Fix It Again Tomorrow - Street Sleeper

Discussion

Hoopsuk said:

Is this project still on the road? or has it been sold on?

It got pushed to the back of the workshop tbh as we got busy with other stuff, oh and 'Nats' came along:

I was going to do a 4 x 4 conversion, but decided against it so all the bits are for sale.

I do plan on wheeling the red one out and doing some trackdays with it this year though.

Edited by Evoluzione on Saturday 24th January 23:11

heisthegaffer said:

Tell us about Nats then...

There isn't much of great interest to say really, yet another 16vt picked up on Ebay... 'Never buy a car because of its colour', they say along with not buying a car you've never seen in the flesh, so I bought it. I figured we could do something with it no matter what, but when I offloaded it from the trailer and got it up on the lift I was pleasantly surprised as was a really solid car - no rust in the usual places.

Yeah it had issues, it looked like the bloke from Fake Taxi had been performing on the back seat, had little chav touches here and there, a good array of warning lights on the dashboard, front grille missing, bonnet release cable broken and a few things I've forgotten.

On the plus side was the colour (Ink black), the aforementioned lack of rust, new clutch, from susp' arms, 'stat & rad.

I got busy over a series of Saturdays making it right again:

Various wiring and sensor issues solved, boost valve fitted and set up, SS exhaust and wheels robbed from a breaker and fitted with ZZ3s, set of coilovers and brakes, fluids and cambelt.

Chav valve and pisspoor filter removed and sold on:

Badly painted centre console and inoperative clock sorted:

De-chavving the interior:

Italia crest badges removed from bonnet, pie key anti-corrosion injection, flatted n polished the bodywork and she looked pretty good:

It's been reasonably reliable for a 17yr old Fiat Coupe and i've only needed towing in twice, once when the fuel pump fuse blew (and the bonnet release cable snapped) and once when a hole blew through the side of an in-tank fuel hose. The latter may have been down to age or the fact we were running it on 33% paint thinners, we'll never know.

Running a chip and decat it's probably around 240 - 250 bhp with the boost valve making it come on pretty hard, it just about holds traction in the wet in 2nd so ok for a road car (imo).

Jobs to do include replacing leaking waterpump and an oil change, apart from that all is good at the moment.

Mr Tidy said:

I just found this - fantastic job!

Just a thought but didn't the Fiat Croma and Lancia Thema use this engine as well?

If you could find one that really would be a sleeper.

Hope there will be an update when you get some time.

Thanks, yes the Lampredi Twin cam was shared between many models over the years; Croma, Thema, Dedra, Delta and Coupe all had the version with balancer shafts, some with 8v heads, some 16v. There were older designs and versions of the engine too, these were used in the 131, 124 and others. Some people are taking the newer 16v (integrale type) head and putting it on the 131 type block, apparently the main bolts holes line up, but it's not something i've done personally - just the heads for a few of them.Just a thought but didn't the Fiat Croma and Lancia Thema use this engine as well?

If you could find one that really would be a sleeper.

Hope there will be an update when you get some time.

The 8v head was overlooked by many (including me years ago) in pursuit of more power and efficiency which to be fair the 16v head does provide, but the old 8 design is capable of quite a lot given the correct treatment. This is one on standard cambelts:

And one with a wider belt kit I developed:

I've had a few on the flowbench now and made it work quite well. The most notable one went to Norway to a chap called Glenn who I worked with (remotely) on his 'Project Dedra', this is proper Sleeper material and he was a great guy to work with, very receptive to instruction and plenty of good ideas himself too being a mechanic and competing in Motorsport.

Between us we created the Worlds most powerful Dedra at 485bhp, I'm not sure, but this may be the most anyone has ever got from the 8v engine which was used in most of the cars mentioned earlier (not Coupe), including the integrale too of course.

You can read an overview on my blog here:

http://deltaparts1.blogspot.co.uk/2014/01/8v-power...

A result like that had us breaking out the really posh Jaffa cakes:

Along with some home made real cider....

I'd forgotten about this thread tbh and didn't realise how many interesting projects i'd been involved in lately, if anyones vaguely interested i'll write some more up later.

Ok i'll put some stuff together, we have a wide audience here on PH so probably a bit of everything

I don't think i've got much interesting Coupe stuff Hoops, a couple of pics of one of todays Coupe delights here though, chap was driving it around like this for a few weeks:

No pad, piston hanging out, no brake fluid. I put a litre of oil in the engine and it only just began to show on the dipstick.

I don't think i've got much interesting Coupe stuff Hoops, a couple of pics of one of todays Coupe delights here though, chap was driving it around like this for a few weeks:

No pad, piston hanging out, no brake fluid. I put a litre of oil in the engine and it only just began to show on the dipstick.

carinaman said:

Was that a rear pad it was missing? That would make it very slightly less dodgy.

'In mitigation M'lud it was a rear brake pad that was missing....

Yes just the rear, I believe it had the stopping distance of a Supertanker, but not sure - I didn't drive it, not even into the workshop!'In mitigation M'lud it was a rear brake pad that was missing....

Trust me, I could entertain you at length with tales of this guy alone, I think I only entertain him because he entertains me.

He is the kind that goes to a Steak House with his own piece of Rump in a bag and asks them to cook it for him.

Then complains at the service charge....

carinaman said:

Your customer makes me feel slightly less inept. I've only had one engine fail due to oil starvation. I think I learnt my lesson on that one.

I've always liked Coupes and this has done nothing to stop that.

The 16V Turbo had a 'viscodrive' differential? What are they like with age and mileage? Your tweaks just consume any stickiness left in the diffs?

The Norwegian mechanic with the Dedra is running a Quaife?

'NATS'

That just makes me think of Air Traffic Control at Swannick. Seems to fit an ink black Coupe running pump fuel with some additives.

I've always liked Coupes and this has done nothing to stop that.

The 16V Turbo had a 'viscodrive' differential? What are they like with age and mileage? Your tweaks just consume any stickiness left in the diffs?

The Norwegian mechanic with the Dedra is running a Quaife?

'NATS'

That just makes me think of Air Traffic Control at Swannick. Seems to fit an ink black Coupe running pump fuel with some additives.

The Viscodrive isn't up to much tbh, we call it Discodrive; when you're running enough power the front end just dances all over the place.

As you can see it's just a small drum shaped device on the O/S driveshaft, not a diff (it's got normal open diff in the 'box). Filled with a viscous silicone fluid and plates, it's sealed from the factory and they seem to last ok. They aren't very effective though, and the Q2 diff which is an improvement is just a bit better. It depends how far up the ladder you want to go with the car I guess, from road car to full on high powered race car, the former will overcome them both and need a proper diff fitting - Vincent D has one fitted to his 156 race car, I'll mention that later.

I don't know what Glen is using in his Dedra tbh, not something we discussed apart from him using a plate to strengthen the 'box, I was just asked to sort the engine out. I send a fair bit to Norway, this is Torbens 8v:

.......In the UK before he exported it out there, sadly it didn't last long before the um, 'highly modified' engine expired.

Anyhow in the meantime whilst i'm making right the bits on 'Nats' and idly playing on the 'net whilst getting my lunch I google the number plate, it comes up with a conversation about the car and a link to a photo album where I see this:

Which is from the same photo album as Torbens 'grale, yep, they were both once owned by the same person.

gianlu said:

evoluzione: would you be able to point me to the direction/source for a very cheap/free broken engine and gearbox? I have an Elise chassis sitting around, I'd like to try a fit. Do you know the weight of the engine by any chance (or if it is, generally, a light or heavy engine)?

I've tried VAG 1.8s and Honda lumps in the Elise, I'd like to try something different. I don;t think the 16v has any complicated variable valve system, so I guess many aftermarket ECU (emerald) can be made to work, or is there a preferred choice for these engines?

Thanks a lot

Given you are approx 200 miles away from me no!I've tried VAG 1.8s and Honda lumps in the Elise, I'd like to try something different. I don;t think the 16v has any complicated variable valve system, so I guess many aftermarket ECU (emerald) can be made to work, or is there a preferred choice for these engines?

Thanks a lot

I don't have a total weight, just some components, but they are heavy. The advantage is strength of course, but with a very sturdy cast iron block and similarly strong, but alloy head I would suspect it could be a bit of a boat anchor in an Elise.

From an ECU POV; catered for already and yes relatively simple to get running.

We have a very broad readership here on PH so I've tried to include a few different things of interest at various levels.

I enjoy writing when I'm in the mood and it took a few weeks of various attempts to get it to this, I hope it reads ok. It's a bit late as i'm completing this so i'll probably have to do a few edits!

This is an interesting project I have recently been involved with, it started off with a phone call: "Can you build me an engine which will do 600+ bhp and 9000rpm?"

Feck yeah, right up my Strasse...

A bit of small talk and away we went, made a pleasant change

It soon came to light that not only was he soon to be on his third engine, but he'd also had previous dealings with another specialist, a rather large amount of money had resulted in only an alleged* 410bhp which quite quickly ended up looking like this on it's first track outing:

The turbo used then and now is a GT35, capable of 600+bhp, when I looked at the way the engine had been specced and built I was shocked, but not surprised it wasn't making much power and proving frustrating to drive, it was atrocious.

The owner is a bit of a thrill seeker to say the least, the type who lobs himself out of a plane not intending to open his 'chute for a while, I think it's important to get to know the client a bit as you can tailor the package to their needs, indeed what we needed here was something that was like being hit round the head with a sledgehammer and be just as unbreakable.

So we started again, not much was salvageable from the last engine as you can imagine, the crankshaft, cam cover and intake manifold I think!

Beautiful (and expensive!) Arrows rods bent and with elongated little ends, so much was the distorting force there were scorch marks around them.

What I found really odd was hammer marks inside the bearing housing:

Who takes a hammer to over a grands worth of rods? I guess we'll never know the answer to that one.

New block and head:

We're going to need all the bore wall thickness we can get for this amount of boost/power.

New head and lightened valves:

The head is ported here and with new Trojan valve seats on the exhaust:

It's a much better material as It's hard wearing and transfers the extreme heat this will see, the new guides are made from this too.

A bit on porting

People still say 'Port n polish'. Shine and polish is the last thing you want on an inlet port, the rougher the better here - the actual finish from a carbide burr is ideal, but try convincing a customer that! It's difficult to get tidy, uniform and coarse, but it can be done. If you are doing your own ports just leave them rough, I do.

Shiny exhaust ports and polished combustion chambers maybe? Forget that too, ok, no downside as such, but just don't waste your time, it's 90% about shape. The minute you turn the key it's covered in soot and carbon, it builds up and no amount of polish will stop that, in fact it's a useful insulator.

Another common misconception about porting is that it's just about making them bigger; 'opening up the ports a bit' they will say. Again, it's about shape as well as size and knowing where to make the port bigger (if at all).

A flowbench can be made to do so much more than many realise. Its basic job is to measure CFM (cubic feet per minute) which is how much air is flowing through the port, with a probe attached to one like ours you can also measure velocity in different places which is of course the speed of the inlet charge. If you enlarge the port too much the speed will drop, go too small and it will choke, it's a careful balancing act made even more complicated by the fact that airspeed changes throughout the port! It favours some areas more than others, you can actually fill in 'dead spots' which are too large and widen the busy areas to help things along. By changing the contours in certain places we can manipulate it to get closer to what we need. Manipulate and help yes, you certainly can't force it to go where it doesn't want to go.

Here is some smoke testing I did on an 8v head. I know where the air is going and where it wants to go, but did this to prove it and so everyone else can actually see it. This is the kind of test you need a big draughty workshop for and also do it last thing before you go home!

You can see how the majority of flow hugs the side of the port, the manifold complements this feature and actually sets it up for the turn. Why is this? Well in a two valve per cylinder head you need 'swirl' as this makes for good mixture motion, it's what makes it burn very effectively and comprehensively as it's winding itself down the bore.

Here you can see more proof of what is actually happening, you can see how the smoke has left a deposit on the parts where it is most concentrated. In contrast to that 4 valve heads cause the mixture to tumble as it goes into the cylinder, mixture motion in the chamber is important and these are the two basic ones.

Here I am making another flowbench tool:

Basically it's a valve made from aluminium, but it's rifle drilled down the length with another drilling from the seat across to connect up the hole. The idea here is that I fit it to the head when it's on the flowbench, set it to mid, full lift or whatever and put a pipe on the top of it, this goes to the digital box which converts the vacuum caused by the passing air into figures on the screen. What this means is that I can turn the valve around to various points (360' or like a clock face) and take a reading at say every 30' or so. This allows me to plot on a diagram where the airflow is very precisely and work from there.

^^ Here is a valve opening tool, it's basically a blank cam which I bolt in place and use the M10 x 1 bolts to open the valves. Why 1mm pitch? Well one turn = 1mm of valve lift so it's easy to use and record the results.

When you disassemble an OE built engine study carefully what you see, aside from carbon build up was it blathered in sealant? Unlikely! Apart from some areas like those which may carry water, be a bit corroded and certain gaskets you don't need it either, leave it to the bodgers. If you must use it then do so very sparingly, you don't want it falling off into the engine.

Lightened valve train components here:

Standard valve springs, heavy components, high lift cams and high RPM? Good chance of engine failure

Coilbound at 12mm of lift, round about where we want to be on the inlet cam.

Steel 8 weight crank is unlikely to be bent, but clock it up anyhow, you never know what your dealing with:

End float:

You do not leave anything to chance regardless if it's stock or at any other output, it's laborious, but has to be done, take absolutely nothing for granted, the buck stops here! The bearing or piston manufacturer won't be bailing you out if it goes tits up, even if it's their fault. I think this is where many a lot of amatuer builds fail, there is just no point in investing in hundreds or thousands of pounds worth of measuring equipment for one or two builds so risks get taken.

Oilways are modded here and M12 ARP studs holding the crank caps down:

I don't know who made that thing, it was a bit numb, but does the job though I guess.

Comparison in piston weights, the outgoing and incoming forged:

Comparison of OE rod, piston and the new ones, look carefully and you can see the longer rod and the piston pin pushed right up to the ringlands. Longer rod = more dwell at TDC and more power? No, just allows a shorter piston and creates less vibration.

Block bored out for ARP M12 studs:

Rods balanced:

Timing up the cams with new wider belt fitted:

All cams are designed in house, I haven't used off-the-shelf profiles for years, when you have a flowbench you know what the port is flowing and at what lifts so can spec your cams to suit.

Just about there now!

I was quite happy with the exhaust manifold that came with this car, good size and well formed. It made my life hard at the front though cramming a big rad and intercooler in there without altering the look of the car. I say this because a lot of people can't do it and you see cars without front grilles, bumpers cut to bits, turbos and intercoolers hanging out the front etc.

Not so much the intercooler, that was never going to do the job. There is a fuller explanation on my blog, but to be brief an intercooler has to meet two basic criteria - the first is obvious, the second one gets forgotten and that is it has to flow enough air for the engine to breathe. You have to consider the Cross Sectional Area of the intercooler - and the correct way too, that is across the way the air flows through it.

A standard integrale intercooler measures 3 x 8 and (roughly) half of that is open tubes so 3 x 8 x .5 = 12sq in, this is your CSA.

The cooler we took off was 2 x 8 (x .5) so 8sq in. Yes, amazingly people are paying big money for intercoolers which flow less air than the original.

Good Lord.

When the engine was finished the guy then asked me to fit it and take it for mapping, I took this on as I didn't like to say no and part of me wanted to see the job through. I was reticent though as this part is always difficult as you are out of the comfort zone, no longer in complete control, you are working with other people, their parts and it often doesn't gel very well.

^^ Chinese copy FPR against a genuine one, it failed part way through so mapping session was aborted.

Someone else had wired the ECU, piped the fuel pumps, provided a Chinese FPR, piped the ext wastegate, hammered and broken a few bits and pieces here and there, old crispy wiring, but we worked through it bit by bit and eventually saw 610bhp and 540ft/lbs of torque which I think makes it the most powerful in the UK.

Bit of crappy footage here:

You might wonder why the power curve flatlines at its peak, this is due to it hitting the limit of the map sensor, if it had one installed which read higher we could have seen around another 50bhp. As you can see it spooled pretty early and came on hard and fast, with 4wd it's what you want - with some fiddling with electronic boost control it could be tamed a bit for wet use, but I was asked to build it for drag racing.

It hits so hard and early that the guys at the dyno would not believe me nor the guy whos car it was that it was a GT35, they thought it was a GT30 and had to get under the car to have a look to confirm.

Integrales are by nature, almost bulging at the seams, this one certainly is and then some.

I can only sum the acceleration up in one word; brutal. It's certainly entertaining! In a short space of time your neck muscles are starting to ache from holding your head upright, exactly how long the rest of the car will cope with this under the bonnet I don't know, I do know it won't be long though!

On another note, Project Sausage has been dragged out of its slumber and is being dusted down for some track fun this year, I've never done Blyton before so looking forward to it.

I enjoy writing when I'm in the mood and it took a few weeks of various attempts to get it to this, I hope it reads ok. It's a bit late as i'm completing this so i'll probably have to do a few edits!

This is an interesting project I have recently been involved with, it started off with a phone call: "Can you build me an engine which will do 600+ bhp and 9000rpm?"

Feck yeah, right up my Strasse...

A bit of small talk and away we went, made a pleasant change

It soon came to light that not only was he soon to be on his third engine, but he'd also had previous dealings with another specialist, a rather large amount of money had resulted in only an alleged* 410bhp which quite quickly ended up looking like this on it's first track outing:

The turbo used then and now is a GT35, capable of 600+bhp, when I looked at the way the engine had been specced and built I was shocked, but not surprised it wasn't making much power and proving frustrating to drive, it was atrocious.

- I said alleged above, this is because when we looked at the map there wasn't enough fuel in for that amount of power.

The owner is a bit of a thrill seeker to say the least, the type who lobs himself out of a plane not intending to open his 'chute for a while, I think it's important to get to know the client a bit as you can tailor the package to their needs, indeed what we needed here was something that was like being hit round the head with a sledgehammer and be just as unbreakable.

So we started again, not much was salvageable from the last engine as you can imagine, the crankshaft, cam cover and intake manifold I think!

Beautiful (and expensive!) Arrows rods bent and with elongated little ends, so much was the distorting force there were scorch marks around them.

What I found really odd was hammer marks inside the bearing housing:

Who takes a hammer to over a grands worth of rods? I guess we'll never know the answer to that one.

New block and head:

We're going to need all the bore wall thickness we can get for this amount of boost/power.

New head and lightened valves:

The head is ported here and with new Trojan valve seats on the exhaust:

It's a much better material as It's hard wearing and transfers the extreme heat this will see, the new guides are made from this too.

A bit on porting

People still say 'Port n polish'. Shine and polish is the last thing you want on an inlet port, the rougher the better here - the actual finish from a carbide burr is ideal, but try convincing a customer that! It's difficult to get tidy, uniform and coarse, but it can be done. If you are doing your own ports just leave them rough, I do.

Shiny exhaust ports and polished combustion chambers maybe? Forget that too, ok, no downside as such, but just don't waste your time, it's 90% about shape. The minute you turn the key it's covered in soot and carbon, it builds up and no amount of polish will stop that, in fact it's a useful insulator.

Another common misconception about porting is that it's just about making them bigger; 'opening up the ports a bit' they will say. Again, it's about shape as well as size and knowing where to make the port bigger (if at all).

A flowbench can be made to do so much more than many realise. Its basic job is to measure CFM (cubic feet per minute) which is how much air is flowing through the port, with a probe attached to one like ours you can also measure velocity in different places which is of course the speed of the inlet charge. If you enlarge the port too much the speed will drop, go too small and it will choke, it's a careful balancing act made even more complicated by the fact that airspeed changes throughout the port! It favours some areas more than others, you can actually fill in 'dead spots' which are too large and widen the busy areas to help things along. By changing the contours in certain places we can manipulate it to get closer to what we need. Manipulate and help yes, you certainly can't force it to go where it doesn't want to go.

Here is some smoke testing I did on an 8v head. I know where the air is going and where it wants to go, but did this to prove it and so everyone else can actually see it. This is the kind of test you need a big draughty workshop for and also do it last thing before you go home!

You can see how the majority of flow hugs the side of the port, the manifold complements this feature and actually sets it up for the turn. Why is this? Well in a two valve per cylinder head you need 'swirl' as this makes for good mixture motion, it's what makes it burn very effectively and comprehensively as it's winding itself down the bore.

Here you can see more proof of what is actually happening, you can see how the smoke has left a deposit on the parts where it is most concentrated. In contrast to that 4 valve heads cause the mixture to tumble as it goes into the cylinder, mixture motion in the chamber is important and these are the two basic ones.

Here I am making another flowbench tool:

Basically it's a valve made from aluminium, but it's rifle drilled down the length with another drilling from the seat across to connect up the hole. The idea here is that I fit it to the head when it's on the flowbench, set it to mid, full lift or whatever and put a pipe on the top of it, this goes to the digital box which converts the vacuum caused by the passing air into figures on the screen. What this means is that I can turn the valve around to various points (360' or like a clock face) and take a reading at say every 30' or so. This allows me to plot on a diagram where the airflow is very precisely and work from there.

^^ Here is a valve opening tool, it's basically a blank cam which I bolt in place and use the M10 x 1 bolts to open the valves. Why 1mm pitch? Well one turn = 1mm of valve lift so it's easy to use and record the results.

When you disassemble an OE built engine study carefully what you see, aside from carbon build up was it blathered in sealant? Unlikely! Apart from some areas like those which may carry water, be a bit corroded and certain gaskets you don't need it either, leave it to the bodgers. If you must use it then do so very sparingly, you don't want it falling off into the engine.

Lightened valve train components here:

Standard valve springs, heavy components, high lift cams and high RPM? Good chance of engine failure

Coilbound at 12mm of lift, round about where we want to be on the inlet cam.

Steel 8 weight crank is unlikely to be bent, but clock it up anyhow, you never know what your dealing with:

End float:

You do not leave anything to chance regardless if it's stock or at any other output, it's laborious, but has to be done, take absolutely nothing for granted, the buck stops here! The bearing or piston manufacturer won't be bailing you out if it goes tits up, even if it's their fault. I think this is where many a lot of amatuer builds fail, there is just no point in investing in hundreds or thousands of pounds worth of measuring equipment for one or two builds so risks get taken.

Oilways are modded here and M12 ARP studs holding the crank caps down:

I don't know who made that thing, it was a bit numb, but does the job though I guess.

Comparison in piston weights, the outgoing and incoming forged:

Comparison of OE rod, piston and the new ones, look carefully and you can see the longer rod and the piston pin pushed right up to the ringlands. Longer rod = more dwell at TDC and more power? No, just allows a shorter piston and creates less vibration.

Block bored out for ARP M12 studs:

Rods balanced:

Timing up the cams with new wider belt fitted:

All cams are designed in house, I haven't used off-the-shelf profiles for years, when you have a flowbench you know what the port is flowing and at what lifts so can spec your cams to suit.

Just about there now!

I was quite happy with the exhaust manifold that came with this car, good size and well formed. It made my life hard at the front though cramming a big rad and intercooler in there without altering the look of the car. I say this because a lot of people can't do it and you see cars without front grilles, bumpers cut to bits, turbos and intercoolers hanging out the front etc.

Not so much the intercooler, that was never going to do the job. There is a fuller explanation on my blog, but to be brief an intercooler has to meet two basic criteria - the first is obvious, the second one gets forgotten and that is it has to flow enough air for the engine to breathe. You have to consider the Cross Sectional Area of the intercooler - and the correct way too, that is across the way the air flows through it.

A standard integrale intercooler measures 3 x 8 and (roughly) half of that is open tubes so 3 x 8 x .5 = 12sq in, this is your CSA.

The cooler we took off was 2 x 8 (x .5) so 8sq in. Yes, amazingly people are paying big money for intercoolers which flow less air than the original.

Good Lord.

When the engine was finished the guy then asked me to fit it and take it for mapping, I took this on as I didn't like to say no and part of me wanted to see the job through. I was reticent though as this part is always difficult as you are out of the comfort zone, no longer in complete control, you are working with other people, their parts and it often doesn't gel very well.

^^ Chinese copy FPR against a genuine one, it failed part way through so mapping session was aborted.

Someone else had wired the ECU, piped the fuel pumps, provided a Chinese FPR, piped the ext wastegate, hammered and broken a few bits and pieces here and there, old crispy wiring, but we worked through it bit by bit and eventually saw 610bhp and 540ft/lbs of torque which I think makes it the most powerful in the UK.

Bit of crappy footage here:

You might wonder why the power curve flatlines at its peak, this is due to it hitting the limit of the map sensor, if it had one installed which read higher we could have seen around another 50bhp. As you can see it spooled pretty early and came on hard and fast, with 4wd it's what you want - with some fiddling with electronic boost control it could be tamed a bit for wet use, but I was asked to build it for drag racing.

It hits so hard and early that the guys at the dyno would not believe me nor the guy whos car it was that it was a GT35, they thought it was a GT30 and had to get under the car to have a look to confirm.

Integrales are by nature, almost bulging at the seams, this one certainly is and then some.

I can only sum the acceleration up in one word; brutal. It's certainly entertaining! In a short space of time your neck muscles are starting to ache from holding your head upright, exactly how long the rest of the car will cope with this under the bonnet I don't know, I do know it won't be long though!

On another note, Project Sausage has been dragged out of its slumber and is being dusted down for some track fun this year, I've never done Blyton before so looking forward to it.

Edited by Evoluzione on Friday 3rd April 09:56

Thanks for your comments

Anyhow, meanwhile Nats was eating the inner edges of her rear tyres:

And that is after the tyres were turned over at an earlier date as I was just too busy to do any more.

When this happens it's usually only one thing; the bearings in the rear swinging arms are worn out. They pivot on a pair of tapered bearings, when they wear out not only do you get too much camber:

But also they toe out too so wear out the tyres pretty quickly! Because they are tapered bearings under tension they don't show any movement when you stick the bar in and will still happily pass an MOT.

The parts are cheap, but It's a b1tch of a job, I was lucky here that I think they'd been done before as the through bolts were covered in grease so they came out. When they haven't and they get stuck in you're in for a much bigger job.

Camber afterwards:

It's the reading on the right of the gauge.

As we were prepping Project Sausage for this years onslaught of trackdays I decided to get it mapped again on one of our new ECUS. Last time we did it on Motec we had to stop at 478 bhp due to what we thought was electrical interference so I just left it there. This wasn't before I found this:

If you look carefully you can see the shiny part where the belt was hitting the crank sensor, yep that was what was making the signal go crazy.

I also changed the cam timing slightly and it was back at RS today for mapping, with Chubby Chops at the wheel (and his laptop) the result was more torque, earlier spool and more bhp so it's now pushing out 510bhp, 400ft/lbs and spooling up about 1000rpm earlier

Whilst they are often lazy beggars intent on doing as little as possible, I have to say I do have enormous admiration if not a little envy for a good mapper, the way they flit through the tables and screens making these things run is a fascinating sight - very skilled. I wish I could do my own, but whilst the obvious lack of rolling road is a problem it's very much a case of 'Man's gotta know his limitations' and no, I wouldn't feel very lucky (punk) so stick to what I know.

The turbo, injectors, fuel pump and other components are all pretty much near their maximum, so whilst well matched that's about as far as I can take this motor now.

Anyhow, meanwhile Nats was eating the inner edges of her rear tyres:

And that is after the tyres were turned over at an earlier date as I was just too busy to do any more.

When this happens it's usually only one thing; the bearings in the rear swinging arms are worn out. They pivot on a pair of tapered bearings, when they wear out not only do you get too much camber:

But also they toe out too so wear out the tyres pretty quickly! Because they are tapered bearings under tension they don't show any movement when you stick the bar in and will still happily pass an MOT.

The parts are cheap, but It's a b1tch of a job, I was lucky here that I think they'd been done before as the through bolts were covered in grease so they came out. When they haven't and they get stuck in you're in for a much bigger job.

Camber afterwards:

It's the reading on the right of the gauge.

As we were prepping Project Sausage for this years onslaught of trackdays I decided to get it mapped again on one of our new ECUS. Last time we did it on Motec we had to stop at 478 bhp due to what we thought was electrical interference so I just left it there. This wasn't before I found this:

If you look carefully you can see the shiny part where the belt was hitting the crank sensor, yep that was what was making the signal go crazy.

I also changed the cam timing slightly and it was back at RS today for mapping, with Chubby Chops at the wheel (and his laptop) the result was more torque, earlier spool and more bhp so it's now pushing out 510bhp, 400ft/lbs and spooling up about 1000rpm earlier

Whilst they are often lazy beggars intent on doing as little as possible, I have to say I do have enormous admiration if not a little envy for a good mapper, the way they flit through the tables and screens making these things run is a fascinating sight - very skilled. I wish I could do my own, but whilst the obvious lack of rolling road is a problem it's very much a case of 'Man's gotta know his limitations' and no, I wouldn't feel very lucky (punk) so stick to what I know.

The turbo, injectors, fuel pump and other components are all pretty much near their maximum, so whilst well matched that's about as far as I can take this motor now.

Edited by Evoluzione on Thursday 9th April 07:16

Thanks again for all the replies.

I didn't really go into much detail over inlet port finish as it is a subject all on its own and there are two reasons for a rough port wall.

Again with older style engines we are dealing with two types of 'fluid'; air and petrol, this means a port is a compromise and why DI is king as we can take one out of the equation and just deal with air going through a port, this makes it much simpler and effective.

Modern engines need highly atomised fuel to be efficient, when fuel is travelling down a port it gets splashed all over the place and down the port walls (floor and roof!), we need to reintroduce it into the airflow so here is an easy to understand principle:

Spray some water onto a piece of glass, blow it with air, see it bead and run off in large drops.

Spray water onto sandpaper, blow it with air and it will leave in a much finer form.

And it's as simple as that

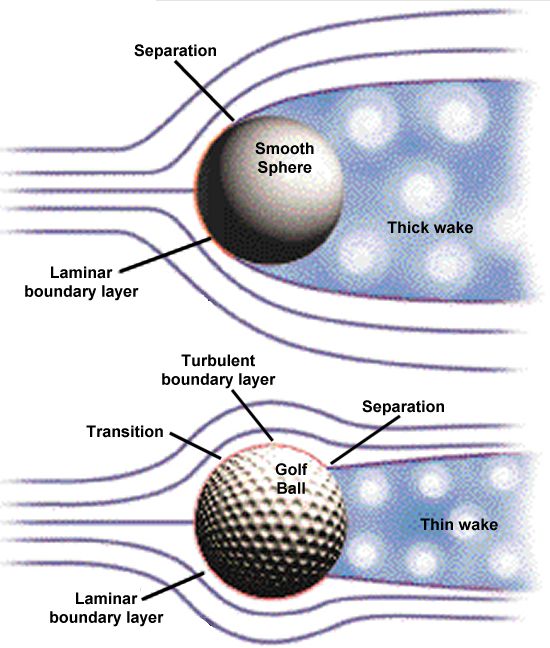

The other phenomenon is something called 'The Boundary layer'.

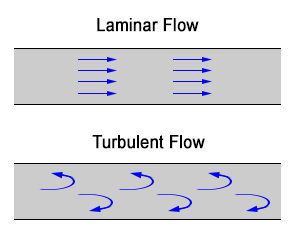

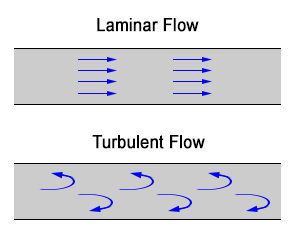

This is a layer of air which exists on the outside of the main body of air, against the wall of whatever it is travelling past - in this case the port walls. When the surface is rough this boundary layer is known as 'turbulent' as it tumbles over itself (as opposed to laminar which is layered, uniform and smooth).

The main body of air uses this tumbling outer layer to keep itself attached to the port and in turn moves faster: Two easy to understand examples:

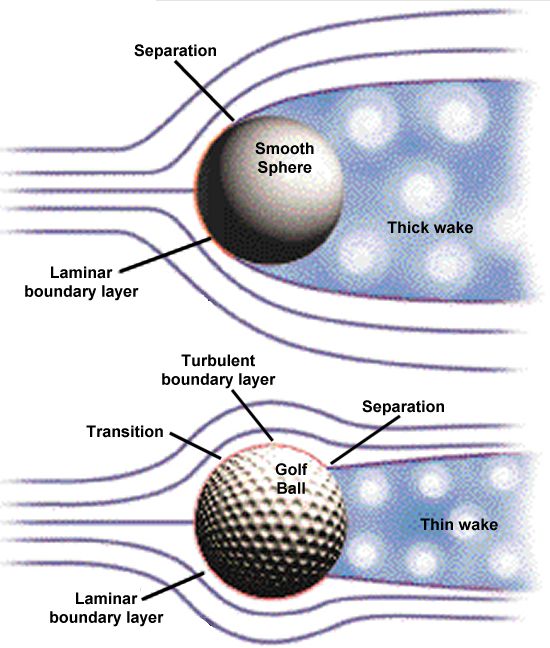

Two golf balls, one smooth, one with dimples, which one flies the farthest? The one with dimples and by quite some margin.

Kids sliding on a varnished wooden floor, introduce some marbles and see how much further they go!

Diagrams of the golf ball analogy:

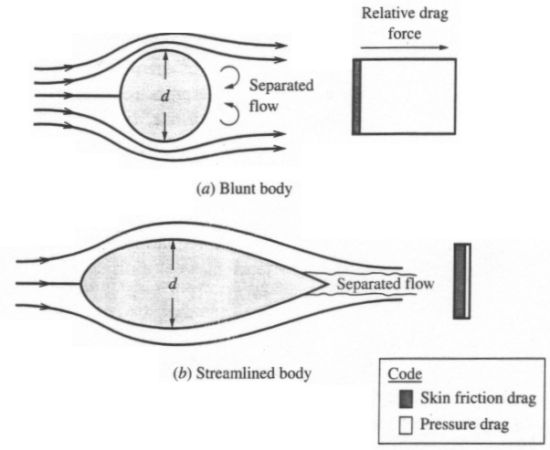

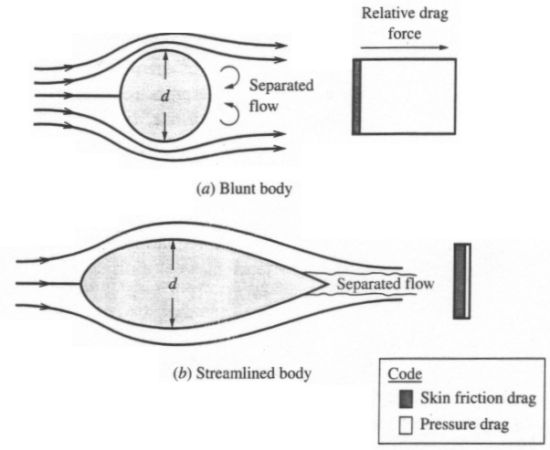

Now as we can see there, it's about leaving a smaller wake and 're-attaching the flow', this leads us to this little pic here:

And then here below you can see how the engine designers have incorporated that piece of aerodynamic design into the ports so the flow reattaches itself after it's been around the valve guide:

It's nothing new, people have been using this for years, but once you start to study airflow (often with the aid of a flowbench) you start to notice this kind of stuff here and there and it clicks into place why it is there. Everyday out on the road you will see 'flow straighteners' or 'turning vanes', but not even realise it, when you do you think f k me, I never knew what those were for and i've been looking at them for 20 - 30 yrs!

k me, I never knew what those were for and i've been looking at them for 20 - 30 yrs!

You can apply some of this theory to inlet ports, it's only worth a few bhp for each successful feature, but when added up they can make a significant improvement, especially in a highly competitive race car.

Mark Benson said:

Loving the writing, lots of nuggets of information that bust some of the common internet myths (ie. port & polish, obvious when you think about it).

As a result (and after reading a fair bit of Dave Walkers musings), I'm a lot less scared of using electronics under the bonnet than I used to be.

I've always liked reading Dave Walkers words, he always seemed very honest and willing to go that extra mile for customers, where does he write these days? I know it used to be CCC and then PPC.Evoluzione said:

Whilst they are often lazy beggars intent on doing as little as possible, I have to say I do have enormous admiration if not a little envy for a good mapper, the way they flit through the tables and screens making these things run is a fascinating sight - very skilled.]

It is, isn't it. We had our Ginetta engine swap mapped by RS a couple of years ago and they got a lovely driveable car out of it while being honest (so many are not) about the power available with the kit we're running.As a result (and after reading a fair bit of Dave Walkers musings), I'm a lot less scared of using electronics under the bonnet than I used to be.

I didn't really go into much detail over inlet port finish as it is a subject all on its own and there are two reasons for a rough port wall.

Again with older style engines we are dealing with two types of 'fluid'; air and petrol, this means a port is a compromise and why DI is king as we can take one out of the equation and just deal with air going through a port, this makes it much simpler and effective.

Modern engines need highly atomised fuel to be efficient, when fuel is travelling down a port it gets splashed all over the place and down the port walls (floor and roof!), we need to reintroduce it into the airflow so here is an easy to understand principle:

Spray some water onto a piece of glass, blow it with air, see it bead and run off in large drops.

Spray water onto sandpaper, blow it with air and it will leave in a much finer form.

And it's as simple as that

The other phenomenon is something called 'The Boundary layer'.

This is a layer of air which exists on the outside of the main body of air, against the wall of whatever it is travelling past - in this case the port walls. When the surface is rough this boundary layer is known as 'turbulent' as it tumbles over itself (as opposed to laminar which is layered, uniform and smooth).

The main body of air uses this tumbling outer layer to keep itself attached to the port and in turn moves faster: Two easy to understand examples:

Two golf balls, one smooth, one with dimples, which one flies the farthest? The one with dimples and by quite some margin.

Kids sliding on a varnished wooden floor, introduce some marbles and see how much further they go!

Diagrams of the golf ball analogy:

Now as we can see there, it's about leaving a smaller wake and 're-attaching the flow', this leads us to this little pic here:

And then here below you can see how the engine designers have incorporated that piece of aerodynamic design into the ports so the flow reattaches itself after it's been around the valve guide:

It's nothing new, people have been using this for years, but once you start to study airflow (often with the aid of a flowbench) you start to notice this kind of stuff here and there and it clicks into place why it is there. Everyday out on the road you will see 'flow straighteners' or 'turning vanes', but not even realise it, when you do you think f

k me, I never knew what those were for and i've been looking at them for 20 - 30 yrs!

k me, I never knew what those were for and i've been looking at them for 20 - 30 yrs!You can apply some of this theory to inlet ports, it's only worth a few bhp for each successful feature, but when added up they can make a significant improvement, especially in a highly competitive race car.

MegaMinion said:

I f king love fluids!

king love fluids!

Awesome write by the way, despite the fact that I've spent all day at uni sat doing CFD and getting home and wanting to do anything but fluid related things I thoroughly enjoyed reading that.

Haha, yes it's an interesting subject when you start looking into it, you'll know much more than me though! king love fluids!

king love fluids! Awesome write by the way, despite the fact that I've spent all day at uni sat doing CFD and getting home and wanting to do anything but fluid related things I thoroughly enjoyed reading that.

Just a bit of an update on Project Sausage.

At a Spring trackday it seemed to me we were getting a bit of 'surprise over steer', it could have been just me, but it seemed to throw me off once when I didn't think i'd lifted, I reckoned the rear end needed an overhaul.

So over the Summer I removed the rear subframe as the rear swinging arm bearings were shot, not only that, but the through bolts were seized in place so I couldn't even get them off with it in place. Whilst it was off I took the opportunity to fit a thicker rear ARB and Poly subframe mounts in place of the old rubber ones.

De rusting and painting would have been good, but I just CBA and it wouldn't have made it go faster. They are made from seriously thick steel and cast iron too.

The clutch was replaced as a matter of course as it had been on a few years and seen a lot of abuse. The actual cerametallic pads on the friction plate were barely worn, but the cover plate friction face was. I just wanted to avoid going to do a TD and the thing failing on me. While the box was off I stripped and rebuilt that too - again, just incase. Everything looked fine which was a relief as they are known for letting go if abused.

Again another 'Well whilst you're at it you might aswell' job with the front subframe. I removed it and fitted a very slightly thicker front ARB (the rear was a much thicker increase). This isn't mine, just a random internet pic:

job with the front subframe. I removed it and fitted a very slightly thicker front ARB (the rear was a much thicker increase). This isn't mine, just a random internet pic:

So you can see the layout. If you look closely you can see the spot welds, it's said that it can flex so I put some seam welds here and there too.

The whole lot was put back together again and off we went to Blyton Park, it's too small and twisty for a big heavy long legged car like the Coupe, but I had a learner with me so not much choice - there isn't much to hit at Blyton. A few pics of the day:

As you can see she corners pretty flat now with what I would say is just enough roll, I managed not to spin anyhow and she felt pretty solid all day.

I've now amassed far too many projects though so am sadly thinking of letting the Coupes go this Autumn, i've got a full 4wd system for one kicking around too, but I just don't have the time to spend with them although I'll miss them if they do go.

At a Spring trackday it seemed to me we were getting a bit of 'surprise over steer', it could have been just me, but it seemed to throw me off once when I didn't think i'd lifted, I reckoned the rear end needed an overhaul.

So over the Summer I removed the rear subframe as the rear swinging arm bearings were shot, not only that, but the through bolts were seized in place so I couldn't even get them off with it in place. Whilst it was off I took the opportunity to fit a thicker rear ARB and Poly subframe mounts in place of the old rubber ones.

De rusting and painting would have been good, but I just CBA and it wouldn't have made it go faster. They are made from seriously thick steel and cast iron too.

The clutch was replaced as a matter of course as it had been on a few years and seen a lot of abuse. The actual cerametallic pads on the friction plate were barely worn, but the cover plate friction face was. I just wanted to avoid going to do a TD and the thing failing on me. While the box was off I stripped and rebuilt that too - again, just incase. Everything looked fine which was a relief as they are known for letting go if abused.

Again another 'Well whilst you're at it you might aswell'

job with the front subframe. I removed it and fitted a very slightly thicker front ARB (the rear was a much thicker increase). This isn't mine, just a random internet pic:

job with the front subframe. I removed it and fitted a very slightly thicker front ARB (the rear was a much thicker increase). This isn't mine, just a random internet pic:

So you can see the layout. If you look closely you can see the spot welds, it's said that it can flex so I put some seam welds here and there too.

The whole lot was put back together again and off we went to Blyton Park, it's too small and twisty for a big heavy long legged car like the Coupe, but I had a learner with me so not much choice - there isn't much to hit at Blyton. A few pics of the day:

As you can see she corners pretty flat now with what I would say is just enough roll, I managed not to spin anyhow and she felt pretty solid all day.

I've now amassed far too many projects though so am sadly thinking of letting the Coupes go this Autumn, i've got a full 4wd system for one kicking around too, but I just don't have the time to spend with them although I'll miss them if they do go.

mattydoh said:

Small world, I have read and admired the work in this thread in the past and just happened to be flitting through again when I realised I now recognised the Sausage - I was in the blue & silver Ginetta on Saturday at Blyton (I'm the owner but not the crasher!). Good to speak to you and hopefully see you out again soon - hope the rest of the day went smoothly!

Have you sourced a rad yet? Should be an easy fix anyhow, just a shame it cut your day a bit short. Isn't Oulton a bit closer for you?

I was a bit miffed when I booked with Trackdays, but my order went to Mazdaontrack who refused to tell me who was going although I could guess. As you know we were on an MX5 trackday - they annoyed me on the bends, I annoyed them on the bends and the straights....

Then they changed the track in the afternoon to make it even tighter and twistier which was worse for us. I'll be more careful when booking next time and as per above some different tracks beckon.

Steve_W said:

What an awesome thread - just sat and read the lot. You've got a nice way of writing - technical stuff and humour all thrown in together.

Coincidentally I was looking through the Retro Rides readers' cars threads and there's a lad in Bulgaria with a car I never heard of before - Dedra Integrale Estate!

He's used bits of a Fiat Coupe to turbo it - with varying degrees of success over the development of the car but he's doing a lot from home so fair play.

I thought you might be interested in his thread anyway, what with your thoughts of a 4x4 setup: http://retrorides.proboards.com/thread/165106/lanc...

Thanks for the link, I had a read whilst I was having my lunch, horrible though it is, it must be one of the rarest cars around. He's got the right idea with a lot of things and made it work quite well on his tight budget, kind of makes you wonder how much damage he could have done with more money!Coincidentally I was looking through the Retro Rides readers' cars threads and there's a lad in Bulgaria with a car I never heard of before - Dedra Integrale Estate!

He's used bits of a Fiat Coupe to turbo it - with varying degrees of success over the development of the car but he's doing a lot from home so fair play.

I thought you might be interested in his thread anyway, what with your thoughts of a 4x4 setup: http://retrorides.proboards.com/thread/165106/lanc...

=To finish first, first you have to finish.=

Old Lampredis never die, they just get more powerful and move home.

If you were ever interested in buying a Coupe and for cheap money then act quick because those times are almost over, good ones are getting rarer and prices are on the up, gone is the day of the 16vt for £500 on Ebay as there aren't many left.

Many 16vts have been scrapped, but the engines often live on and what a life they are now leading in different cars:

It's all about exploiting the rules; in the Alfa Romeo Championship modified class you are allowed to use any engine which was ever used in an Alfa. The Lampredi 16v unit was used in the 155Q4 so the guys are allowed to put it in their Alfas which is when my phone rings. Whilst the 16v lump is relatively basic it's strong when built properly and has one of the best designed cylinder heads of its era so the racers love it. When Alfa announced the new 156 and 147 they claimed to have designed a completely new car, this was not so, the bodyshell has some surprising similarities and the engines fit right in there with little modification.

The silver 156 you see up there has been built from scratch by its owner Vincent, it's running about 450bhp with everything else uprated to match and generally runs near the front even though it's still under development, due to a certain GTV with a supercharged 3.8 V6 driven by a pro driver and an ex BTCC car first place has eluded him so far. He'll be back next year with more go faster bits to have another go.

The 147 is actually also an ex BTCC car which is a lovely thing to look at, only currently running about 270bhp, but very light and with a young, but capable James Nicholls at the wheel it's showing huge promise and again, if it gets some suitable mods over Winter will be one to watch next year. Both these cars took a second place each in Sunday's races at Donington.

Over in Sweden (and again at an attempt to exploit the rules to the max) is Michas 164, this has the earlier Lampredi 8v engine fitted from this:

Which goes to live in this:

As they did originally do a 164 turbo road car.

If you run a 2 valve per cylinder engine you can run less weight than a multivalve engined car, again he's been so close to a championship win for a while so i'm hoping to give it that little bit extra for next year this is as far as it's got so far:

From filthy to clean to rust free and painted in three stages, rebore and deck next.

Over in Japan they have a complete race series dedicated to the integrale, the orange Evo cutting through the field to win this years championship has a 2.2 fitted with the stroker crank and many other parts coming from here in the UK too.

I dunno what's going on here tbh, looks like some kind of Sprint circuit maybe and yes that's an S4 Stradale in the background

Japan has shed a lot of integrales over the years, it must run into hundreds, I don't think anyone knew they had so many of them and I guess a bit sad for their enthusiasts, but in places like New Zealand, Australia, Canada and America people have been able to get their dream car.

Old Lampredis never die, they just get more powerful and move home.

If you were ever interested in buying a Coupe and for cheap money then act quick because those times are almost over, good ones are getting rarer and prices are on the up, gone is the day of the 16vt for £500 on Ebay as there aren't many left.

Many 16vts have been scrapped, but the engines often live on and what a life they are now leading in different cars:

It's all about exploiting the rules; in the Alfa Romeo Championship modified class you are allowed to use any engine which was ever used in an Alfa. The Lampredi 16v unit was used in the 155Q4 so the guys are allowed to put it in their Alfas which is when my phone rings. Whilst the 16v lump is relatively basic it's strong when built properly and has one of the best designed cylinder heads of its era so the racers love it. When Alfa announced the new 156 and 147 they claimed to have designed a completely new car, this was not so, the bodyshell has some surprising similarities and the engines fit right in there with little modification.

The silver 156 you see up there has been built from scratch by its owner Vincent, it's running about 450bhp with everything else uprated to match and generally runs near the front even though it's still under development, due to a certain GTV with a supercharged 3.8 V6 driven by a pro driver and an ex BTCC car first place has eluded him so far. He'll be back next year with more go faster bits to have another go.

The 147 is actually also an ex BTCC car which is a lovely thing to look at, only currently running about 270bhp, but very light and with a young, but capable James Nicholls at the wheel it's showing huge promise and again, if it gets some suitable mods over Winter will be one to watch next year. Both these cars took a second place each in Sunday's races at Donington.

Over in Sweden (and again at an attempt to exploit the rules to the max) is Michas 164, this has the earlier Lampredi 8v engine fitted from this:

Which goes to live in this:

As they did originally do a 164 turbo road car.

If you run a 2 valve per cylinder engine you can run less weight than a multivalve engined car, again he's been so close to a championship win for a while so i'm hoping to give it that little bit extra for next year this is as far as it's got so far:

From filthy to clean to rust free and painted in three stages, rebore and deck next.

Over in Japan they have a complete race series dedicated to the integrale, the orange Evo cutting through the field to win this years championship has a 2.2 fitted with the stroker crank and many other parts coming from here in the UK too.

I dunno what's going on here tbh, looks like some kind of Sprint circuit maybe and yes that's an S4 Stradale in the background

Japan has shed a lot of integrales over the years, it must run into hundreds, I don't think anyone knew they had so many of them and I guess a bit sad for their enthusiasts, but in places like New Zealand, Australia, Canada and America people have been able to get their dream car.

Edited by Evoluzione on Saturday 5th December 18:58

A few pics from this Summers occasional day trips to North Yorks:

AutoGrass near York:

Tan Hill is the highest pub in the UK, it's normal to be snowed in completely for periods of time in Winter, a snowmobile and the front attachment from a snow plough are permanently parked outside.

And it was farewell to NATS today, the new owner took her down to a new home in Birmingham.

The tilt n slide sunroof in PJ was always too low in the car, when I had my helmet on I had to drive with my head on one side. A few nuts and a bit of trim removed and off it came:

A template made from MDF:

New panel cut and formed around the template bit by bit:

In the background there you can see my old slapper lurking I made it at college years ago from a cart spring with some tube welded on for a handle, it's a great tool for forming metal panels like this.

I made it at college years ago from a cart spring with some tube welded on for a handle, it's a great tool for forming metal panels like this.

Fitted into place and ready for welding:

Because it's got two flanges butted together it's an easy weld to do without burning the lovely sun bleached pink paint

I primed it before fitting and sealing around it with PU before hitting it with some top coat.

A few more jobs will be done as & when over Winter, a speed related boost controller amongst one of them to curb its habit of spinning the wheels in first and second gear being the most important, I can generally regulate it with my foot, but the power delivery is comically vicious and any novices driving can't do it so this will help.

AutoGrass near York:

Tan Hill is the highest pub in the UK, it's normal to be snowed in completely for periods of time in Winter, a snowmobile and the front attachment from a snow plough are permanently parked outside.

And it was farewell to NATS today, the new owner took her down to a new home in Birmingham.

The tilt n slide sunroof in PJ was always too low in the car, when I had my helmet on I had to drive with my head on one side. A few nuts and a bit of trim removed and off it came:

A template made from MDF:

New panel cut and formed around the template bit by bit:

In the background there you can see my old slapper lurking

I made it at college years ago from a cart spring with some tube welded on for a handle, it's a great tool for forming metal panels like this.

I made it at college years ago from a cart spring with some tube welded on for a handle, it's a great tool for forming metal panels like this.Fitted into place and ready for welding:

Because it's got two flanges butted together it's an easy weld to do without burning the lovely sun bleached pink paint

I primed it before fitting and sealing around it with PU before hitting it with some top coat.

A few more jobs will be done as & when over Winter, a speed related boost controller amongst one of them to curb its habit of spinning the wheels in first and second gear being the most important, I can generally regulate it with my foot, but the power delivery is comically vicious and any novices driving can't do it so this will help.

Edited by Evoluzione on Saturday 5th December 18:17

Yes I saw it on Ebay, It got taken off before the end so don't know if it sold or what it went for, presumably it did as I haven't seen it for sale since.

The black ones seem to do good money, i've just got another one in, don't know whether to sell as is, break or make it right and run it myself for a while as yet.

The black ones seem to do good money, i've just got another one in, don't know whether to sell as is, break or make it right and run it myself for a while as yet.

Thanks for the reminder, not a massive amount to report due to busy work and home life hence the silence.

The boost controller is coming along, just not finished yet. I'm using the defunct ABS to tell the ECU what road speed is, it will then know what gear i'm in and lower the boost pressure in first and second gear so it grips rather than spinning the wheels.

For those who don't know, the basics of ABS is a sensor on each hub which is sensing the teeth revolving in front of it, when they stop (wheel lock up) it signals to the ECU and pump to release the brakes on that wheel, it can also monitor wheel speed by counting the speed of the teeth.

The ABS on Sausage was binned years ago, mainly because it was in the way, but also for weight saving. The hubs are still there though, so I swapped the sender which counts the teeth for a more suitable one, did some wiring and programmed the ECU to read it. Amazingly it worked I just had to tell the ECU what road speed was in the various gears which I could have done it on the road, but it was much easier in the workshop with the car on the lift.

I just had to tell the ECU what road speed was in the various gears which I could have done it on the road, but it was much easier in the workshop with the car on the lift.

It sounds here like i'm some kind of wiring ECU guru, but far from it, that's the advantage of having your ECUs made direct in the UK - you can ring them to guide you through this kind of stuff and any other problems.

I've plumbed & wired The Mac Daddy which will take the signal from the ECU and operate the wastegate actuator:

But that's as far as i've got and is as far as I can probably get too on my own as it's a bit more in depth and technical getting the Mac to work, I think it will end up going to the Dyno for final setting up.

Whilst out testing what i've done so far was working ok I had a new VXR bound up out of nowhere, swarming all over my behind making a right nuisance of himself, probably thinking haha, old shed of a Fiat.

Anyhow a long straight opened up, no cars in sight and he makes his move so I also dropped a cog, nailed it and coupled up Warpdrive, he got alongside then went backwards so fast I thought he'd found reverse. There was no danger, no side by side duelling, gripping the wheel, clenching teeth etc, just 2 seconds of instantaneous, hilarious, annihilation by some rusty old shed, which was one of the things I set out to do in the first place.

The car had a combined water/oil cooler fitted which has always worked well, although I think the rocking of the engine under load had put too much strain (via the stainless steel oil hoses) on the internal oil cooler fittings which ruptured internally. Luckily it happened just before I opened the bonnet so I spotted the oily water spewing out of the over pressurised expansion tank overflow, It could have been game over for the engine had it gone unnoticed. I pulled it off, cut the oil cooler out (it lived in the rad end tank), made up a blanking plate and had it welded up so it's just an engine water cooling rad now. I flushed the engine several times before adding a dishwasher tab and letting that do its stuff, flushed some more then filled with antifreeze & water.

I had a new larger than OE oil cooler sat on the shelf so pulled that down, got some hoses made up and put it where the original had been (you'll see pics and explanation on P1 and 2 about the history of all this). It's already got a duct which feeds air to it and some louvres in the wheel arch liner to pull the air out, but I felt it needed a bit more, so sourced some bumper end louvres and will be fitting those as well.

Speccing and building engines is likemaking love to a beautiful woman bringing kids up: You've laboured over them, done your best and know them intimately, but you've got to let go in the end and hope they go on to do well, they get in with the right crowd and someone else looks out for them like you did.

The engine I started a few posts up for the 164 ended up like this

It made around 485bhp and took a few wins, but wasn't installed very well, so sadly didn't take a championship win as it could have done as the chap is a good driver.

Just not a good mechanic.

It's coming back in for a stripdown, check and rebuild (Lord knows what delights i'm going to find in there after what i've heard), but hopefully now we've ironed out all the other issues it will be a stronger package next year.

Then this pile of old bits turned up:

It's a very early Thema turbo engine and an interesting build as it was Fiat/Lancias first attempt at a balancer shaft block with piston cooling oil jets, so whilst everything was there, it was done in a different way to what it was later on. This provided a bit of a challenge with a few specially made parts, I also noticed that at some point in its life someone had put Lancia Beta cams in there, so a bit of a bonus for the owner who had no idea.

It ended up in the back of a Montecarlo with a turbo strapped to it. Eventual output will be down to turbo size and it's starting off with a relatively small one so 250 ish to start off with. This doesn't sound a lot, but the car only weighs around a ton and that's double the original power output and the small turbo will spool good and early, especially the way i've set the cams up. A lot of engine outputs and behaviour are now done on the computer, cross referenced with real life dyno data I can accurately predict what is going to happen and when.

I think that's about it of anything of interest which fits into this thread!

The boost controller is coming along, just not finished yet. I'm using the defunct ABS to tell the ECU what road speed is, it will then know what gear i'm in and lower the boost pressure in first and second gear so it grips rather than spinning the wheels.

For those who don't know, the basics of ABS is a sensor on each hub which is sensing the teeth revolving in front of it, when they stop (wheel lock up) it signals to the ECU and pump to release the brakes on that wheel, it can also monitor wheel speed by counting the speed of the teeth.

The ABS on Sausage was binned years ago, mainly because it was in the way, but also for weight saving. The hubs are still there though, so I swapped the sender which counts the teeth for a more suitable one, did some wiring and programmed the ECU to read it. Amazingly it worked

I just had to tell the ECU what road speed was in the various gears which I could have done it on the road, but it was much easier in the workshop with the car on the lift.

I just had to tell the ECU what road speed was in the various gears which I could have done it on the road, but it was much easier in the workshop with the car on the lift.It sounds here like i'm some kind of wiring ECU guru, but far from it, that's the advantage of having your ECUs made direct in the UK - you can ring them to guide you through this kind of stuff and any other problems.

I've plumbed & wired The Mac Daddy which will take the signal from the ECU and operate the wastegate actuator:

But that's as far as i've got and is as far as I can probably get too on my own as it's a bit more in depth and technical getting the Mac to work, I think it will end up going to the Dyno for final setting up.

Whilst out testing what i've done so far was working ok I had a new VXR bound up out of nowhere, swarming all over my behind making a right nuisance of himself, probably thinking haha, old shed of a Fiat.

Anyhow a long straight opened up, no cars in sight and he makes his move so I also dropped a cog, nailed it and coupled up Warpdrive, he got alongside then went backwards so fast I thought he'd found reverse. There was no danger, no side by side duelling, gripping the wheel, clenching teeth etc, just 2 seconds of instantaneous, hilarious, annihilation by some rusty old shed, which was one of the things I set out to do in the first place.

The car had a combined water/oil cooler fitted which has always worked well, although I think the rocking of the engine under load had put too much strain (via the stainless steel oil hoses) on the internal oil cooler fittings which ruptured internally. Luckily it happened just before I opened the bonnet so I spotted the oily water spewing out of the over pressurised expansion tank overflow, It could have been game over for the engine had it gone unnoticed. I pulled it off, cut the oil cooler out (it lived in the rad end tank), made up a blanking plate and had it welded up so it's just an engine water cooling rad now. I flushed the engine several times before adding a dishwasher tab and letting that do its stuff, flushed some more then filled with antifreeze & water.

I had a new larger than OE oil cooler sat on the shelf so pulled that down, got some hoses made up and put it where the original had been (you'll see pics and explanation on P1 and 2 about the history of all this). It's already got a duct which feeds air to it and some louvres in the wheel arch liner to pull the air out, but I felt it needed a bit more, so sourced some bumper end louvres and will be fitting those as well.

Speccing and building engines is like

The engine I started a few posts up for the 164 ended up like this

It made around 485bhp and took a few wins, but wasn't installed very well, so sadly didn't take a championship win as it could have done as the chap is a good driver.

Just not a good mechanic.

It's coming back in for a stripdown, check and rebuild (Lord knows what delights i'm going to find in there after what i've heard), but hopefully now we've ironed out all the other issues it will be a stronger package next year.

Then this pile of old bits turned up:

It's a very early Thema turbo engine and an interesting build as it was Fiat/Lancias first attempt at a balancer shaft block with piston cooling oil jets, so whilst everything was there, it was done in a different way to what it was later on. This provided a bit of a challenge with a few specially made parts, I also noticed that at some point in its life someone had put Lancia Beta cams in there, so a bit of a bonus for the owner who had no idea.

It ended up in the back of a Montecarlo with a turbo strapped to it. Eventual output will be down to turbo size and it's starting off with a relatively small one so 250 ish to start off with. This doesn't sound a lot, but the car only weighs around a ton and that's double the original power output and the small turbo will spool good and early, especially the way i've set the cams up. A lot of engine outputs and behaviour are now done on the computer, cross referenced with real life dyno data I can accurately predict what is going to happen and when.

I think that's about it of anything of interest which fits into this thread!

Edited by Evoluzione on Friday 7th October 19:20

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff