E36 Track Car - Replacement Engine Build(s)

Discussion

So chaps, is it not better to put some decent mileage on an engine before pounding it round a track?

That would generally be my route. I've done a fair few track days and it really is tough on the engine.

Op - I would be reluctant on buying a used engine unless you can verify that it is in good health.

That would generally be my route. I've done a fair few track days and it really is tough on the engine.

Op - I would be reluctant on buying a used engine unless you can verify that it is in good health.

Dr Imran T said:

So chaps, is it not better to put some decent mileage on an engine before pounding it round a track?

I put some decent road mileage on my engine before the first track day - what I didn't do was upgrade the oil to something that would cope with the stress of a track dayDr Imran T said:

So chaps, is it not better to put some decent mileage on an engine before pounding it round a track?

That would generally be my route. I've done a fair few track days and it really is tough on the engine.

Op - I would be reluctant on buying a used engine unless you can verify that it is in good health.

Yeah, well had around 1200 miles on it before taking it to Oulton, but with it only being a track day car, its not used all that often. Luckily its the only real failure I've had in 7-8 years of track days, even with engines in the past that have only been run in on a dyno. I guess its just the luck of the draw to some extent also.That would generally be my route. I've done a fair few track days and it really is tough on the engine.

Op - I would be reluctant on buying a used engine unless you can verify that it is in good health.

Yeah, I would much rather build one, which I've just posted below. You generally can't trust anything anyone says, unless you were there when it was built...

After some thought, and the realisation people were really asking ridiculous money for M3 engines, even on 70k miles, it just wasn't an option.

From browsing the US forums a handful of people had done the 'cheap' 3.0L engine, using the rotating assembly from an M54B30, i.e. E46 330i, etc. I couldn't really find much information about it in the UK, just a few vague threads on various forums with no real definitive information. These engines were for sale ranging from £200-300, nearly a 10th of the price people had M3 engines listed for. After a bit of waiting, one came up local on the cheap end of that scale and I went to collect it..

Considering I only really wanted the crank, pistons and rods from this, I found out the rest of it (inc. ancillaries) were selling well on eBay, after some patience and once everything had gone, essentially the internals ended up costing nothing.

To eliminate a problem with the M50 block used in the previous build, I had the machine work done to my good spare..

The bores were also double checked for roundness to be 110% sure, and all came out great.

The M50, M52 and M54 engines are very similar internally, the M54 having different coolant/oil pathways, dual VANOS and various other things. They share the same 84mm bore, and the extra capacity is gained by an 89mm stroke on the crank in the M54, over the 84mm stroke on a 2.8L.

M54B30 Crank..

M54B30 Piston vs M52B28 Piston..

The M54B30 and M52B28 rods are the same, so you could use either. I kept the pistons with their rods either way. In summary:

M50B25 (2.5L Petrol, 1990-1996, E36 325i and E34 525i) - Steel/Iron Block, 84mm Bore, 75mm Stroke - 189hp, 181lbft.

M52B28 (2.8L Petrol, 1992-2001, E36 328i, E39 528i, E38 728i, Z3 2.8) - Aluminium Block, 84mm Bore, 84mm Stroke - 190hp, 210lbft.

M54B30 (3.0L Petrol, 2000-2006, E46 330i, E39 530i, E60 530i, X3/5 3.0, Z4 3.0) - Aluminium Block, 84mm Bore, 89.6mm Stroke - 230hp, 220lbft.

Again, did not know whether to trust the head that was used previously, so I had my spare head cleaned, skimmed, new stem seals again and then finally pressure tested to be 110% sure. All came back OK.

The pistons, rods and other bits were properly cleaned at the same time..

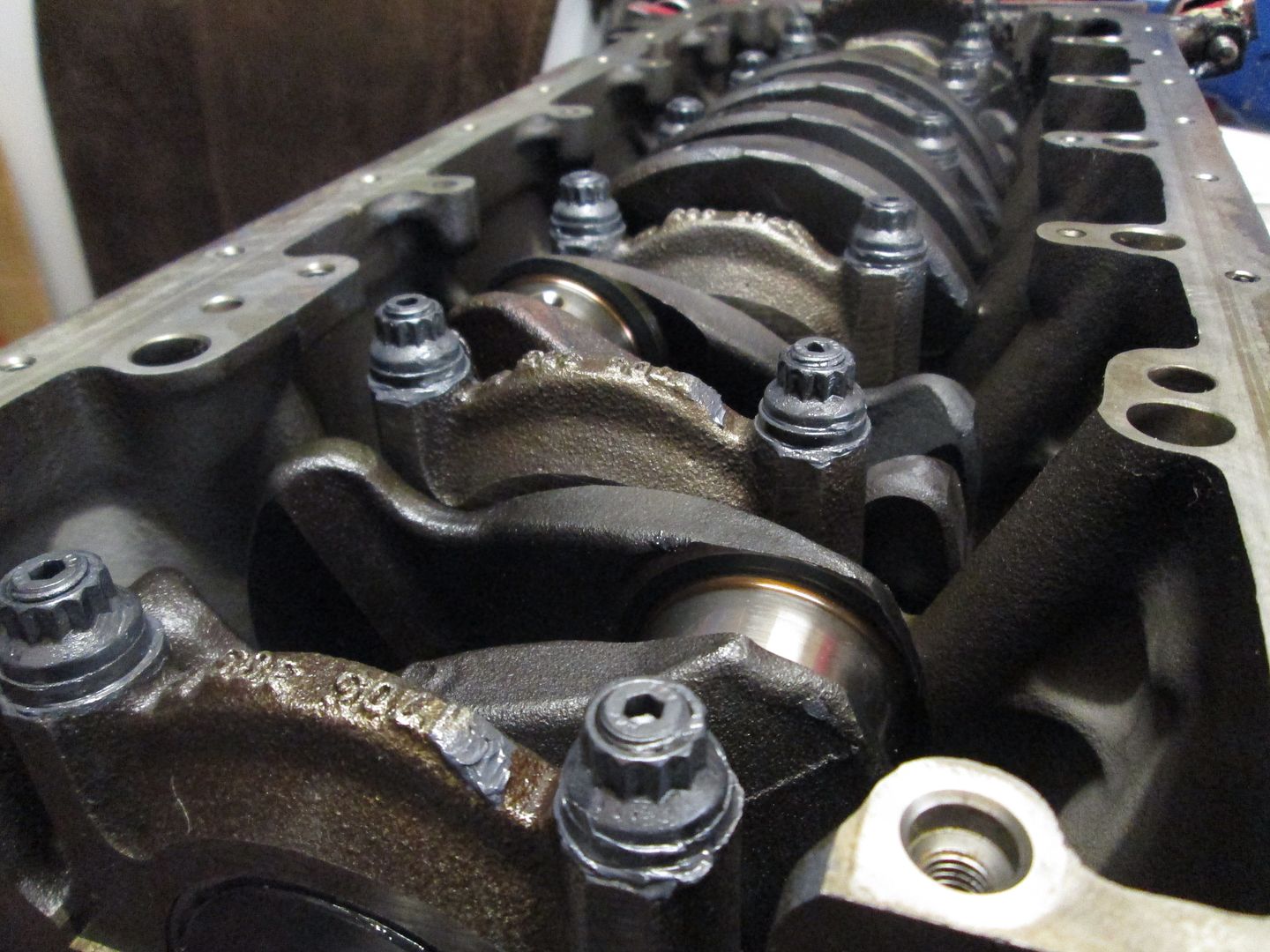

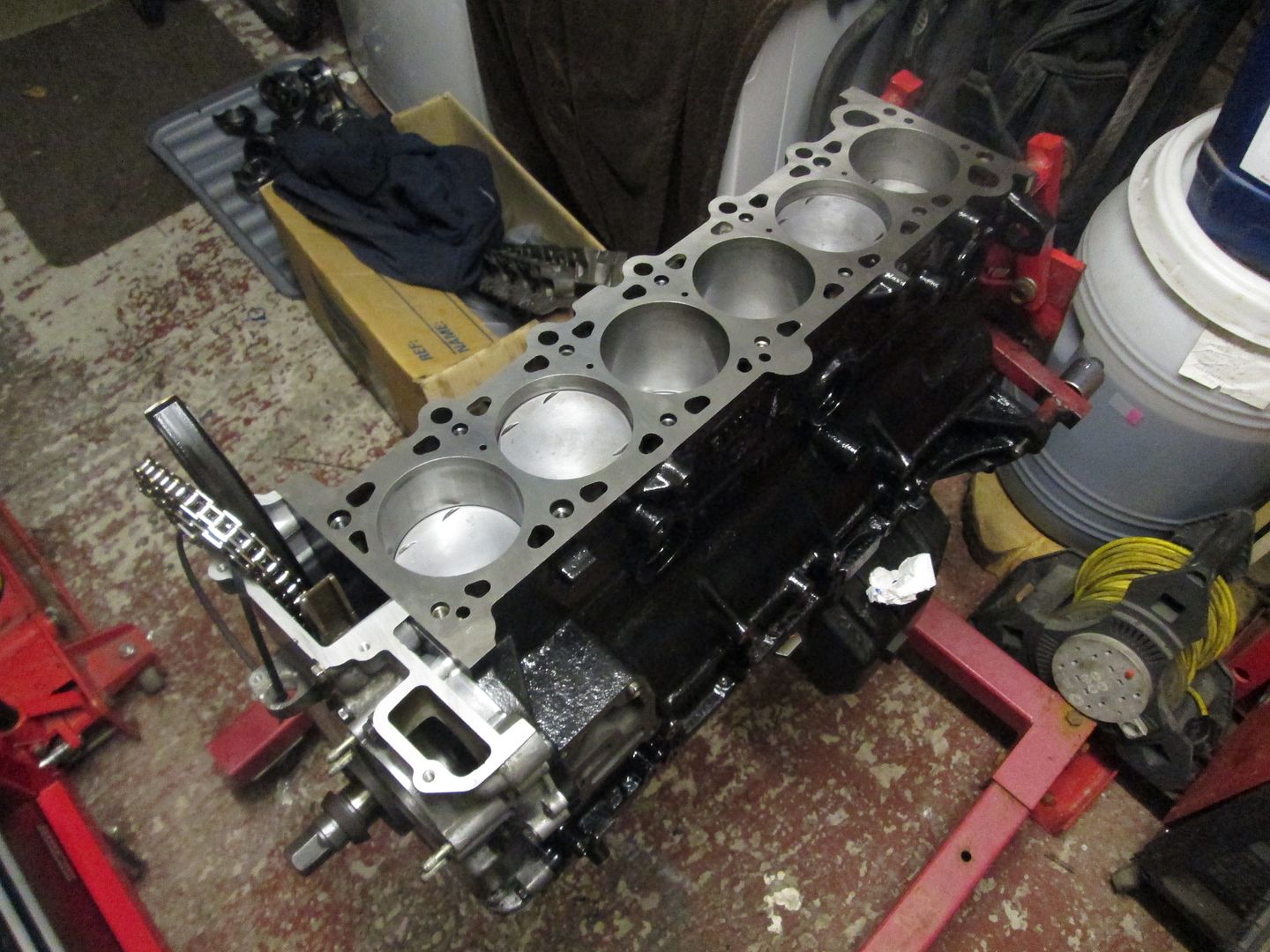

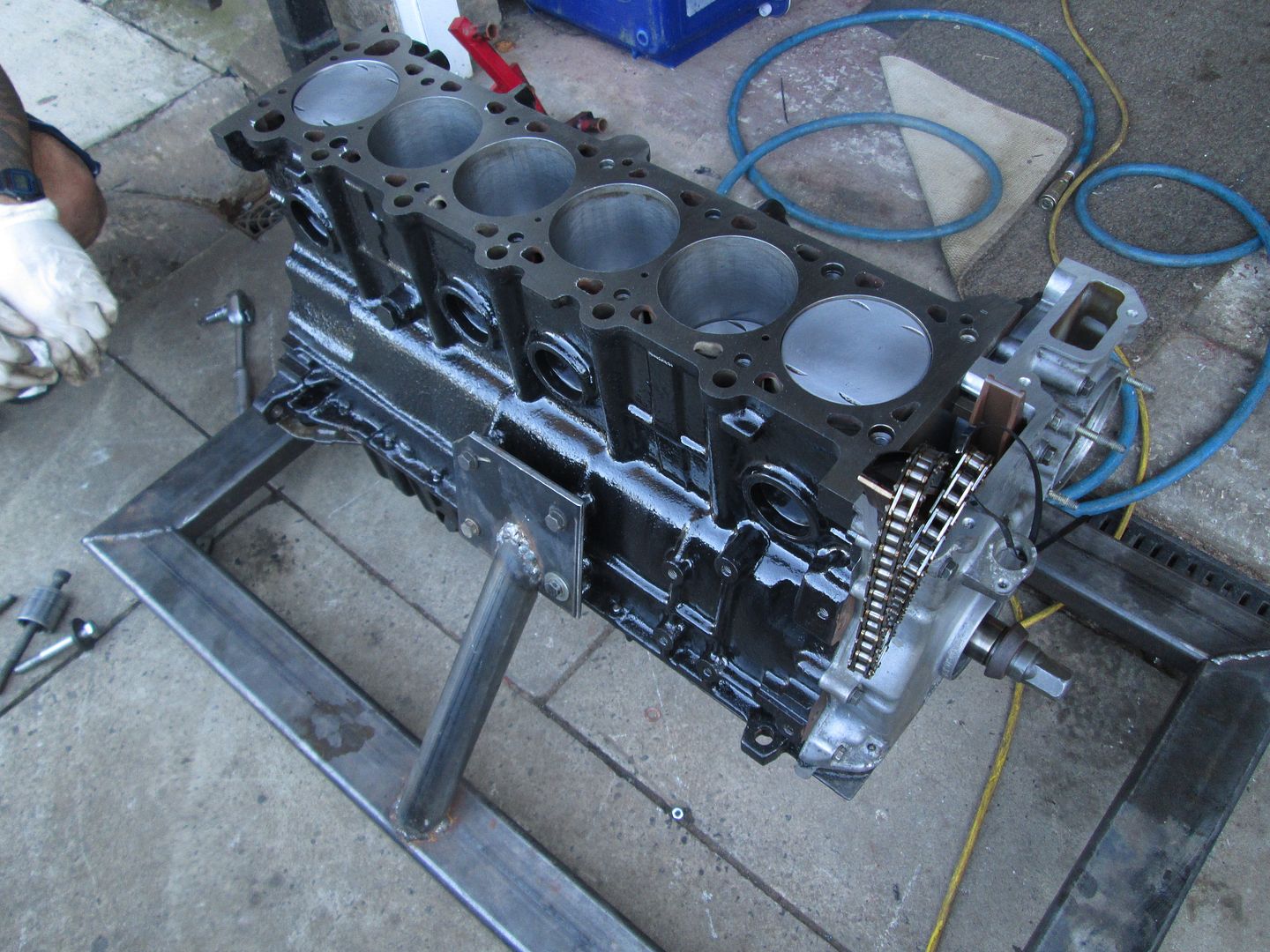

So the block was given a quick coat of paint, then the oil jets put in place, and some bearings fitted..

There had been a ridiculous increase in the price of mains bolts at BMW since I last had them, and it was actually cheaper to purchase ARP hardware..

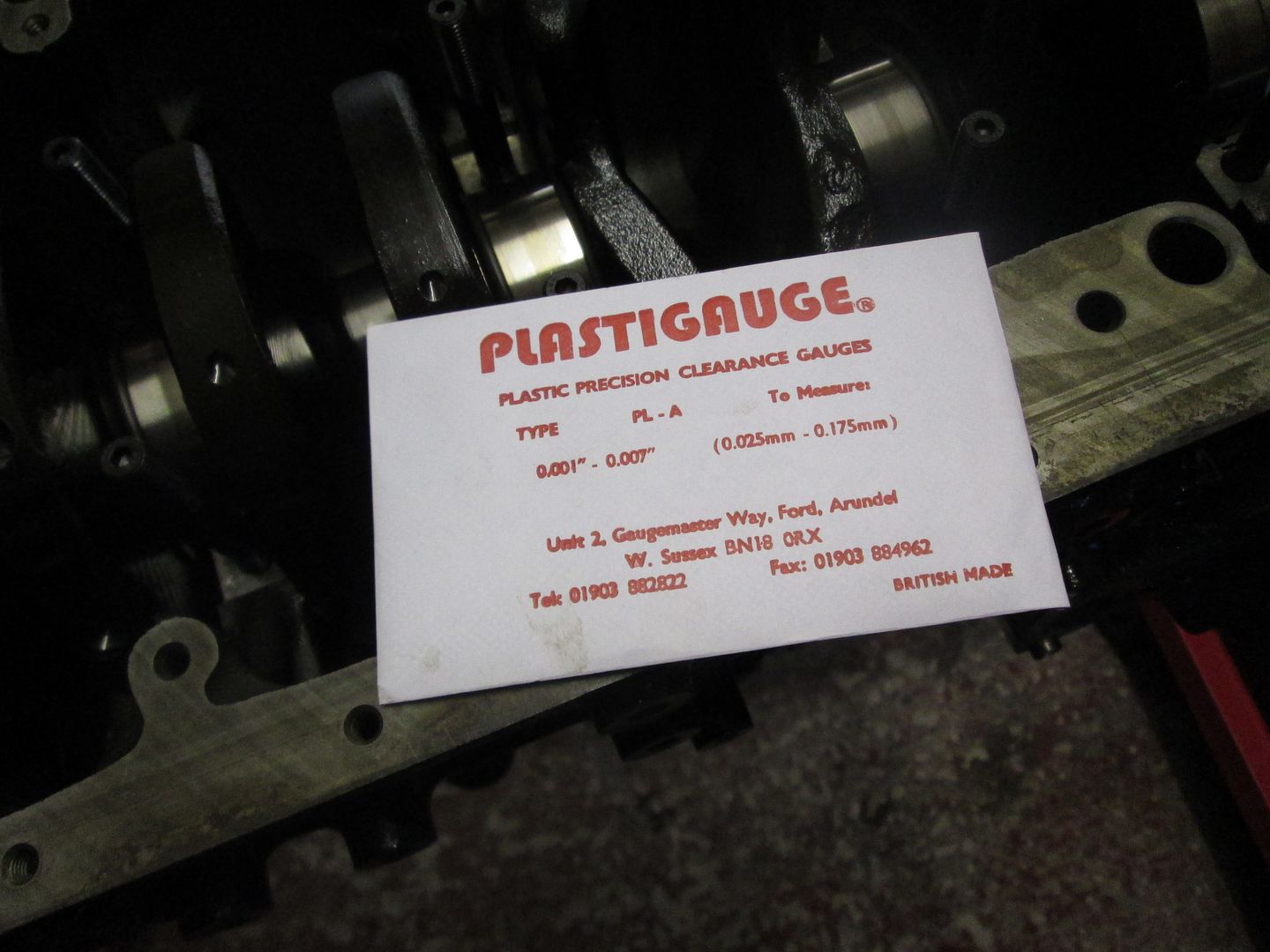

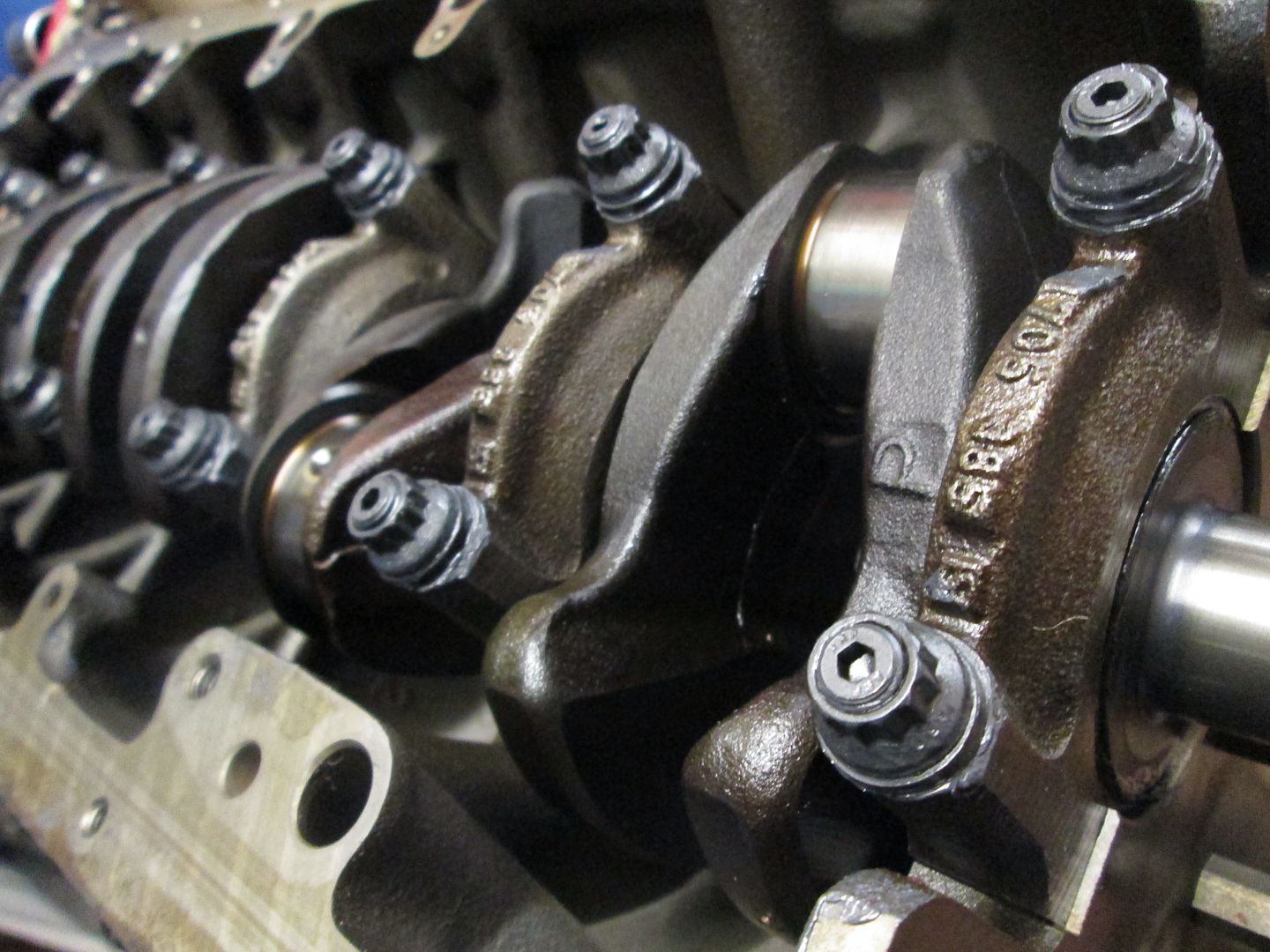

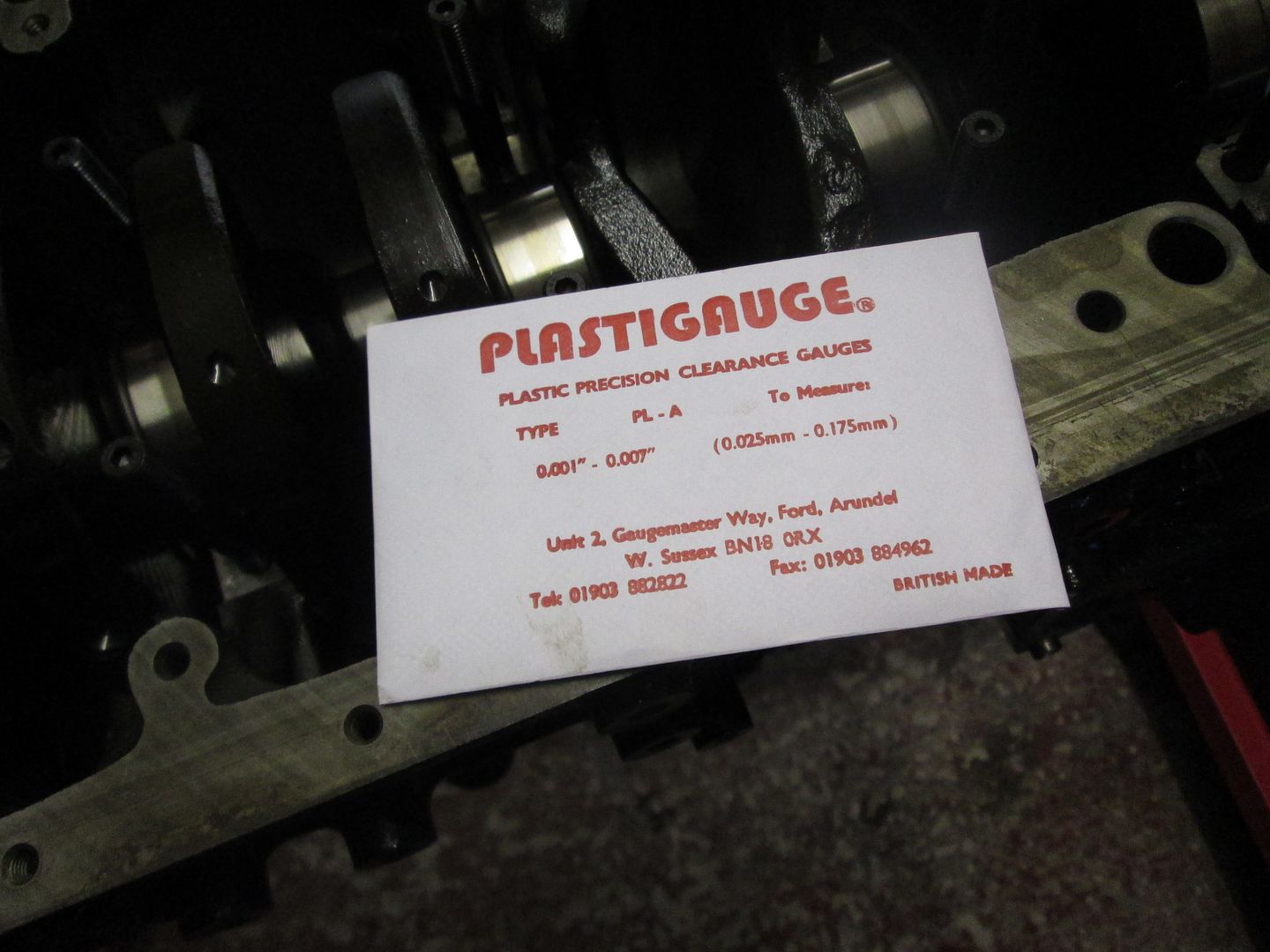

Degreased and checked the crank over, then dropped it into the block and checked the clearances..

Factory clearance is 0.020mm <> 0.058mm, all were identical at circa 0.038mm.

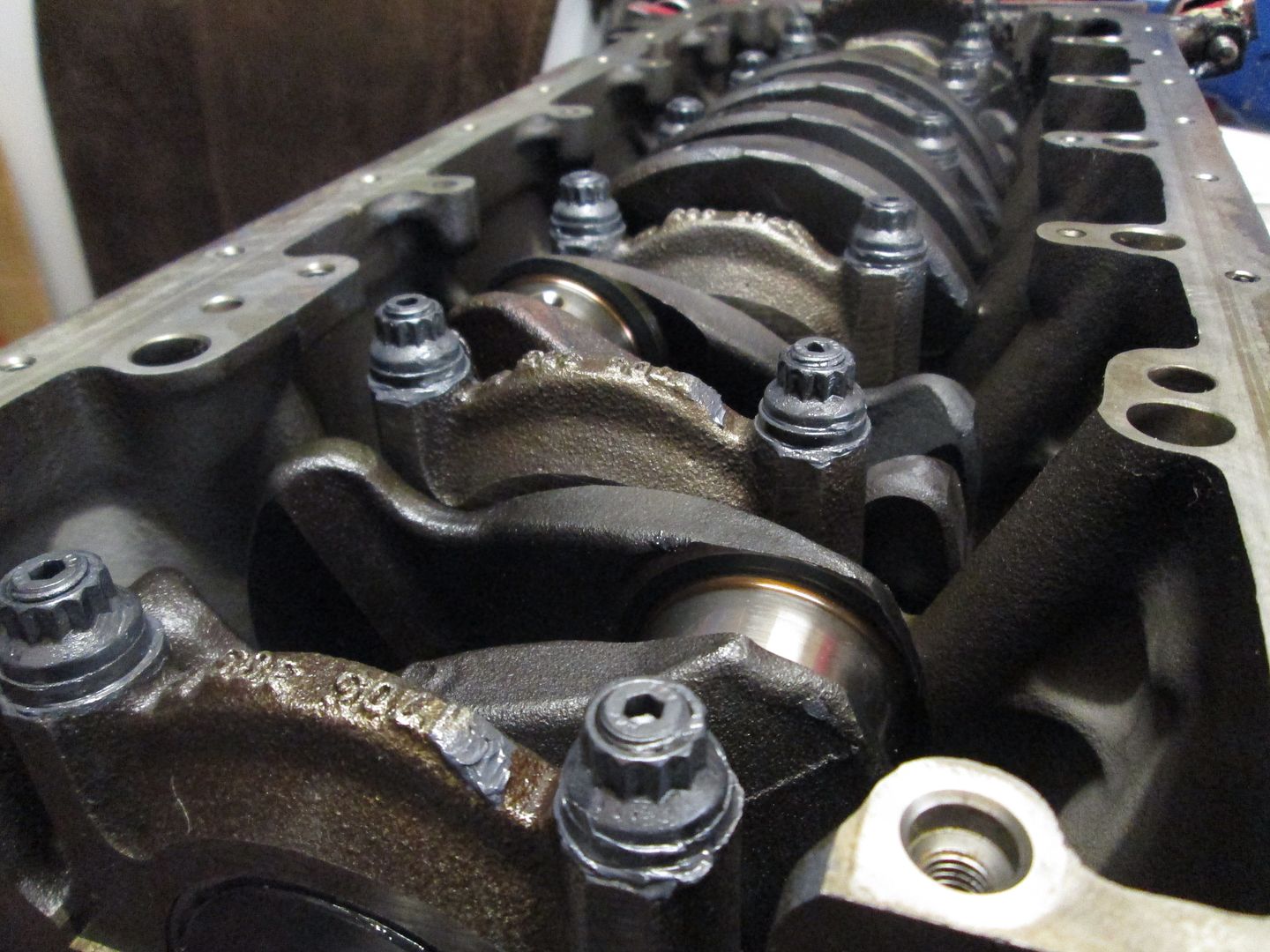

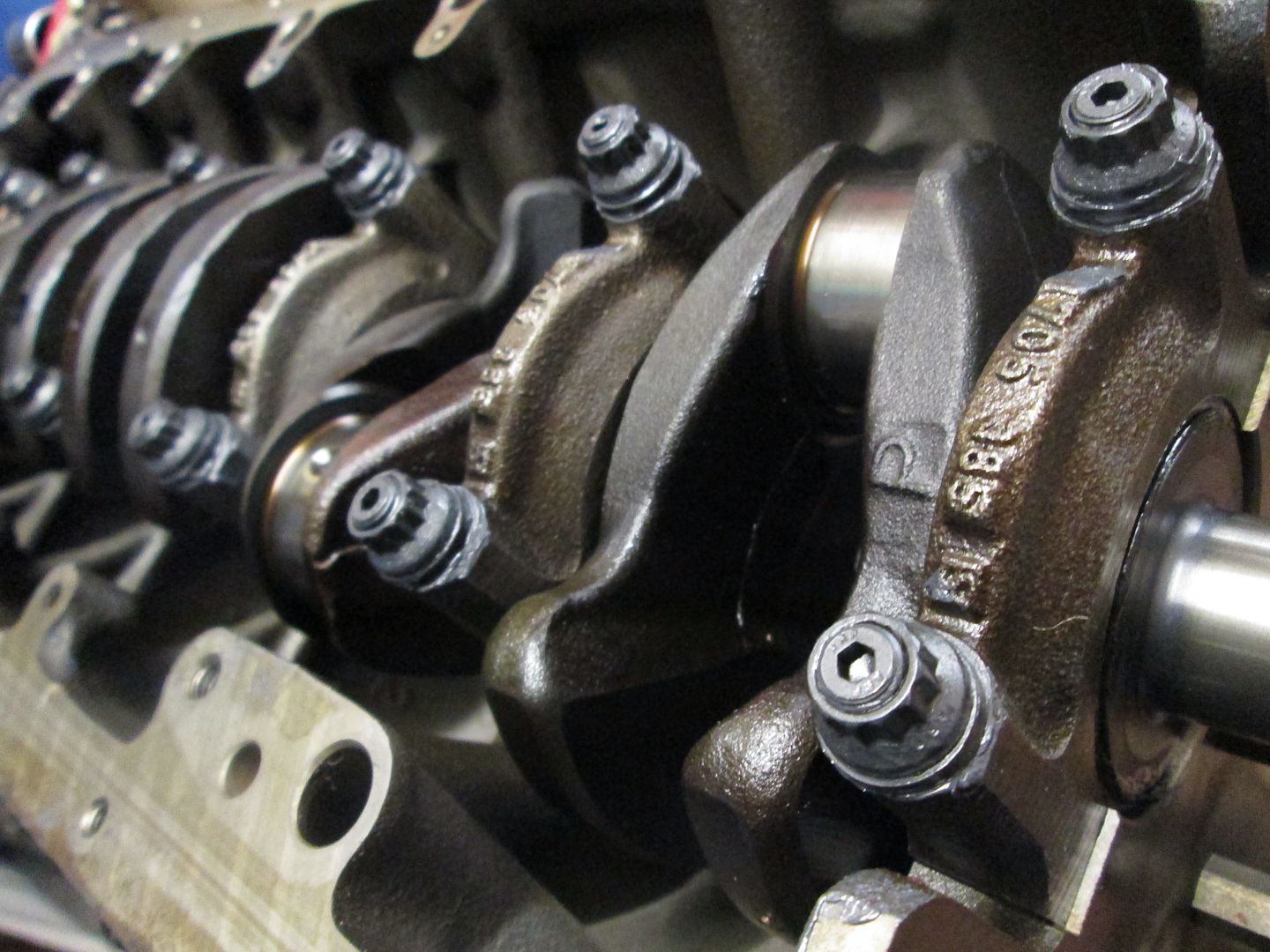

Removed the caps, cleaned, and added assembly grease again. Then torqued the caps down with the ARP ultra torque grease as per the spec..

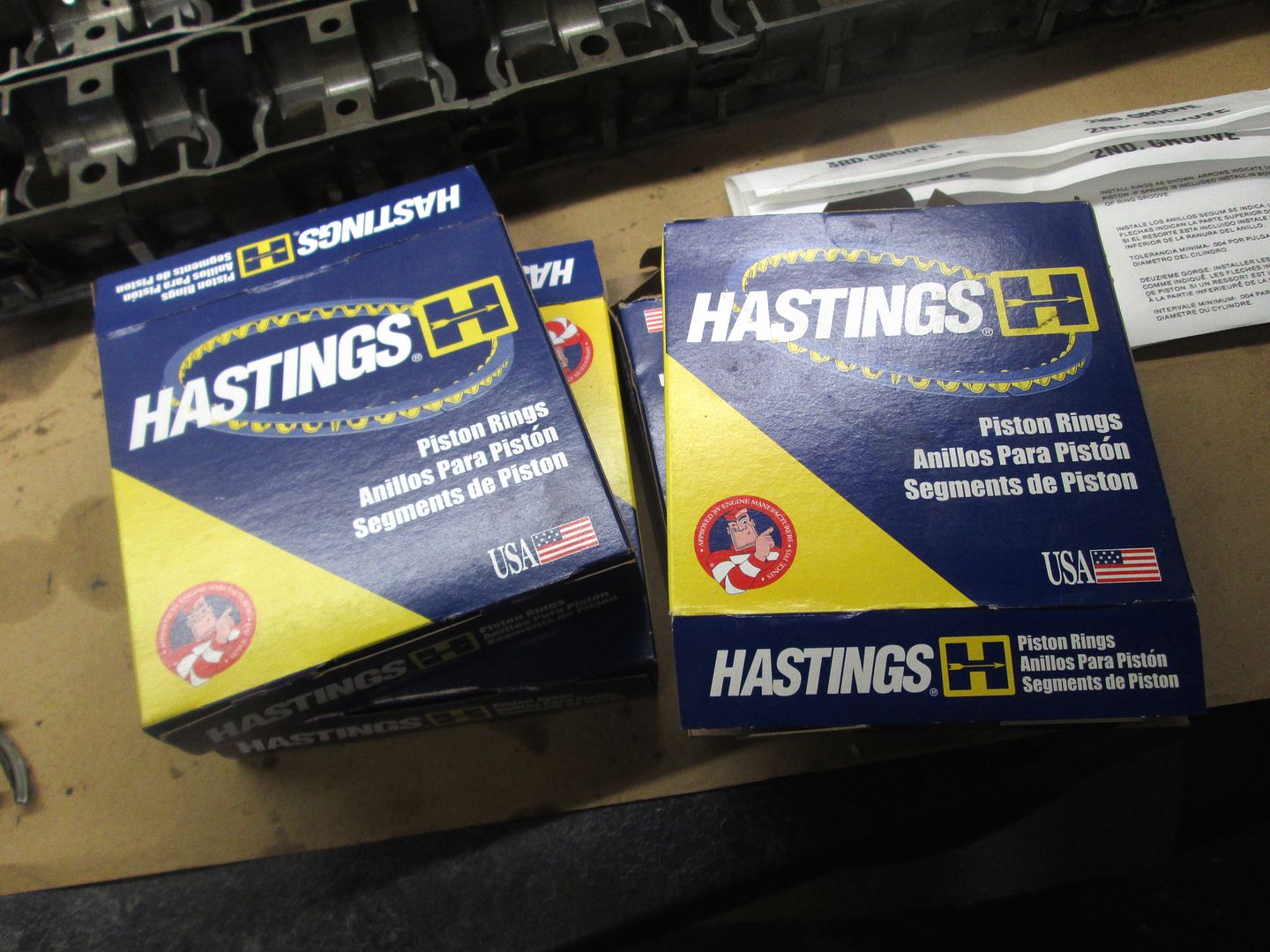

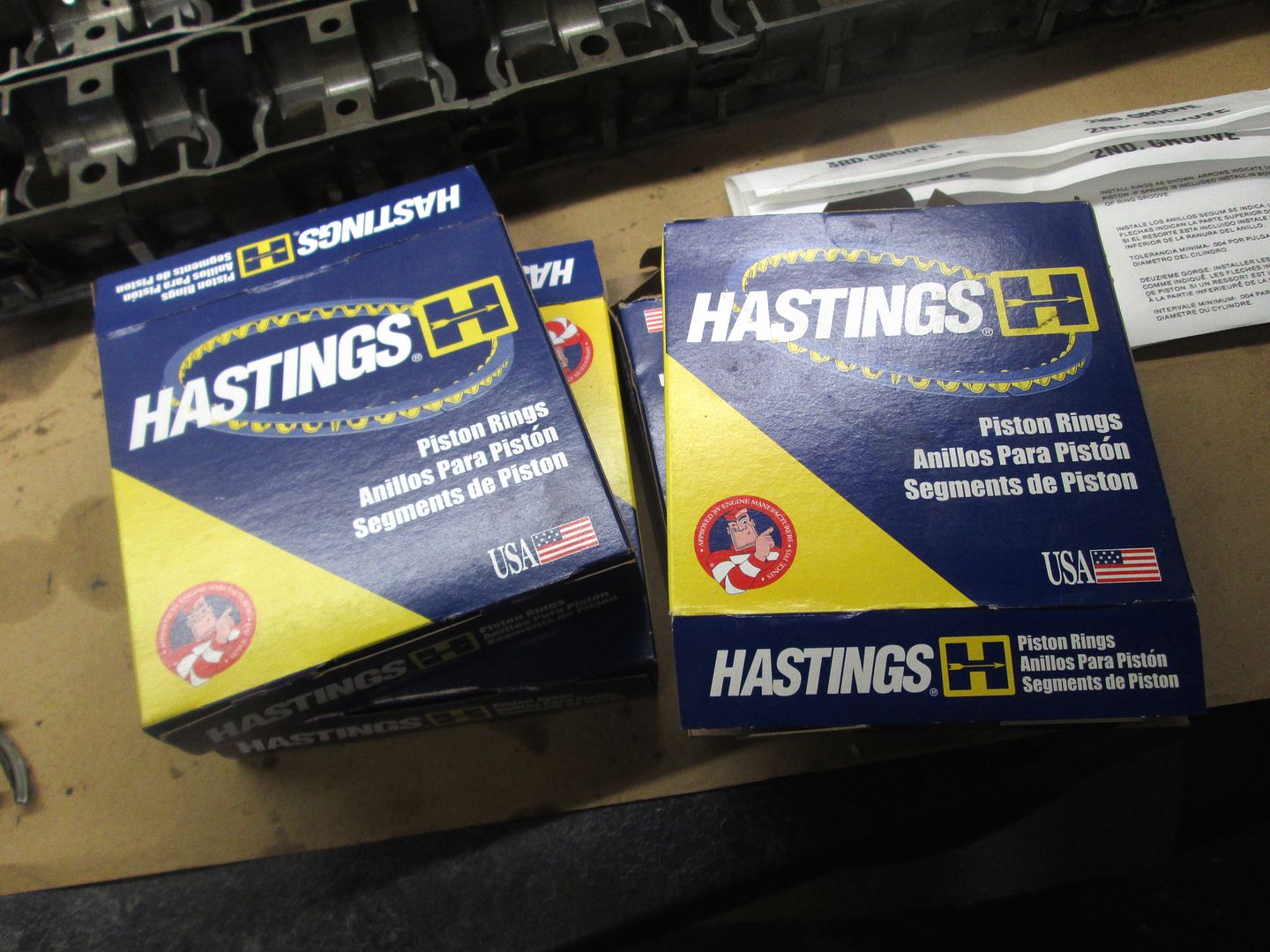

New piston rings for the M54B30 pistons, as they are completely different and should be replaced anyway..

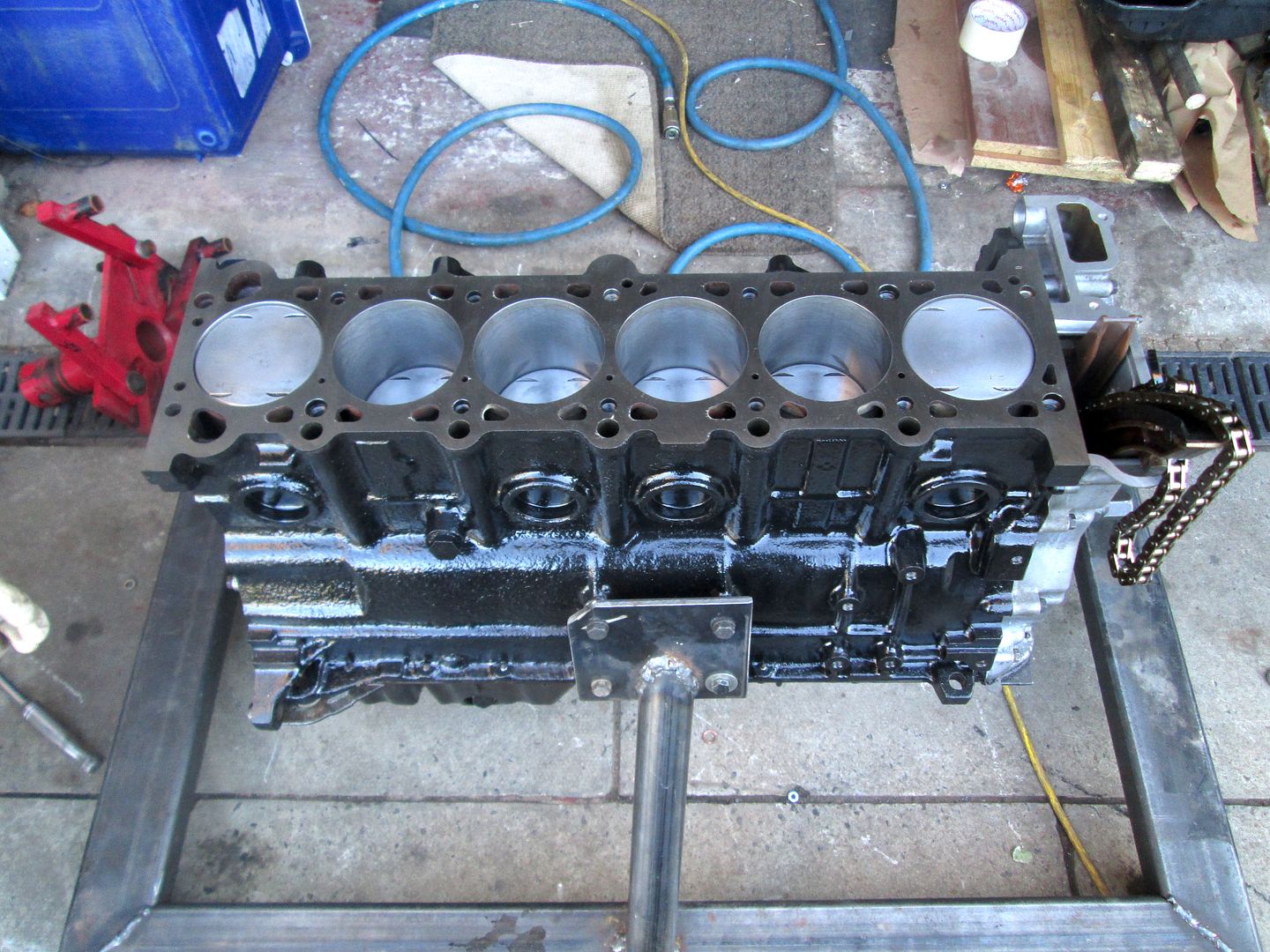

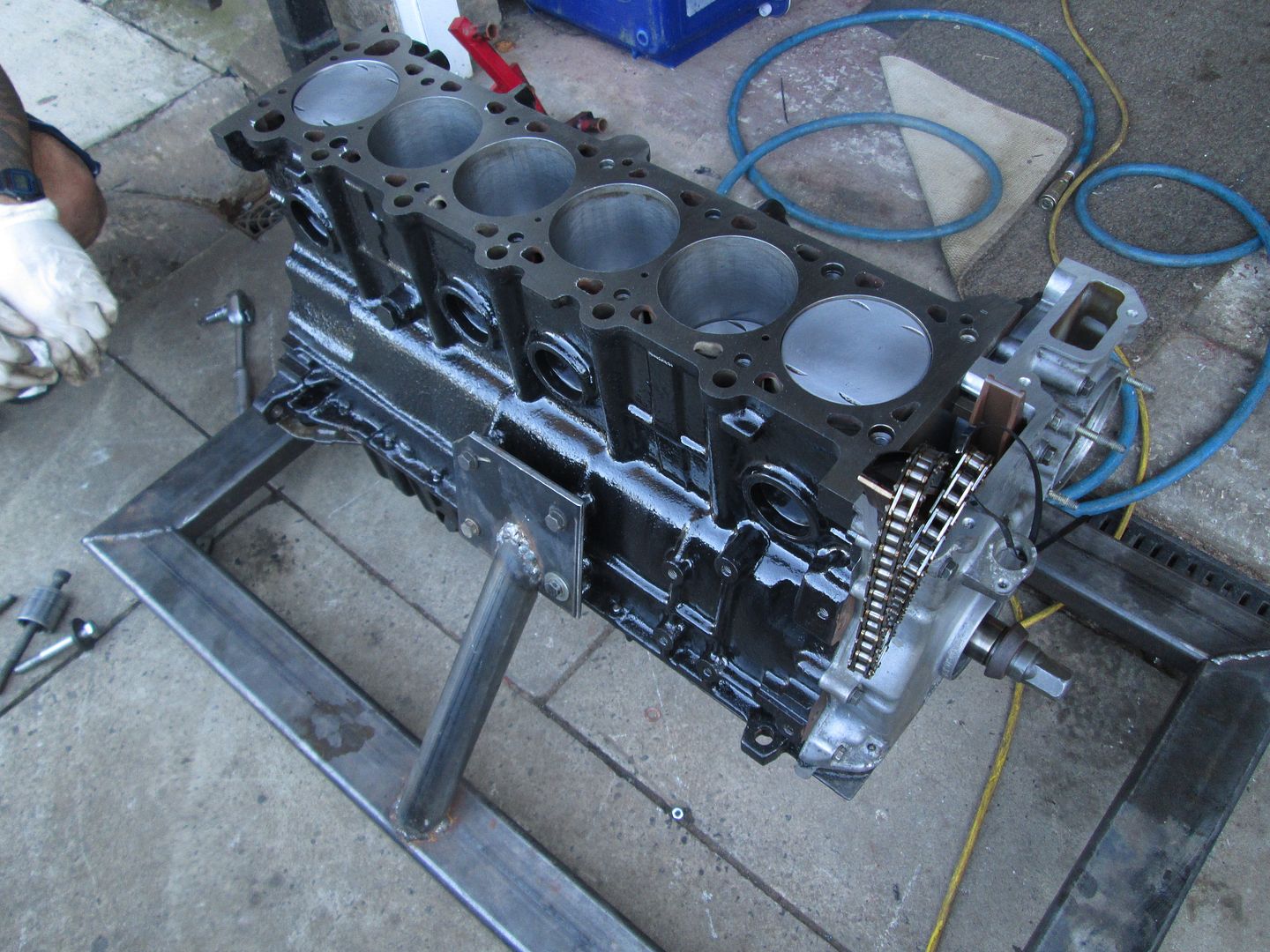

Gapped, fitted to the piston and then dropped into the block..

The windage/baffle plate needed more modification to clear the ARP studs, and longer stroke of the M54 crank, but its all easy stuff.

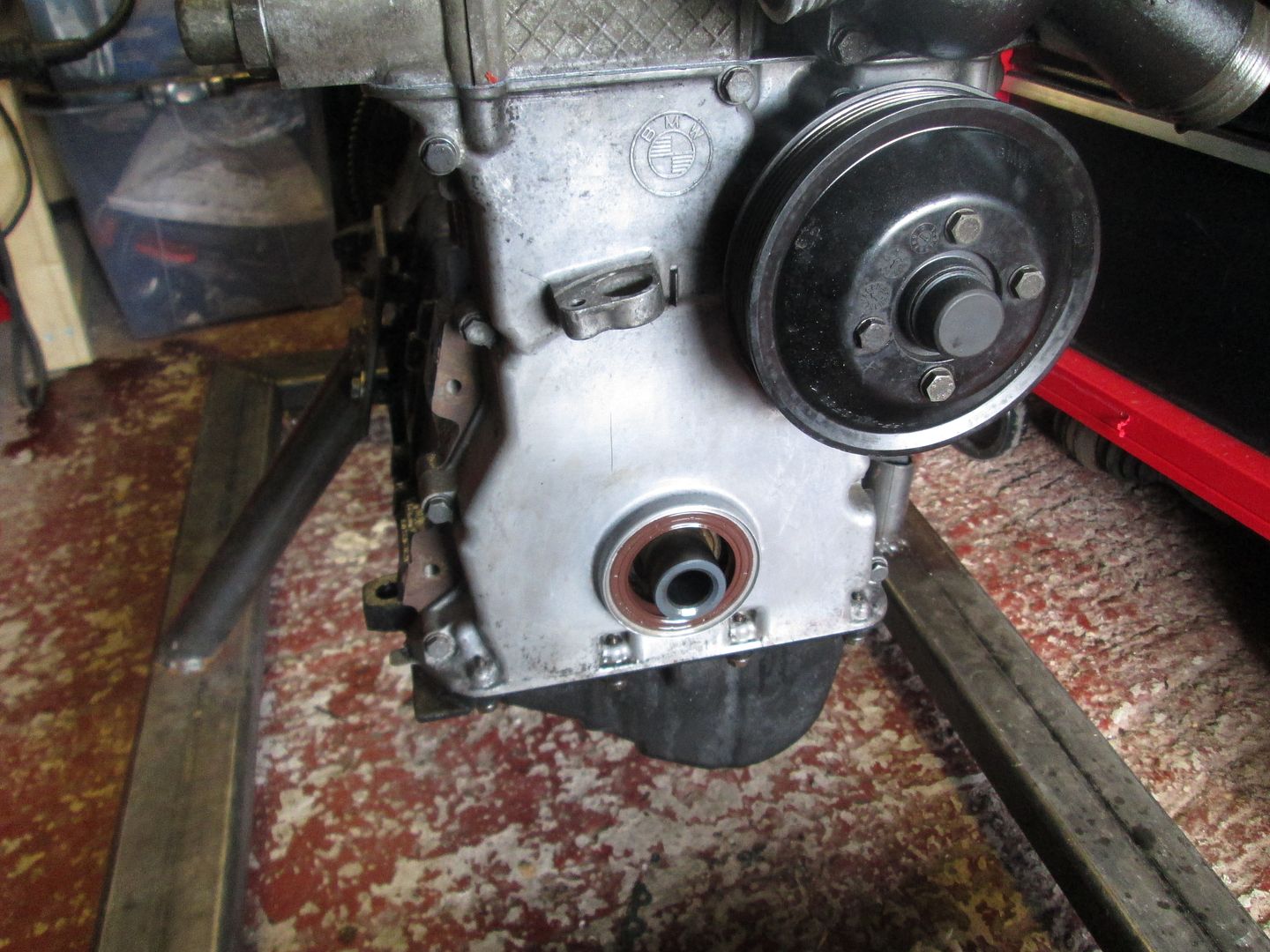

Timing gear, covers, oil pump, sump back on with a new gasket..

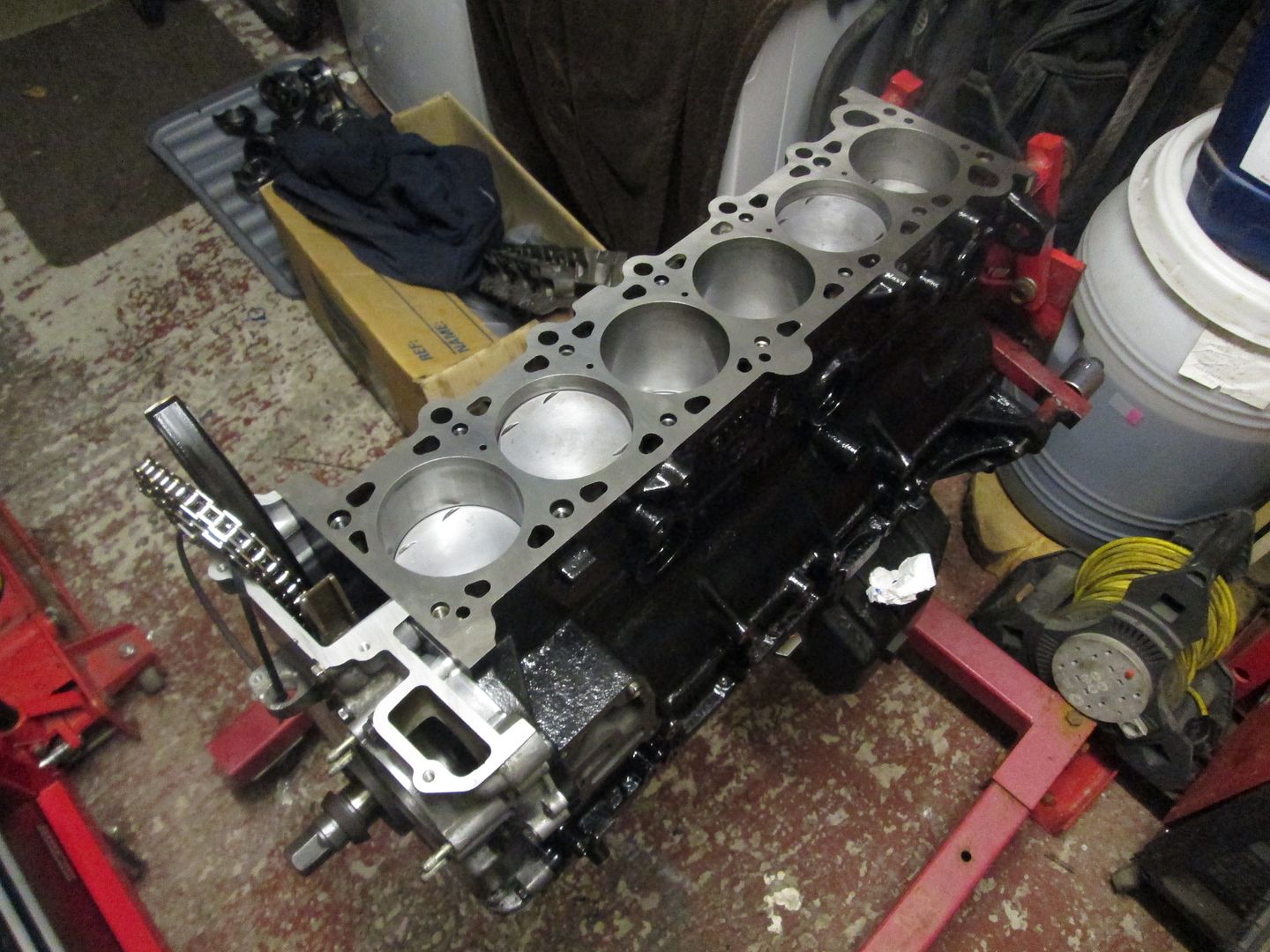

You can see here how the M54 assembly sits a few mm below the deck when used in an M50 block, as expected..

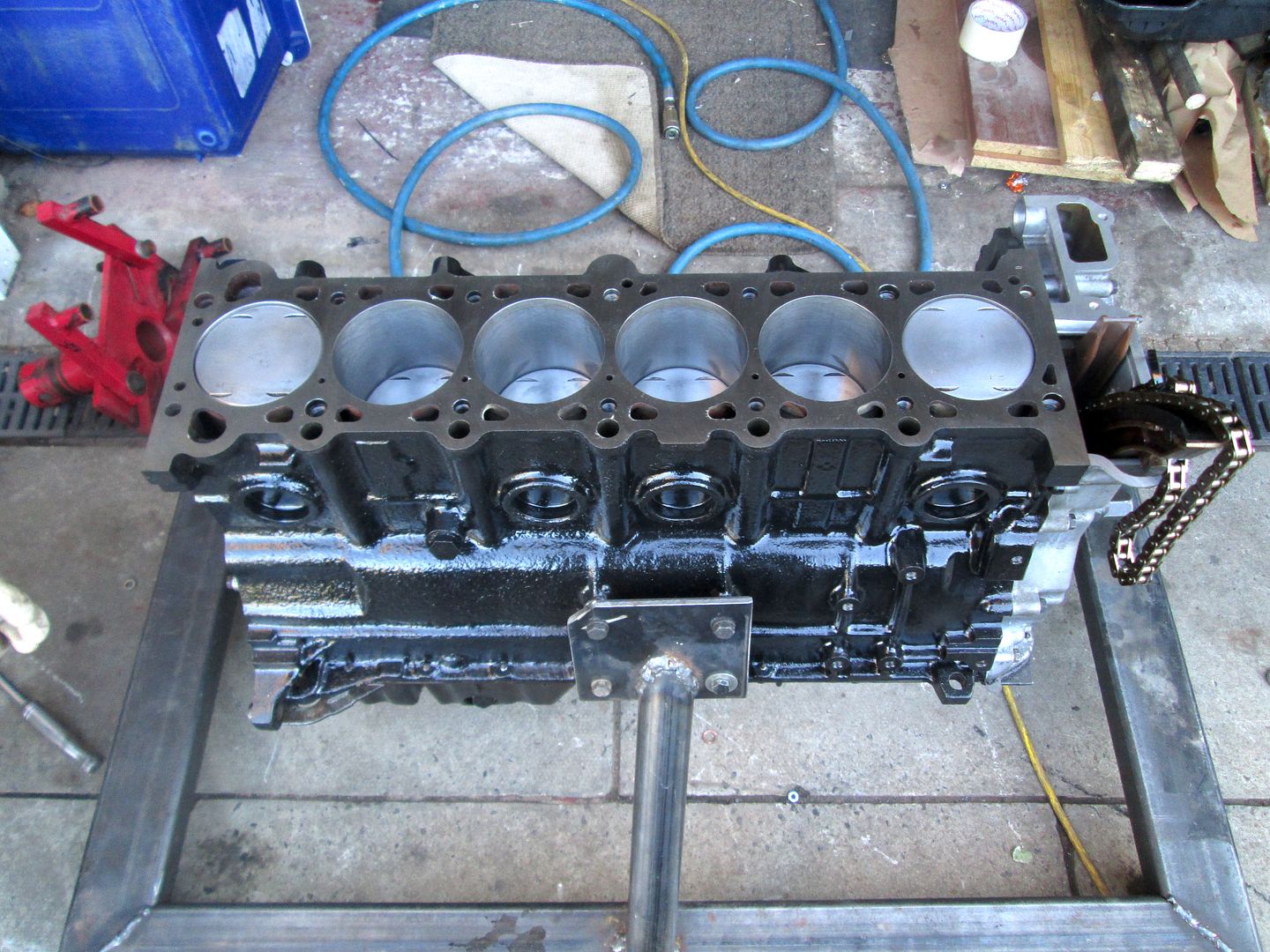

Cleaned the block face one last time, then fitted two new dowels and a new headgasket..

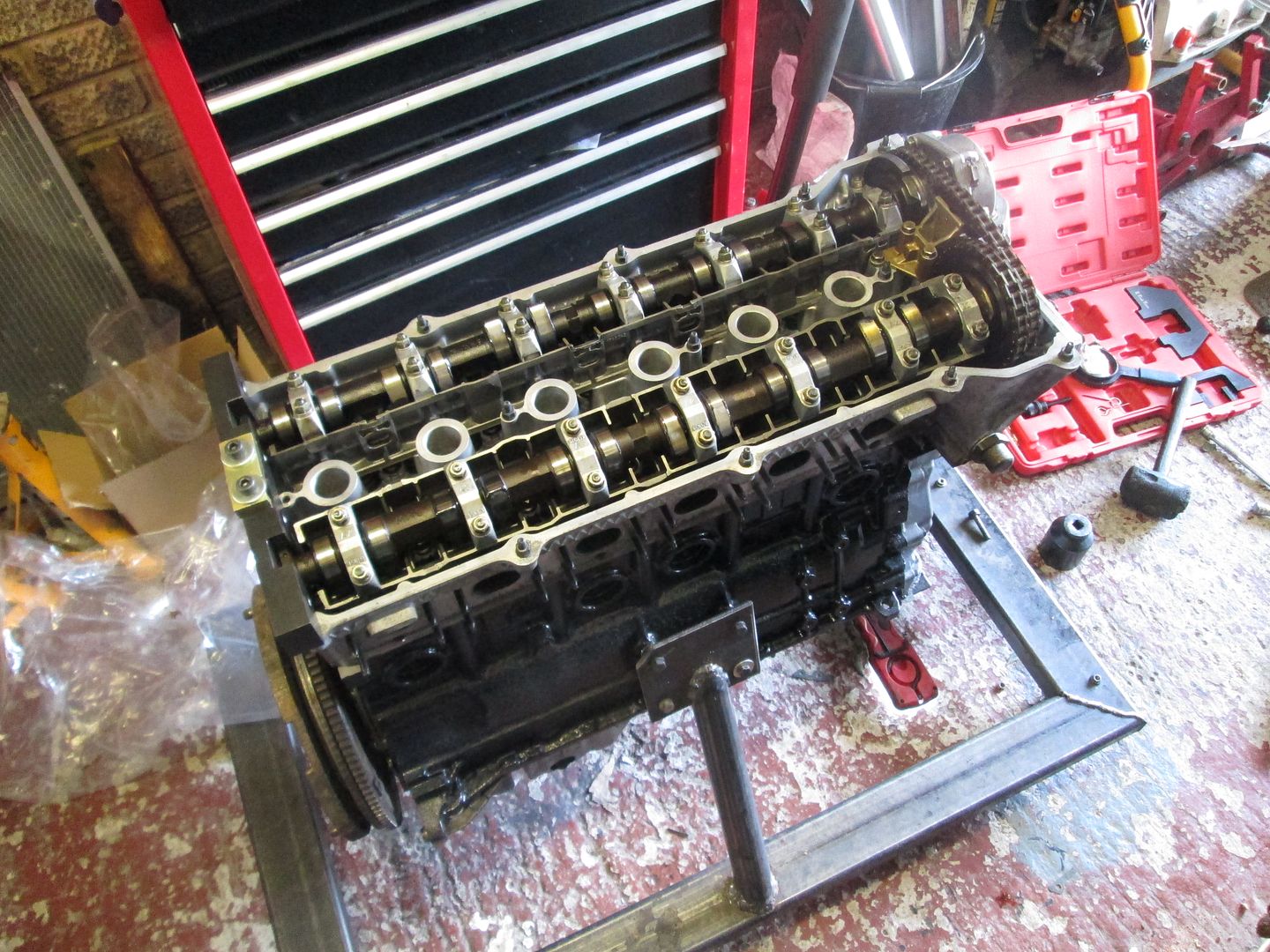

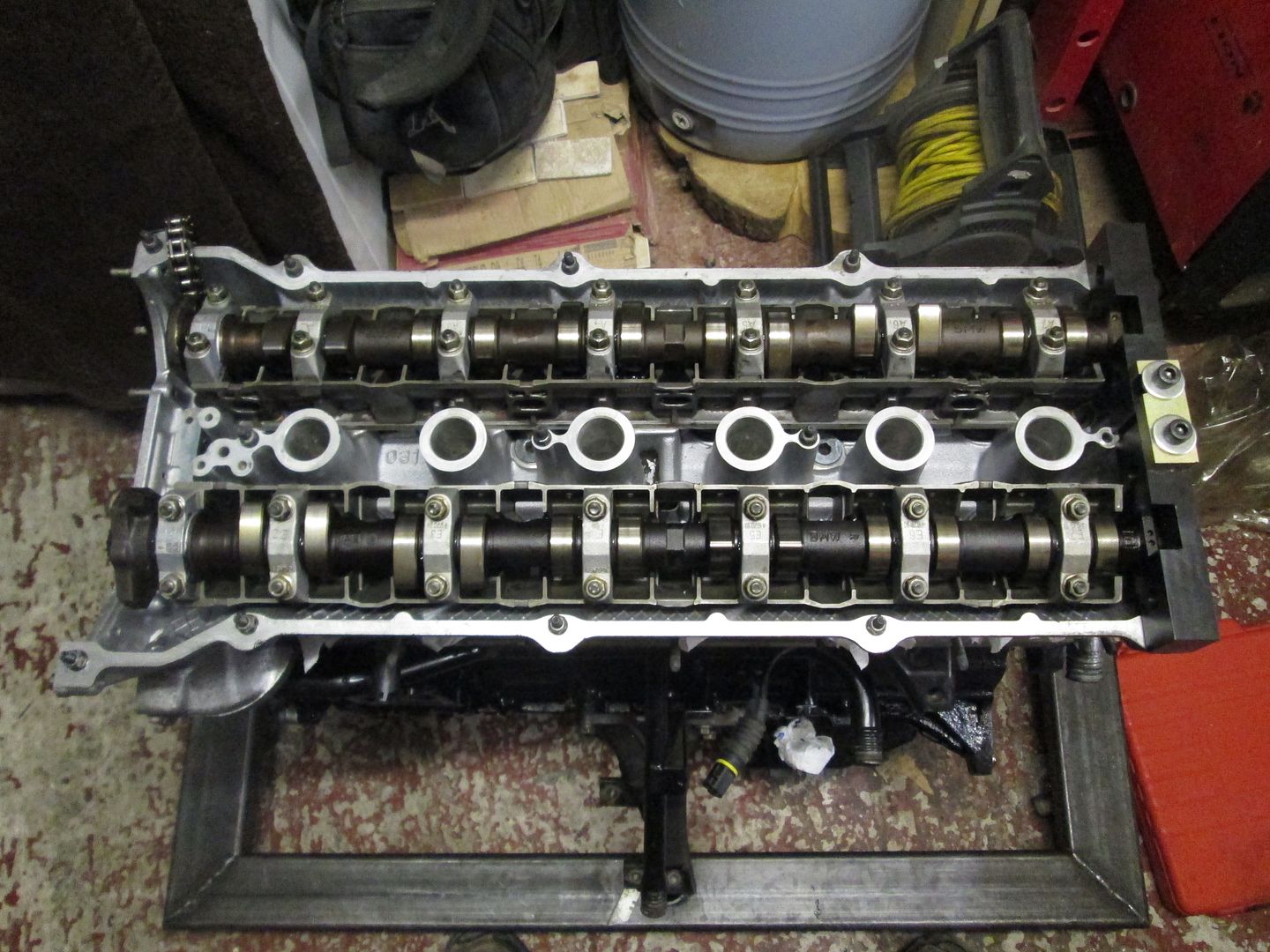

Dropped the head on, new head bolts again. All held full torque correctly..

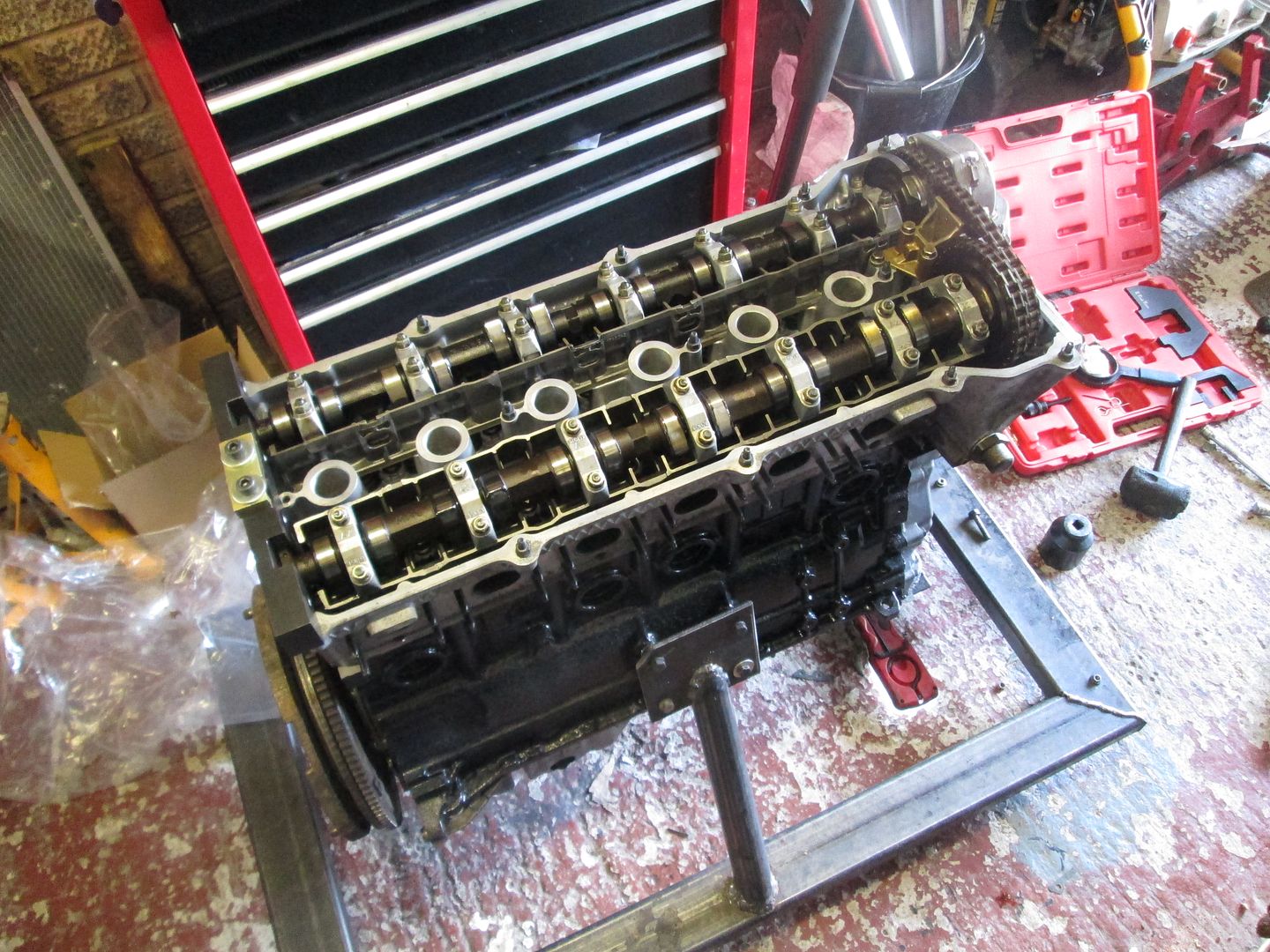

Before assembling the rest of the head, I wanted to strip all 24 hydraulic tappets apart and clean them, to check all were operating at full travel..

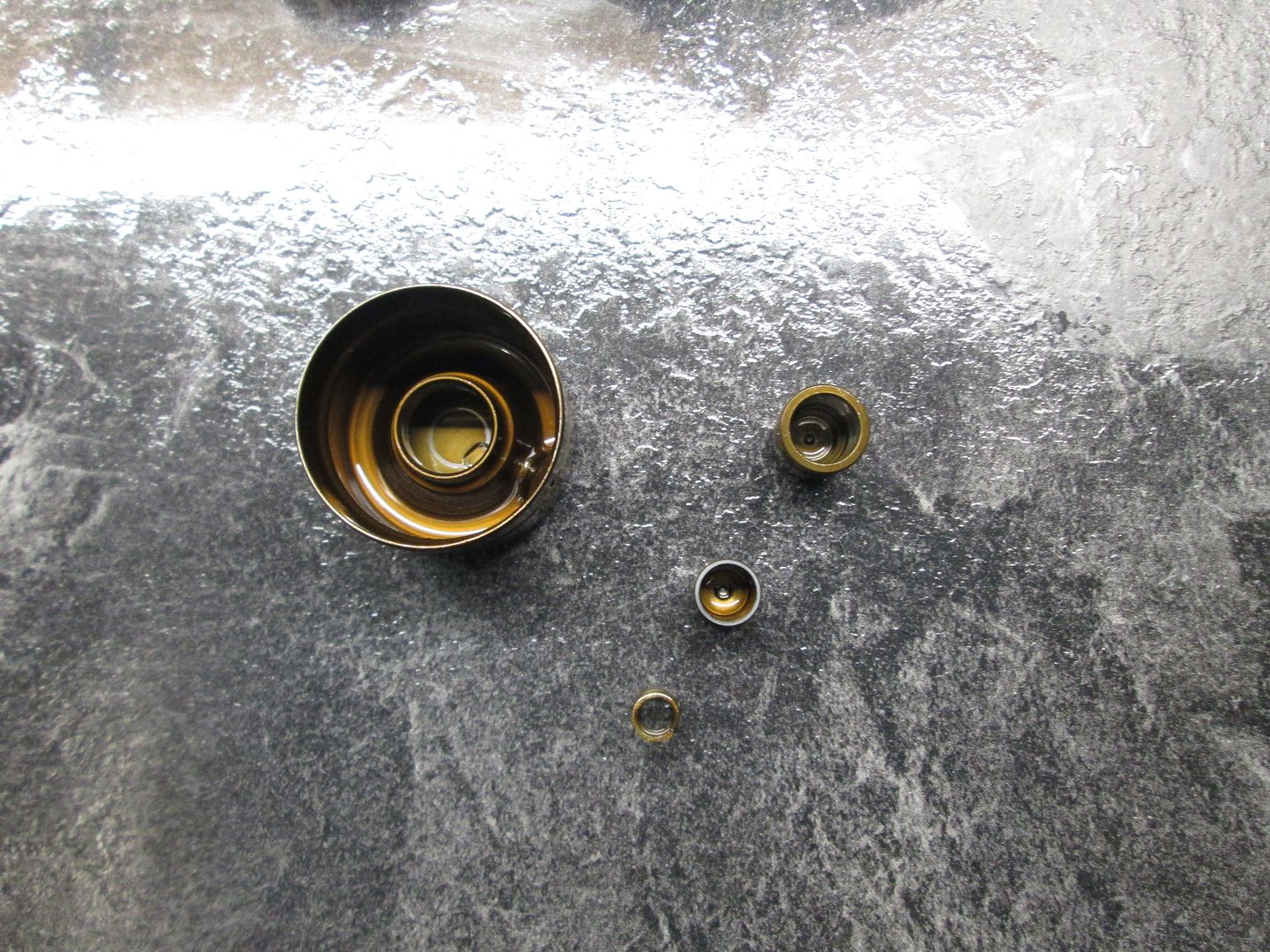

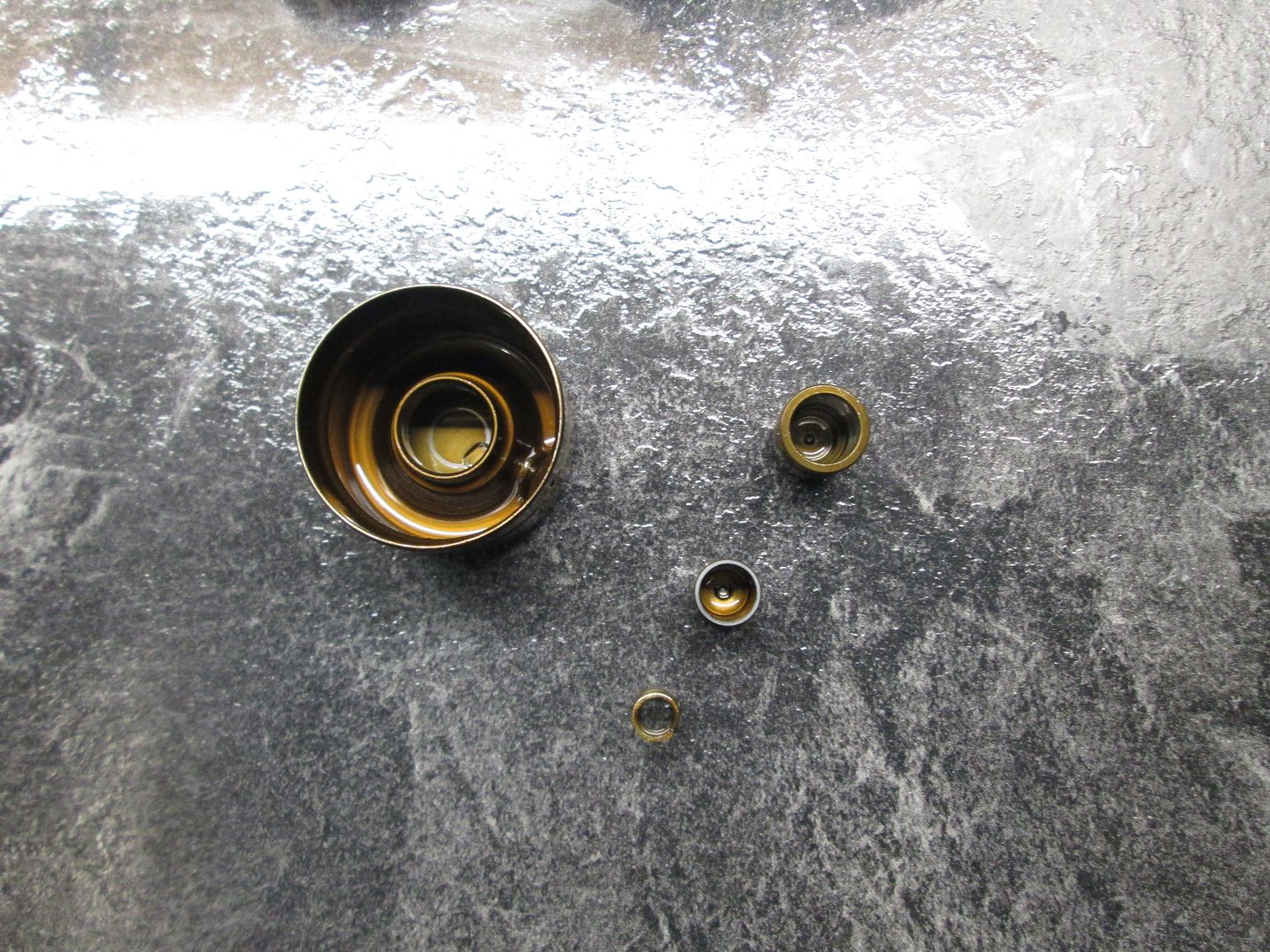

Every component cleaned in degreaser, then every piston cleaned fully before re-assembly with fresh oil. There was a lot of old oil build up inside every component. Every single piston had brown burnt on (15 years worth) oil deposits round the bottom, and none of them would freely move in and out of the housing. I would say approximately 20 out of the 24 were all stuck in one position. To show the difference, the freshly cleaned/assembled one is on the right, old on the left. You can see how the piston is stuck in..

As you can see here, the internal part of the tappet has a build up of old oil on both ends, which causes the moving part to stick in as above. The one on the left has been cleaned.

Further disassembly reveals all the components - the actual internal parts are very small..

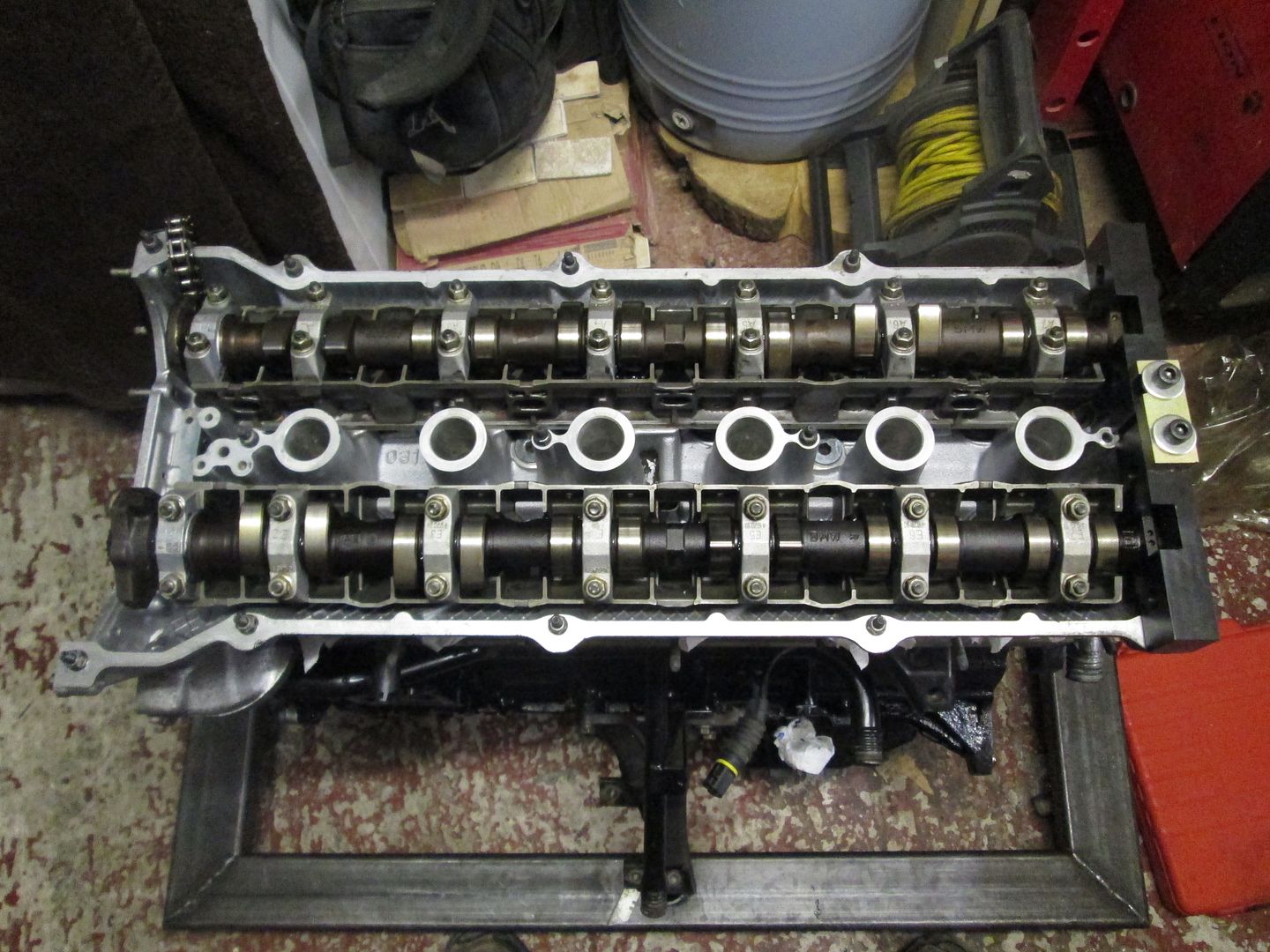

With everything clean and smooth, all 24 were reassembled. Before vs after..

https://www.youtube.com/watch?v=C0Fr12S_86U

With them all operating correctly, they were dropped into the head with assembly grease on the cam carriers..

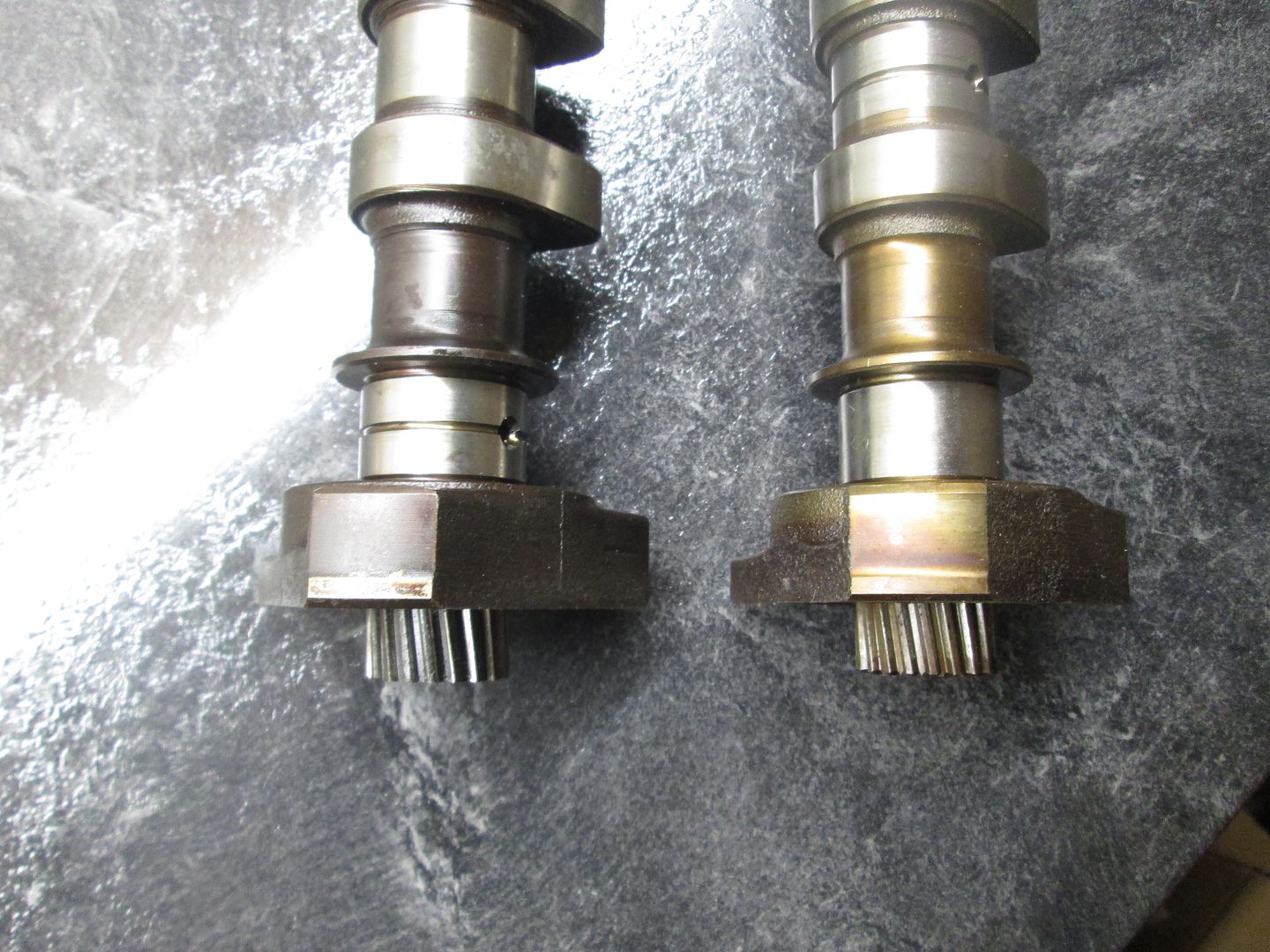

As mentioned above, the M54B30 uses dual VANOS, where the M50B25 and M52B28 use single. The hardware/gears on the inlet camshaft is the same between all three, just the M54 has an additional VANOS unit on the exhaust cam. The M54B30 inlet camshaft has a slightly more aggressive profile than the other two, being 240deg duration and 9.7mm lift, whereas the others are 228deg duration and 9.0mm lift. As you can see, they are very similar:

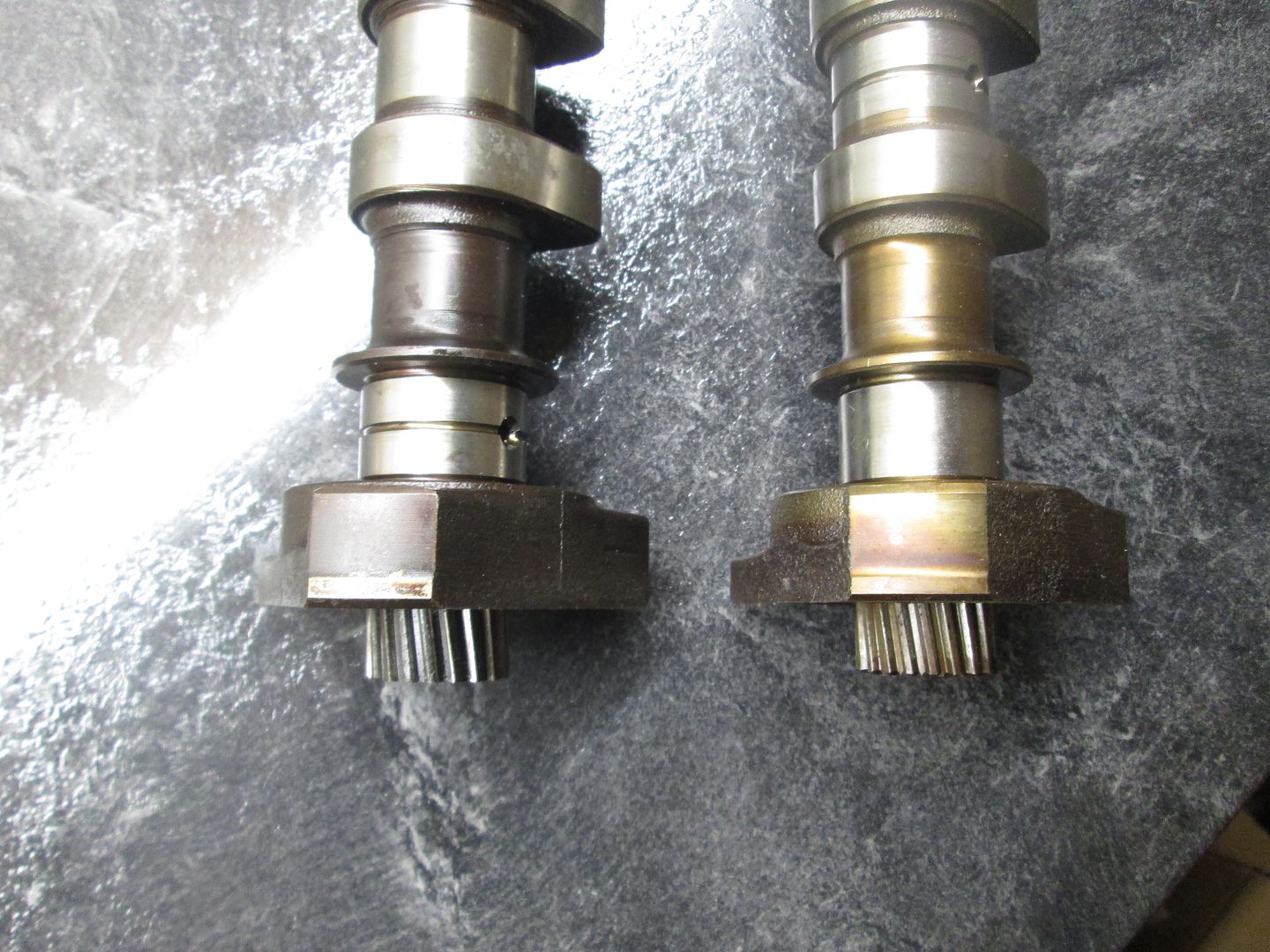

It will time up with the standard timing tools, which lock onto the blocks at the end of the camshafts. It will also drop straight into the M52B28 camshaft trays without issue. Even though the VANOS hardware is the same, the M54 uses a slightly longer engagement spline, so to allow use on an M52 unit it has to be machined by 5mm. M52 on the left, M54 on the right:

So the camshaft went onto a lathe..

..and the result is an M54B30 inlet camshaft that will fit into the M52 head, with a bit more lift and duration. This was then fitted, along with the M52B28 exhaust camshaft, and locked at TDC..

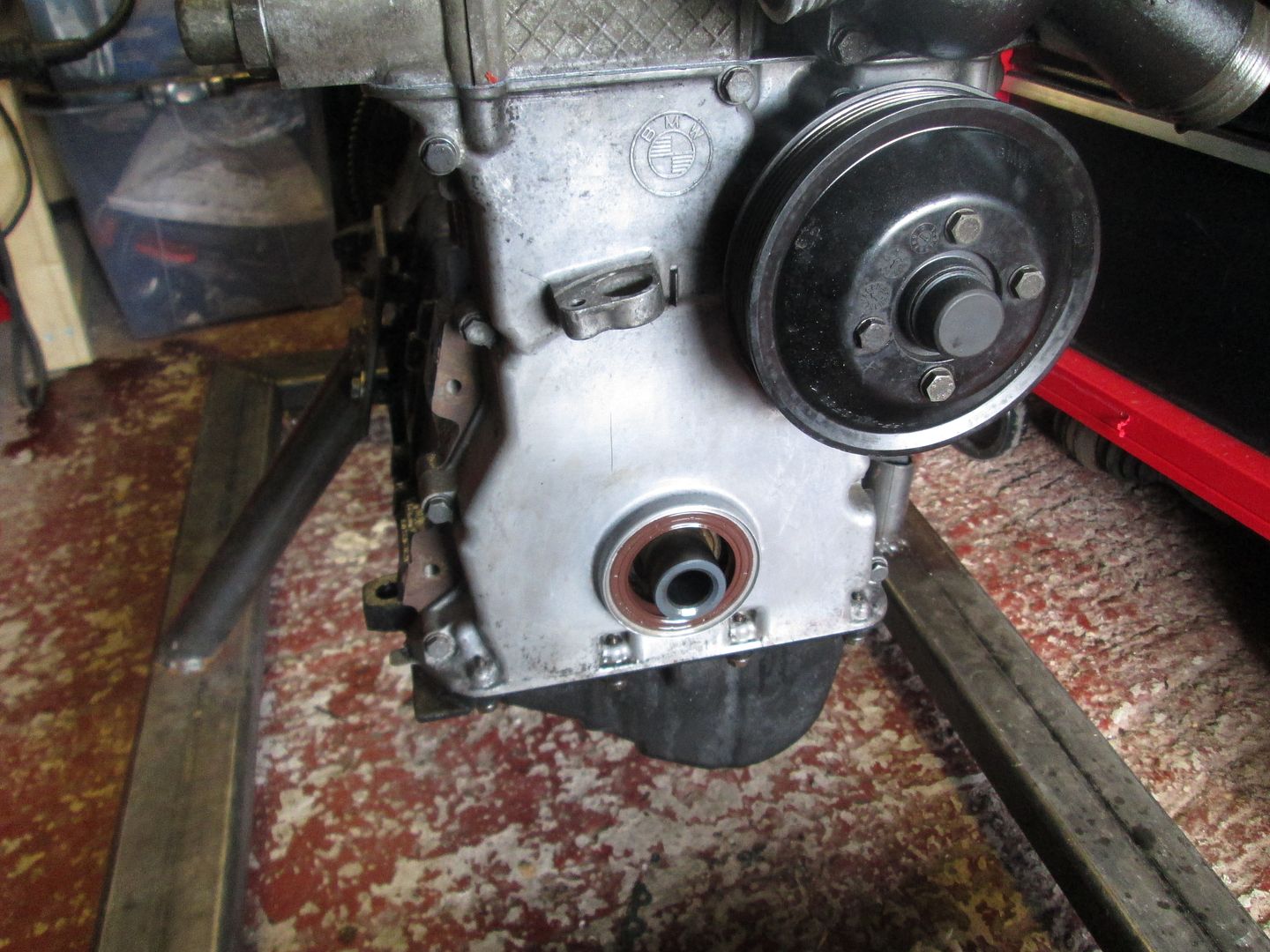

The camshaft gears were fitted along with upper chain and tensioners, timed up then VANOS unit bolted into place. Span the engine over a few times to check the timing and the tools dropped right in. Fitted the thermostat housing with new seals, then a new front crank seal. The front pulley then went on, with a new crank bolt again and torqued to spec. Cleaned up the rocker cover mating face and fitted that, finishing with some new spark plugs and the M54/E46 coil packs.

Before fitting this to the car, I wanted to make a few other changes...

From browsing the US forums a handful of people had done the 'cheap' 3.0L engine, using the rotating assembly from an M54B30, i.e. E46 330i, etc. I couldn't really find much information about it in the UK, just a few vague threads on various forums with no real definitive information. These engines were for sale ranging from £200-300, nearly a 10th of the price people had M3 engines listed for. After a bit of waiting, one came up local on the cheap end of that scale and I went to collect it..

Considering I only really wanted the crank, pistons and rods from this, I found out the rest of it (inc. ancillaries) were selling well on eBay, after some patience and once everything had gone, essentially the internals ended up costing nothing.

To eliminate a problem with the M50 block used in the previous build, I had the machine work done to my good spare..

The bores were also double checked for roundness to be 110% sure, and all came out great.

The M50, M52 and M54 engines are very similar internally, the M54 having different coolant/oil pathways, dual VANOS and various other things. They share the same 84mm bore, and the extra capacity is gained by an 89mm stroke on the crank in the M54, over the 84mm stroke on a 2.8L.

M54B30 Crank..

M54B30 Piston vs M52B28 Piston..

The M54B30 and M52B28 rods are the same, so you could use either. I kept the pistons with their rods either way. In summary:

M50B25 (2.5L Petrol, 1990-1996, E36 325i and E34 525i) - Steel/Iron Block, 84mm Bore, 75mm Stroke - 189hp, 181lbft.

M52B28 (2.8L Petrol, 1992-2001, E36 328i, E39 528i, E38 728i, Z3 2.8) - Aluminium Block, 84mm Bore, 84mm Stroke - 190hp, 210lbft.

M54B30 (3.0L Petrol, 2000-2006, E46 330i, E39 530i, E60 530i, X3/5 3.0, Z4 3.0) - Aluminium Block, 84mm Bore, 89.6mm Stroke - 230hp, 220lbft.

Again, did not know whether to trust the head that was used previously, so I had my spare head cleaned, skimmed, new stem seals again and then finally pressure tested to be 110% sure. All came back OK.

The pistons, rods and other bits were properly cleaned at the same time..

So the block was given a quick coat of paint, then the oil jets put in place, and some bearings fitted..

There had been a ridiculous increase in the price of mains bolts at BMW since I last had them, and it was actually cheaper to purchase ARP hardware..

Degreased and checked the crank over, then dropped it into the block and checked the clearances..

Factory clearance is 0.020mm <> 0.058mm, all were identical at circa 0.038mm.

Removed the caps, cleaned, and added assembly grease again. Then torqued the caps down with the ARP ultra torque grease as per the spec..

New piston rings for the M54B30 pistons, as they are completely different and should be replaced anyway..

Gapped, fitted to the piston and then dropped into the block..

The windage/baffle plate needed more modification to clear the ARP studs, and longer stroke of the M54 crank, but its all easy stuff.

Timing gear, covers, oil pump, sump back on with a new gasket..

You can see here how the M54 assembly sits a few mm below the deck when used in an M50 block, as expected..

Cleaned the block face one last time, then fitted two new dowels and a new headgasket..

Dropped the head on, new head bolts again. All held full torque correctly..

Before assembling the rest of the head, I wanted to strip all 24 hydraulic tappets apart and clean them, to check all were operating at full travel..

Every component cleaned in degreaser, then every piston cleaned fully before re-assembly with fresh oil. There was a lot of old oil build up inside every component. Every single piston had brown burnt on (15 years worth) oil deposits round the bottom, and none of them would freely move in and out of the housing. I would say approximately 20 out of the 24 were all stuck in one position. To show the difference, the freshly cleaned/assembled one is on the right, old on the left. You can see how the piston is stuck in..

As you can see here, the internal part of the tappet has a build up of old oil on both ends, which causes the moving part to stick in as above. The one on the left has been cleaned.

Further disassembly reveals all the components - the actual internal parts are very small..

With everything clean and smooth, all 24 were reassembled. Before vs after..

https://www.youtube.com/watch?v=C0Fr12S_86U

With them all operating correctly, they were dropped into the head with assembly grease on the cam carriers..

As mentioned above, the M54B30 uses dual VANOS, where the M50B25 and M52B28 use single. The hardware/gears on the inlet camshaft is the same between all three, just the M54 has an additional VANOS unit on the exhaust cam. The M54B30 inlet camshaft has a slightly more aggressive profile than the other two, being 240deg duration and 9.7mm lift, whereas the others are 228deg duration and 9.0mm lift. As you can see, they are very similar:

It will time up with the standard timing tools, which lock onto the blocks at the end of the camshafts. It will also drop straight into the M52B28 camshaft trays without issue. Even though the VANOS hardware is the same, the M54 uses a slightly longer engagement spline, so to allow use on an M52 unit it has to be machined by 5mm. M52 on the left, M54 on the right:

So the camshaft went onto a lathe..

..and the result is an M54B30 inlet camshaft that will fit into the M52 head, with a bit more lift and duration. This was then fitted, along with the M52B28 exhaust camshaft, and locked at TDC..

The camshaft gears were fitted along with upper chain and tensioners, timed up then VANOS unit bolted into place. Span the engine over a few times to check the timing and the tools dropped right in. Fitted the thermostat housing with new seals, then a new front crank seal. The front pulley then went on, with a new crank bolt again and torqued to spec. Cleaned up the rocker cover mating face and fitted that, finishing with some new spark plugs and the M54/E46 coil packs.

Before fitting this to the car, I wanted to make a few other changes...

B'stard Child said:

I put some decent road mileage on my engine before the first track day - what I didn't do was upgrade the oil to something that would cope with the stress of a track day

Ok, I'm aware of the running in process and the correct use of oils. This is critical. I would always use a specific track day oil too. Road oil could often be beyond its limits on track resulting.in expensive damage.

Always worth doing a litte prep before track days - that said sometimes it's bad luck and one can do little more.

Dr Imran T said:

B'stard Child said:

I put some decent road mileage on my engine before the first track day - what I didn't do was upgrade the oil to something that would cope with the stress of a track day

Ok, I'm aware of the running in process and the correct use of oils. This is critical. I would always use a specific track day oil too. Road oil could often be beyond its limits on track resulting.in expensive damage.

Always worth doing a litte prep before track days - that said sometimes it's bad luck and one can do little more.

I wanted to sort the M3 exhaust manifolds out properly... as #1, I hate having old flanges that never join properly, #2, the weight of the standard exhaust system (albeit modified) is just a joke, and #3, the standard flexi was damaged and needed replacing. So the standard manifolds in standard form (M3 3.2 Evo, as they have the Lambda holes. The 3.0 does not)..

I wanted to have a flexi on each manifold instead, then bring the two pipes into one for simplicity and weight. Quite a common change in the US.

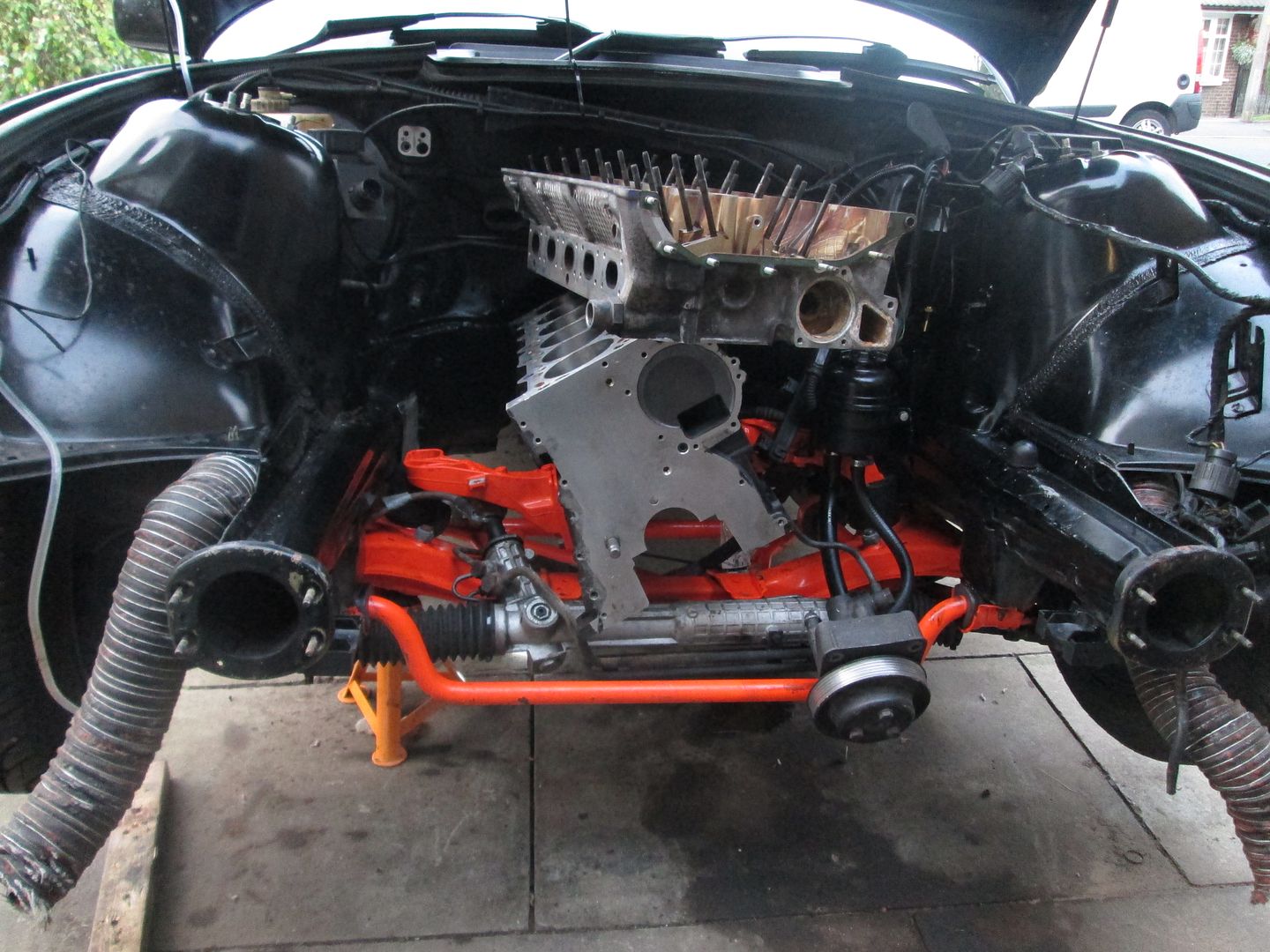

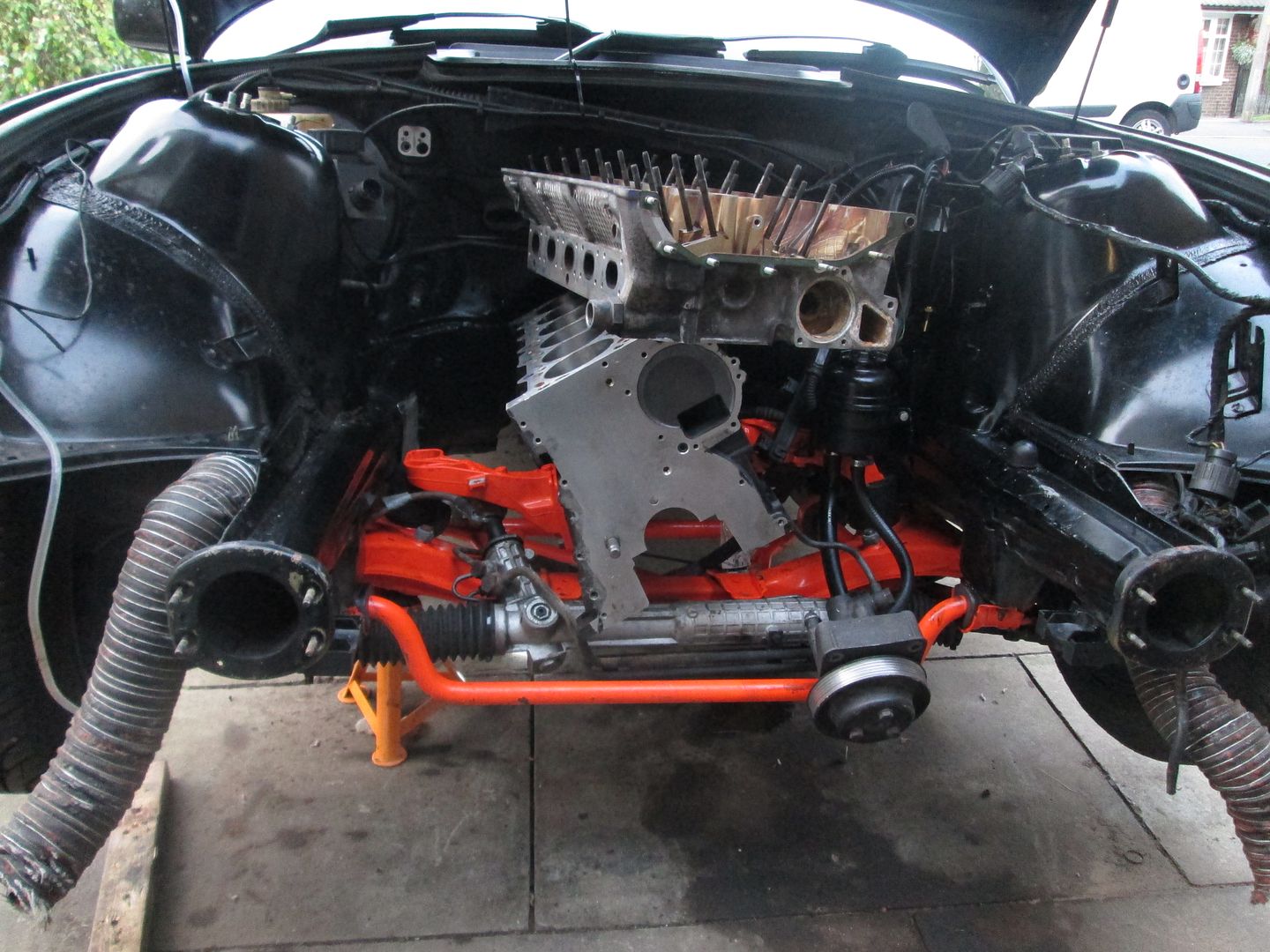

To get the fitment and clearance spot on, I mounted a scrap block/head in the car along with my spare gearbox, so I could easily move things about..

After bolting things to the mockup engine a few times, and some cutting/positioning, I had the flexis and bends in place. Using stainless only here..

The final piece which brings the two manifolds into one pipe was then checked and marked up. V-band is going on the end to join the exhaust system rather than a normal flange.

(Ignore the old flywheel, its simply used for timing the engine up)

Once I was happy with the fitment after a few more tests, I took the lot to be TIG'd by a friend. We also added the missing lambda boss back in, along with an additional one downstream for a wideband sensor.

The M20 flywheel and clutch setup were then re-fitted, and the gearbox put onto the new 3.0L. I also cut a small section out of the gearbox bell housing to aid clearance on the rear manifold - in the past this has just sat up against the gearbox, but didn't want to risk putting too much stress on it and having issues with cracks in the future. Im assuming this is because they are 3.2 manifolds which use the 6 speed box and probably are cast to miss this.

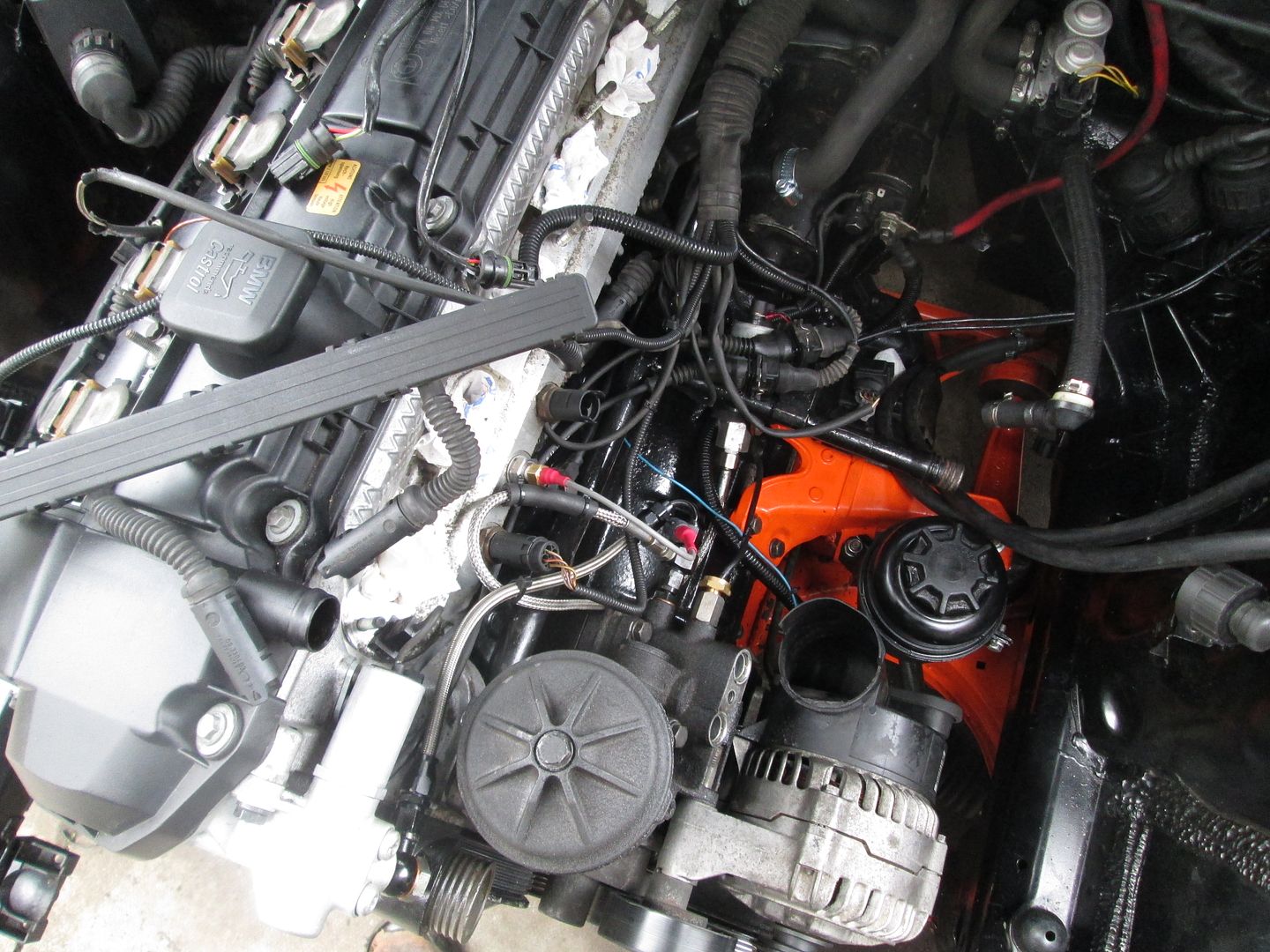

Fitted the mounts and dropped it in. Very tight going in now with the manifold/collector being longer than it was, but going slow enough it did go in fine..

Originally I was going to take it somewhere to have an exhaust made, then decided I could probably do it myself with better quality components for half the cost. I had a few recommendations on local places, but either they were too busy or far too expensive in the end.

I used five mandrel bends (3 x 20degree, 2 x 40degree), a small straight section and a pipe former. Decided to go with two good quality 'Simons' silencers. Everything is 304 stainless, including brackets and silencers. Every joint has been sleeved by 40mm to ensure strength.

With a bit of patience, measuring everything twice and quite a bit of test fitting, everything went together fine. The v-band makes fitting/removal a breeze. The system now sits closer to the chassis and all mounts have been made from scratch, nothing OEM on there anymore. I tacked everything together..

The standard exhaust, in original form (without being modified to match the M3 manifolds) weighed a whopping 36kg. The new system, just under 7kg. Quite some saving in the exhaust alone! I took the new exhaust to be TIG'd..

Then fitted it to the car..

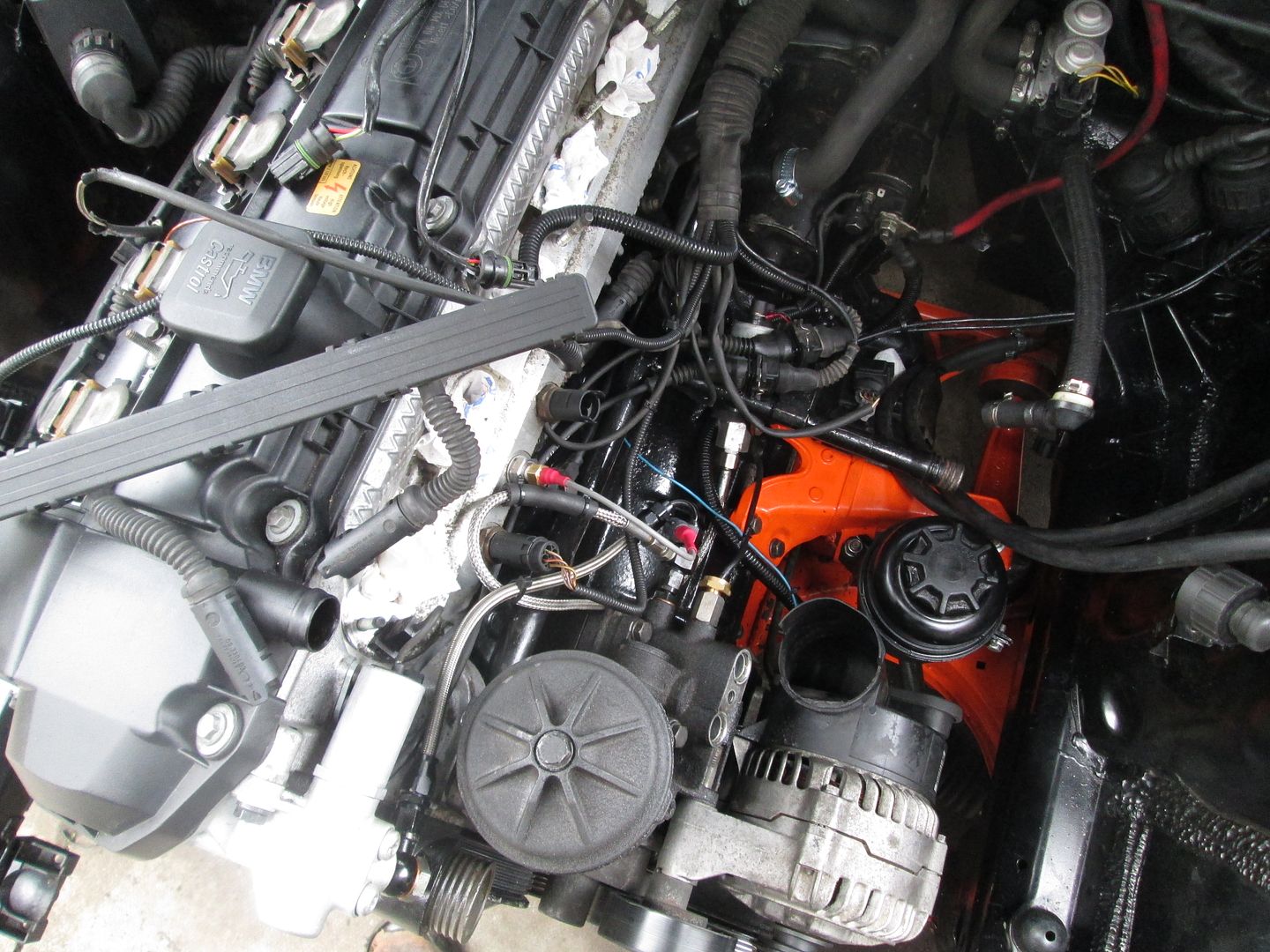

As someone previously mentioned, gauges.. I run an Innovate Oil Pressure/Temperature gauge, and an SPA Water Temperature Gauge. These have additional senders - water is in a spare outlet on the head next to the OEM sensor, and oil pressure/temperature come from the oil filter housing..

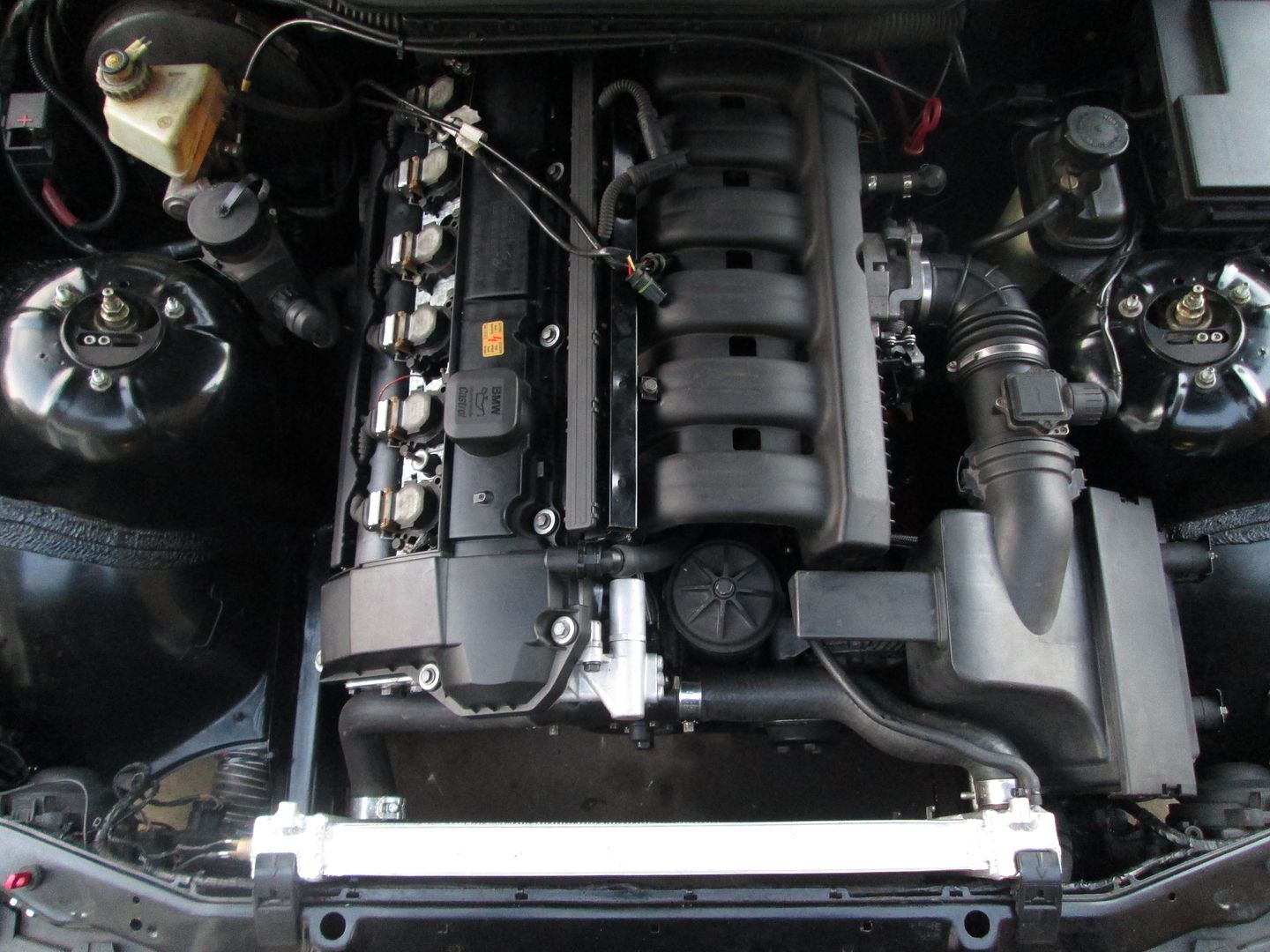

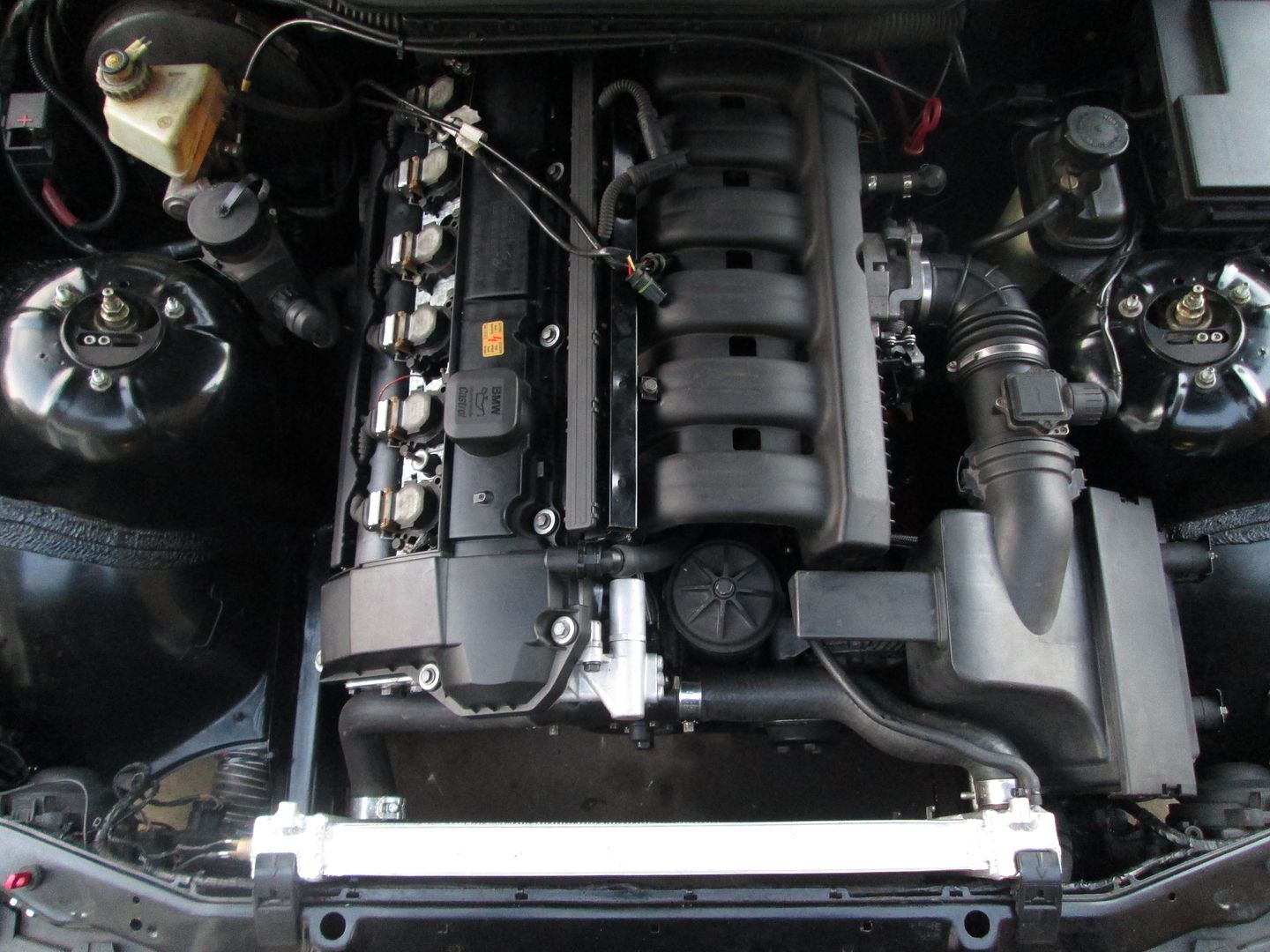

With the new engine now having an exhaust, everything else just needed building back up and fluids adding..

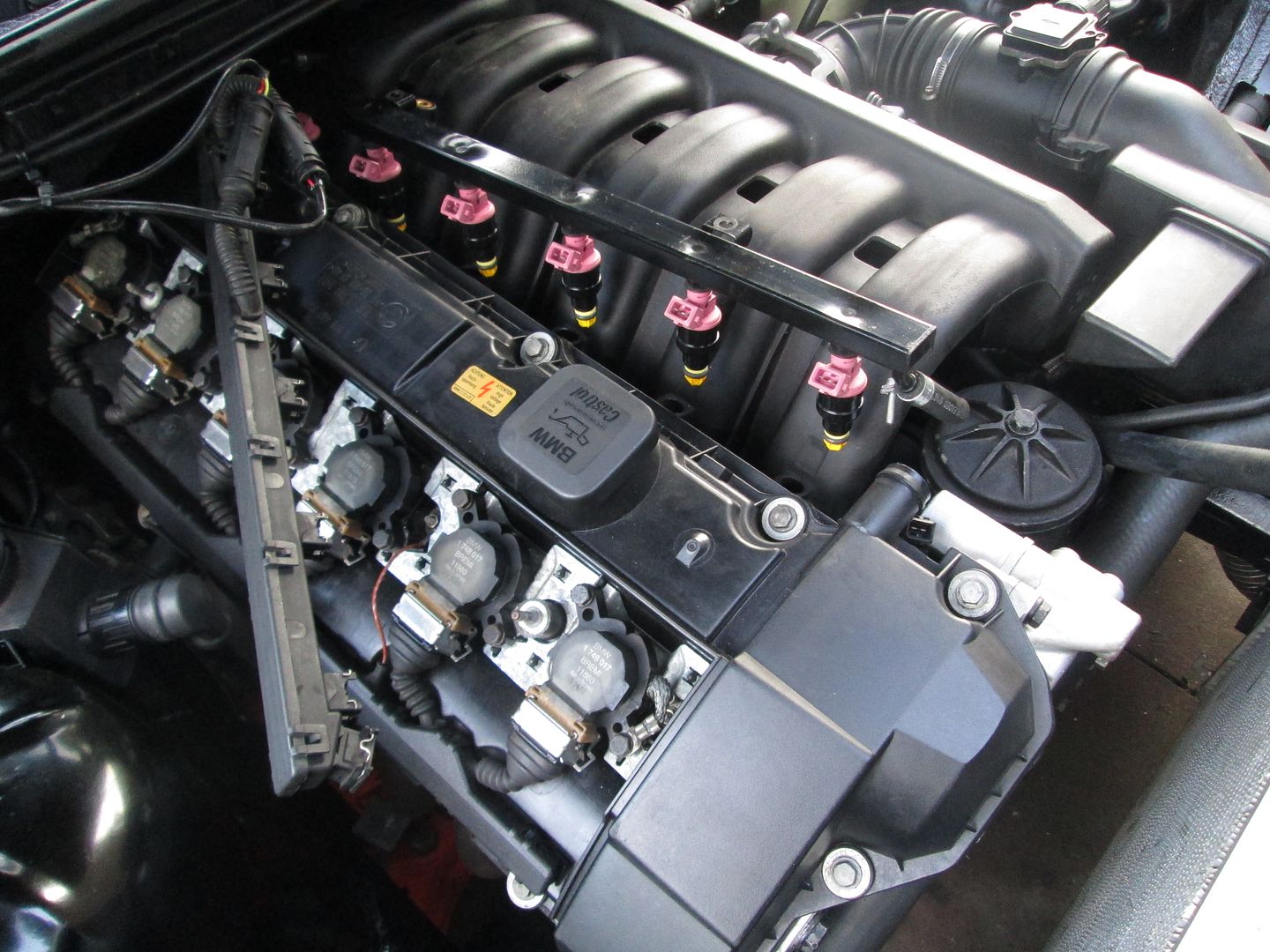

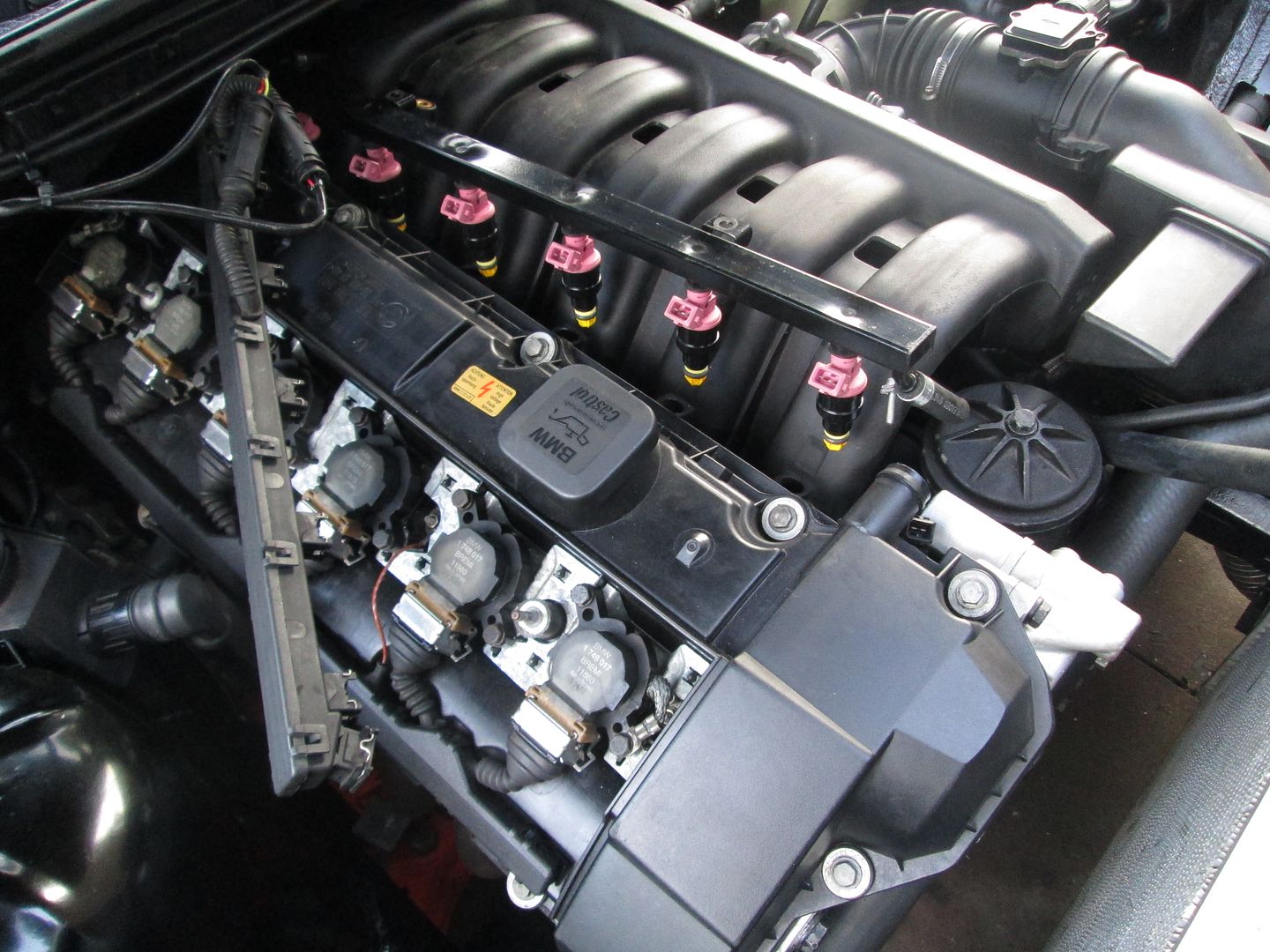

I also had a spare set of injectors reconditioned, to ensure they were all balanced and none of them had an issue. I run an M50 fuel rail if anyone wonders why it looks different.

Fitted my AEM wideband into the additional lambda boss now on the exhaust, and mounted the gauge inside. The engine will remain on the M52 management, and calibration adjusted as we go along.

Filled the engine with mineral oil, coolant and then cranked over to build some oil pressure. Plugged the ECU back in and fired it up..

https://www.youtube.com/watch?v=3hacr1F4Ags

Happy that there were no leaks, the last job was to get a method of logging data before running the 3.0L in..

I wanted to have a flexi on each manifold instead, then bring the two pipes into one for simplicity and weight. Quite a common change in the US.

To get the fitment and clearance spot on, I mounted a scrap block/head in the car along with my spare gearbox, so I could easily move things about..

After bolting things to the mockup engine a few times, and some cutting/positioning, I had the flexis and bends in place. Using stainless only here..

The final piece which brings the two manifolds into one pipe was then checked and marked up. V-band is going on the end to join the exhaust system rather than a normal flange.

(Ignore the old flywheel, its simply used for timing the engine up)

Once I was happy with the fitment after a few more tests, I took the lot to be TIG'd by a friend. We also added the missing lambda boss back in, along with an additional one downstream for a wideband sensor.

The M20 flywheel and clutch setup were then re-fitted, and the gearbox put onto the new 3.0L. I also cut a small section out of the gearbox bell housing to aid clearance on the rear manifold - in the past this has just sat up against the gearbox, but didn't want to risk putting too much stress on it and having issues with cracks in the future. Im assuming this is because they are 3.2 manifolds which use the 6 speed box and probably are cast to miss this.

Fitted the mounts and dropped it in. Very tight going in now with the manifold/collector being longer than it was, but going slow enough it did go in fine..

Originally I was going to take it somewhere to have an exhaust made, then decided I could probably do it myself with better quality components for half the cost. I had a few recommendations on local places, but either they were too busy or far too expensive in the end.

I used five mandrel bends (3 x 20degree, 2 x 40degree), a small straight section and a pipe former. Decided to go with two good quality 'Simons' silencers. Everything is 304 stainless, including brackets and silencers. Every joint has been sleeved by 40mm to ensure strength.

With a bit of patience, measuring everything twice and quite a bit of test fitting, everything went together fine. The v-band makes fitting/removal a breeze. The system now sits closer to the chassis and all mounts have been made from scratch, nothing OEM on there anymore. I tacked everything together..

The standard exhaust, in original form (without being modified to match the M3 manifolds) weighed a whopping 36kg. The new system, just under 7kg. Quite some saving in the exhaust alone! I took the new exhaust to be TIG'd..

Then fitted it to the car..

As someone previously mentioned, gauges.. I run an Innovate Oil Pressure/Temperature gauge, and an SPA Water Temperature Gauge. These have additional senders - water is in a spare outlet on the head next to the OEM sensor, and oil pressure/temperature come from the oil filter housing..

With the new engine now having an exhaust, everything else just needed building back up and fluids adding..

I also had a spare set of injectors reconditioned, to ensure they were all balanced and none of them had an issue. I run an M50 fuel rail if anyone wonders why it looks different.

Fitted my AEM wideband into the additional lambda boss now on the exhaust, and mounted the gauge inside. The engine will remain on the M52 management, and calibration adjusted as we go along.

Filled the engine with mineral oil, coolant and then cranked over to build some oil pressure. Plugged the ECU back in and fired it up..

https://www.youtube.com/watch?v=3hacr1F4Ags

Happy that there were no leaks, the last job was to get a method of logging data before running the 3.0L in..

B'stard Child said:

I love that you thought about the exhaust routing - I mean I built an exhaust for my Monza and then had to redo it when I realised that the whole system needed removal to remove the box every time I needed to change the clutch - so I had to do it again

I recognise the car in your profile picture - long shot but were you at an RAF Marham day in 2009 by any chance?f0xy said:

B'stard Child said:

I love that you thought about the exhaust routing - I mean I built an exhaust for my Monza and then had to redo it when I realised that the whole system needed removal to remove the box every time I needed to change the clutch - so I had to do it again

I recognise the car in your profile picture - long shot but were you at an RAF Marham day in 2009 by any chance?

Dr Imran T said:

So chaps, is it not better to put some decent mileage on an engine before pounding it round a track?

That would generally be my route. I've done a fair few track days and it really is tough on the engine.

Op - I would be reluctant on buying a used engine unless you can verify that it is in good health.

Personal preference. Ran mine in on track.That would generally be my route. I've done a fair few track days and it really is tough on the engine.

Op - I would be reluctant on buying a used engine unless you can verify that it is in good health.

Hands down, one of the best threads I've read on here. Amazing attention to detail, I was unaware that the M50/52/54 were quite that interchangeable!

So the Engine is currently running the M50 block with M54 crank/rods/pistons with the M52B28 head? and just to top it off the M20 solid mass flywheel/clutch upgrade, astonishing.

If you don't mind me asking, how much did the machining cost for the head/block etc?

The exhaust looks like a quality bit of engineering, is there a noticeable difference between the standard and custom one in terms of noise? I find that the standard exhaust with a lightweight aftermarket backbox drones terribly and would like to rectify it. A friend of mine has turbocharged his E36 323 and had a custom exhaust made for it 3" straight-through with only a small backbox and claims that it does not drone at all.

Anyway fantastic work and I look forward to more updates!

So the Engine is currently running the M50 block with M54 crank/rods/pistons with the M52B28 head? and just to top it off the M20 solid mass flywheel/clutch upgrade, astonishing.

If you don't mind me asking, how much did the machining cost for the head/block etc?

The exhaust looks like a quality bit of engineering, is there a noticeable difference between the standard and custom one in terms of noise? I find that the standard exhaust with a lightweight aftermarket backbox drones terribly and would like to rectify it. A friend of mine has turbocharged his E36 323 and had a custom exhaust made for it 3" straight-through with only a small backbox and claims that it does not drone at all.

Anyway fantastic work and I look forward to more updates!

Another Fluffer said:

Hands down, one of the best threads I've read on here. Amazing attention to detail, I was unaware that the M50/52/54 were quite that interchangeable!

So the Engine is currently running the M50 block with M54 crank/rods/pistons with the M52B28 head? and just to top it off the M20 solid mass flywheel/clutch upgrade, astonishing.

If you don't mind me asking, how much did the machining cost for the head/block etc?

The exhaust looks like a quality bit of engineering, is there a noticeable difference between the standard and custom one in terms of noise? I find that the standard exhaust with a lightweight aftermarket backbox drones terribly and would like to rectify it. A friend of mine has turbocharged his E36 323 and had a custom exhaust made for it 3" straight-through with only a small backbox and claims that it does not drone at all.

Anyway fantastic work and I look forward to more updates!

Yeah thats correct. Well, its actually an M50B25 head, which is the same anyway. This was used as it has an additional coolant sensor location on the head (as per the post above), because the M50's used two separate sensors for the ECU/Dash, whereas the M52's used a single sensor. So the Engine is currently running the M50 block with M54 crank/rods/pistons with the M52B28 head? and just to top it off the M20 solid mass flywheel/clutch upgrade, astonishing.

If you don't mind me asking, how much did the machining cost for the head/block etc?

The exhaust looks like a quality bit of engineering, is there a noticeable difference between the standard and custom one in terms of noise? I find that the standard exhaust with a lightweight aftermarket backbox drones terribly and would like to rectify it. A friend of mine has turbocharged his E36 323 and had a custom exhaust made for it 3" straight-through with only a small backbox and claims that it does not drone at all.

Anyway fantastic work and I look forward to more updates!

I have a local place for machining who I've used for years, so pay different prices to the norm. Generally you're probably looking at £25-30 for a skim and a bit more for honing. Varies quite a bit but its worth going somewhere thats recommended over the cheapest price.

The standard exhaust was very quiet originally, so a long while ago the back box was cut open and the baffles changed, which did increase noise a bit, but it was still under 90db. The new exhaust was 98db @ 4500rpm when at Oulton around a month ago. It does not really drone, its just noisy anyway as there is nothing inside the car..

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff