Project Berg Stormer (1984 mk1 Golf 20vT Berg cup racer)

Discussion

With inters approaching this weekend we have been scrambling to get the car ready.

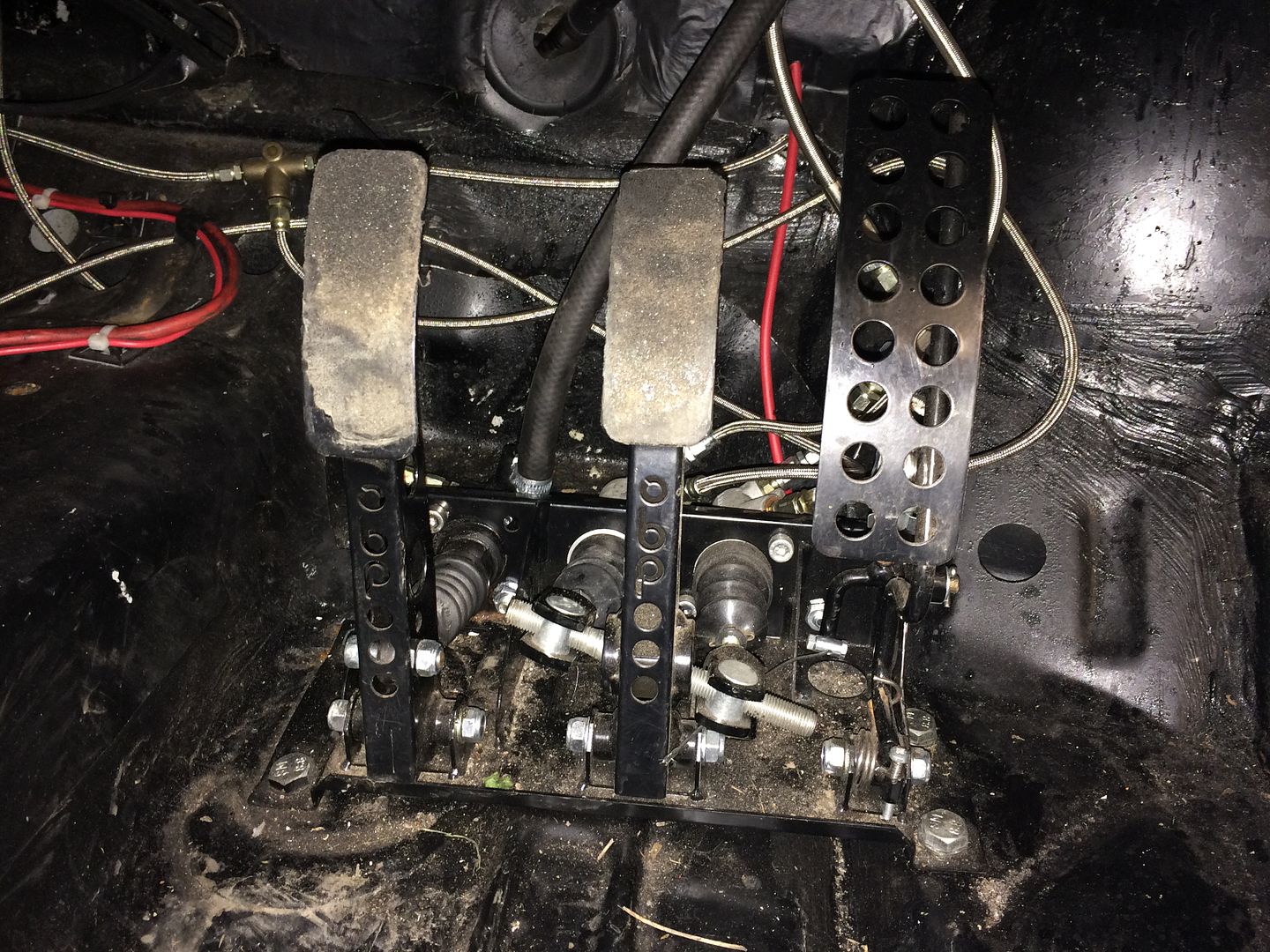

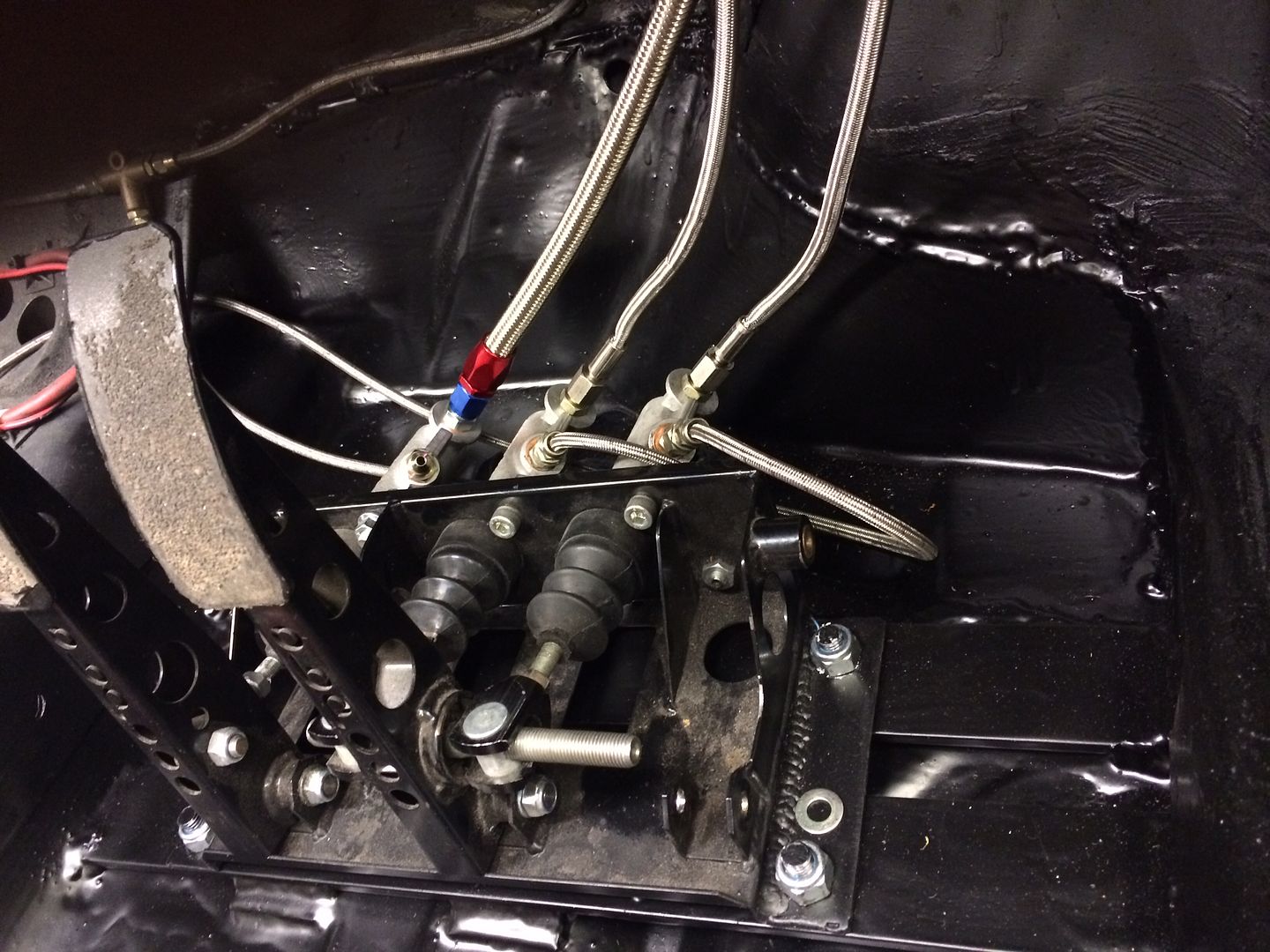

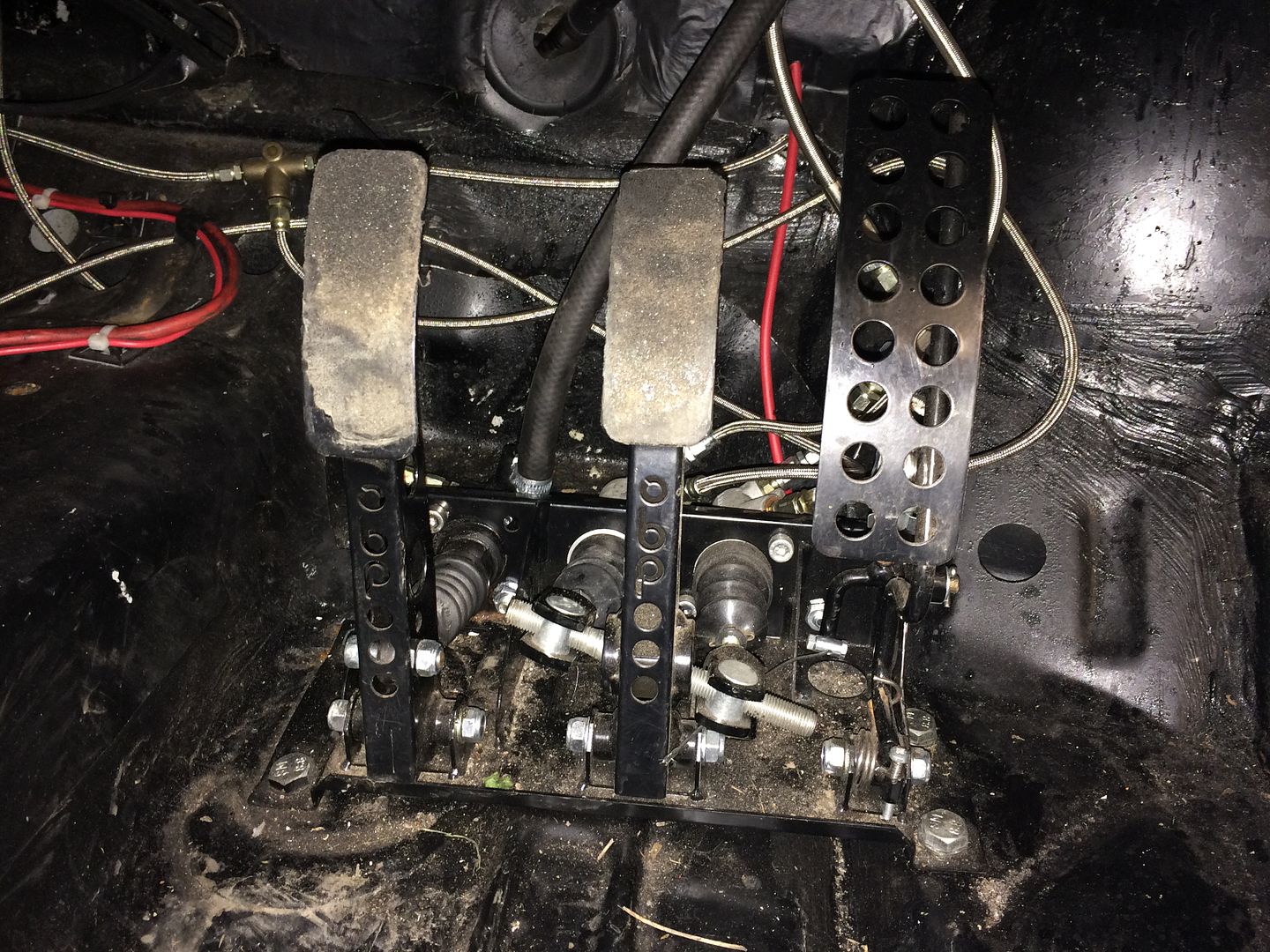

One thing we decided after the clutch incident was that we wanted to tidy up was that we needed to tidy up the pedal box area. It was functional, but not pretty. As you can see in the pic below, the hole cut in the foot plate was all ragged and the pedal box wasnt quite straight. Also, there was a lot of flex when stamping on the brakes.

So out it came.

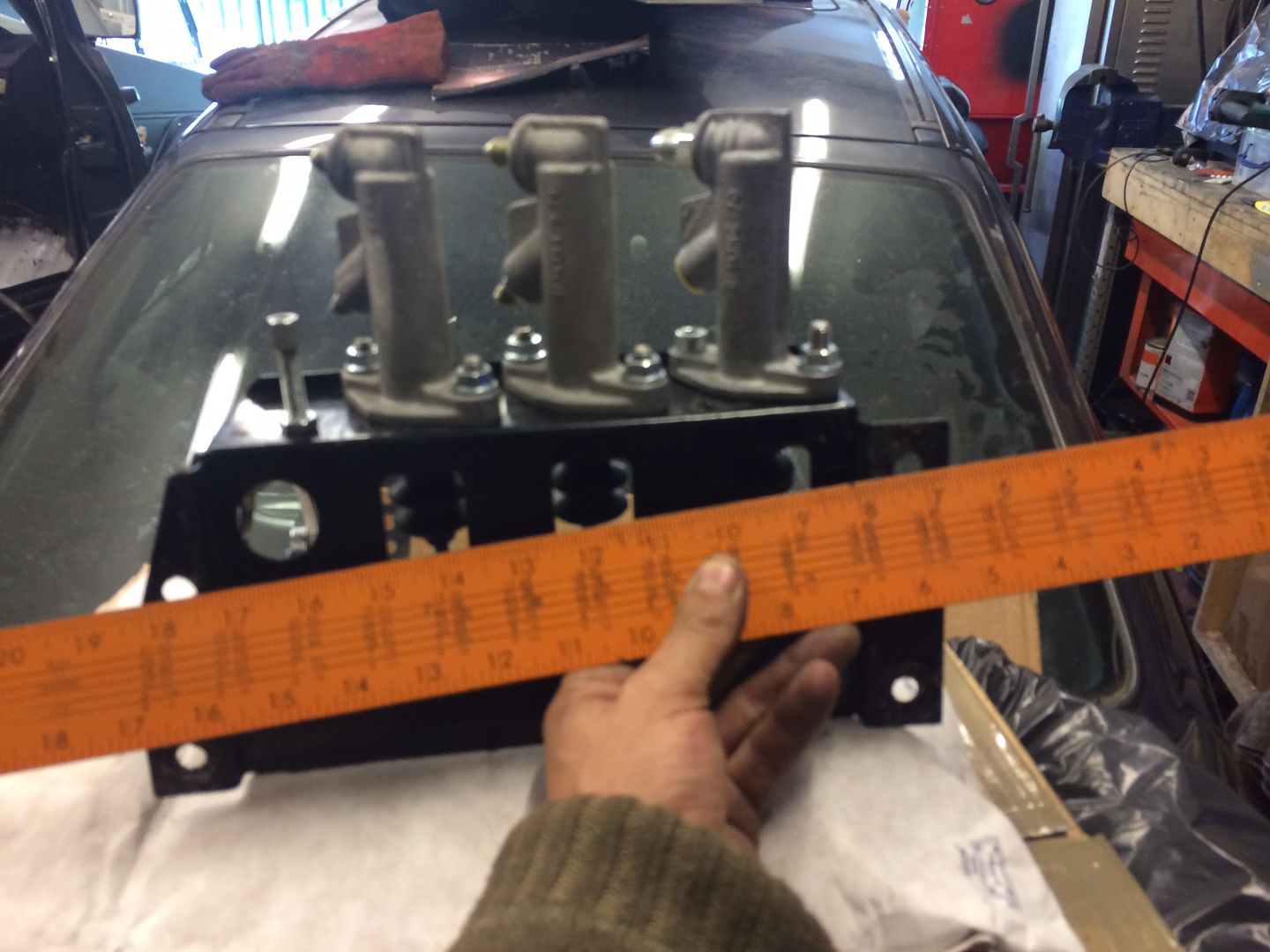

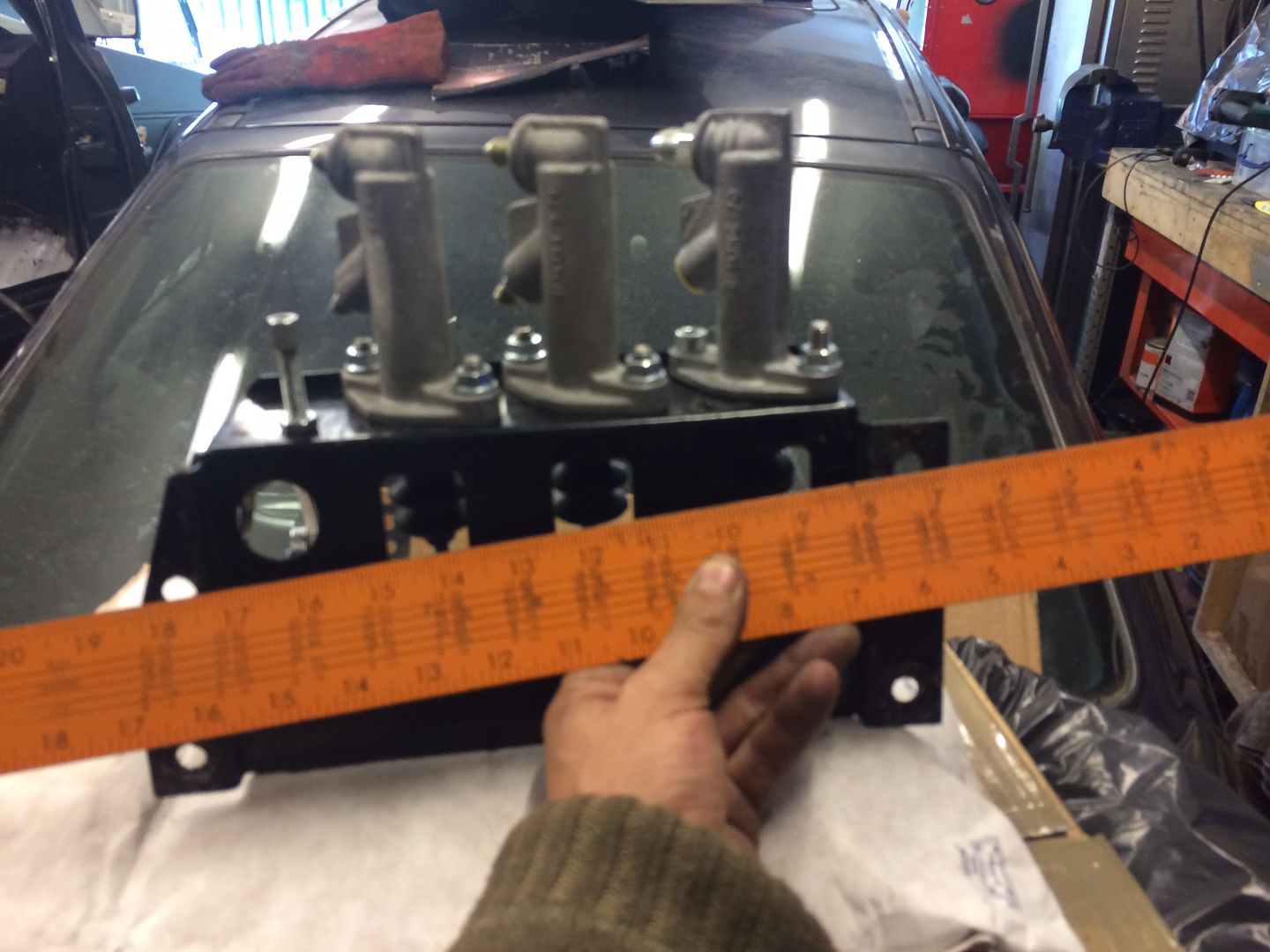

While it was on the bench, we properly adjusted the bias bar.

According to OBP, the clevis pins either side of the pedal, should be a max of 5mm from the pedal body for proper bias adjustment. Ours were around 15mm

Then the clean up started. We started cutting and cleaning

While we were in the foot well area, we decided to remove the old seat cross member and weld in some stronger seat mounts

All cleaned up and seem welded. Later one, I rounded the left hand edge of the cut out with a hammer and dolly to make it nice, but forgot to take a pic

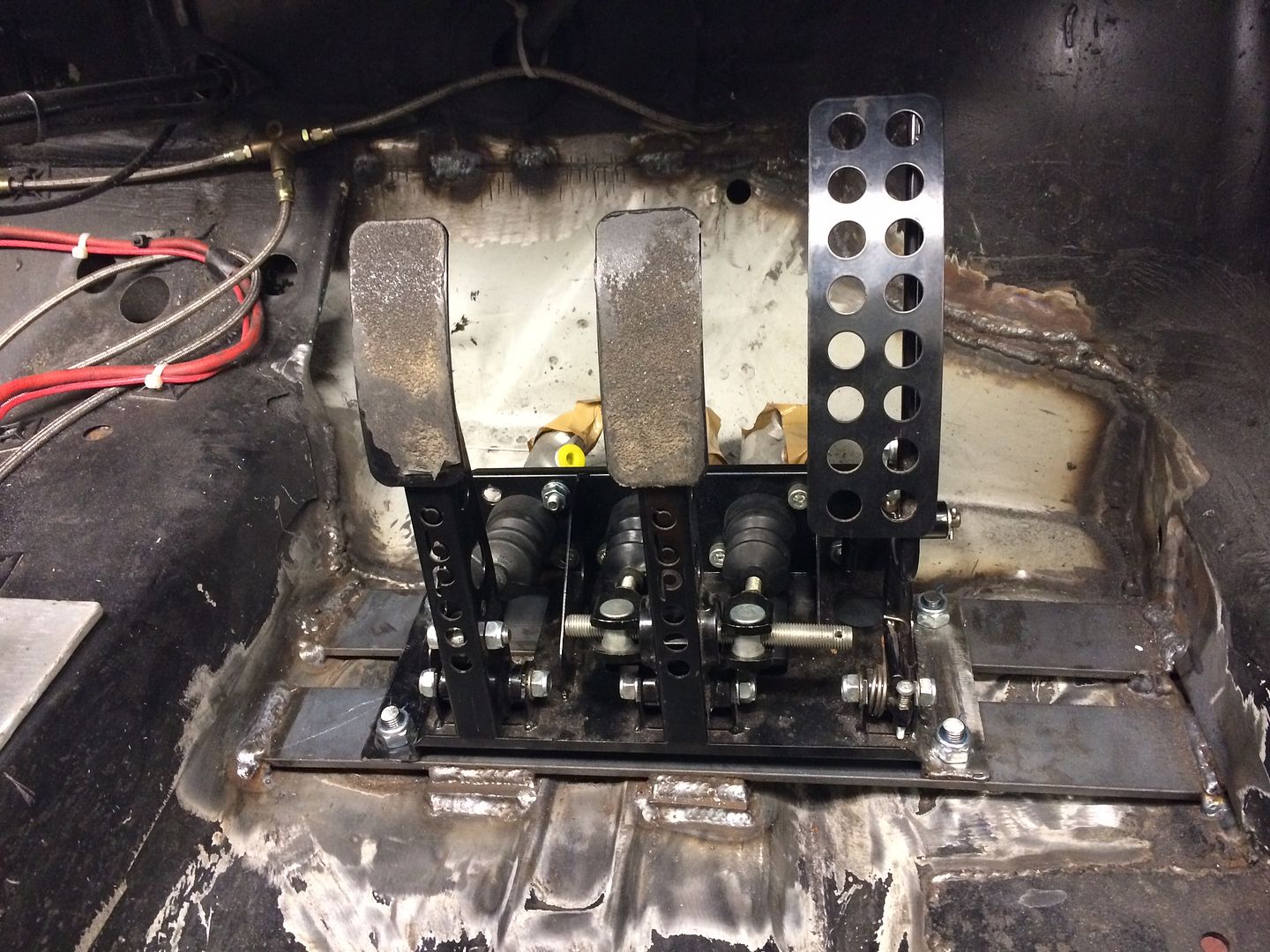

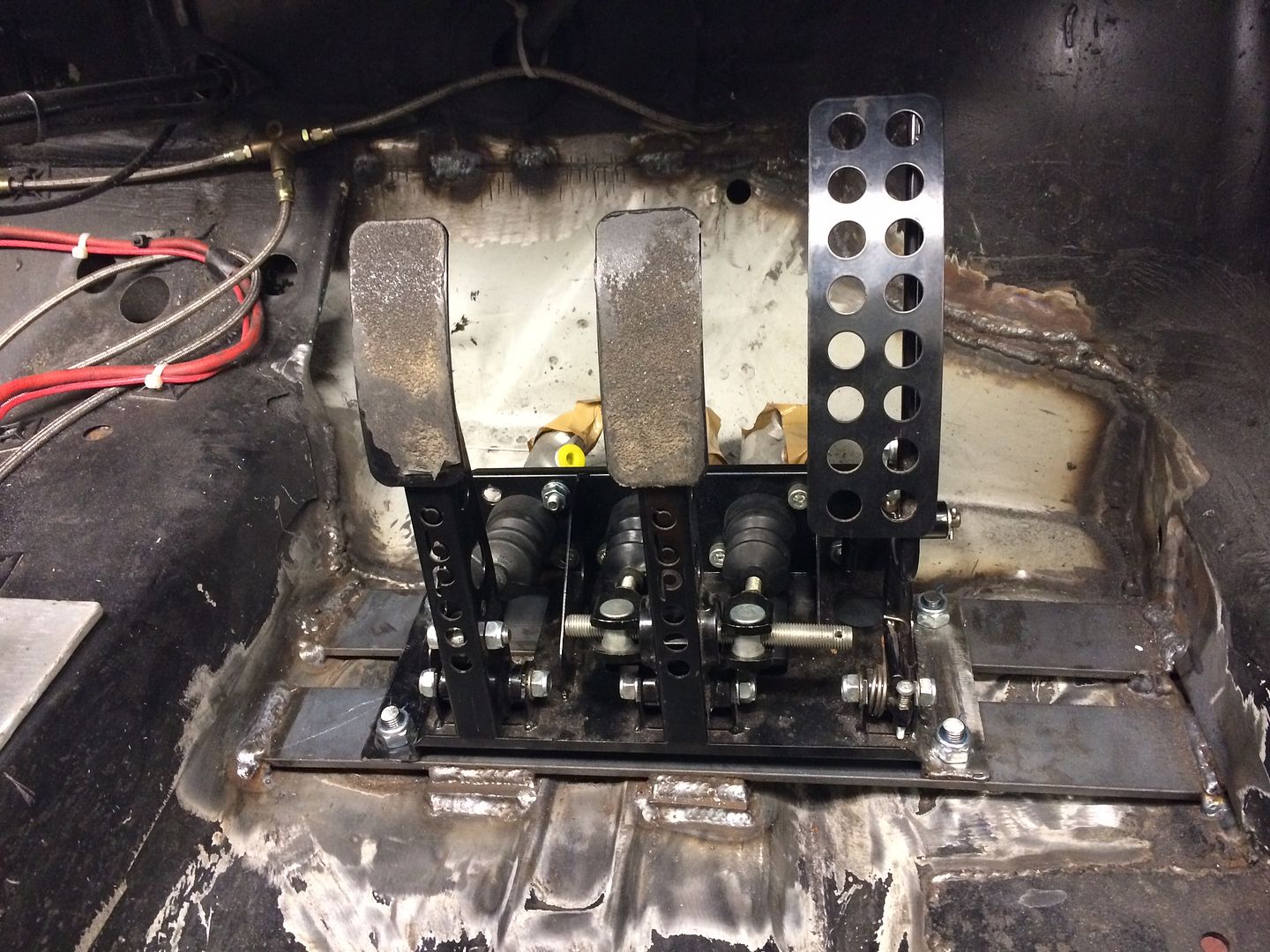

We decided rather bolt the pedal box to the flimsy floor, we should beef up the mount area with some flat bar

but problem. The OBP pedal box is designed to bolt into a mk1 with minimal fab, so the holes are skewed, and we wanted to put the bracing down straight

So we welded a corner on, and a bit of plate above and re positioned the mounting hole

This should be a lot more solid

Next it was time to sort out the seat rails. We welded some pate to the sills to strengthen them and then added some nice thick walled box

followed by a quick coat of epoxy and then some matt black

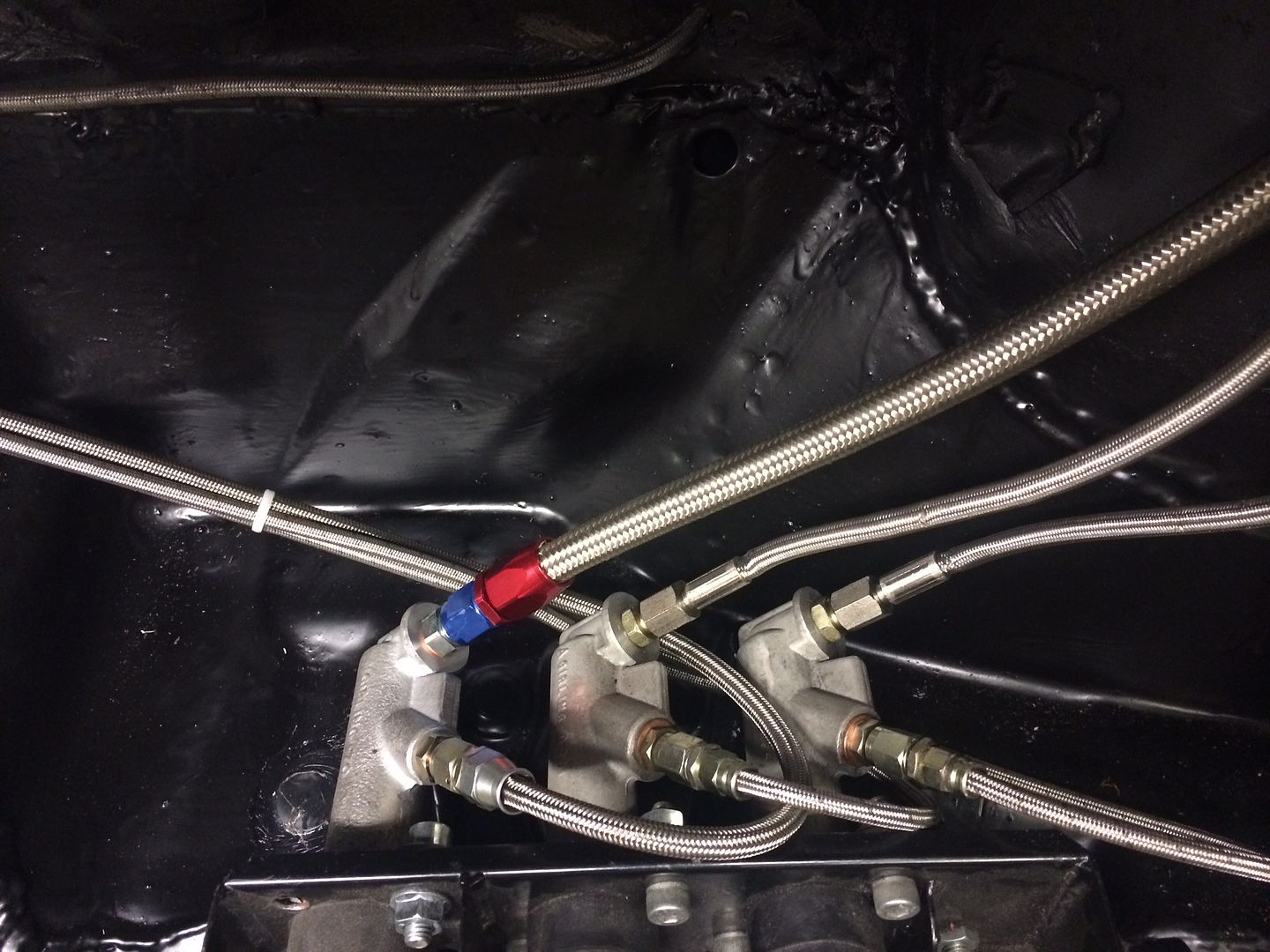

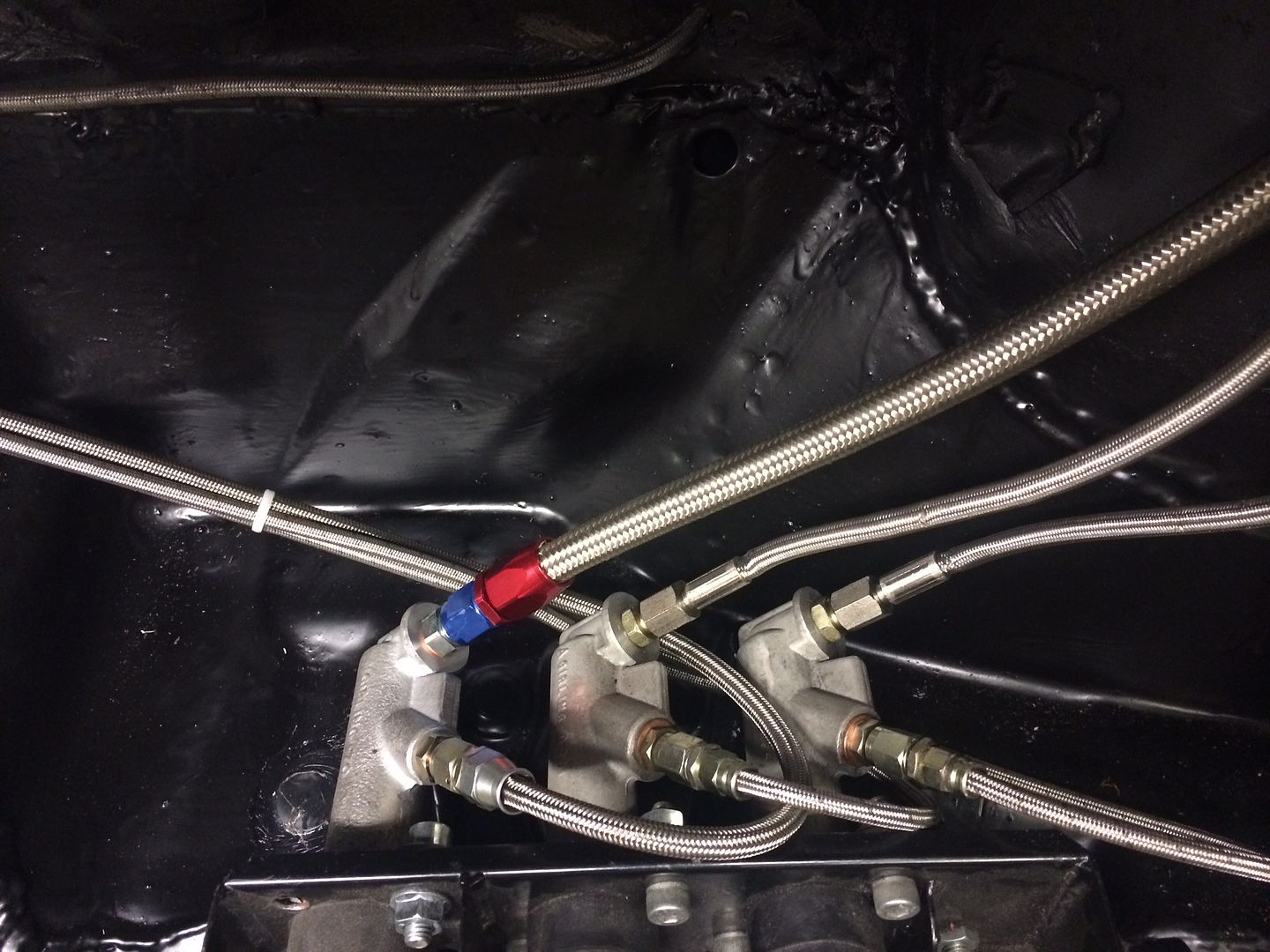

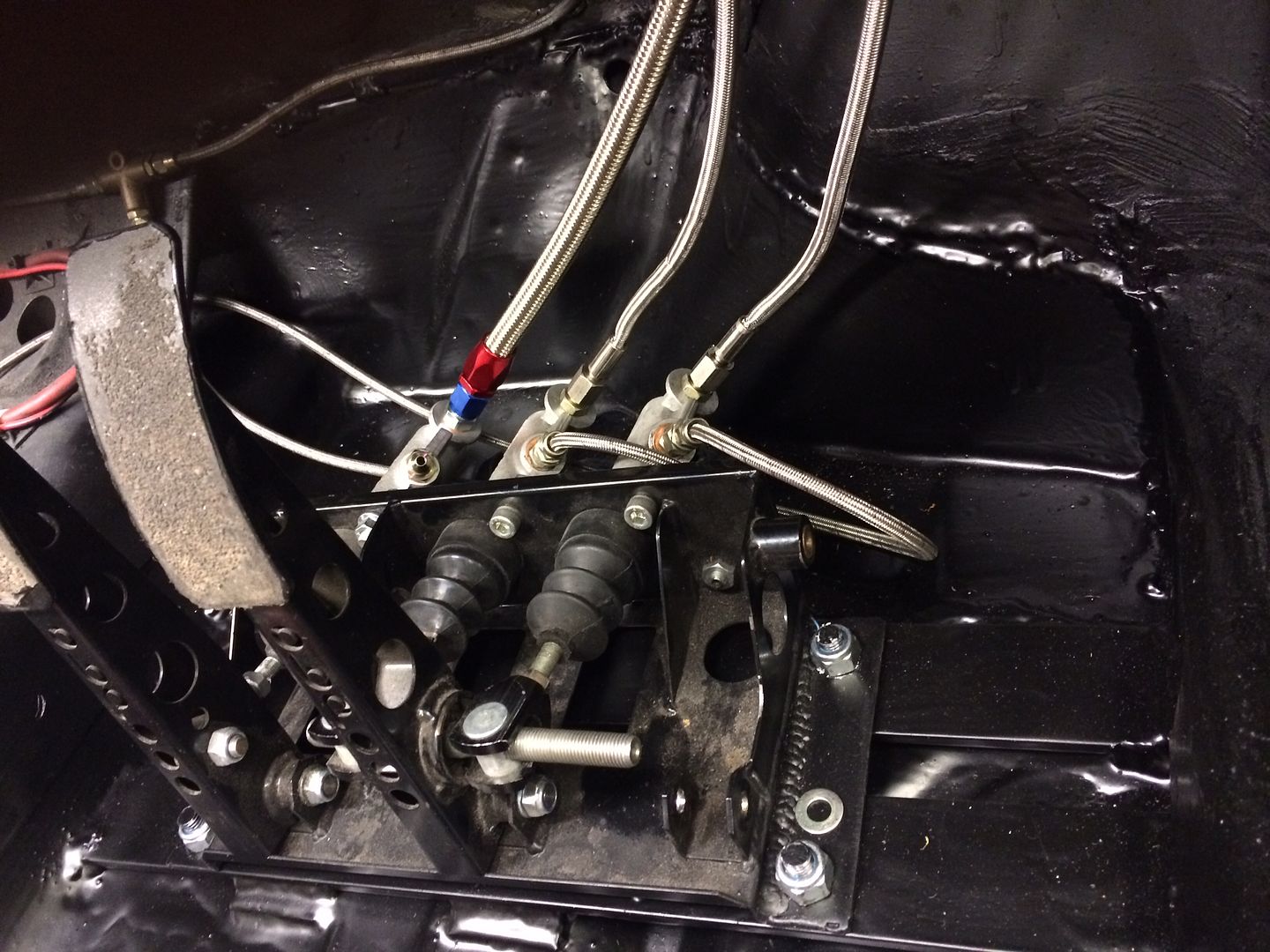

The pedals were then plumbed back in with nice looped pig tails. mmm much neater

We also fitted the bias adjuster onto the dash which wasnt previously fitted

With the functional side sorted, it was time to turn our attention to the cosmetics. We decided it was time to change the livery and repair some of the damage on around the body.

more on that post inters

Will be interesting to see if anyone spots the car with the new livery

One thing we decided after the clutch incident was that we wanted to tidy up was that we needed to tidy up the pedal box area. It was functional, but not pretty. As you can see in the pic below, the hole cut in the foot plate was all ragged and the pedal box wasnt quite straight. Also, there was a lot of flex when stamping on the brakes.

So out it came.

While it was on the bench, we properly adjusted the bias bar.

According to OBP, the clevis pins either side of the pedal, should be a max of 5mm from the pedal body for proper bias adjustment. Ours were around 15mm

Then the clean up started. We started cutting and cleaning

While we were in the foot well area, we decided to remove the old seat cross member and weld in some stronger seat mounts

All cleaned up and seem welded. Later one, I rounded the left hand edge of the cut out with a hammer and dolly to make it nice, but forgot to take a pic

We decided rather bolt the pedal box to the flimsy floor, we should beef up the mount area with some flat bar

but problem. The OBP pedal box is designed to bolt into a mk1 with minimal fab, so the holes are skewed, and we wanted to put the bracing down straight

So we welded a corner on, and a bit of plate above and re positioned the mounting hole

This should be a lot more solid

Next it was time to sort out the seat rails. We welded some pate to the sills to strengthen them and then added some nice thick walled box

followed by a quick coat of epoxy and then some matt black

The pedals were then plumbed back in with nice looped pig tails. mmm much neater

We also fitted the bias adjuster onto the dash which wasnt previously fitted

With the functional side sorted, it was time to turn our attention to the cosmetics. We decided it was time to change the livery and repair some of the damage on around the body.

more on that post inters

Will be interesting to see if anyone spots the car with the new livery

So the story continues.

With GTi International fast approaching it was time to focus on the cosmetics.

First up was body repair. Being a track car, there were lots of small areas of localised damage.

There was a small crack on one of the wheel arches

to repair, I drilled a small 3mm hole at the very tip of the crack. This stops the crack growing under stress, I also V'd out the crack from both sides using a dremel, then used some mole grips to re align the fiber glass and hold it in place.

I then mixed up some P40 filler and applied it to both sides of the crack. Once set, I removed the mole grips and did the same to the area previously covered. At this point, I am about 20 mins into the repair. Nice and quick

After its dry, its your basic prep for paint, sand, skim of filler, a squirt of primer, then paint and you are left with this

While the paint was out, we decided to give the car a gorilla paint job. We gave the rear quarter a going over to covers some scratches, and also the drivers door and bonnet.

The beauty of matt black paint is, you dont need to struggle with blending and lacquering. Just feather into the old paint and let it dry for an invisible finish

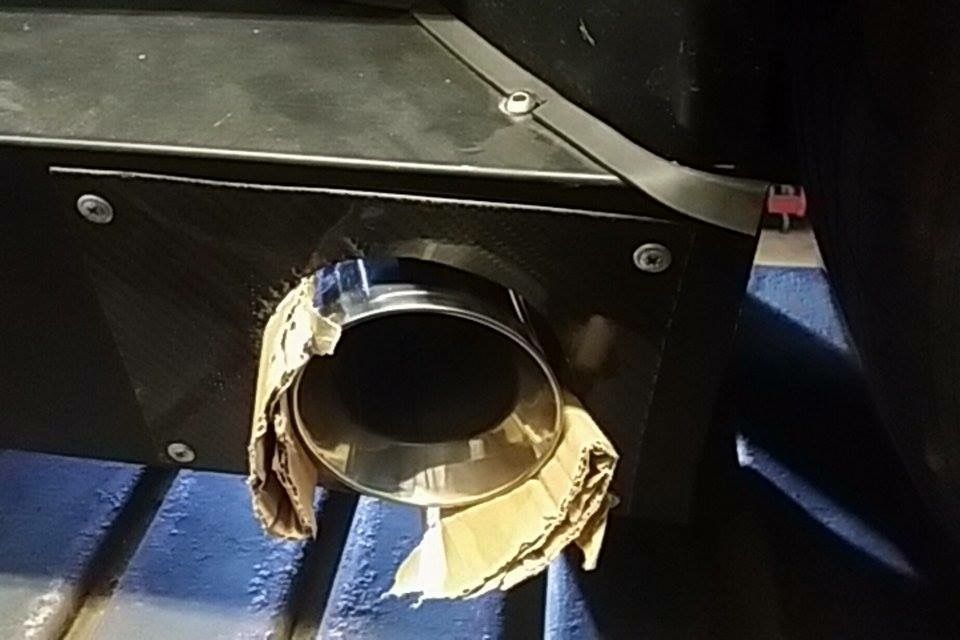

Next up, we needed to tackle air con as it gets damn hot in the car on sunny days.

we drilled out the perspex windows

and installed some popout helicopter vents

after our experience at the players show, we decided it was worth taking some wet weather precautions too so we made a litte rain shield for the ecu

Then finally came the moment I had been waiting patiently for all week!!

a parcel arrived from Syco Graphix with the all new livery.

with the all new livery.

The night before Inters, we started applying the stickers. We were up till 1am but I hope you will agree, it was worth it.

and here is the finished result

And seemed to go down well at inters. Lots of positive comments

Also thanks to Si Gray for taking some awesome pics of my car

Hope you all like the progress to date. I would love to hear your thoughts on the graphics too. They are probably a bit marmite.

Cheers

Amit

With GTi International fast approaching it was time to focus on the cosmetics.

First up was body repair. Being a track car, there were lots of small areas of localised damage.

There was a small crack on one of the wheel arches

to repair, I drilled a small 3mm hole at the very tip of the crack. This stops the crack growing under stress, I also V'd out the crack from both sides using a dremel, then used some mole grips to re align the fiber glass and hold it in place.

I then mixed up some P40 filler and applied it to both sides of the crack. Once set, I removed the mole grips and did the same to the area previously covered. At this point, I am about 20 mins into the repair. Nice and quick

After its dry, its your basic prep for paint, sand, skim of filler, a squirt of primer, then paint and you are left with this

While the paint was out, we decided to give the car a gorilla paint job. We gave the rear quarter a going over to covers some scratches, and also the drivers door and bonnet.

The beauty of matt black paint is, you dont need to struggle with blending and lacquering. Just feather into the old paint and let it dry for an invisible finish

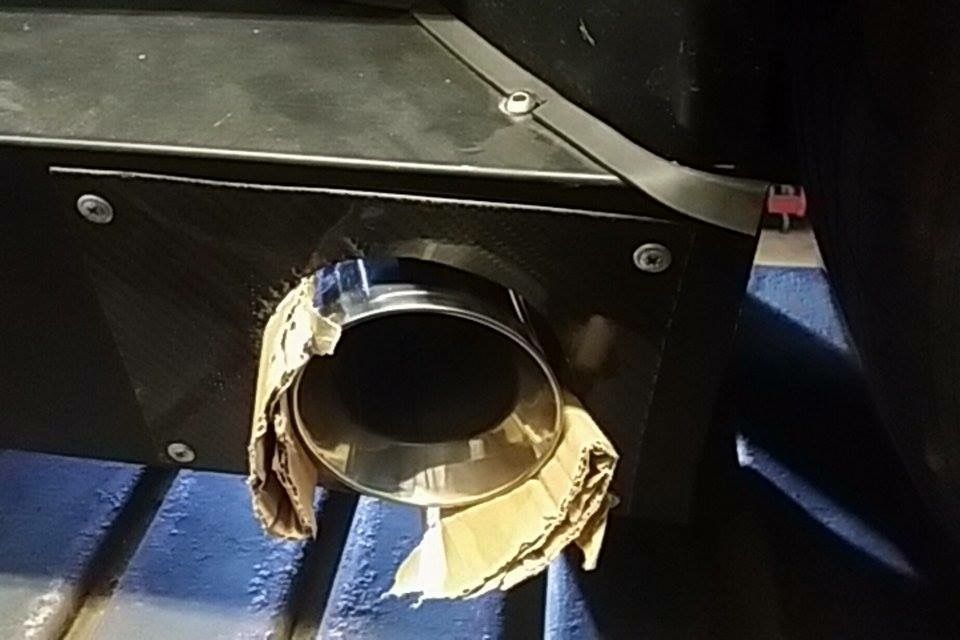

Next up, we needed to tackle air con as it gets damn hot in the car on sunny days.

we drilled out the perspex windows

and installed some popout helicopter vents

after our experience at the players show, we decided it was worth taking some wet weather precautions too so we made a litte rain shield for the ecu

Then finally came the moment I had been waiting patiently for all week!!

a parcel arrived from Syco Graphix

with the all new livery.

with the all new livery.

The night before Inters, we started applying the stickers. We were up till 1am but I hope you will agree, it was worth it.

and here is the finished result

And seemed to go down well at inters. Lots of positive comments

Also thanks to Si Gray for taking some awesome pics of my car

Hope you all like the progress to date. I would love to hear your thoughts on the graphics too. They are probably a bit marmite.

Cheers

Amit

The problem with the OBP pedal box is that it is not very good. Pressed steel is no match for the forged alloy designs from the likes of Tilton and AP Racing. I know a few guys who have tried the OBP ones and just sacked them off for the more expensive units.

Car looks good in those pics though OP

Car looks good in those pics though OP

So guys.. time for an update

The First big show of the season for me was the APEX Festival where I was going to be a track demo car, and I wanted to make some major improvements to the interior.

Most of the dash didnt work after the 20v conversion. No speedo, no tacho. I didnt like how the CAE shifter was mounted, the floors looked shabby, the doors looked shabby so decided the focus for this year would be interior.. but we didnt stop there.. it would only be fair to make some performance improvements too.

So on with the story.

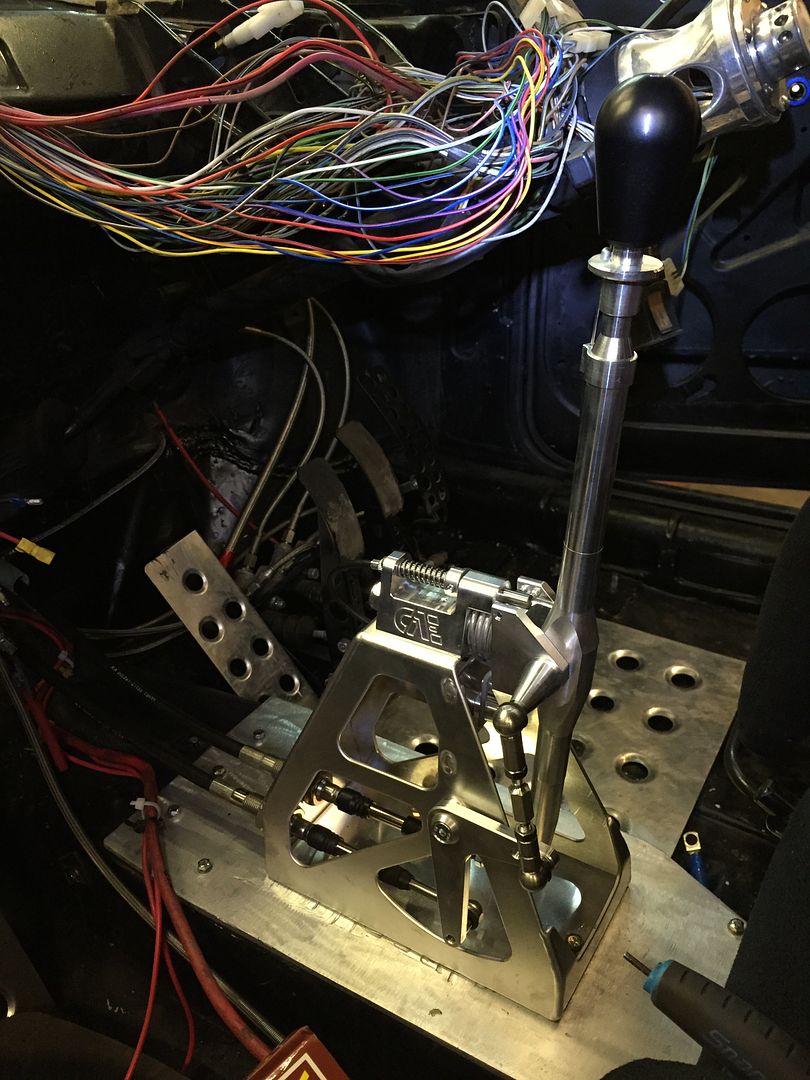

A reminder of how the dash and shifter looked. The CAE shifter I had was designed for a corrado so had to mount it on an ugly plinth to get the right height, and the dash was just the standard mk1 dash. not very race car.. so I stripped out the lot.

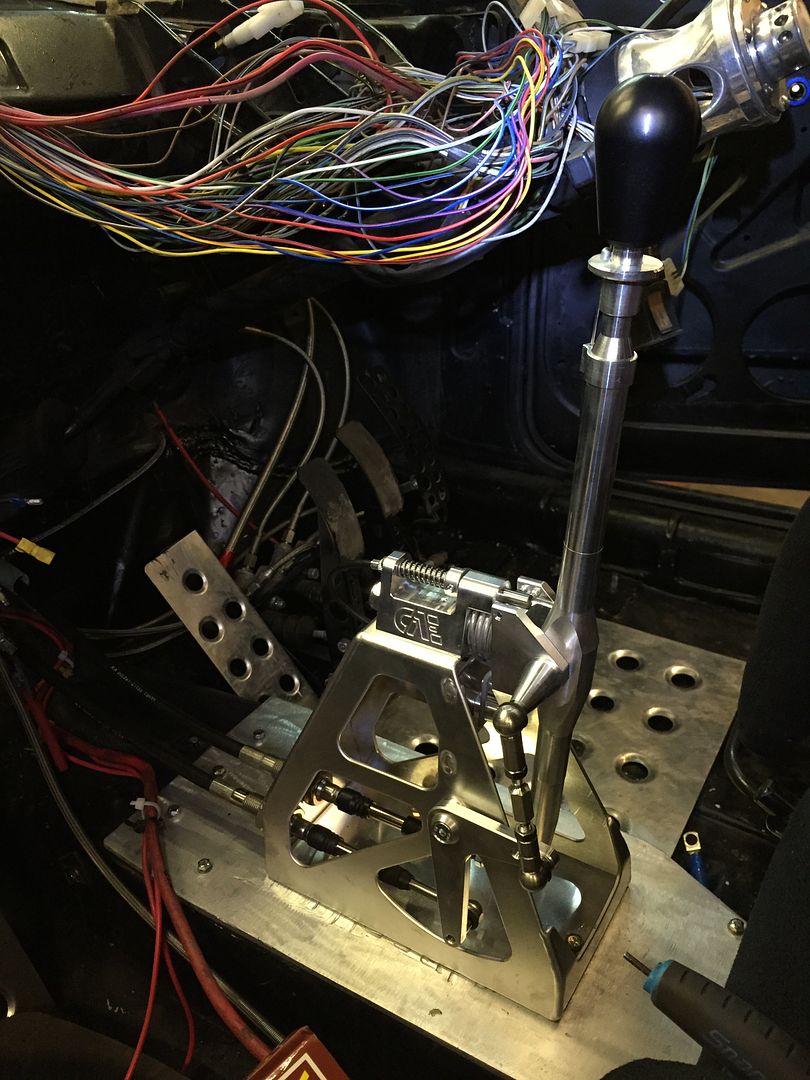

I purchased the proper mk1 CAE shifter and installed it which looks a thousand times better. I also got rid of the hydraulic hand brake as we never used it.

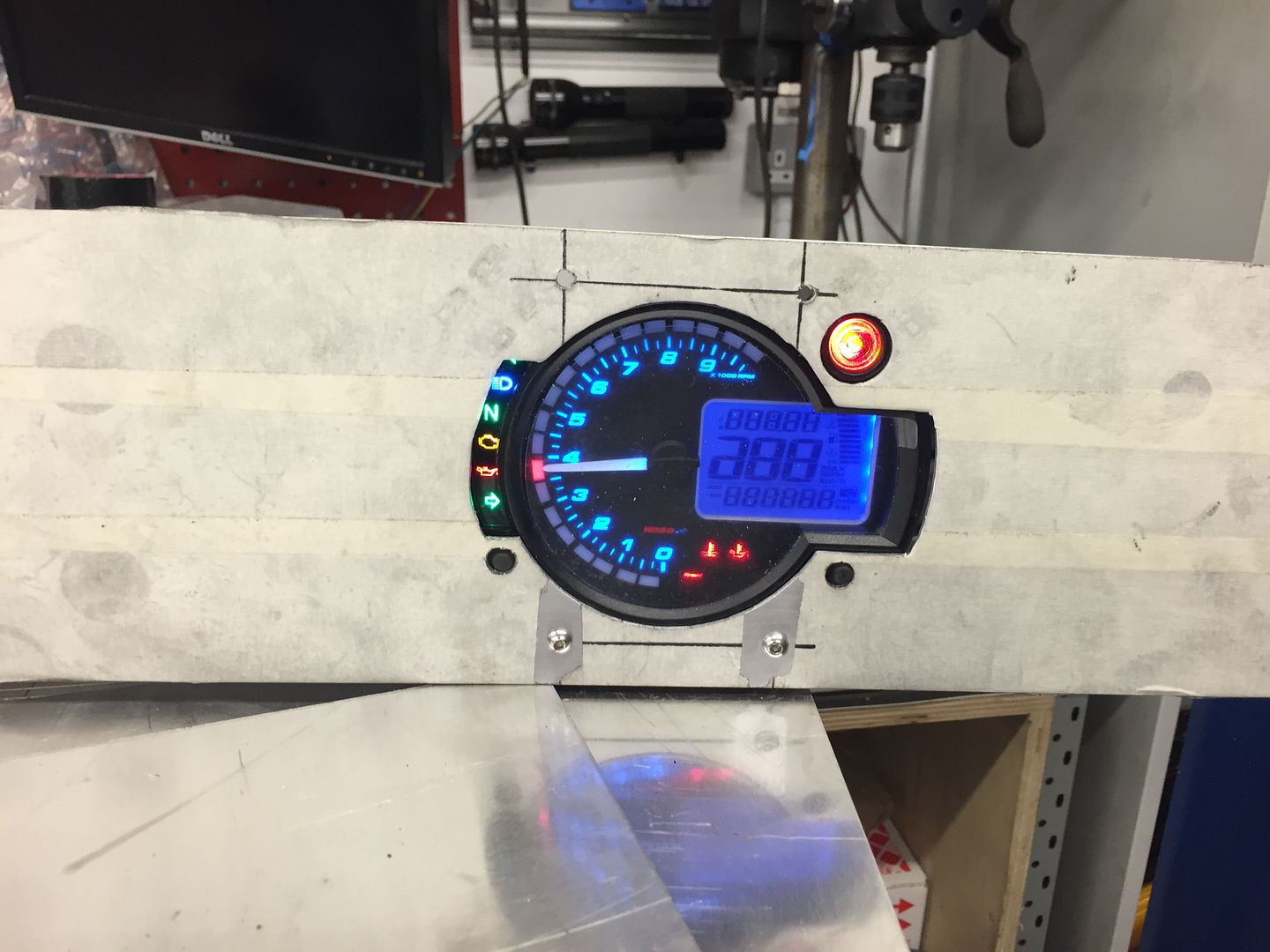

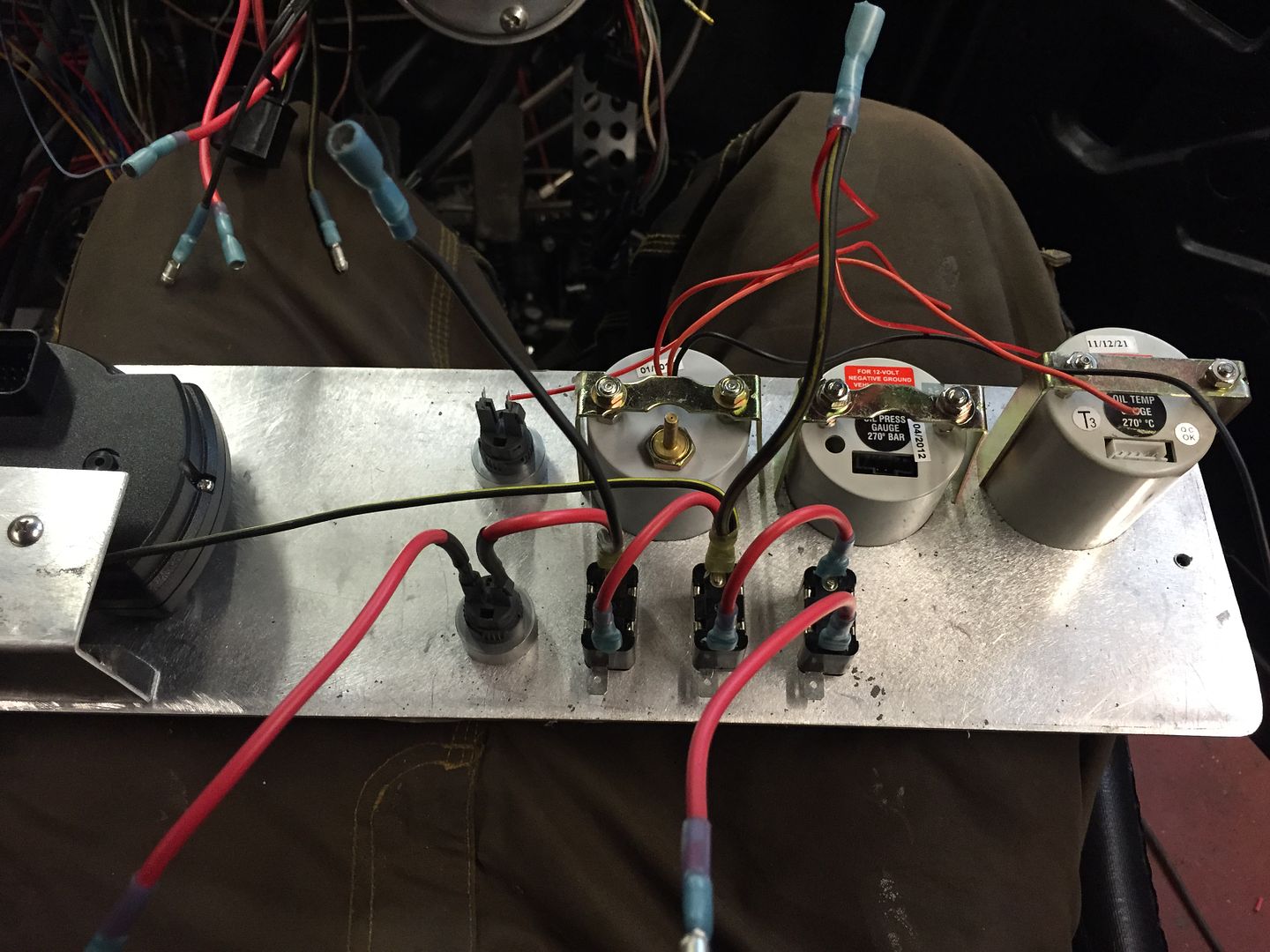

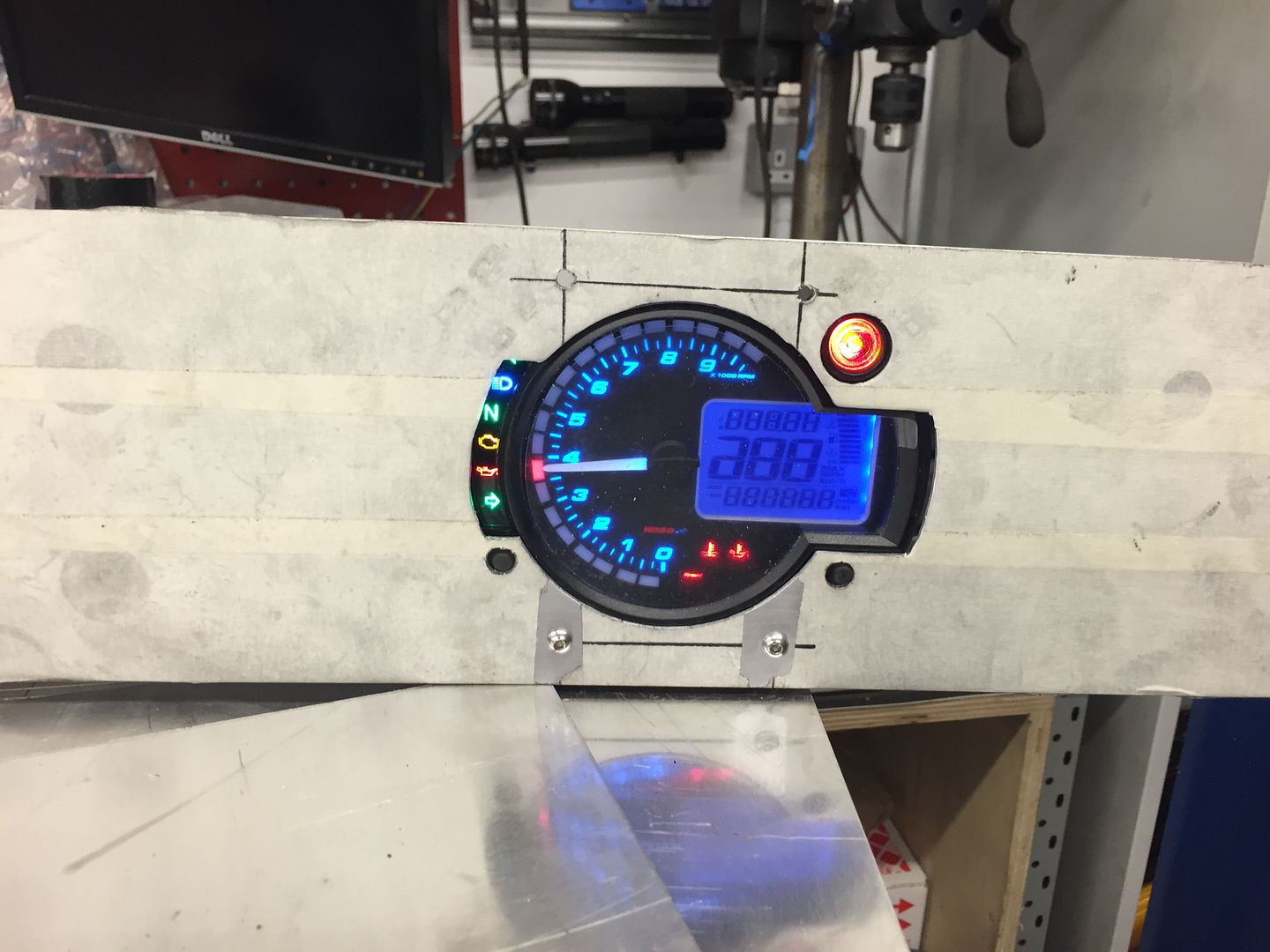

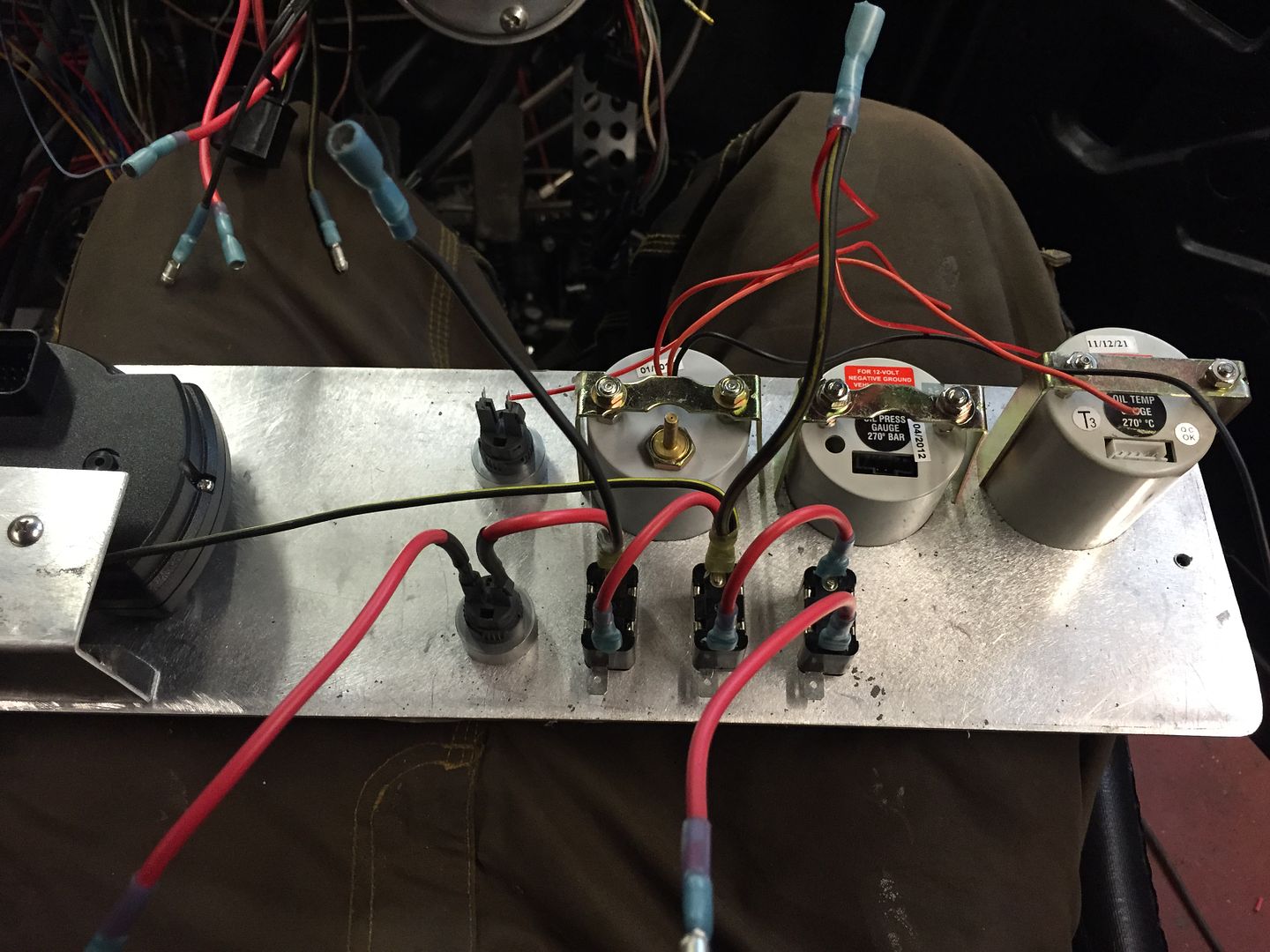

Then got to start making a new dash panel. I decided to use a Koso RX1n motor cylcle gauge as the main instrument. It has every thing I need. RPM up to 10k with shift light, speed, oil temp, water temp, indicator leds etc pretty much everything you would find in the mk1 dash

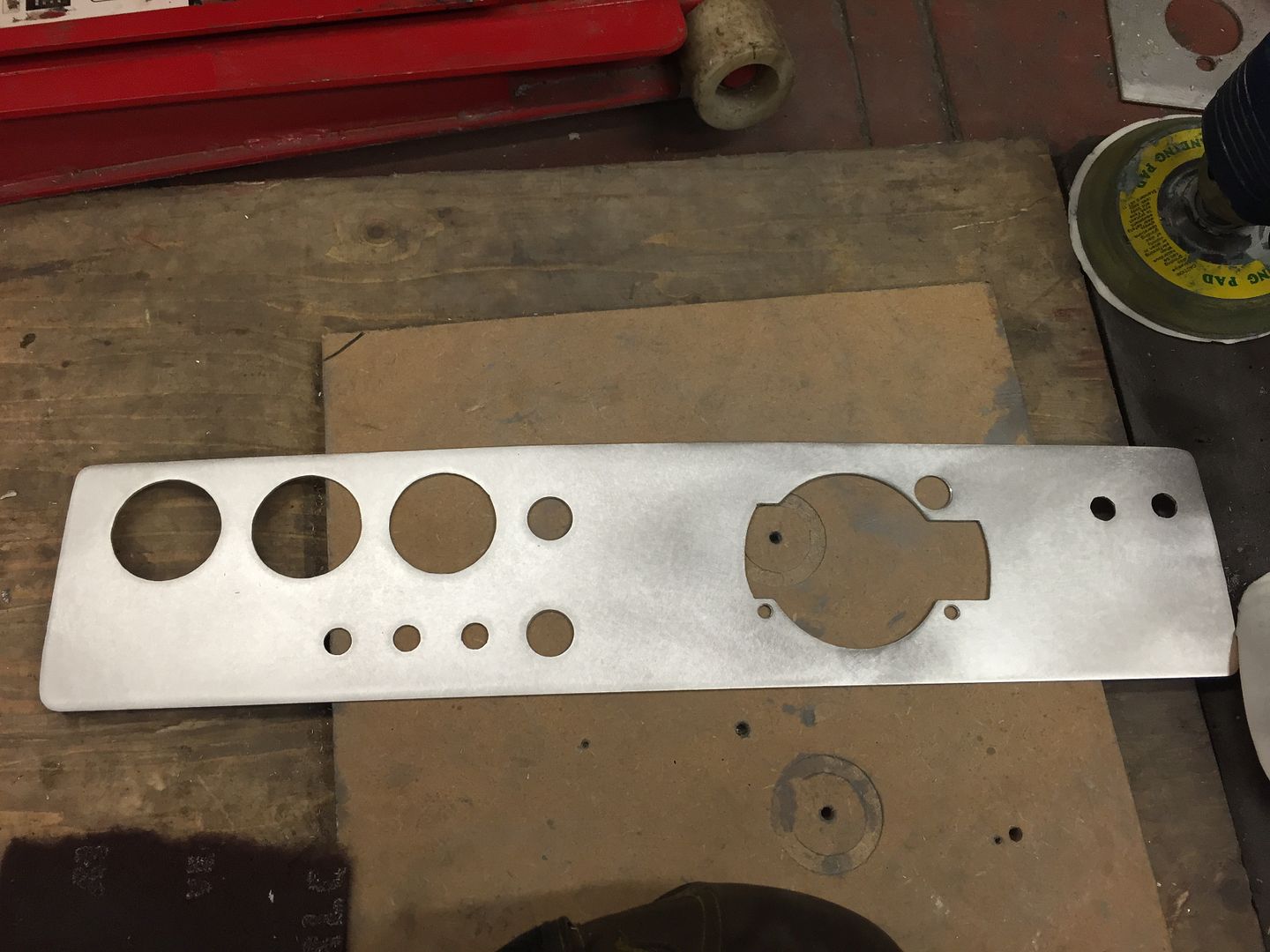

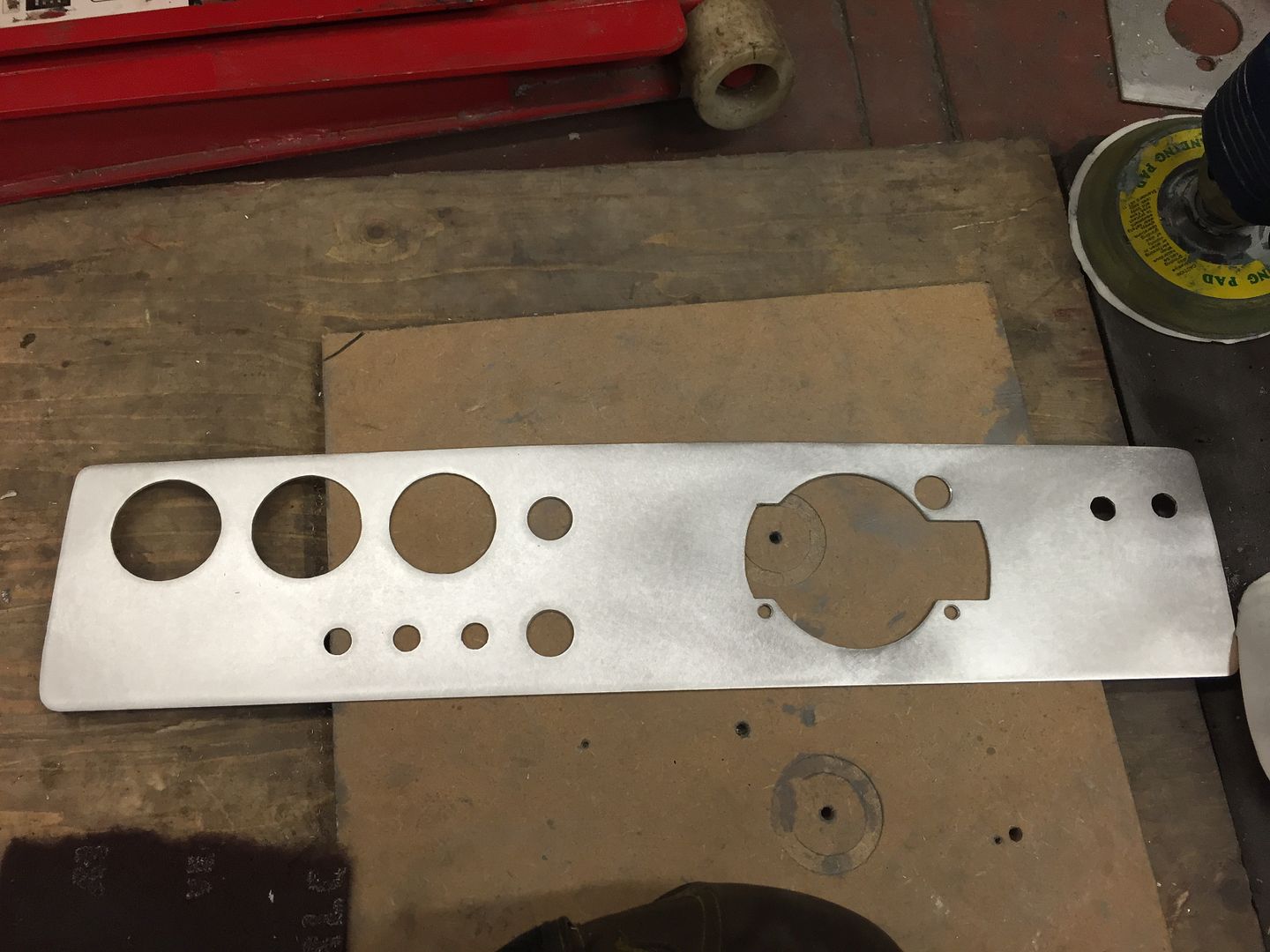

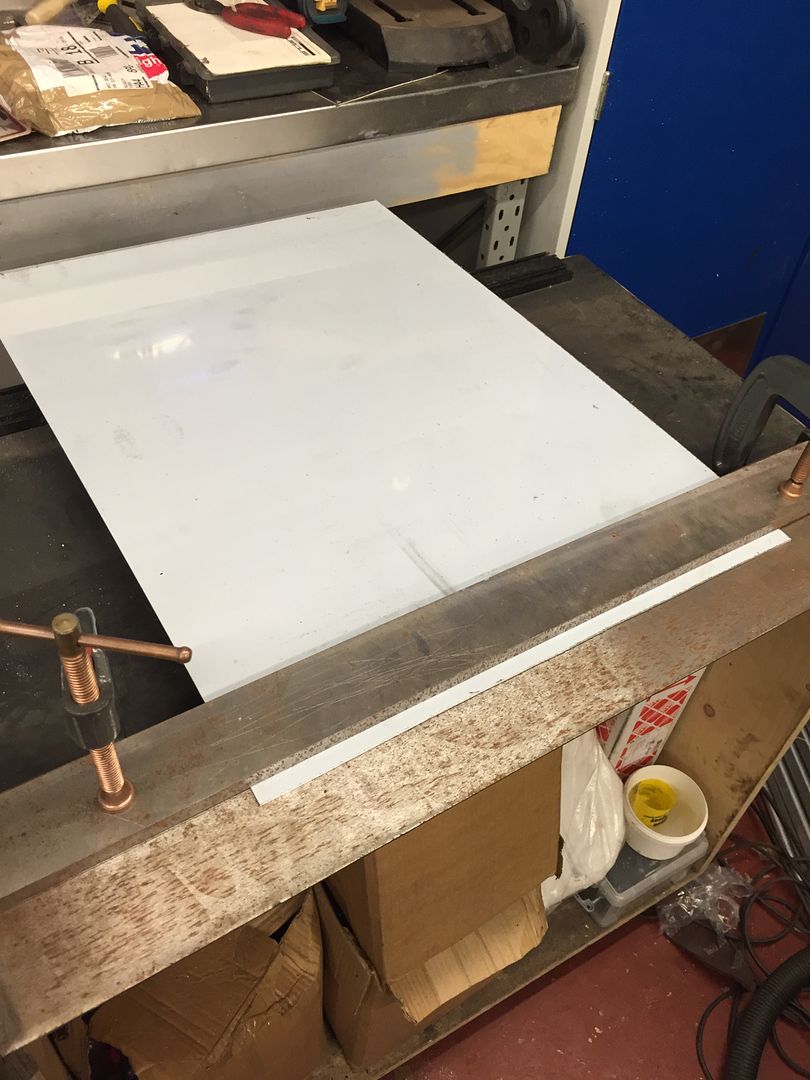

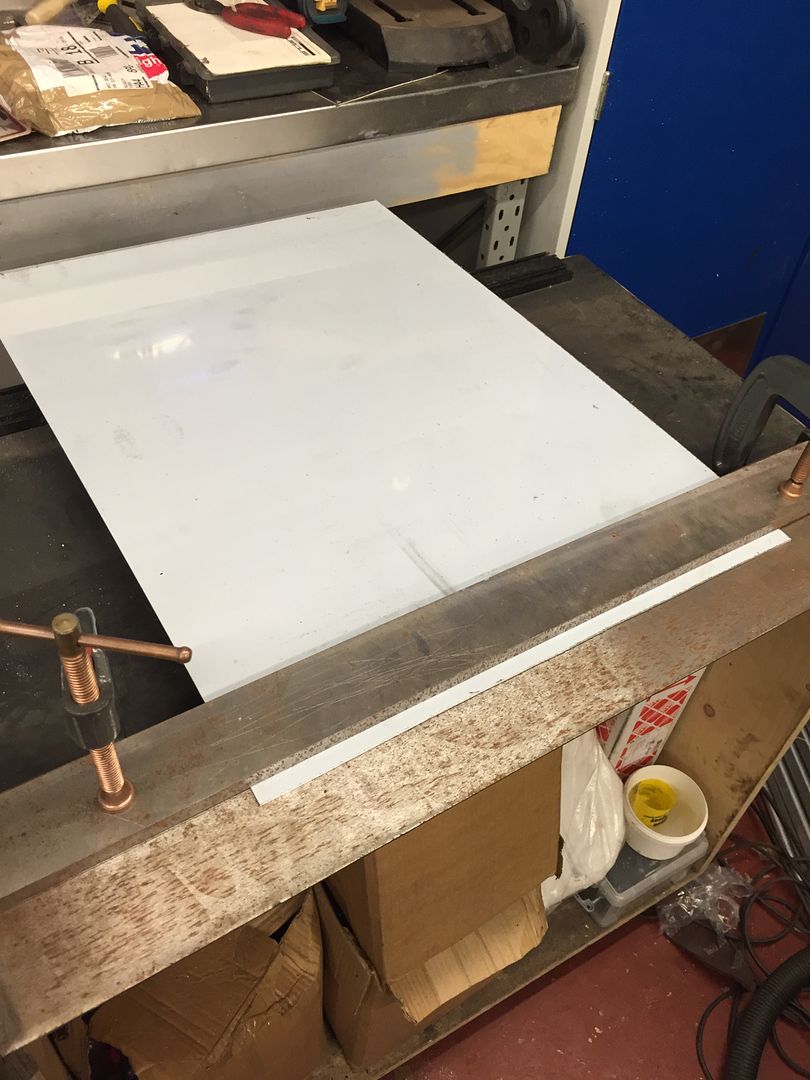

I bought a sheet of 2mm ally and made a panel that would fit perfectly into the mk1 binnacle

and gave it a nice brushed finish using a scotch bright pad.

I then test fitted the gauge, and wired it up to see how it looked.

Lovely

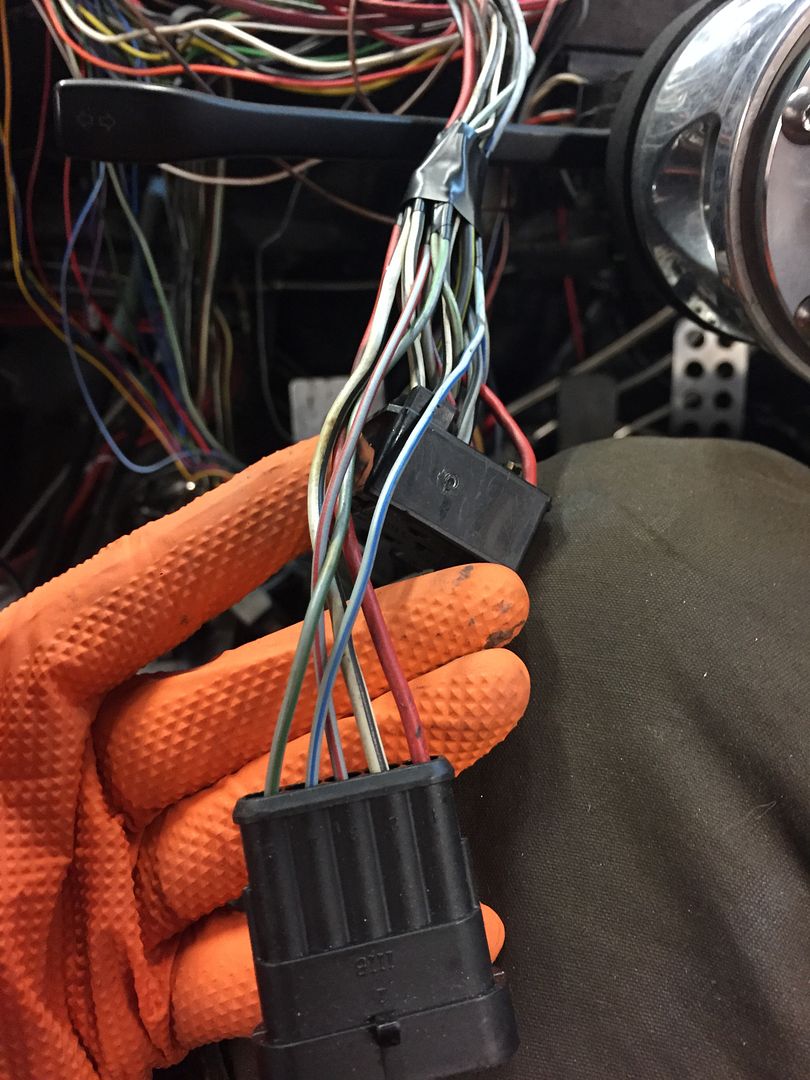

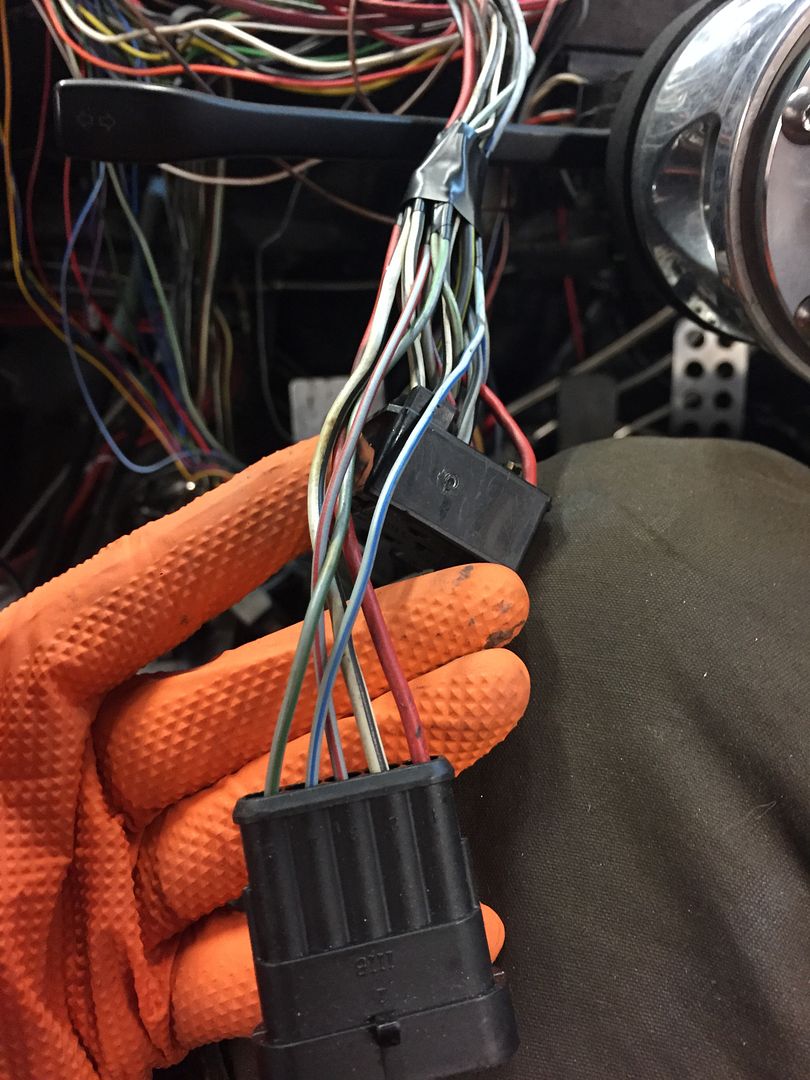

Next job was to hit up the wiring.. now this was a LONG process mapping all the wiring, figuring out the mk1 bits, the 20v bits etc. but got there in the end.

I spliced in new connectors to the existing wiring in case the original dash needs to go back in for what ever reason

and got a bit OCD with the soldering iron and heatshrink

end result

and a couple of vids

showing new starting procedure

and the wired partially working gauge

Chuffed to bits.. of I set to apex festival.

20mins from arrival, this happened.

If you can figure out what going on, thats me broken down on the M25.. As I was driving, I lost all power and couldnt restart the car. Oh well got some great pics out of it

Lovely MR RAC gave me a lift home

It transpired that my grasp of autoelectronics wasnt as good as I first thought. When I swapped the dash panel out, I didnt connect the alt warning light wire because the new gauge didnt have an alt warning light. Not connecting this wire meant the alternator wasnt energised and my piddly race battery went flat after about an hour of driving.

The First big show of the season for me was the APEX Festival where I was going to be a track demo car, and I wanted to make some major improvements to the interior.

Most of the dash didnt work after the 20v conversion. No speedo, no tacho. I didnt like how the CAE shifter was mounted, the floors looked shabby, the doors looked shabby so decided the focus for this year would be interior.. but we didnt stop there.. it would only be fair to make some performance improvements too.

So on with the story.

A reminder of how the dash and shifter looked. The CAE shifter I had was designed for a corrado so had to mount it on an ugly plinth to get the right height, and the dash was just the standard mk1 dash. not very race car.. so I stripped out the lot.

I purchased the proper mk1 CAE shifter and installed it which looks a thousand times better. I also got rid of the hydraulic hand brake as we never used it.

Then got to start making a new dash panel. I decided to use a Koso RX1n motor cylcle gauge as the main instrument. It has every thing I need. RPM up to 10k with shift light, speed, oil temp, water temp, indicator leds etc pretty much everything you would find in the mk1 dash

I bought a sheet of 2mm ally and made a panel that would fit perfectly into the mk1 binnacle

and gave it a nice brushed finish using a scotch bright pad.

I then test fitted the gauge, and wired it up to see how it looked.

Lovely

Next job was to hit up the wiring.. now this was a LONG process mapping all the wiring, figuring out the mk1 bits, the 20v bits etc. but got there in the end.

I spliced in new connectors to the existing wiring in case the original dash needs to go back in for what ever reason

and got a bit OCD with the soldering iron and heatshrink

end result

and a couple of vids

showing new starting procedure

and the wired partially working gauge

Chuffed to bits.. of I set to apex festival.

20mins from arrival, this happened.

If you can figure out what going on, thats me broken down on the M25.. As I was driving, I lost all power and couldnt restart the car. Oh well got some great pics out of it

Lovely MR RAC gave me a lift home

It transpired that my grasp of autoelectronics wasnt as good as I first thought. When I swapped the dash panel out, I didnt connect the alt warning light wire because the new gauge didnt have an alt warning light. Not connecting this wire meant the alternator wasnt energised and my piddly race battery went flat after about an hour of driving.

Back to the story..

With Apex out of the way, it was time to get ready for players and continue on the interior improvements.

Now that I had a new dash panel, I no longer need the little atv gauge that showed me water temp. That gave me great space to relocate the kill switch that used to live in base of the shifter tower.

I remade the whole panel because I wasnt happy with the previous USB charging ports

and fitted it in the ash try position

I also revisited the dash panel and cleaned up some of my hasty work from before

Adding some nice detail around the cut out

Up till now, I had never had a working speedo in the car. Always relying on GPS app on my phone.

My car has a 20v conversion so the first thing I tried was using the VSS signal straight out the gearbox sender into the new gauge, but it was the wrong voltage so didnt work.

Decided it would be best to use the hall sender that came with the gauge. I installed it to pick up the heads off the drive shaft bolts which worked a treat!

With the dash side of things complete, it was time to move onto the floors

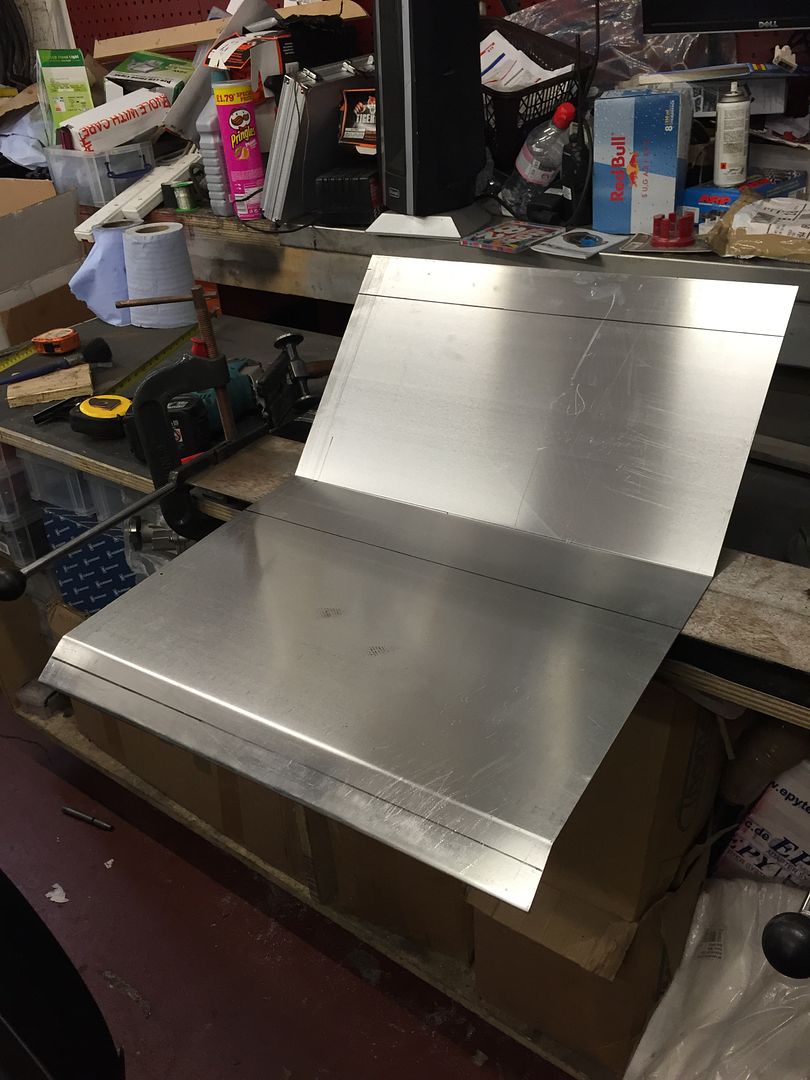

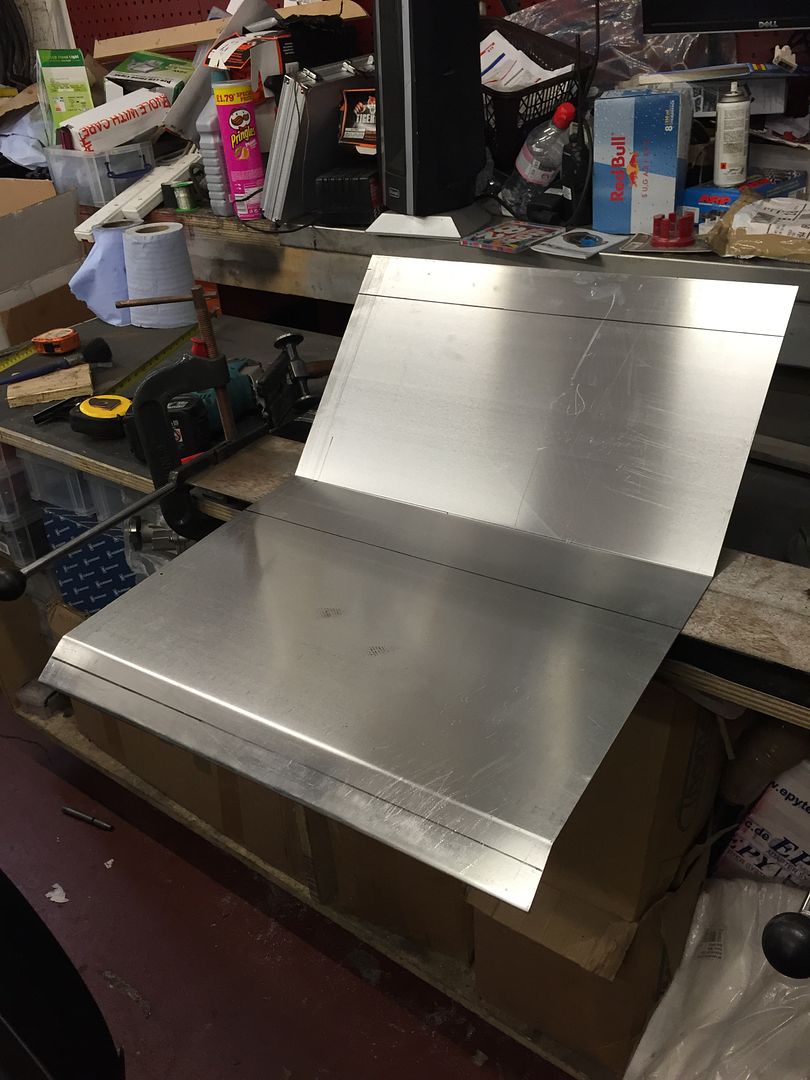

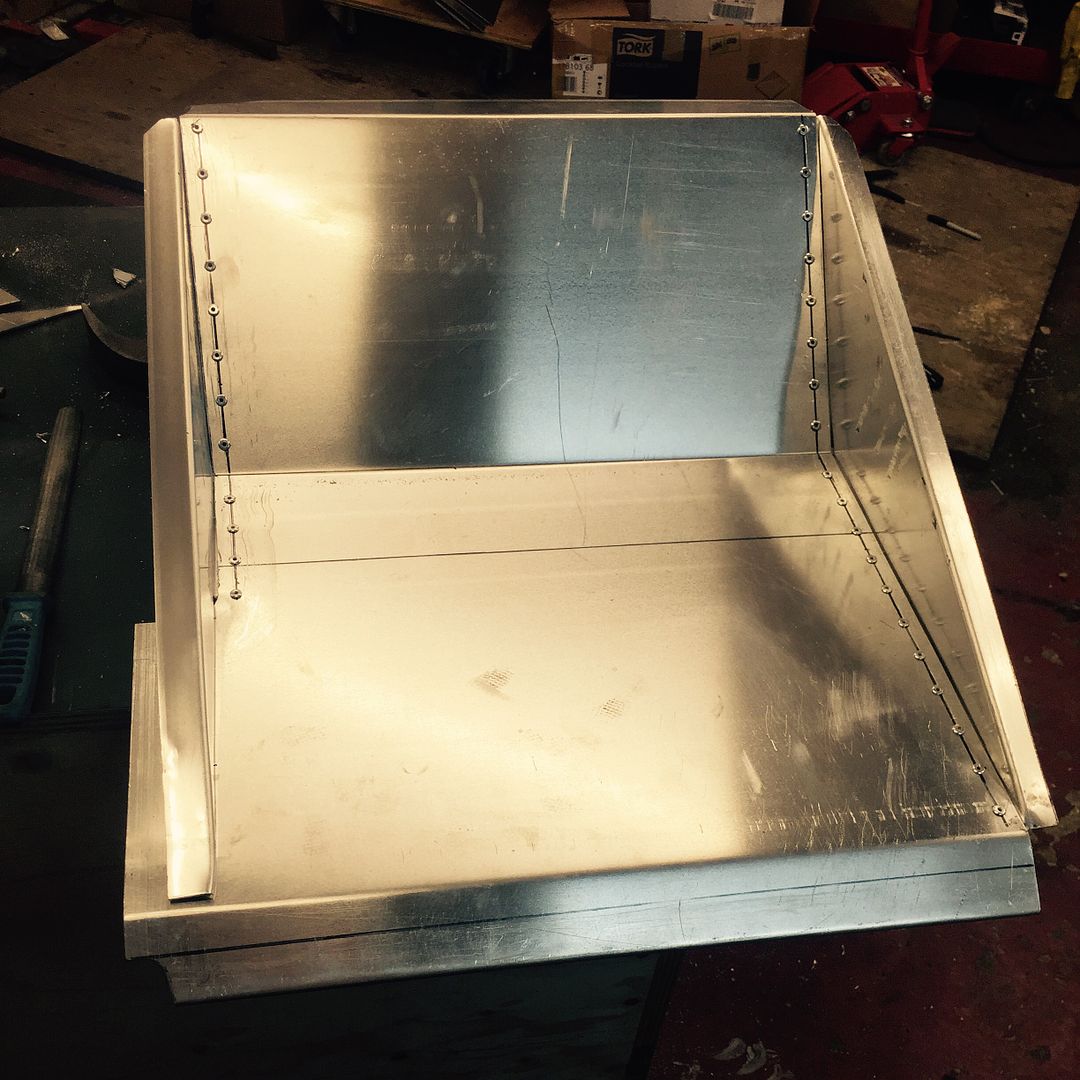

I bought some 2mm ally sheet and decided to make a fitted navigator foot rest and rally floor plate.

I got to work with my crappy bench folder.

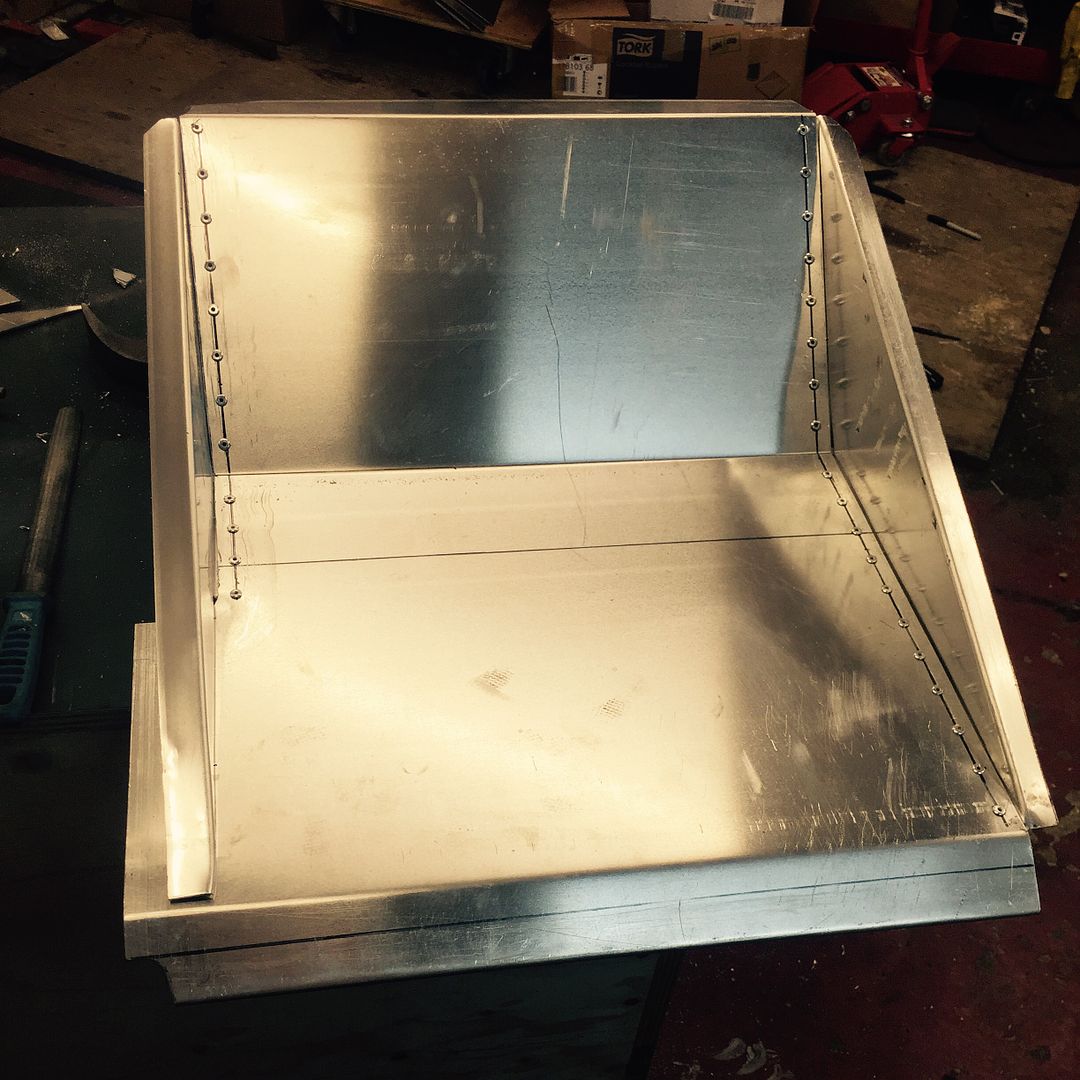

and all riveted together as I dont have a tig

before finally fitting it to the car, I punched some holes and added some grip tape

and then made something similar for the drivers side

More tomorrow

With Apex out of the way, it was time to get ready for players and continue on the interior improvements.

Now that I had a new dash panel, I no longer need the little atv gauge that showed me water temp. That gave me great space to relocate the kill switch that used to live in base of the shifter tower.

I remade the whole panel because I wasnt happy with the previous USB charging ports

and fitted it in the ash try position

I also revisited the dash panel and cleaned up some of my hasty work from before

Adding some nice detail around the cut out

Up till now, I had never had a working speedo in the car. Always relying on GPS app on my phone.

My car has a 20v conversion so the first thing I tried was using the VSS signal straight out the gearbox sender into the new gauge, but it was the wrong voltage so didnt work.

Decided it would be best to use the hall sender that came with the gauge. I installed it to pick up the heads off the drive shaft bolts which worked a treat!

With the dash side of things complete, it was time to move onto the floors

I bought some 2mm ally sheet and decided to make a fitted navigator foot rest and rally floor plate.

I got to work with my crappy bench folder.

and all riveted together as I dont have a tig

before finally fitting it to the car, I punched some holes and added some grip tape

and then made something similar for the drivers side

More tomorrow

Update time.

The next area to tackle was the clutch. It had started to slip so we pulled to box and made a few other improvements while we were at it.

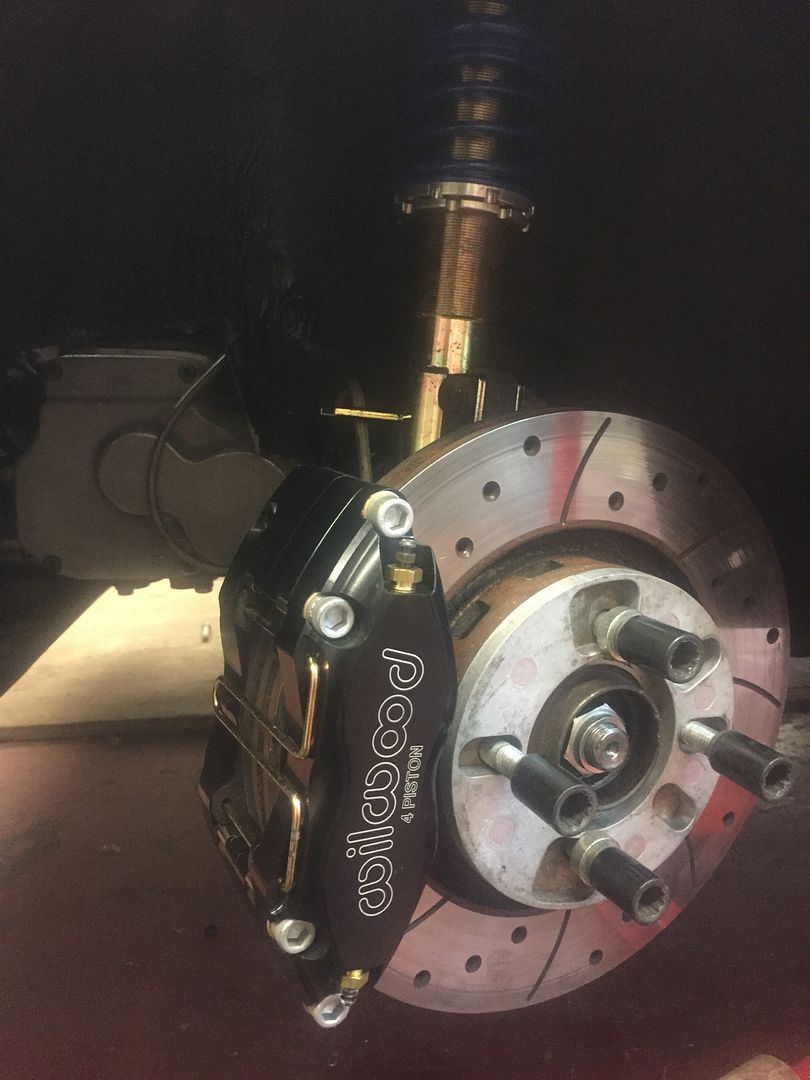

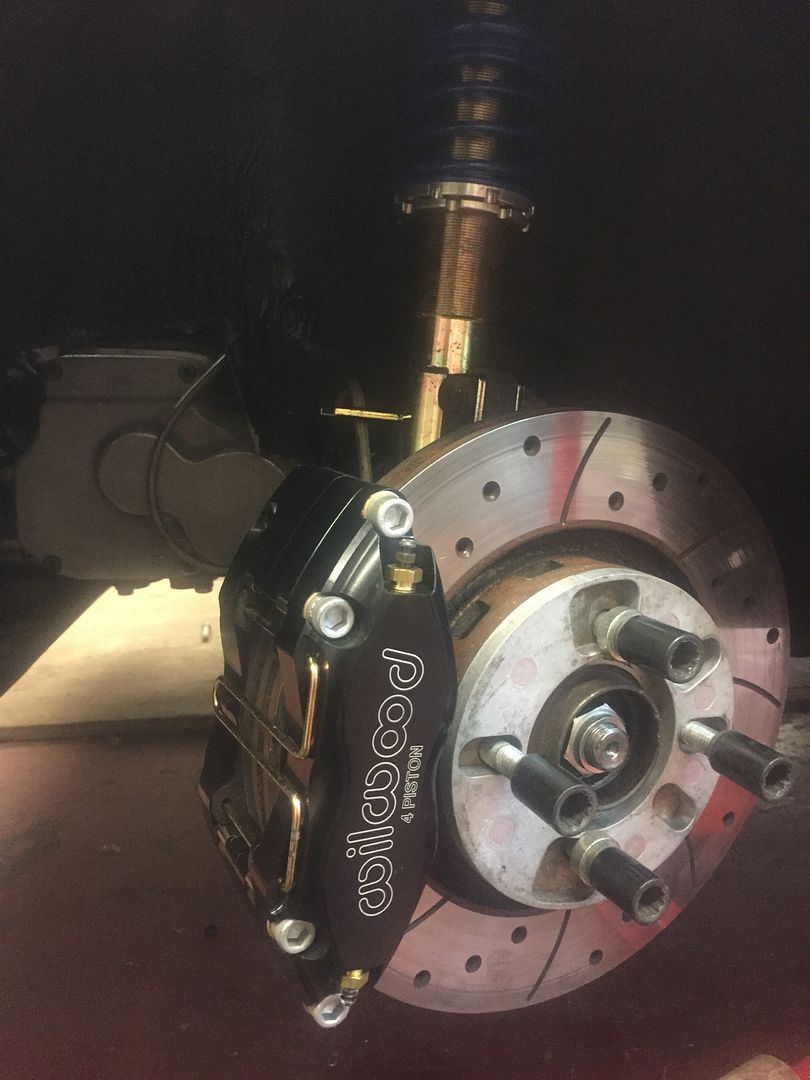

First up, a 6spd Quaife Dog box, new brakes, and new coilovers

Then it was time for a road test..

Boy was that epic! Check out the vid here. The sound of the dog box is incredible.

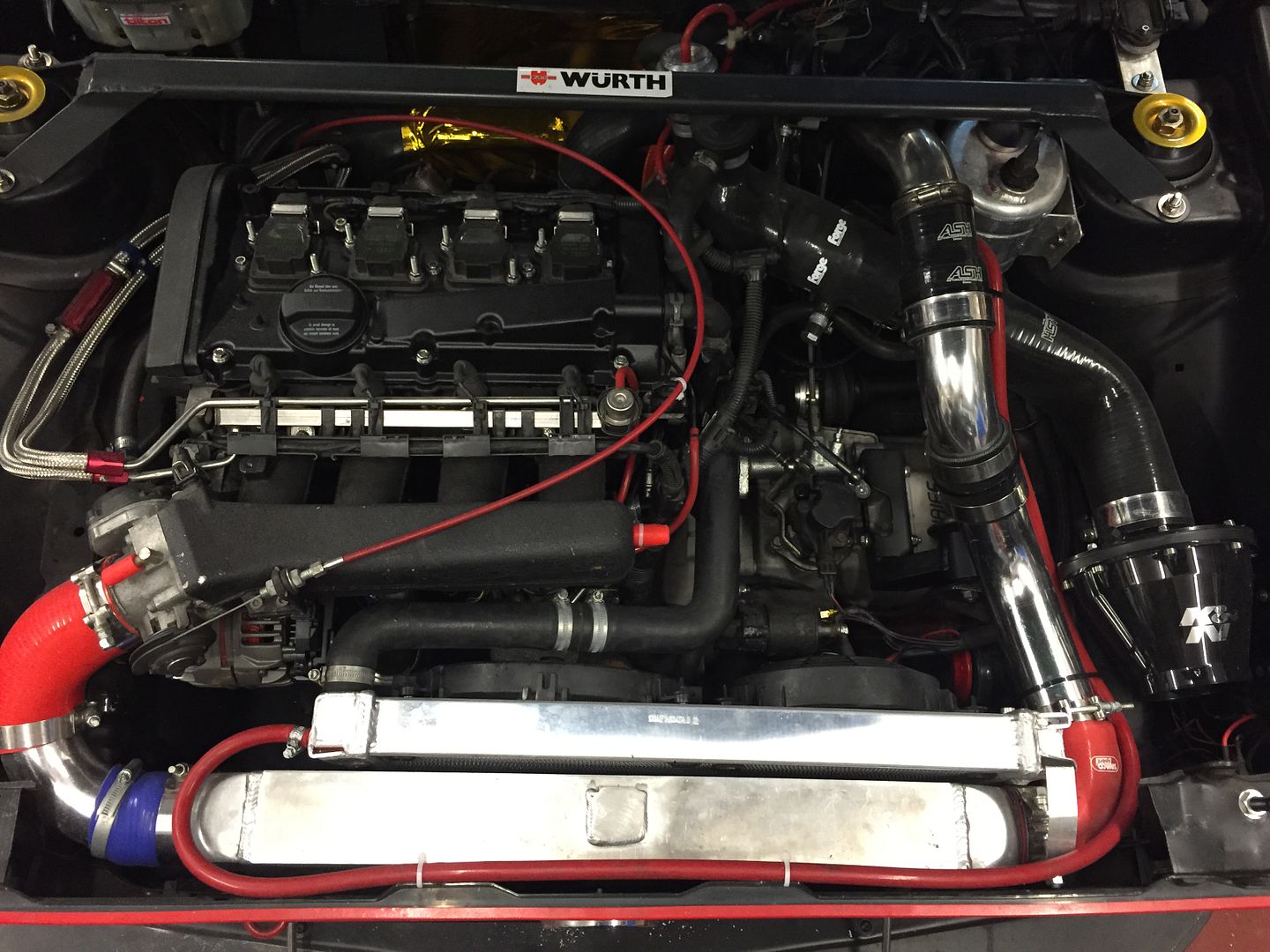

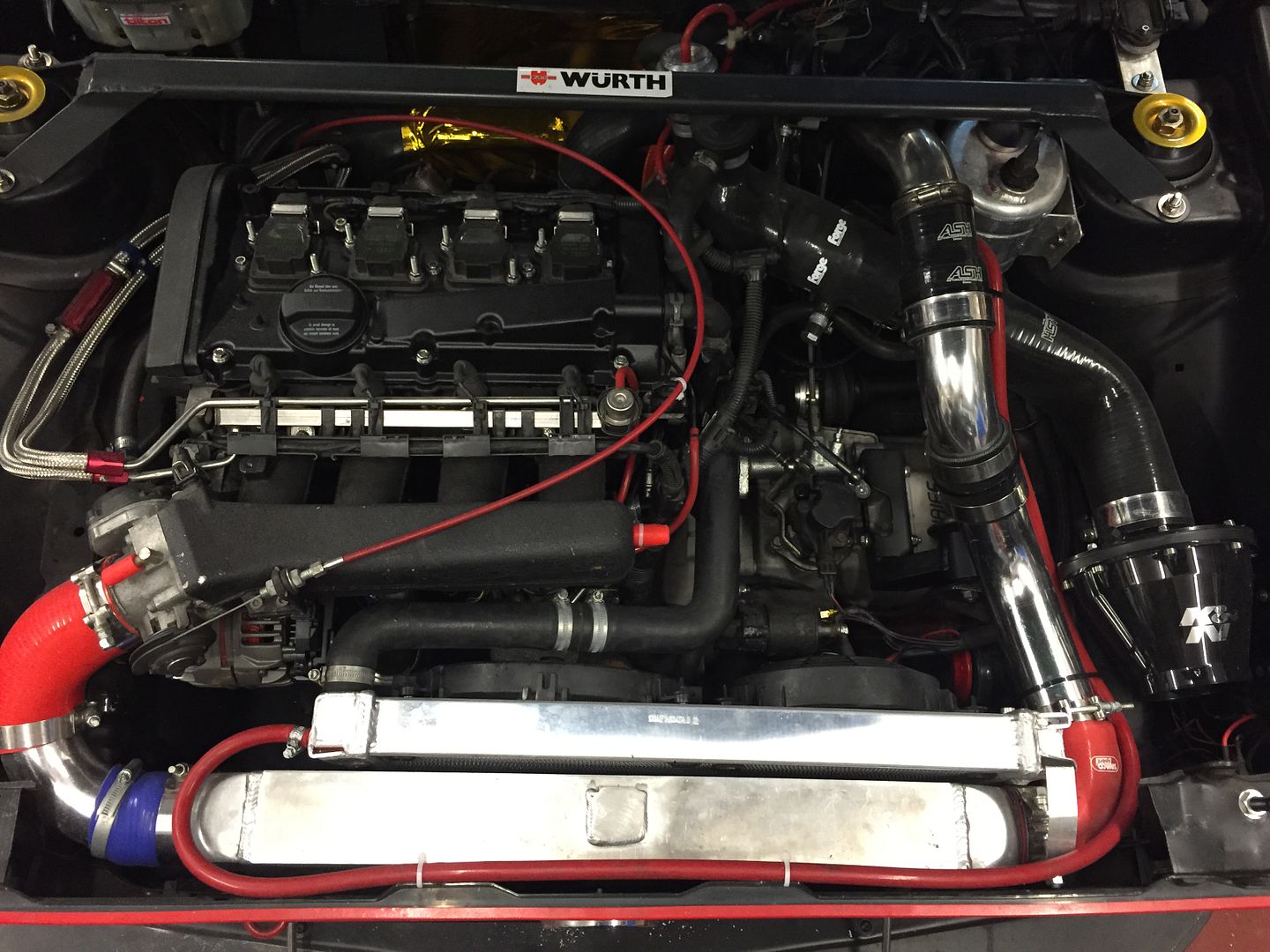

We also decided to give the engine bay a bit of love as it was looking a bit tired.

Powder coated the cam cover, new rad, powder coated top mounts, new fluid res, re did the boost plumbing, and the list goes on

Finished result

Powder coated the cam cover, new rad, powder coated top mounts, new fluid res, re did the boost plumbing, and the list goes on

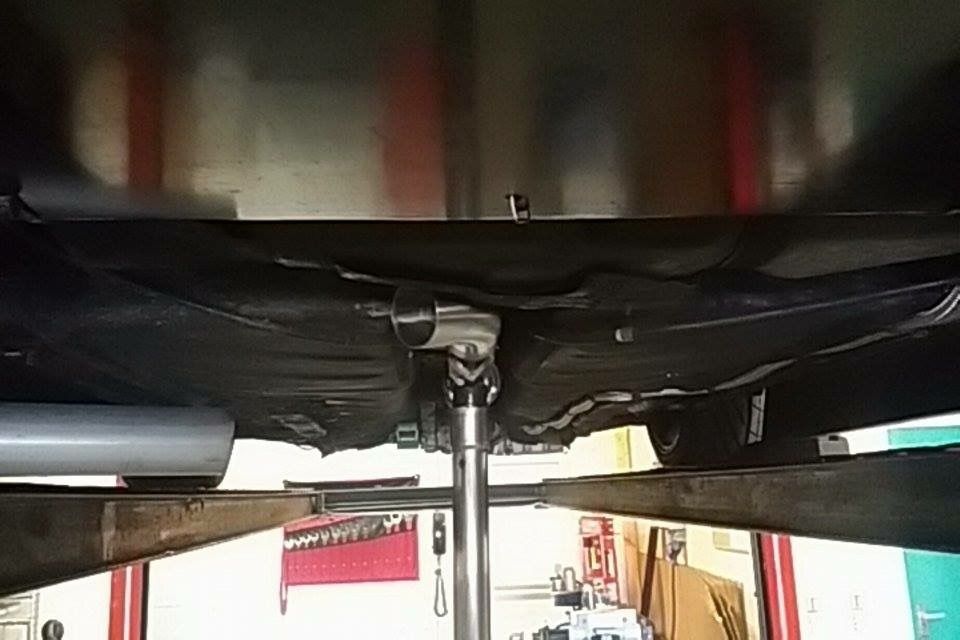

Next up was the exhaust

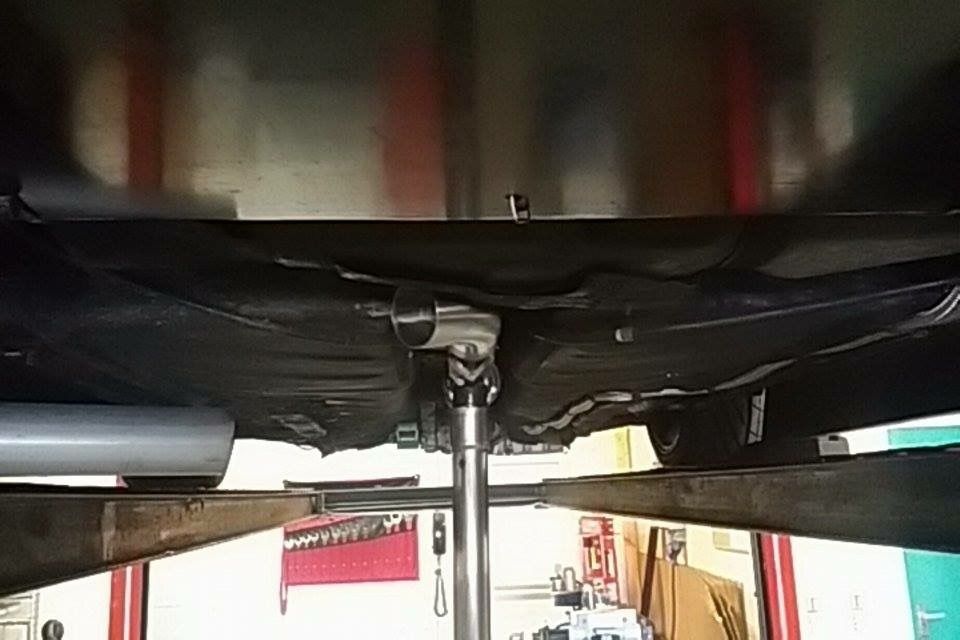

The current system was hashed together using off the shelf bends and clamped together. It hung down low and we were constantly catching it and ripping it off..

After smashing it one last time, enough was enough so I took the car down to Style Dynamix to have a custom tucked exhaust made.

The boys did a great job.

And that was us sorted for players.

And as far as I could tell, the car was a hit.

Thanks to Jack Lindley and MFA for some great pics.

The next area to tackle was the clutch. It had started to slip so we pulled to box and made a few other improvements while we were at it.

First up, a 6spd Quaife Dog box, new brakes, and new coilovers

Then it was time for a road test..

Boy was that epic! Check out the vid here. The sound of the dog box is incredible.

We also decided to give the engine bay a bit of love as it was looking a bit tired.

Powder coated the cam cover, new rad, powder coated top mounts, new fluid res, re did the boost plumbing, and the list goes on

Finished result

Powder coated the cam cover, new rad, powder coated top mounts, new fluid res, re did the boost plumbing, and the list goes on

Next up was the exhaust

The current system was hashed together using off the shelf bends and clamped together. It hung down low and we were constantly catching it and ripping it off..

After smashing it one last time, enough was enough so I took the car down to Style Dynamix to have a custom tucked exhaust made.

The boys did a great job.

And that was us sorted for players.

And as far as I could tell, the car was a hit.

Thanks to Jack Lindley and MFA for some great pics.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff