it spent in the garage before being sold on. It had an overheating problem and the new owner found that the water pump drive shaft had broken - apparently a common problem.

I used to work in a Saab dealer in 1979 - remember the first blue 900's with powder blue interior - aren't interior colours these days so boring? The first 900's came with transit protection wax that was very hard to shift off the paintwork - ended up trying petrol(!) and then they were sent off for steam cleaning - can't have done the long term durability much good....

We had a 99 5 door shell round the back being stripped for spares - apparently the car hit a kerb at 90mph and rolled but true to Saab's solidity all the doors still opened perfectly.

Have you considered trying TIG welding on bodywork patching - kit is cheap these days and quicker than spotwelding/easier to control?

Interested to see how well dilute phosphoric acid works - citric acid is also apparently good at rust removal.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff