Peugeot 205 Saloon Libre - RWD Space-Frame Silhouette Racer

Discussion

There we go!

More progress on the front uprights today, and I have the main body of them done. It's late again so I'll just add pictures and a few words.

so I'll just add pictures and a few words.

These little top caps are very fiddly!

Made a little jig for it - reversible for the other side, too.

I had to make another forming tool for these upper parts, as they have a tighter radius than the lower legs.

And then a flash of welding later.. I have a massive erection.

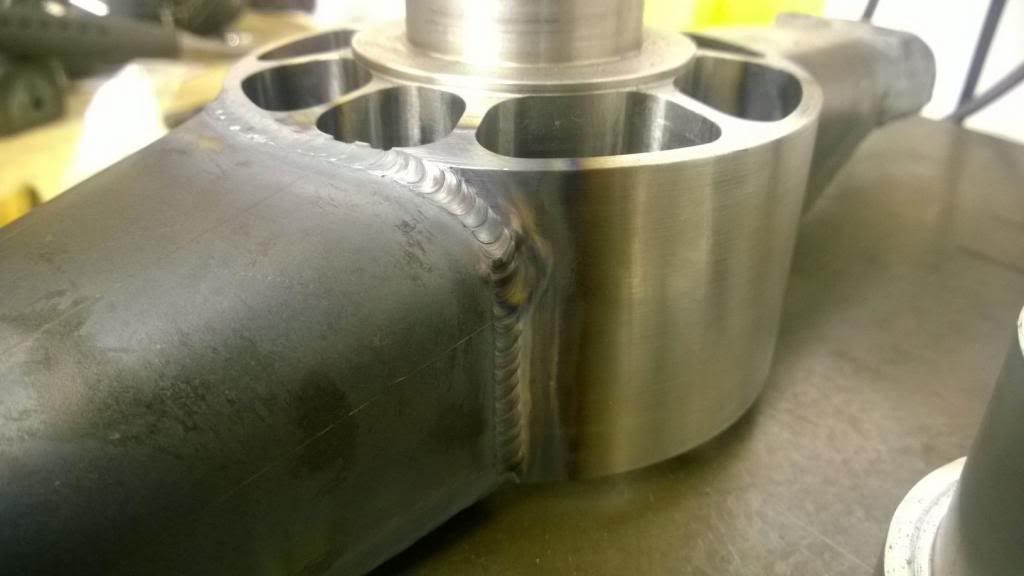

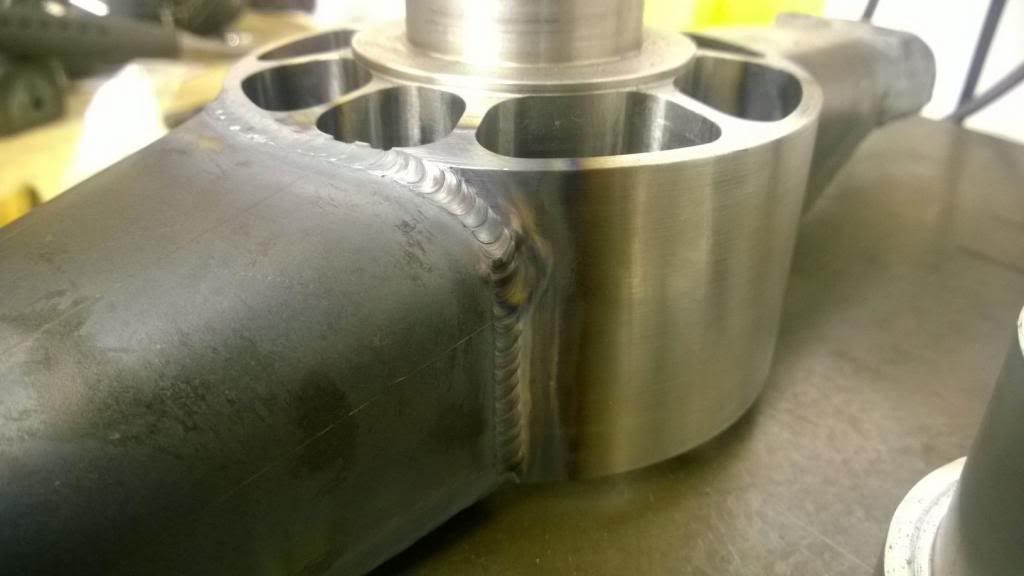

And finally some slutty weld close-ups.

So pleased with how they're coming out! I'm going to have a slow day tomorrow as I ache all over, so the next update will be at the weekend when hopefully these are finished.

More progress on the front uprights today, and I have the main body of them done. It's late again

so I'll just add pictures and a few words.

so I'll just add pictures and a few words.These little top caps are very fiddly!

Made a little jig for it - reversible for the other side, too.

I had to make another forming tool for these upper parts, as they have a tighter radius than the lower legs.

And then a flash of welding later.. I have a massive erection.

And finally some slutty weld close-ups.

So pleased with how they're coming out! I'm going to have a slow day tomorrow as I ache all over, so the next update will be at the weekend when hopefully these are finished.

Thanks guys, glad people are enjoying the build!

I have a desk job as an engineer, but was very lucky to get my placement year with some highly skilled fabricators at BTB Exhausts, so I learnt a lot from there. It's a hobby at the moment, but I don't want to work behind a desk for the rest of my life so I figure the best way to get out of that is to get stuck in to this!

I have a desk job as an engineer, but was very lucky to get my placement year with some highly skilled fabricators at BTB Exhausts, so I learnt a lot from there. It's a hobby at the moment, but I don't want to work behind a desk for the rest of my life so I figure the best way to get out of that is to get stuck in to this!

CamMoreRon said:

Thanks guys, glad people are enjoying the build!

I have a desk job as an engineer, but was very lucky to get my placement year with some highly skilled fabricators at BTB Exhausts, so I learnt a lot from there. It's a hobby at the moment, but I don't want to work behind a desk for the rest of my life so I figure the best way to get out of that is to get stuck in to this!

Yep, with a nice documented build log (in a folder [for the old school]) and the web its a class CV that is for sure.I have a desk job as an engineer, but was very lucky to get my placement year with some highly skilled fabricators at BTB Exhausts, so I learnt a lot from there. It's a hobby at the moment, but I don't want to work behind a desk for the rest of my life so I figure the best way to get out of that is to get stuck in to this!

Trtj said:

Megaflow said:

Quick question, have you done and hand calc's or FEA on the spindles in the uprights?

I ask because they look very light.

Very large diameter probably allows for this?I ask because they look very light.

Trtj said:

How the hell do you fit all this progress in around a desk job as an engineer? All I have managed in the last month is to wack a new slave cyl on my mini! Mind you having a woman in your life is a hobby ruiner

Simple solution: no woman.

I've taken this week off work, so it isn't always like this mid-week! Also helps that there is f

k all else to do around here.

k all else to do around here.

CamMoreRon said:

Trtj said:

Megaflow said:

Quick question, have you done and hand calc's or FEA on the spindles in the uprights?

I ask because they look very light.

Very large diameter probably allows for this?I ask because they look very light.

Thanks for the kind words, chaps.

Yesterday, predictably, I was hungover. So today I tried to make up for lost time by getting on with the brake calliper mounts, and as such there is a lack of in-progress photos! Anywho.. I made a jig, then fiddled about profiling some sheet metal, then welded it all up. Behold!

So today I tried to make up for lost time by getting on with the brake calliper mounts, and as such there is a lack of in-progress photos! Anywho.. I made a jig, then fiddled about profiling some sheet metal, then welded it all up. Behold!

I tried the caliper on..

Then fitted the disc to a spare hub and checked everything fit ok. (I actually did this while it was all tacked up, but this makes a better picture!)

Now, true to routine, it's time for a very late dinner.

Yesterday, predictably, I was hungover.

So today I tried to make up for lost time by getting on with the brake calliper mounts, and as such there is a lack of in-progress photos! Anywho.. I made a jig, then fiddled about profiling some sheet metal, then welded it all up. Behold!

So today I tried to make up for lost time by getting on with the brake calliper mounts, and as such there is a lack of in-progress photos! Anywho.. I made a jig, then fiddled about profiling some sheet metal, then welded it all up. Behold!

I tried the caliper on..

Then fitted the disc to a spare hub and checked everything fit ok. (I actually did this while it was all tacked up, but this makes a better picture!)

Now, true to routine, it's time for a very late dinner.

That looks s t!

t!

Who am I kidding? It looks fantastic. As deltashed said earlier, I too am not worthy of posting here. I've worked in engineering for 28 years, but in commercial/admin after my apprenticeship. Threads like yours really make me wish I'd carried on with the practical side, so that I may be able to construct something to half the standard you're doing. Due to this absence of skill, I have to content myself with watching threads like yours.

Just keep thinking of people like me, and keep the updates frequent & detailed please.

t!

t!

Who am I kidding? It looks fantastic. As deltashed said earlier, I too am not worthy of posting here. I've worked in engineering for 28 years, but in commercial/admin after my apprenticeship. Threads like yours really make me wish I'd carried on with the practical side, so that I may be able to construct something to half the standard you're doing. Due to this absence of skill, I have to content myself with watching threads like yours.

Just keep thinking of people like me, and keep the updates frequent & detailed please.

Haha thanks, I'll be sure to keep the updates as in-depth as I can!

Aaaaaaaaaaand finished! (Or as good as..) The steering arms were quite tricky, but they look great now that they're on.

Megaflow - no weights just yet, but I will do so once they're powder coated!

So, sadly I'm back to work tomorrow.. which is a shame as I'm so close to getting the wheels on! Hopefully that will be a nice job for next weekend.

Aaaaaaaaaaand finished! (Or as good as..) The steering arms were quite tricky, but they look great now that they're on.

Megaflow - no weights just yet, but I will do so once they're powder coated!

So, sadly I'm back to work tomorrow.. which is a shame as I'm so close to getting the wheels on! Hopefully that will be a nice job for next weekend.

OK I am going to ask a silly question. While the welding looks very well done and I am sure all the surfaces are prepped properly is there any need for weld inspection? Be it surface flaws or volumetric cracks/flaws. I have no experience of how mass prodcution parts are sampled and NDE/DE tested never mind how a one off project fairs though. You may be confident that the welds are not porous, material is flaw free and there is additional redundancy/FOS in your stress utilisations. To be honest there is a chunkiness to the build which tells me it will take a beating.

Being from an oil and gas background I am concious the weld inspection and testing I see is largely pushed by the fact there are pressurised volumes of hazardous fluids or gases and the insurance companies need to see bits of paper to be happy.

OK silly question over.

Being from an oil and gas background I am concious the weld inspection and testing I see is largely pushed by the fact there are pressurised volumes of hazardous fluids or gases and the insurance companies need to see bits of paper to be happy.

OK silly question over.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff