Ferrari F430 Spider

Discussion

Thanks all. The 16M is my favourite car and this started out as me trying to recreate one, so I really don't have a problem with it being called a replica. I think the word has negative connotations because they usually stop at bodykits or are generally poor imitations. To a collector of course my car will never be a 16M, but to me it will be because I'm focused on the specification and ultimately how it drives and feels to own; not what it was registered as.

The project did evolve so I may well look at the badges at some point if nothing else other than to save the 0.5kg of weight. If I do change them I will likely use CNC machined 3mm carbon which I'll then paint. The OEM badges are really nice, though, so I may well never do it.

The other aspect to this is the paddles themselves. One of the reasons I dislike the originals is the distance between the finger contact area and the fulcrum, which results in circa 25mm of travel from the initial touch to microswitch activation and a slight lack of rigidity. In contrast the wheel mounted paddles I'm using have just 5mm of movement before switch activation and feel rock solid, but importantly that 16.67% reduction in travel means my solution will have a signal back at the TCU before the OEM setup has even registered a press on the switches.

Is that just engine designation? (Some of your diagrams also have 136 on them).Yes, it is: F131 is the chassis code and F136 is the F430 engine code.

The project did evolve so I may well look at the badges at some point if nothing else other than to save the 0.5kg of weight. If I do change them I will likely use CNC machined 3mm carbon which I'll then paint. The OEM badges are really nice, though, so I may well never do it.

True Gaucho said:

Impressive stuff as always! Is there any potential that introducing this extra interface between the paddles and gearbox wil cause any slow down in gearshift times? I'm sure the answer is no, given your focus on improving the car, but thought I'd ask :-)

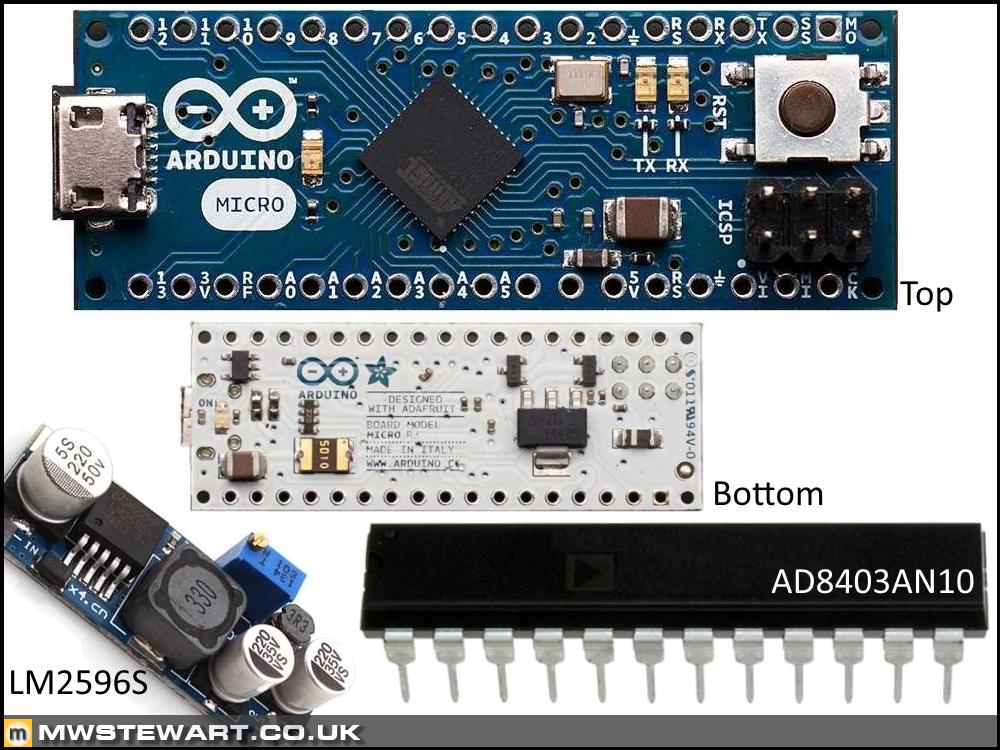

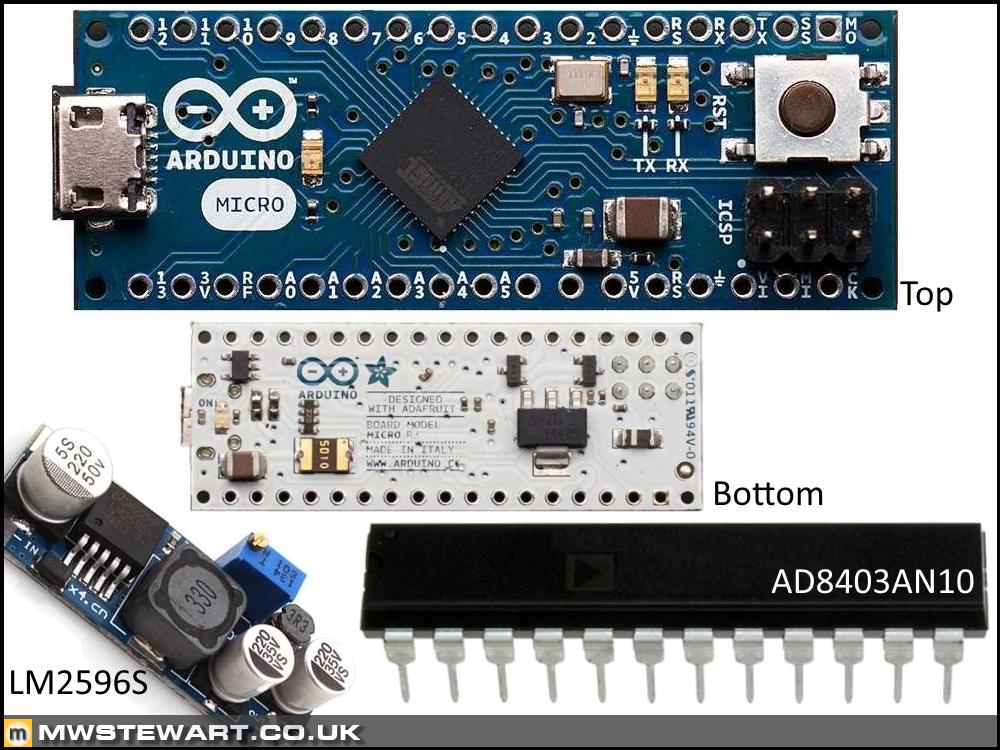

Great question. That was at the core of my design decisions and why a mechanical relay was never an option. The slowest device in the circuit is the AD8403AN10 digital potentiometer which can accept updates at 10MHz clock speed, so even cutting that in half to 5MHz to allow for the data transmission and actuation of pots, that's a potential 5,000,000,000 updates per second i.e. completely undetectable. In comparison the TCU itself has to do an exponential amount more and communicate on two different buses before a change is activated, and even that's undetectable by us humans.The other aspect to this is the paddles themselves. One of the reasons I dislike the originals is the distance between the finger contact area and the fulcrum, which results in circa 25mm of travel from the initial touch to microswitch activation and a slight lack of rigidity. In contrast the wheel mounted paddles I'm using have just 5mm of movement before switch activation and feel rock solid, but importantly that 16.67% reduction in travel means my solution will have a signal back at the TCU before the OEM setup has even registered a press on the switches.

ferrisbueller said:

mwstewart said:

The model designation for the F430 is F131. I've learnt there is a different suffix for the various models and knowing that sometimes aids me when identifying parts.

F131 E - Standard car

F131 EA - Challenge

F131 LP - Scuderia

F131 JD - 16M specific parts

I had thought the 360 is 131 and the 430 is 136.F131 E - Standard car

F131 EA - Challenge

F131 LP - Scuderia

F131 JD - 16M specific parts

Is that just engine designation? (Some of your diagrams also have 136 on them).

gcpeters said:

I would worry about using those Arduinos, they are designed for the "Maker" community and have been known to fail, often! Same with RPi3s etc etc. There is going to be some latency introduced but I guess until you test you will never know

I wouldn't trust the Chinese versions that sell really cheap on eBay so I went for a genuine board. I think it will be fine - it's pretty simple really - but I will make sure the connections and mountings are secure.

mwstewart said:

I’ve purchased a Genuino (Ardunino) Micro which is a small microcontroller with a number of input and output pins that comes with a development environment so that custom code can be uploaded to it, and so the possibilities are endless. I’ve also picked up a AD8403AN10 quad channel digital potentiometer which I will communicate with from the Arduino over something called the Serial Peripheral Interface Bus. Finally, a LM2596S based voltage regulator to ensure the components receive a steady 5v regardless of alternator and battery output.

I'm going to write some code that will vary the resistance of three pots to match paddle position. The three outputs being connected to the up, down, and standy wires to the TCU.

I'll package the whole lot in a small enclosure to create a steering wheel paddle module.

Braking update

I'm going to use another Arduino to create an EPB module to control the two Brembo EPB motors. At this stage I don't know if the Speciale EPB motors have integrated hall effect sensors to detect when the parking brake is fully engaged, or whether I'll use a current sensing circuit to determine that.

This is my field and whilst i think you'll probably do a good job of it, there are a LOT of pitfalls to be wary of when doing automotive electronics!

I'm going to write some code that will vary the resistance of three pots to match paddle position. The three outputs being connected to the up, down, and standy wires to the TCU.

I'll package the whole lot in a small enclosure to create a steering wheel paddle module.

Braking update

I'm going to use another Arduino to create an EPB module to control the two Brembo EPB motors. At this stage I don't know if the Speciale EPB motors have integrated hall effect sensors to detect when the parking brake is fully engaged, or whether I'll use a current sensing circuit to determine that.

1) google "automotive load dump". That should suitably scare you. Your LM2596, whilst a reasonable choice, assuming you don't have to meet EMC requirements, is insufficient on its own. It will need to be protected against input voltage transients

2) Digital pots, whilst easy to use, bring some penalties, and issues. You need to be very sure what happens in any reset / power-up or brownout state for example. They also have a very limited current capability, and can have grounding issues, if the ground potential of your current source is not the same as the pots ground. I'd suggest, for this simple task requiring just a few different resistance settings to simple switch fixed resistance values in and out, using a suitable transistor (ULM2003 is an easy to interface too choice)

3) Fail safe - in this application, you may want to consider a hardware watchdog that drives a suitable analogue switch or small relay, which should the processor fail (or your code have issues) or brown-out, immediately isolates the system from the TCU, so you don't get any ghost shifting etc. Whilst the TCU probably is smart enough to ignore "stupid" shift requests, id want to be robust against this myself

4) EPB - note, this is a SAFETY CRITICAL component. Your engineering, design and VALIDATION needs to be top notch.........

Don't be put off, just make sure you read up, understand, and engineer properly, which i more than think you are capable of ;-)

Max_Torque said:

This is my field and whilst i think you'll probably do a good job of it, there are a LOT of pitfalls to be wary of when doing automotive electronics!

1) google "automotive load dump". That should suitably scare you. Your LM2596, whilst a reasonable choice, assuming you don't have to meet EMC requirements, is insufficient on its own. It will need to be protected against input voltage transients

2) Digital pots, whilst easy to use, bring some penalties, and issues. You need to be very sure what happens in any reset / power-up or brownout state for example. They also have a very limited current capability, and can have grounding issues, if the ground potential of your current source is not the same as the pots ground. I'd suggest, for this simple task requiring just a few different resistance settings to simple switch fixed resistance values in and out, using a suitable transistor (ULM2003 is an easy to interface too choice)

3) Fail safe - in this application, you may want to consider a hardware watchdog that drives a suitable analogue switch or small relay, which should the processor fail (or your code have issues) or brown-out, immediately isolates the system from the TCU, so you don't get any ghost shifting etc. Whilst the TCU probably is smart enough to ignore "stupid" shift requests, id want to be robust against this myself

4) EPB - note, this is a SAFETY CRITICAL component. Your engineering, design and VALIDATION needs to be top notch.........

Don't be put off, just make sure you read up, understand, and engineer properly, which i more than think you are capable of ;-)

Thanks Max, much appreciated! Your advice has found me discovering and reading into ISO 16750-2 and it now surprises me even more that some people are happy to relay on the Arduino's internal regulator. I'll post up my work as I go so if you've any further advice I'll gladly take it.1) google "automotive load dump". That should suitably scare you. Your LM2596, whilst a reasonable choice, assuming you don't have to meet EMC requirements, is insufficient on its own. It will need to be protected against input voltage transients

2) Digital pots, whilst easy to use, bring some penalties, and issues. You need to be very sure what happens in any reset / power-up or brownout state for example. They also have a very limited current capability, and can have grounding issues, if the ground potential of your current source is not the same as the pots ground. I'd suggest, for this simple task requiring just a few different resistance settings to simple switch fixed resistance values in and out, using a suitable transistor (ULM2003 is an easy to interface too choice)

3) Fail safe - in this application, you may want to consider a hardware watchdog that drives a suitable analogue switch or small relay, which should the processor fail (or your code have issues) or brown-out, immediately isolates the system from the TCU, so you don't get any ghost shifting etc. Whilst the TCU probably is smart enough to ignore "stupid" shift requests, id want to be robust against this myself

4) EPB - note, this is a SAFETY CRITICAL component. Your engineering, design and VALIDATION needs to be top notch.........

Don't be put off, just make sure you read up, understand, and engineer properly, which i more than think you are capable of ;-)

I've also joined EEVblog - I see you also participate there.

mwstewart said:

Max_Torque said:

This is my field and whilst i think you'll probably do a good job of it, there are a LOT of pitfalls to be wary of when doing automotive electronics!

1) google "automotive load dump". That should suitably scare you. Your LM2596, whilst a reasonable choice, assuming you don't have to meet EMC requirements, is insufficient on its own. It will need to be protected against input voltage transients

2) Digital pots, whilst easy to use, bring some penalties, and issues. You need to be very sure what happens in any reset / power-up or brownout state for example. They also have a very limited current capability, and can have grounding issues, if the ground potential of your current source is not the same as the pots ground. I'd suggest, for this simple task requiring just a few different resistance settings to simple switch fixed resistance values in and out, using a suitable transistor (ULM2003 is an easy to interface too choice)

3) Fail safe - in this application, you may want to consider a hardware watchdog that drives a suitable analogue switch or small relay, which should the processor fail (or your code have issues) or brown-out, immediately isolates the system from the TCU, so you don't get any ghost shifting etc. Whilst the TCU probably is smart enough to ignore "stupid" shift requests, id want to be robust against this myself

4) EPB - note, this is a SAFETY CRITICAL component. Your engineering, design and VALIDATION needs to be top notch.........

Don't be put off, just make sure you read up, understand, and engineer properly, which i more than think you are capable of ;-)

Thanks Max, much appreciated! Your advice has found me discovering and reading into ISO 16750-2 and it now surprises me even more that some people are happy to relay on the Arduino's internal regulator. I'll post up my work as I go so if you've any further advice I'll gladly take it.1) google "automotive load dump". That should suitably scare you. Your LM2596, whilst a reasonable choice, assuming you don't have to meet EMC requirements, is insufficient on its own. It will need to be protected against input voltage transients

2) Digital pots, whilst easy to use, bring some penalties, and issues. You need to be very sure what happens in any reset / power-up or brownout state for example. They also have a very limited current capability, and can have grounding issues, if the ground potential of your current source is not the same as the pots ground. I'd suggest, for this simple task requiring just a few different resistance settings to simple switch fixed resistance values in and out, using a suitable transistor (ULM2003 is an easy to interface too choice)

3) Fail safe - in this application, you may want to consider a hardware watchdog that drives a suitable analogue switch or small relay, which should the processor fail (or your code have issues) or brown-out, immediately isolates the system from the TCU, so you don't get any ghost shifting etc. Whilst the TCU probably is smart enough to ignore "stupid" shift requests, id want to be robust against this myself

4) EPB - note, this is a SAFETY CRITICAL component. Your engineering, design and VALIDATION needs to be top notch.........

Don't be put off, just make sure you read up, understand, and engineer properly, which i more than think you are capable of ;-)

I've also joined EEVblog - I see you also participate there.

Interior parts retrim and paddles

Part of the Christmas present from my OH was a retrim to my spec of various leather interior parts. The present wasn't a surprise but the results were. The chap who did this for me works for Bentley and is one of the few remaining who do so; his team deal with really bespoke requests and rectification of any defects from the robotised production process.

I've gone with red leather for the control interfaces but not the Ferrari Rosso leather because it looks a bit dull next to Rosso paint. As this was a 599 GTO wheel the rear was covered in Alcantara, but I've changed it to black smooth grain Nappa. The bottom is Alcantara 9040 Deep Black which will match some other trim parts yet to be completed.

I am over the moon with how my paddle conversion turned out.

The extended paddles are back from paint and match my wheels, F1 panel, interior air vents, and HVAC control knobs.

Extended paddles fitted.

Handbrake lever in perforated red leather.

A new handbrake gatier for the Scuderia console, this time in leather.

I've gone for plain red leather for the centre console tray inserts.

As with all convertible cars the interior trim is subject to more dust than a hard top car so I've taken the opportunity to clean behind any trim that's been removed.

Some of the new parts and Scuderia centre console fitted.

Headlamps

I have the headlamps apart to rebuild with the carbon inserts and I've taken the opportunity to change the bezel colour again: I repainted them in silver as per the Scuderia but there's nothing else on the car that colour, so I've had them repainted to match the wheels and other grey bits.

Misc

Hel stainless brake lines. I use Hel on my cars because they are a British company and also because the entire assembly is stainless.

I found Graypaul Nottingham were selling off new old stock of the original door catches. I don't expect the plastic insert to last any decent length of time but they were for sale at less than it would have cost me to have my originals re-plated.

The door jamb trim on my car had cracked in a few places and as expected, Ferrari charge a lot for it despite it being fairly standard square profile edge trim. I picked up a couple of metres for just over £6 and will see how it compares - there are many variations available.

Weight saving

Baselining the first table at 100.57kg. I'll start a new table from here. I moved the headlamps into this new table because fitting was delayed by the newly painted parts.

Sprung weight saved: 78.16 kg

Unsprung weight saved: 24.97 kg

Total weight saved: 103.13 kg

Part of the Christmas present from my OH was a retrim to my spec of various leather interior parts. The present wasn't a surprise but the results were. The chap who did this for me works for Bentley and is one of the few remaining who do so; his team deal with really bespoke requests and rectification of any defects from the robotised production process.

I've gone with red leather for the control interfaces but not the Ferrari Rosso leather because it looks a bit dull next to Rosso paint. As this was a 599 GTO wheel the rear was covered in Alcantara, but I've changed it to black smooth grain Nappa. The bottom is Alcantara 9040 Deep Black which will match some other trim parts yet to be completed.

I am over the moon with how my paddle conversion turned out.

The extended paddles are back from paint and match my wheels, F1 panel, interior air vents, and HVAC control knobs.

Extended paddles fitted.

Handbrake lever in perforated red leather.

A new handbrake gatier for the Scuderia console, this time in leather.

I've gone for plain red leather for the centre console tray inserts.

As with all convertible cars the interior trim is subject to more dust than a hard top car so I've taken the opportunity to clean behind any trim that's been removed.

Some of the new parts and Scuderia centre console fitted.

Headlamps

I have the headlamps apart to rebuild with the carbon inserts and I've taken the opportunity to change the bezel colour again: I repainted them in silver as per the Scuderia but there's nothing else on the car that colour, so I've had them repainted to match the wheels and other grey bits.

Misc

Hel stainless brake lines. I use Hel on my cars because they are a British company and also because the entire assembly is stainless.

I found Graypaul Nottingham were selling off new old stock of the original door catches. I don't expect the plastic insert to last any decent length of time but they were for sale at less than it would have cost me to have my originals re-plated.

The door jamb trim on my car had cracked in a few places and as expected, Ferrari charge a lot for it despite it being fairly standard square profile edge trim. I picked up a couple of metres for just over £6 and will see how it compares - there are many variations available.

Weight saving

Baselining the first table at 100.57kg. I'll start a new table from here. I moved the headlamps into this new table because fitting was delayed by the newly painted parts.

| Original Part | Fitted Quantity | Original Part (kg) | Replacement Part (kg) | Sprung Saving (kg) | Unsprung Saving (kg) | Replacement Part |

|---|---|---|---|---|---|---|

| Pedals - brake | 1 | 0.987 | 0.627 | 0.36 | - | 16M/Scuderia |

| Pedals - brake and clutch height adjuster bracket | 1 | 0.086 | 0 | 0.086 | - | Removed - unused |

| Brakes - ABS/ESP - acceleration sensor | 1 | 0.091 | 0 | 0.091 | - | Removed - function provided by CAN yaw |

| Pedals - Pedals - accelerator assembly | 1 | 0.883 | 0.869 | 0.014 | - | 16M/Scuderia |

| Door hinges | 4 | 0.705 | 0.5005 | 0.818 | - | Machined to reduce weight |

| Dashboard plaque 'F430 Spider' - carbon version | 1 | 0.025 | 0.086 | -0.061 | - | '16M Scuderia Spider - Limited 499' |

| Interior - centre console, complete (carbon driving zone) | 1 | 2.253 | 1.341 | 0.912 | - | 16M (carbon) |

| Headlamps - standard | 2 | 0.349 | 0.177 | 0.344 | - | 16M (carbon) |

Sprung weight saved: 78.16 kg

Unsprung weight saved: 24.97 kg

Total weight saved: 103.13 kg

Mr Stewart, would you mind pointing me in the direction of the tuner selling those extended paddles? My C63 needs a longer set for some of my more spirited driving days and I'm loathe to fit stick on extenders but that's about all I've been able to find. Clearly my Google skills are not up to much!

Thanks in advance!

James

Thanks in advance!

James

James B said:

Mr Stewart, would you mind pointing me in the direction of the tuner selling those extended paddles? My C63 needs a longer set for some of my more spirited driving days and I'm loathe to fit stick on extenders but that's about all I've been able to find. Clearly my Google skills are not up to much!

Thanks in advance!

James

Hi James,Thanks in advance!

James

http://www.car-lab.com - they had a very small amount for sale and I've not seen them since. Whatever you end up with make sure they are the right ones because there are quite a few variations, and some look very similar from the outside but have different internals. I've seen the stick on 'covers' and don't think much to them at all.

Give me a shout if you need a hand and I will try to help.

Cheers,

Mark

Robbins said:

Great work as always mwstewart. Do you think the loss of 103+kg will affect the ride? Enough to affect damping any significant amount? Or are you anticipating minimal noticeable change?

Thanks. If I was using standard suspension the weight loss would have the effect of hardening the ride, which is a good thing - the standard suspension is a touch too soft on the Spider. I've gone for the full Scuderia suspension, though.mwstewart said:

Hi James,

http://www.car-lab.com - they had a very small amount for sale and I've not seen them since. Whatever you end up with make sure they are the right ones because there are quite a few variations, and some look very similar from the outside but have different internals. I've seen the stick on 'covers' and don't think much to them at all.

Give me a shout if you need a hand and I will try to help.

Cheers,

Mark

Mark,http://www.car-lab.com - they had a very small amount for sale and I've not seen them since. Whatever you end up with make sure they are the right ones because there are quite a few variations, and some look very similar from the outside but have different internals. I've seen the stick on 'covers' and don't think much to them at all.

Give me a shout if you need a hand and I will try to help.

Cheers,

Mark

That's great thanks. Looks like nothing on their site now but I'll drop them a message to see if they can help.

All the best with the continued progress on the car(s). Always a good read when you update the threads!!

OP, you mentioned your thoughts about doing this as a business but that you work too slow.

How about you complete this project, sell it and use the funds to pay for the first year's salaries and take on some skilled guys on - and become project manager as well as tech/engineer?

That way you could take on multiple projects over the year and make a go of it. Although the Singer comparison is interesting, what about being able to turn around an old hot hatch, for instance? Or grabbing a few LHD Renault 5's from France, converting them to RHD and dropping a V6 in the back and making something like a Turbo2 replica?

Or perhaps a business around some type of rebodying and modifying of Mk3 MR2's, for instance? Seems to me you could pretty much do anything that the majority of us PH types would be interested in.

How about you complete this project, sell it and use the funds to pay for the first year's salaries and take on some skilled guys on - and become project manager as well as tech/engineer?

That way you could take on multiple projects over the year and make a go of it. Although the Singer comparison is interesting, what about being able to turn around an old hot hatch, for instance? Or grabbing a few LHD Renault 5's from France, converting them to RHD and dropping a V6 in the back and making something like a Turbo2 replica?

Or perhaps a business around some type of rebodying and modifying of Mk3 MR2's, for instance? Seems to me you could pretty much do anything that the majority of us PH types would be interested in.

ReaderScars said:

OP, you mentioned your thoughts about doing this as a business but that you work too slow.

How about you complete this project, sell it and use the funds to pay for the first year's salaries and take on some skilled guys on - and become project manager as well as tech/engineer?

That way you could take on multiple projects over the year and make a go of it. Although the Singer comparison is interesting, what about being able to turn around an old hot hatch, for instance? Or grabbing a few LHD Renault 5's from France, converting them to RHD and dropping a V6 in the back and making something like a Turbo2 replica?

Or perhaps a business around some type of rebodying and modifying of Mk3 MR2's, for instance? Seems to me you could pretty much do anything that the majority of us PH types would be interested in.

Like this idea a lot! ReaderScars - You're my kind of PHer!How about you complete this project, sell it and use the funds to pay for the first year's salaries and take on some skilled guys on - and become project manager as well as tech/engineer?

That way you could take on multiple projects over the year and make a go of it. Although the Singer comparison is interesting, what about being able to turn around an old hot hatch, for instance? Or grabbing a few LHD Renault 5's from France, converting them to RHD and dropping a V6 in the back and making something like a Turbo2 replica?

Or perhaps a business around some type of rebodying and modifying of Mk3 MR2's, for instance? Seems to me you could pretty much do anything that the majority of us PH types would be interested in.

Waiting for these guys to release their 6R4 replica: http://speed3automotive.co.uk/models.aspx

I'm also eyeing up an RS200 rebody on an MR2.3!

All whilst refurbishing my 106 XSi to 'fast road' spec... Slowly! Or MWS pace, as I like to call it

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff